2015 ARKH-P3-Production Facilities

.pdf

SEPARATOR (skid mounted)

11

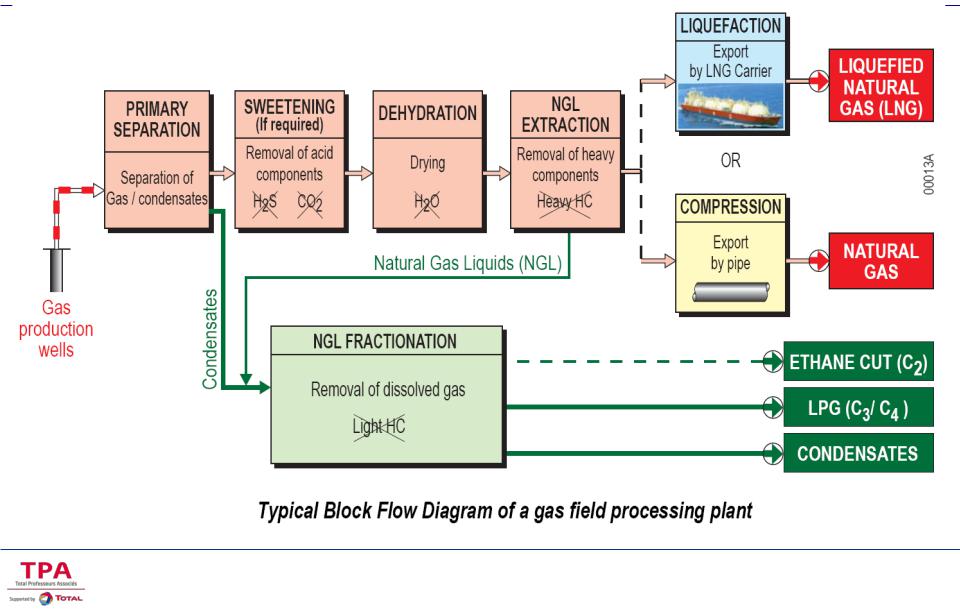

GAS TREATMENT

12

GAS PROCESSING

|

COMPOUNDS |

PROBLEMS |

||

|

|

|

|

|

|

WATER |

Hydrates (with free water) |

||

|

|

Gas Water Dew Point |

||

|

|

|

|

|

|

ACID GASES |

Corrosion (with free water) |

|

|

|

(H2S and/or CO2) |

Safety (H2S content) |

||

|

|

Gas Calorific Value (CO2 content) |

||

|

|

|

|

|

|

HEAVY COMPONENTS |

Condensation (Transportation line) |

||

|

(C5+) |

Gas Hydrocarbon Dew Point |

||

|

|

Gas Calorific Value (too high C5+ content) |

||

|

|

|

|

|

|

|

|

|

|

13

Hydrates at 25°C = gas + water

DIRTY ICE : water lattice in which methane, ethane, propane, butane, CO2, H2S molecules are embedded (CLATHRATES) Specific gravity = 0.96 to 0.98

Normally form with hydrocarbon stream containing free water dispersed or not, but may form in hydrocarbon gases saturated with water vapor without free water

STABLE AT HIGH PRESSURE ( >10 bar ) AND LOW TEMPERATURE ( < 25 °C )

BLOCK flowlines, chokes, valves, instrumentation

FOUL and PLUG heat exchangers ERODE chokes, control valves, turbo expander

REMOVING HYDRATE PLUGS BY DEPRESSURISATION

CAN REQUIRE DAYS OF FLOW INTERRUPTION

14

Hydrates = gas ice

H20 particles around CH4

15

GAS TREATMENT

16

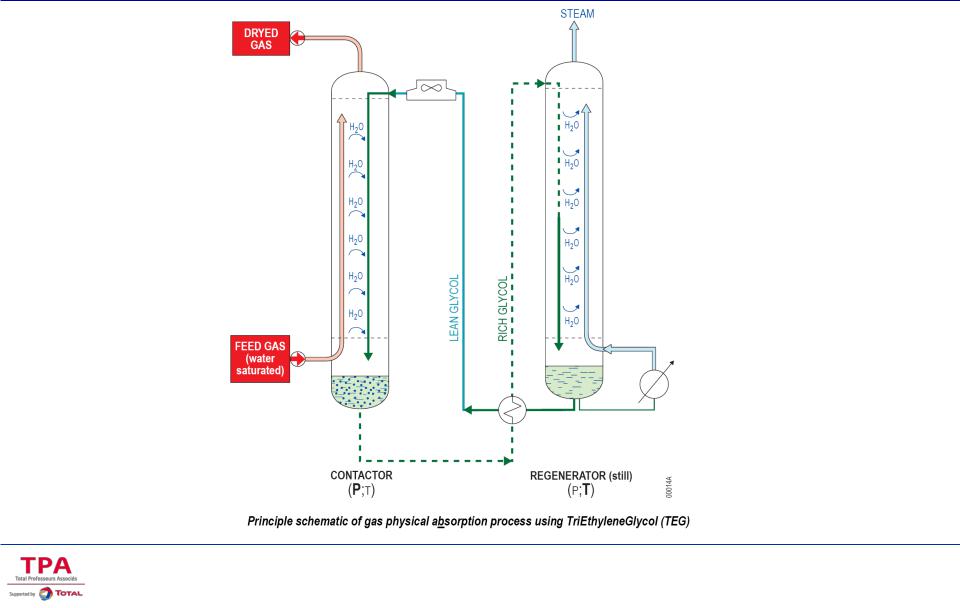

DEHYDRATION: GLYCOL UNIT PRINCIPLE

17

DEHYDRATION: ON SITE TEG UNIT

Saih Rahwl – Oman, 1998 "One of the biggest glycol units in the world"

18

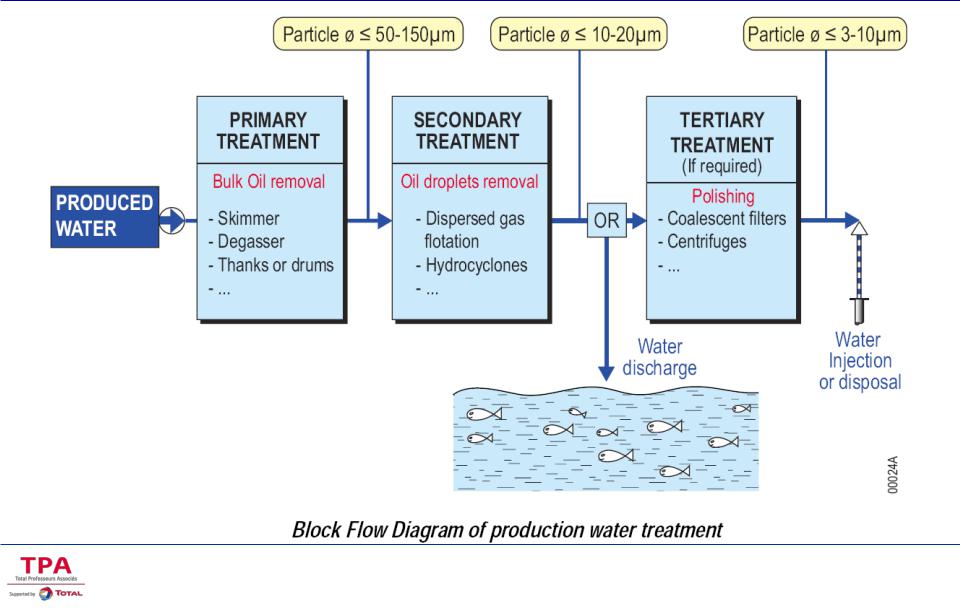

PRODUCTION WATER TREATMENT

19

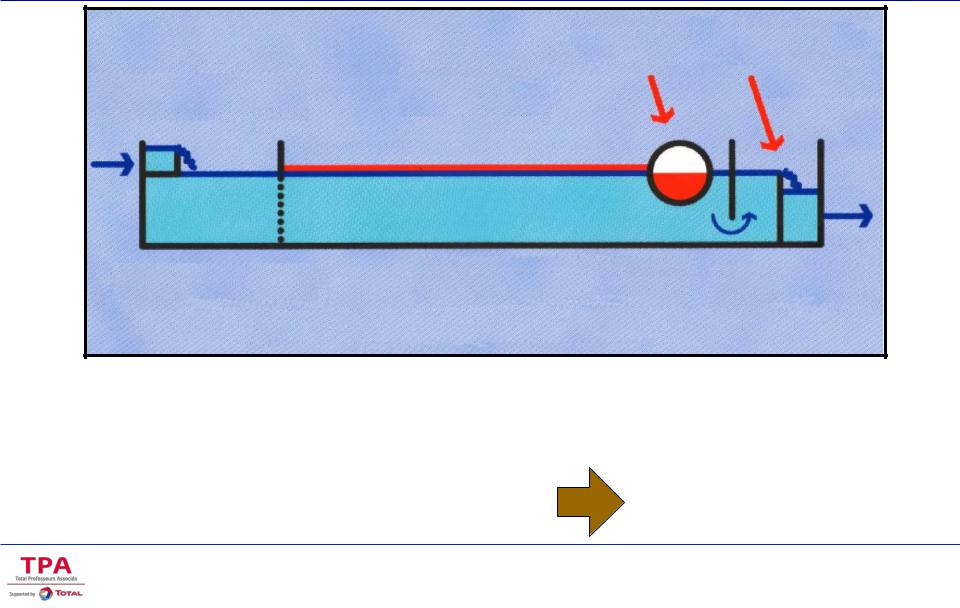

SIMPLE GRAVITATIONAL TECHNIQUES: API TANK

HC recoveryLevel maintenance

Tranquillisation Settling

Inlet compartment |

Basin proper |

Outlet compartment |

T Residence 1 hour minimum

EXAMPLE: for 3000 m3/d ≈ 25 m long

≈ 3 m wide ONSHORE ONLY!!!!!

≈ 2 m depth

20