PAROC

Несгораемая каменная вата PAROC. Тепловая и звуковая изоляция конструкций любого типа: кровельная и фасадная теплоизоляция, высокотемпературная и противопожарная изоляции, плиты и маты для технической изоляции, сэндвич"панели для быстровозводимых зданий.

Адрес: 19049 Москва ул. Мытная, д.3, офис 10 (этаж 8) 197110 Санкт"Петербург ул. Вязовая, 10

Тел/факс: Москва: Тел.: (495)984"58"56, Факс: (495)984"58"57 Санкт"Петербург: Тел.: +7 (812) 336"47"21, Факс: +7 (812) 336"47"22

E mail: luba.bondareva@paroc.com

URL: www.paroc.ru

ОПИСАНИЕ ПРЕДОСТАВЛЕННЫХ МАТЕРИАЛОВ

01 |

|

Каталог Строительной Изоляции PAROC |

|

>>> |

|

|

|

|

|

|

|

|

|

|

02 |

|

Каталог Технической Изоляции PAROC |

|

>>> |

|

|

|

|

|

|

|

|

|

|

03 |

|

Судовая Изоляция PAROC |

|

>>> |

|

|

|

|

|

|

|

|

|

|

04 |

|

Теория Изоляции |

|

>>> |

|

|

|

|

|

|

|

|

|

|

05 |

|

Строительная изоляция PAROC. Брошюры и Каталоги |

|

>>> |

|

|

|

|

|

|

|

|

|

|

06 |

|

Строительная изоляция PAROC. Монтажные схемы |

|

>>> |

|

|

|

|

|

|

|

|

|

|

07 |

|

Строительная изоляция PAROC. Сертификаты |

|

>>> |

|

|

|

|

|

|

|

|

|

|

08 |

|

Строительная изоляция PAROC (анг.) |

|

>>> |

|

|

|

|

|

|

|

|

|

|

09 |

|

Сэндвич"панели PAROC |

|

>>> |

|

|

|

|

|

|

|

|

|

|

10 |

|

Сэндвич"панели PAROC. Чертежи в формате AutoCAD (.dwg) |

|

>>> |

|

|

|

|

|

|

|

|

|

|

11 |

|

Техническая изоляция PAROC (англ.) |

|

>>> |

|

|

|

|

|

|

|

|

|

|

12 |

|

Техническая изоляция PAROC. Брошюры и каталоги |

|

>>> |

|

|

|

|

|

|

|

|

|

|

13 |

|

Техническая изоляция PAROC. Монтажные инструкции |

|

>>> |

|

|

|

|

|

|

|

|

|

|

14 |

|

Техническая изоляция PAROC. Звукопоглощение материалов |

|

>>> |

|

|

|

|

|

|

|

|

|

|

15 |

|

Техническая изоляция PAROC. Паспорта изделий. Сертификаты |

|

>>> |

|

|

|

|

|

|

|

|

|

|

16 |

|

Техническая изоляция PAROC. Технические презентации по материалам |

|

>>> |

|

|

|

|

|

|

|

|

|

|

17 |

|

Техническая изоляция PAROC. Расчетные программы толщины изоляции |

|

>>> |

|

|

|

|

|

|

|

|

|

|

18 |

|

Цены на продукцию PAROC |

|

>>> |

|

|

|

|

|

www.Know-House.ru

Panel System

6.10 INT

July 2001

AST ®

Advanced Structural Technology

Introduction

Strength |

|

Durability |

|

Fire safety |

|

|

|

|

|

“AST is a quality profile of selected issues, significantly important to structural sandwich constructions, with reference to objective quality measures”.

AST, Advanced Structural Technology, has been developed as a tool for the customer to ensure that the product he is buying meets the most demanding requirements for load-bearing sandwich panels, representing the highest quality standard in terms of strength, durability and fire safety.

AST panels comprise three superior properties

•Strength: Controlled and reliable strength properties

•Durability: Long-term durability to guarantee the panel properties during a building´s lifetime

•Fire safety: Non-combustible core and fire safe construction

AST sets a technical quality profile for the reliable selection and control of basic raw materials, manufacturing processes and the final product, making visible hidden characteristics that differentiate between AST panels and inferior products.

The quality assurance procedure of AST sandwich panels includes internal testing according to the European Recommendations for Sandwich Panels and third party control by authorised institutes according to type approval and certificate agreements.

AST four stage quality system

•Suppliers’ quality control

•Reception control

•Control of manufacturing quality

•Control of finished AST sandwich panel with full-scale strength tests

Strength

Sandwich panels are based on interaction between the different materials, providing optimal strength properties. That is why the bonding between the core and the facings is one of the most critical parts in sandwich panel manufacturing.

AST in structural sandwich panels is based on a non-combustible structural core, bonded on both sides to colourcoated steel sheets or facings of any other structural material, creating an interactive composite structure which resolves the complex loads acting upon it. Composite structures are generally dimensioned for load combinations of wind, snow and temperature according to national building standards.

AST strength definition

•Equal strength properties in all cross sections of a panel, to ensure homogeneous load capability.

•The strength values used in dimensioning of AST panels measured and evaluated according to the ECCS/CIB recommendations.

•Bonding strength equal or greater than 100 kN/m2

The most efficient way to measure the interactive quality of a sandwich panel is to conduct a tensile strength test. In structural panels the tensile strength of the bonding between the face and the core shall always exceed the tensile strength of the core material itself (always failure in the core). The AST bonding strength threshold value is 100 kN/m2. The shear failure must always occur in the insulation layer to ensure safe performance in all circumstances.

Compression in facing |

Shear in core |

Tension in facing

Compression in core

Load-bearing stresses resolved by composite action

The use of the best properties of each material |

core material resolve compression and tension |

is the basis in panel design. The structural core |

stresses caused by bending of the panel, ensuring |

takes the shear and compression stresses between |

the load-bearing capacity for the panels. |

the surface layers. Facings on both sides of the |

|

Load |

|

[kN/m2] |

1. |

|

|

|

Compression |

|

2. |

2. |

Shear |

|

|

|

3. |

|

Wrinkling |

1. |

4. |

|

|

|

Deflection |

3.

4.

Span

[m]

Principle load – span curve

The dimensioning criteria for the load-bearing capacity of sandwich panels for various spans are compression and shear strength for short spans, wrinkling for medium spans and deflection for long spans.

Wrinkling strength [MN/m2]

|

Risk area |

|

Reliable area |

|

|

|

AST threshold value |

|

|

0 |

50 |

100 |

150 |

200 |

Tensile strength

[kN/m2]

Bonding strength

The AST bonding strength threshold value

is 100 kN/m2. In the risk area the spreading is bigger and therefore the same tensile strength can result in a big difference in the measured wrinkling strength of the panel.

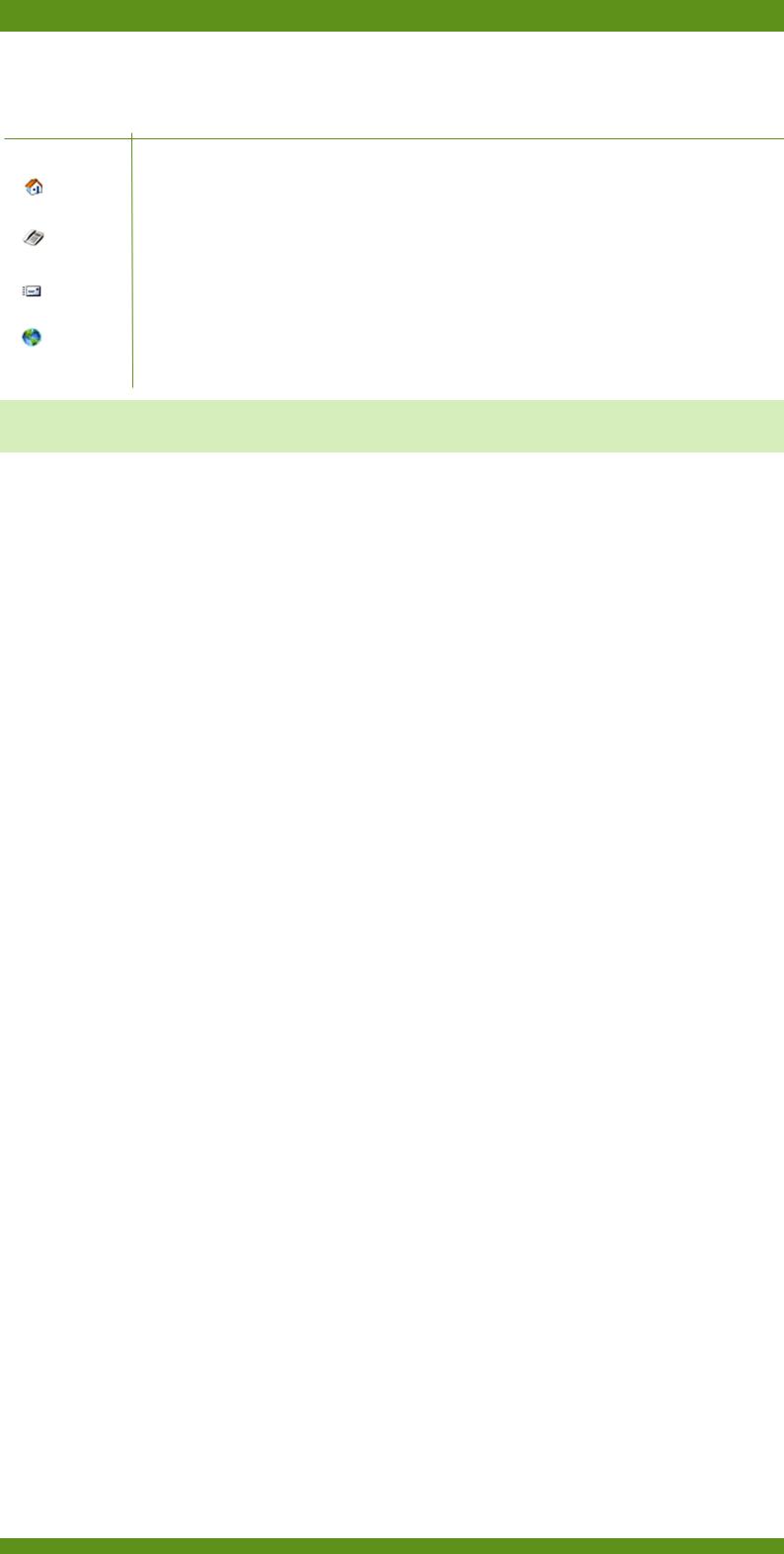

Paroc Panel System – Strength

In Paroc Panels the AST demand that strength properties have to be equal in each crosssection is solved by the lamella orientation and the fully bonded facings. Paroc Structural stone wool slabs are cut into lamellas and rotated so that the very fine mineral fibres are aligned and directed at 90° to the steel surface to ensure the most efficient interaction in the sandwich panel. The lamellas are laid lengthways in a special pattern and pressed together.

The interior side of steel sheet facings in the Paroc panels has a multi-primer system to ensure the bonding between the adhesive and the zinc layer of a steel sheet. The adhesive is specially developed to fulfil the high strength and durability demands on the structural bonding between the core and the facings.

The following table shows long-term quality test values for Paroc Panels with different core type.

|

AST threshold value |

Panels with |

Panels with |

|

core type 50C/F |

core type 75C/F |

|

|

|

||

|

|

|

|

Bonding strength, |

100 |

230 |

350 |

kN/m2 |

Paroc Panel System

Ɉɩɢɫɚɧɢɟ ɫɢɫɬɟɦɵ

2.00 RU

ɂɸɧɶ 2001

PAROC

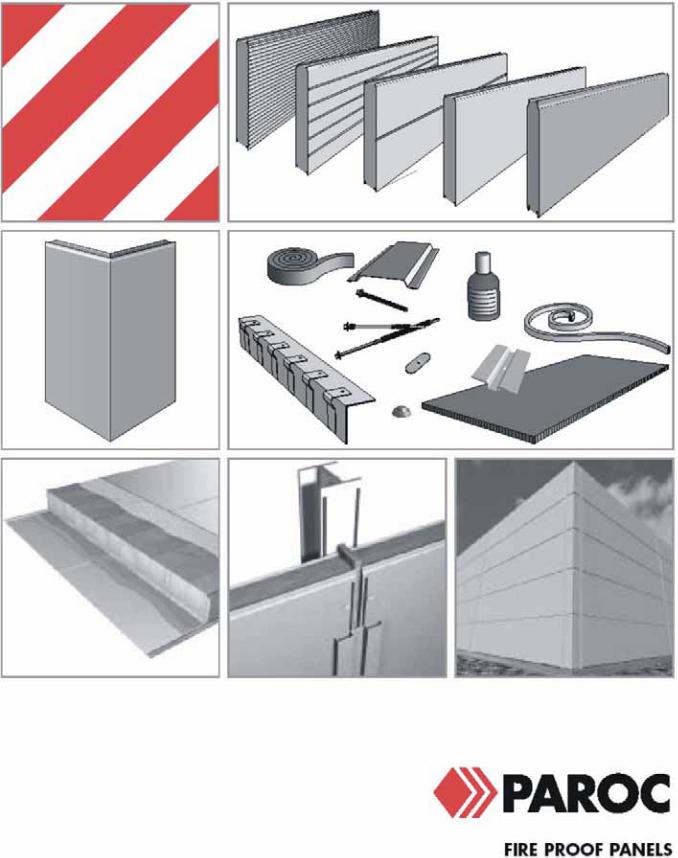

OȽɇȿɋɌɈɃɄɂȿ ɉȺɇȿɅɂ

ȼȼȿȾȿɇɂȿ

ȼȼȿȾȿɇɂȿ

Paroc Panel System – ɡɚɥɨɝ ɜɚɲɟɝɨ ɭɫɩɟɯɚ

ȼɟɞɭɳɢɣ ɩɪɨɢɡɜɨɞɢɬɟɥɶ |

Ɉɞɧɚɤɨ, ɚɪɯɢɬɟɤɬɭɪɧɵɟ ɜɨɡɦɨɠɧɨɫɬɢ ɢ |

Ʉɨɦɩɚɧɢɹ Paroc Oy Ab, Panel |

ɧɟɨɫɩɨɪɢɦɵɟ ɩɪɟɢɦɭɳɟɫɬɜɚ ɷɬɢɯ |

System ɪɚɡɪɚɛɚɬɵɜɚɟɬ, |

ɱɪɟɡɜɵɱɚɣɧɨ ɥɟɝɤɢɯ, ɫɨɜɪɟɦɟɧɧɵɯ ɢ |

ɩɪɨɢɡɜɨɞɢɬ ɢ ɪɟɚɥɢɡɭɟɬ ɧɚ |

ɜɵɫɨɤɨɬɟɯɧɨɥɨɝɢɱɧɵɯ ɩɚɧɟɥɟɣ ɫɞɟɥɚɥɢ |

ɦɢɪɨɜɨɦ ɪɵɧɤɟ ɫɬɪɨɣɦɚɬɟɪɢɚɥɨɜ |

ɢɯ ɩɪɢɦɟɧɟɧɢɟ ɟɫɬɟɫɬɜɟɧɧɵɦ ɢ ɞɥɹ |

ɜɵɫɨɤɨɤɚɱɟɫɬɜɟɧɧɵɟ ɫɛɨɪɧɵɟ |

ɫɬɪɨɢɬɟɥɶɫɬɜɚ ɡɞɚɧɢɣ ɤɨɦɦɟɪɱɟɫɤɨɝɨ, |

ɫɷɧɞɜɢɱ-ɩɚɧɟɥɢ ɧɚ ɨɫɧɨɜɟ |

ɨɛɳɟɫɬɜɟɧɧɨɝɨ ɢ ɞɟɥɨɜɨɝɨ ɧɚɡɧɚɱɟɧɢɹ. |

ɤɨɧɫɬɪɭɤɰɢɨɧɧɨɣ ɤɚɦɟɧɧɨɣ ɜɚɬɵ |

ɋɨɨɬɜɟɬɫɬɜɢɟ ɬɪɟɛɨɜɚɧɢɹɦ |

Paroc. |

ɫɬɚɧɞɚɪɬɨɜ ɨɫɧɨɜɧɵɯ ɪɵɧɤɨɜ |

Paroc Panel System ɞɨɛɢɥɚɫɶ |

ɇɟɫɝɨɪɚɟɦɵɟ ɩɚɧɟɥɢ Paroc ɩɪɨɲɥɢ |

ɥɢɞɢɪɭɸɳɢɯ ɩɨɡɢɰɢɣ ɧɚ ɬɟɯ |

ɢɫɩɵɬɚɧɢɹ ɧɚ ɫɨɨɬɜɟɬɫɬɜɢɟ ɬɢɩɨɜɵɦ |

ɪɵɧɤɚɯ, ɝɞɟ ɩɪɟɞɫɬɚɜɥɟɧɚ ɟɺ |

ɫɬɚɧɞɚɪɬɚɦ ɨɝɧɟɫɬɨɣɤɨɫɬɢ, ɩɪɨɱɧɨɫɬɢ ɢ |

ɩɪɨɞɭɤɰɢɹ. ɍɫɩɟɲɧɵɣ ɨɩɵɬ |

ɬɟɩɥɨɢɡɨɥɹɰɢɨɧɧɵɯ ɫɜɨɣɫɬɜ ɜ |

ɩɨɫɬɚɜɨɤ ɜ ɛɨɥɟɟ ɱɟɦ 30 ɫɬɪɚɧ |

ɧɟɫɤɨɥɶɤɢɯ ɫɬɪɚɧɚɯ ɦɢɪɚ. |

ɩɪɟɜɪɚɬɢɥ Paroc ɜ ɧɚɞɟɠɧɨɝɨ |

ɋɟɪɬɢɮɢɰɢɪɨɜɚɧɧɵɟ ɫɜɨɣɫɬɜɚ ɧɚɲɢɯ |

ɦɟɠɞɭɧɚɪɨɞɧɨɝɨ ɩɚɪɬɧɟɪɚ. |

ɩɚɧɟɥɟɣ ɹɜɥɹɸɬɫɹ ɩɪɟɞɦɟɬɨɦ |

ɇɟɫɝɨɪɚɟɦɵɟ ɫɷɧɞɜɢɱ-ɩɚɧɟɥɢ |

ɩɨɫɬɨɹɧɧɨɝɨ ɤɨɧɬɪɨɥɹ ɫɨ ɫɬɨɪɨɧɵ |

Paroc ɩɪɨɢɡɜɨɞɹɬɫɹ ɧɚ ɡɚɜɨɞɚɯ ɜ |

ɨɮɢɰɢɚɥɶɧɵɯ ɨɪɝɚɧɢɡɚɰɢɣ ɢ |

Ɏɢɧɥɹɧɞɢɢ ɢ ȼɟɥɢɤɨɛɪɢɬɚɧɢɢ ɢ |

ɜɧɭɬɪɟɧɧɟɣ ɫɥɭɠɛɵ ɤɨɧɬɪɨɥɹ ɤɚɱɟɫɬɜɚ |

ɩɨɫɬɚɜɥɹɸɬɫɹ, ɜ ɨɫɧɨɜɧɨɦ, ɜ |

ɩɪɨɞɭɤɰɢɢ. |

ɫɬɪɚɧɵ ɋɟɜɟɪɧɨɣ, Ɂɚɩɚɞɧɨɣ ɢ |

Paroc Panel System ɫɨɨɬɜɟɬɫɬɜɭɟɬ |

ȼɨɫɬɨɱɧɨɣ ȿɜɪɨɩɵ ɢ ɜ Ⱥɡɢɚɬɫɤɨ- |

ɬɪɟɛɨɜɚɧɢɹɦ ɫɬɚɧɞɚɪɬɚ ɤɚɱɟɫɬɜɚ ISO |

Ɍɢɯɨɨɤɟɚɧɫɤɢɣ ɪɟɝɢɨɧ. |

9001. ɗɬɨ ɨɡɧɚɱɚɟɬ, ɱɬɨ ɜɫɹ |

|

ɬɟɯɧɨɥɨɝɢɱɟɫɤɚɹ ɰɟɩɨɱɤɚ, ɧɚɱɢɧɚɹ ɨɬ |

ɋɨɜɪɟɦɟɧɧɚɹ ɬɟɯɧɨɥɨɝɢɹ |

ɨɛɪɚɛɨɬɤɢ ɫɵɪɶɹ ɢ ɡɚɤɚɧɱɢɜɚɹ |

ɫɬɪɨɢɬɟɥɶɫɬɜɚ |

ɩɪɨɢɡɜɨɞɫɬɜɨɦ ɢ ɬɪɚɧɫɩɨɪɬɢɪɨɜɤɨɣ |

Ɂɚ ɪɚɡɪɚɛɨɬɤɨɣ Paroc Panel |

ɝɨɬɨɜɵɯ ɢɡɞɟɥɢɣ, ɪɚɛɨɬɚɟɬ ɜ |

System ɫɬɨɹɥɚ ɢɞɟɹ ɫɨɡɞɚɧɢɹ |

ɫɨɨɬɜɟɬɫɬɜɢɢ ɫ ɬɪɟɛɨɜɚɧɢɹɦɢ |

ɪɚɰɢɨɧɚɥɶɧɨɝɨ ɩɪɨɞɭɤɬɚ, |

ɫɟɪɬɢɮɢɰɢɪɨɜɚɧɧɨɣ ɫɢɫɬɟɦɵ ɤɨɧɬɪɨɥɹ |

ɨɬɜɟɱɚɸɳɟɝɨ ɬɪɟɛɨɜɚɧɢɹɦ |

ɤɚɱɟɫɬɜɚ. Ʉɪɨɦɟ ɷɬɨɝɨ, Paroc Panel |

ɫɨɜɪɟɦɟɧɧɵɯ ɡɞɚɧɢɣ: ɨɬɥɢɱɧɵɣ |

System ɢɦɟɟɬ ɫɟɪɬɢɮɢɤɚɬɵ Det Norske |

ɜɧɟɲɧɢɣ ɜɢɞ, ɫɠɚɬɵɟ ɫɪɨɤɢ |

Veritas ɢ Loss Prevention Certification |

ɫɬɪɨɢɬɟɥɶɫɬɜɚ, ɨɝɧɟɫɬɨɣɤɨɫɬɶ, |

Board Limited (LPCB). |

ɷɧɟɪɝɨɫɛɟɪɟɠɟɧɢɟ, ɝɢɛɤɨɫɬɶ ɢ |

Ɏɢɧɫɤɢɣ ɐɟɧɬɪ ɬɟɯɧɢɱɟɫɤɢɯ |

ɜɵɫɨɤɢɣ ɷɤɨɧɨɦɢɱɟɫɤɢɣ ɷɮɮɟɤɬ. |

ɢɫɫɥɟɞɨɜɚɧɢɣ ɬɚɤɠɟ ɫɟɪɬɢɮɢɰɢɪɨɜɚɥ |

ɋɨɜɦɟɫɬɧɨ ɫɎɢɧɫɤɢɦ ɐɟɧɬɪɨɦ |

ɧɚɲɭ ɩɪɨɞɭɤɰɢɸ: ɋɟɪɬɢɮɢɤɚɬ VTT ʋ |

ɬɟɯɧɢɱɟɫɤɢɯ ɢɫɫɥɟɞɨɜɚɧɢɣ, Paroc |

3/96 ɨɬ 30.09.96. |

Group ɪɚɡɪɚɛɨɬɚɥɚ ɧɟɫɝɨɪɚɟɦɵɟ |

|

ɩɚɧɟɥɢ Paroc ɫ ɭɧɢɤɚɥɶɧɵɦ |

|

ɧɚɩɨɥɧɢɬɟɥɟɦ – |

|

ɤɨɧɫɬɪɭɤɰɢɨɧɧɨɣ ɤɚɦɟɧɧɨɣ |

|

ɜɚɬɨɣ Paroc, ɤɨɬɨɪɵɟ ɛɵɥɢ |

|

ɩɪɟɞɧɚɡɧɚɱɟɧɵ .ɢɡɧɚɱɚɥɶɧɨ. ɞɥɹ |

|

ɫɨɨɪɭɠɟɧɢɹ ɨɛɴɟɤɬɨɜ |

|

ɩɪɨɦɵɲɥɟɧɧɨɝɨ ɢ ɫɤɥɚɞɫɤɨɝɨ |

|

ɧɚɡɧɚɱɟɧɢɹ, ɫɩɨɪɬɢɜɧɵɯ |

|

ɫɨɨɪɭɠɟɧɢɣ ɢ ɬ.ɩ. |

|

Ɋɵɧɨɤ ɫɛɵɬɚ ɧɟɫɝɨɪɚɟɦɵɯ ɫɬɪɨɢɬɟɥɶɧɵɯ ɩɚɧɟɥɟɣ Paroc ɩɨɫɬɨɹɧɧɨ ɪɚɫɲɢɪɹɟɬɫɹ ɜ ɫɢɥɭ ɢɯ ɨɱɟɜɢɞɧɵɯ ɩɪɟɢɦɭɳɟɫɬɜ:

xɧɚɞɟɠɧɨɫɬɶ ɢ ɤɚɱɟɫɬɜɨ

xɷɤɨɧɨɦɢɱɟɫɤɚɹ

ɷɮɮɟɤɬɢɜɧɨɫɬɶ

xɛɵɫɬɪɵɣ ɦɨɧɬɚɠ

ɇɚɞɟɠɧɨɫɬɶ ɢ ɤɚɱɟɫɬɜɨ

ɉɟɪɟɞɨɜɚɹ ɬɟɯɧɨɥɨɝɢɹ ɩɪɨɢɡɜɨɞɫɬɜɚ ɢ ɩɪɢɦɟɧɟɧɢɹ ɫɟɧɞɜɢɱ ɩɚɧɟɥɟɣ , AST, ɛɵɥɚ ɪɚɡɪɚɛɨɬɚɧɚ ɞɥɹ ɬɨɝɨ, ɱɬɨɛɵ ɩɪɨɞɭɤɰɢɹ, ɤɨɬɨɪɚɹ ɩɨɫɬɚɜɥɹɟɬɫɹ ɧɚɲɢɦ ɤɥɢɟɧɬɚɦ, ɫɨɨɬɜɟɬɫɬɜɨɜɚɥɚ ɫɚɦɵɦ ɠɟɫɬɤɢɦ ɬɪɟɛɨɜɚɧɢɹɦ, ɩɪɟɞɴɹɜɥɹɟɦɵɦ ɤ ɧɟɫɭɳɢɦ ɫɷɧɞɜɢɱ-ɩɚɧɟɥɹɦ. AST ɩɨɡɜɨɥɹɟɬ ɞɨɛɢɬɶɫɹ ɜɵɫɨɤɢɯ ɩɪɨɱɧɨɫɬɧɵɯ ɯɚɪɚɤɬɟɪɢɫɬɢɤ, ɧɚɞɟɠɧɵɯ ɩɚɪɚɦɟɬɪɨɜ ɢɡɧɨɫɨɫɬɨɣɤɨɫɬɢ ɢ ɨɝɧɟɫɬɨɣɤɨɫɬɢ ɩɚɧɟɥɟɣ Paroc. ɋɚɦɵɟ ɡɧɚɱɢɦɵɟ ɯɚɪɚɤɬɟɪɢɫɬɢɤɢ ɧɚɲɟɣ ɩɪɨɞɭɤɰɢɢ ɧɟ ɦɨɝɭɬ ɛɵɬɶ ɨɰɟɧɟɧɵ ɜɢɡɭɚɥɶɧɨ, ɨɞɧɚɤɨ ɨɧɢ ɦɨɝɭɬ ɛɵɬɶ ɢɡɦɟɪɟɧɵ ɢ ɩɪɨɤɨɧɬɪɨɥɢɪɨɜɚɧɵ ɧɚ ɷɬɚɩɟ ɩɪɨɢɡɜɨɞɫɬɜɚ. ɇɟɫɝɨɪɚɟɦɵɟ ɩɚɧɟɥɢ Paroc ɜɵɩɭɫɤɚɸɬɫɹ ɜ ɫɨɨɬɜɟɬɫɬɜɢɢ ɫ ɬɟɯɧɨɥɨɝɢɟɣ AST.

2 |

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: AST® ɉɟɪɟɞɨɜɚɹ ɬɟɯɧɨɥɨɝɢɹ ɩɪɨɢɡɜɨɞɫɬɜɚ ɢ ɩɪɢɦɟɧɟɧɢɹ ɫɟɧɞɜɢɱɶ ɩɚɧɟɥɟɣ |

|

ȼȼȿȾȿɇɂȿ |

|

ɋɨɞɟɪɠɚɧɢɟ |

|

|

Ɉɝɧɟɫɬɨɣɤɢɟɩɚɧɟɥɢ Paroc |

4 |

|

ɉɨɠɚɪɧɚɹɛɟɡɨɩɚɫɧɨɫɬɶ |

5 |

|

ɗɤɨɧɨɦɧɵɟɫɦɫɬɟɦɵ |

6 |

|

ɋɢɫɬɟɦɚɬɢɡɚɰɢɹ |

7 |

|

Ɋɚɰɢɨɧɚɥɶɧɨɫɬɶɢ |

|

|

|

8 |

|

ɮɭɧɤɰɢɨɧɚɥɶɧɨɫɬɶ |

|

|

Ⱥɪɯɢɬɟɤɬɭɪɧɵɟɪɟɲɟɧɢɹ |

10 |

|

Ɂɚɳɢɬɚɠɢɡɧɢɢɢɦɭɳɟɫɬɜɚ |

12 |

|

ɉɚɧɟɥɢɞɥɹ„ɱɢɫɬɵɯ“ ɩɪɨɢɡɜɨɞɫɬɜ

14

Ɂɜɭɤɨɢɡɨɥɹɰɢɹɢ

ɡɜɭɤɨɩɨɝɥɨɳɟɧɢɟ

15

ȼɵɫɨɤɢɟɷɤɫɩɥɭɚɬɚɰɢɨɧɧɵɟ

ɯɚɪɚɤɬɟɪɢɫɬɢɤɢ ɧɚɨɫɧɨɜɟ AST®

16

Ɋɚɫɱɟɬɞɥɢɧɧɵɯɩɪɨɥɟɬɨɜ Ʉɚɱɟɫɬɜɟɧɧɵɟɯɚɪɚɤɬɟɪɢɫɬɢɤɢ 18

Ɇɢɧɢɦɢɡɚɰɢɹɤɚɩɢɬɚɥɶɧɵɯɡɚɬɪɚɬ 20 ɡɚɫɱɟɬɛɨɝɚɬɨɝɨɨɩɵɬɚɢ ɷɮɮɟɤɬɢɜɧɨɝɨɨɛɫɥɭɠɢɜɚɧɢɹ

22

Ɉɬɜɟɬɫɬɜɟɧɧɨɫɬɶɤɨɦɩɚɧɢɢ

Ɍɟɯɧɢɱɟɫɤɢɟɞɚɧɧɵɟɢɪɟɤɨɦɟɧɞɚɰɢɢ, ɩɪɢɜɟɞɟɧɧɵɟɜɞɚɧɧɨɣɩɭɛɥɢɤɚɰɢɢ, ɨɫɧɨɜɚɧɵɜɩɟɪɜɭɸɨɱɟɪɟɞɶɧɚɦɚɬɟɪɢɚɥɚɯ ȿɜɪɨɩɟɣɫɤɢɯɊɟɤɨɦɟɧɞɚɰɢɣɩɨɫɷɧɞɜɢɱɩɚɧɟɥɹɦ, ɋɟɪɬɢɮɢɤɚɬɚʋ163\01, ɜɵɞɚɧɧɨɝɨɎɢɧɫɤɢɦɐɟɧɬɪɨɦɬɟɯɧɢɱɟɫɤɢɯ ɢɫɫɥɟɞɨɜɚɧɢɣɢɧɚɩɪɚɤɬɢɱɟɫɤɨɦɨɩɵɬɟ. ȼ ɫɬɪɚɧɚɯ, ɝɞɟɩɚɧɟɥɶɧɵɟɫɢɫɬɟɦɵParoc ɩɪɨɲɥɢɬɢɩɨɜɭɸɫɟɪɬɢɮɢɤɚɰɢɸ, ɥɢɛɨ ɢɦɟɸɬɫɹɫɨɛɫɬɜɟɧɧɵɟ ɫɬɚɧɞɚɪɬɵ, ɩɚɧɟɥɢɢ ɫɬɪɨɢɬɟɥɶɧɵɟɪɟɲɟɧɢɹ ɧɚɢɯɨɫɧɨɜɟ ɩɪɨɢɡɜɨɞɹɬɫɹɜɫɨɨɬɜɟɬɫɬɜɢɢɫɭɤɚɡɚɧɧɵɦɢ ɫɬɚɧɞɚɪɬɚɦɢɢɢɯɩɚɪɚɦɟɬɪɵɦɨɝɭɬ ɨɬɥɢɱɚɬɶɫɹɨɬɩɪɢɜɟɞɟɧɧɵɯɜɞɚɧɧɨɦ

ɦɚɬɟɪɢɚɥɟ. Paroc Panel System ɧɟɫɟɬ ɨɬɜɟɬɫɬɜɟɧɧɨɫɬɶɬɨɥɶɤɨɡɚɢɧɮɨɪɦɚɰɢɸɨ ɫɜɨɣɫɬɜɚɯɫɷɧɞɜɢɱ-ɩɚɧɟɥɟɣ, ɫɨɞɟɪɠɚɳɭɸɫɹ ɜɧɚɫɬɨɹɳɟɦɢɡɞɚɧɢɢ. Ʌɸɛɚɹɞɪɭɝɚɹ ɩɪɟɞɫɬɚɜɥɟɧɧɚɹɢɧɮɨɪɦɚɰɢɹ, ɧɚɩɪɢɦɟɪ, ɨɬɧɨɫɢɬɟɥɶɧɨɩɪɟɞɩɨɥɨɠɢɬɟɥɶɧɨɣɧɟɫɭɳɟɣ ɫɩɨɫɨɛɧɨɫɬɢ ɫɷɧɞɜɢɱ-ɩɚɧɟɥɟɣ ɨɬɧɨɫɢɬɟɥɶɧɨɧɚɝɪɭɡɤɚɦ, ɩɨɞɛɨɪɚɪɚɡɦɟɪɨɜ ɢɫɟɱɟɧɢɣ, ɪɚɛɨɱɟɝɨɩɪɨɟɤɬɢɪɨɜɚɧɢɹɢ ɦɨɧɬɚɠɚ, ɞɨɥɠɧɚɪɚɫɫɦɚɬɪɢɜɚɬɶɫɹɬɨɥɶɤɨɜ ɤɚɱɟɫɬɜɟɫɩɪɚɜɨɱɧɨɣ. ȼɫɟɩɪɚɜɚɡɚɳɢɳɟɧɵ, ɜɤɥɸɱɚɹɩɪɚɜɚɧɚɪɚɡɪɚɛɨɬɤɭɩɪɨɞɭɤɰɢɢɢ ɢɧɵɟɢɡɦɟɧɟɧɢɹ, ɜɬɨɦɱɢɫɥɟ, ɢɡɦɟɧɟɧɢɹ, ɫɜɹɡɚɧɧɵɟɫɧɚɫɬɨɹɳɟɣɩɭɛɥɢɤɚɰɢɟɣ.

3

ɈɌ ɉȺɇȿɅȿɃ – Ʉ ɋɂɋɌȿɆȺɆ

ɈɌ ɉȺɇȿɅȿɃ – Ʉ ɋɂɋɌȿɆȺɆ

Ɉɝɧɟɫɬɨɣɤɢɟ ɩɚɧɟɥɢ Paroc

ɇɟɫɝɨɪɚɟɦɵɟɩɚɧɟɥɢParoc®

ɇɟɫɝɨɪɚɟɦɵɟɩɚɧɟɥɢParoc – ɷɬɨ ɜɵɫɨɤɨɬɟɯɧɨɥɨɝɢɱɧɵɟɫɷɧɞɜɢɱ-ɩɚɧɟɥɢ ɧɚɨɫɧɨɜɟɤɨɧɫɬɪɭɤɰɢɨɧɧɨɣɤɚɦɟɧɧɨɣ ɜɚɬɵParoc. ɉɨɜɟɪɯɧɨɫɬɢɩɚɧɟɥɟɣ, ɜɵɩɨɥɧɟɧɧɵɟɢɡɥɢɫɬɨɜɨɣɫɬɚɥɢ, ɪɚɛɨɬɚɸɬɫɨɜɦɟɫɬɧɨɫɫɟɪɞɟɱɧɢɤɨɦɢɡ ɤɚɦɟɧɧɨɣɜɚɬɵ, ɨɛɪɚɡɭɹɢɡɞɟɥɢɟɫ ɜɵɫɨɤɢɦɢɷɤɫɩɥɭɚɬɚɰɢɨɧɧɵɦɢ ɯɚɪɚɤɬɟɪɢɫɬɢɤɚɦɢɢɜɫɟɦɢɫɜɨɣɫɬɜɚɦɢ ɞɥɹɫɬɪɨɢɬɟɥɶɧɵɯɧɭɠɞ. ɉɚɧɟɥɢParoc ɨɛɥɚɞɚɸɬɭɧɢɤɚɥɶɧɵɦɢɩɚɪɚɦɟɬɪɚɦɢ ɨɝɧɟɫɬɨɣɤɨɫɬɢ, ɩɪɨɱɧɨɫɬɢ, ɝɟɪɦɟɬɢɱɧɨɫɬɢɢɬɟɩɥɨɢɡɨɥɹɰɢɢɩɪɢ ɩɪɢɦɟɧɟɧɢɢɜɤɚɱɟɫɬɜɟɧɚɪɭɠɧɵɯ ɫɬɟɧɨɜɵɯɨɝɪɚɠɞɟɧɢɣ, ɚɬɚɤɠɟ ɜɧɭɬɪɟɧɧɢɯɩɟɪɟɝɨɪɨɞɨɤɢɩɨɬɨɥɨɱɧɵɯ ɤɨɧɫɬɪɭɤɰɢɣ. ɉɪɟɜɨɫɯɨɞɧɵɟ ɯɚɪɚɤɬɟɪɢɫɬɢɤɢɧɟɫɝɨɪɚɟɦɵɯɫɷɧɞɜɢɱɩɚɧɟɥɟɣ Paroc ɨɛɟɫɩɟɱɢɜɚɸɬɫɹɡɚɫɱɟɬ ɩɪɢɦɟɧɟɧɢɹɉɟɪɟɞɨɜɨɣɌɟɯɧɨɥɨɝɢɢ ɩɪɨɢɡɜɨɞɫɬɜɚɢɩɪɢɦɟɧɟɧɢɹɫɟɧɞɜɢɱ ɩɚɧɟɥɟɣ(AST).

ɍɧɢɤɚɥɶɧɵɣɦɚɬɟɪɢɚɥɫɟɪɞɟɱɧɢɤɚ

Paroc Structural®

ɍɧɢɤɚɥɶɧɚɹɤɚɦɟɧɧɚɹɜɚɬɚParoc Structural® – ɩɪɨɞɭɤɬ, ɪɚɡɪɚɛɨɬɚɧɧɵɣ ɝɪɭɩɩɨɣɤɨɦɩɚɧɢɣParoc Group, ɢɦɟɸɳɟɣɛɨɥɟɟɱɟɦ60-ɥɟɬɧɢɣ ɨɩɵɬɜ ɨɛɥɚɫɬɢɬɟɯɧɨɥɨɝɢɣ ɩɪɨɢɫɜɨɞɫɬɜɚɢ ɩɪɢɦɟɧɟɧɢɹɤɚɦɟɧɧɨɣɜɚɬɵ. ɋɨɝɥɚɫɧɨ ɫɬɚɧɞɚɪɬɚɦɬɟɯɧɨɥɨɝɢɢAST, ɤɚɦɟɧɧɚɹ ɜɚɬɚParoc ɹɜɥɹɟɬɫɹɧɟɝɨɪɸɱɟɣ, ɜɨɥɨɤɧɚɨɪɢɟɧɬɢɪɨɜɚɧɵɜɨɞɧɨɦ ɧɚɩɪɚɜɥɟɧɢɢ, ɱɬɨɨɛɟɫɩɟɱɢɜɚɟɬ ɤɨɧɬɪɨɥɢɪɭɟɦɵɟɩɪɨɱɧɨɫɬɧɵɟ ɯɚɪɚɤɬɟɪɢɫɬɢɤɢɢɡɞɟɥɢɹ. Ɍɟɯɧɨɥɨɝɢɹ ɩɪɨɢɡɜɨɞɫɬɜɚParoc Panel System

ɩɨɡɜɨɥɹɟɬɤɨɧɬɪɨɥɢɪɨɜɚɬɶɢ

ɪɟɝɭɥɢɪɨɜɚɬɶɩɚɪɚɦɟɬɪɵɩɪɨɱɧɨɫɬɢɢ ɨɝɧɟɫɬɨɣɤɨɫɬɢɫɟɪɞɟɱɧɢɤɚɩɚɧɟɥɢ. ȼɵɩɭɫɤɚɸɬɫɹɫɟɪɞɟɱɧɢɤɢɫɥɟɞɭɸɳɢɯ ɦɚɪɨɤ: 50ɋ, 50F, 75C ɢ75F, ɝɞɟ50 ɢ75

ɭɤɚɡɵɜɚɟɬɩɪɨɱɧɨɫɬɶɫɟɪɞɟɱɧɢɤɚɧɚ ɪɚɪɭɲɚɸɳɟɟɭɫɢɥɢɟɩɪɬɫɠɚɬɢɣ, ɚ ɛɭɤɜɟɧɧɨɟɨɛɨɡɧɚɱɟɧɢɟɋɢɥɢF ɨɛɨɡɧɚɱɚɟɬɫɬɟɩɟɧɶɨɝɧɟɫɬɨɣɤɨɫɬɢ ɫɟɪɞɟɱɧɢɤɚ. Ʉɨɧɫɬɪɭɤɬɢɜɧɚɹɤɚɦɟɧɧɚɹ ɜɚɬɚParoc ɜɵɩɭɫɤɚɟɬɫɹ ɩɪɟɢɦɭɳɟɫɬɜɟɧɧɨ ɞɥɹɩɪɨɢɡɜɨɞɫɬɜɚ ɨɝɧɟɫɬɨɣɤɢɯɫɷɧɞɜɢɱ-ɩɚɧɟɥɟɣ.

ɉɪɨɱɧɚɹɢɧɚɞɟɠɧɚɹɫɤɥɟɣɤɚ |

Ʉɨɦɩɨɧɟɧɬɵɨɝɧɟɫɬɨɣɤɢɯɩɚɧɟɥɟɣ |

|

ɉɪɨɱɧɨɫɬɶɫɷɧɞɜɢɱ-ɩɚɧɟɥɢɧɚɩɪɹɦɭɸ |

Paroc: |

|

ɡɚɜɢɫɢɬɨɬɜɡɚɢɦɨɞɟɣɫɬɜɢɹɦɟɠɞɭ |

(1) |

Ɉɰɢɧɤɨɜɚɧɧɵɣɫɬɚɥɶɧɨɣɥɢɫɬ(275 |

ɫɟɪɞɟɱɧɢɤɨɦɢɡɤɨɧɫɬɪɭɤɬɢɜɧɨɣ |

|

ɝ/ɦ2) ɫɩɨɤɪɵɬɢɟɦ, ɜɫɨɨɬɜɟɬɫɬɜɢɢ |

ɤɚɦɟɧɧɨɣɜɚɬɵɢɧɚɪɭɠɧɵɦɢɳɢɬɚɦɢ |

|

ɫɷɤɨɥɨɝɢɱɟɫɤɢɦɢɬɪɟɛɨɜɚɧɢɹɦɢ. |

ɩɚɧɟɥɢ, ɜɵɩɨɥɧɟɧɧɵɦɢɢɡɥɢɫɬɨɜɨɣ |

(2) |

ɋɩɟɰɢɚɥɶɧɵɣɤɥɟɣ, |

ɫɬɚɥɢ. ɋɨɨɬɜɟɬɫɬɜɟɧɧɨ, ɫɤɥɟɣɤɚ |

|

ɫɨɨɬɜɟɬɫɬɜɭɸɳɢɣɬɪɟɛɨɜɚɧɢɹɦ |

ɹɜɥɹɟɬɫɹɫɚɦɵɦɜɚɠɧɵɦɷɬɚɩɨɦ |

|

AST ɩɨɯɚɪɚɤɬɟɪɢɫɬɢɤɚɦɫɢɥɵ |

ɬɟɯɧɨɥɨɝɢɱɟɫɤɨɝɨɩɪɨɰɟɫɫɚ. Ʉɥɟɣ, |

|

ɫɰɟɩɥɟɧɢɹɢɞɨɥɝɨɜɟɱɧɨɫɬɢ; |

ɩɪɢɦɟɧɹɟɦɵɣɞɥɹɷɬɢɯɰɟɥɟɣ, |

|

ɧɚɧɨɫɢɬɫɹɧɚɜɫɸɩɥɨɳɚɞɶ |

ɪɚɡɪɚɛɨɬɚɧɫɩɟɰɢɚɥɶɧɨɞɥɹɬɨɝɨ, ɱɬɨɛɵ |

|

ɩɨɜɟɪɯɧɨɫɬɢ. |

ɨɛɟɫɩɟɱɢɬɶɫɨɨɬɜɟɬɫɬɜɢɟɜɵɫɨɤɢɦ |

(3) |

ɇɟɝɨɪɸɱɢɣɫɟɪɞɟɱɧɢɤɢɡɥɚɦɟɥɟɣ |

ɬɪɟɛɨɜɚɧɢɹɦ, ɩɪɟɞɴɹɜɥɹɟɦɵɦɤ |

|

ɤɨɧɫɬɪɭɤɬɢɜɧɨɣɤɚɦɟɧɧɨɣɜɚɬɵ |

ɩɪɨɱɧɨɫɬɢɢɞɨɥɝɨɜɟɱɧɨɫɬɢ ɫɤɥɟɣɤɢ |

|

ɨɛɟɫɩɟɱɢɜɚɟɬɨɞɢɧɚɤɨɜɵɟ |

ɦɟɠɞɭɫɟɪɞɟɱɧɢɤɨɦɢɥɢɰɟɜɵɦɢ |

|

ɩɪɨɱɧɨɫɬɧɵɟɯɚɪɚɤɬɟɪɢɫɬɢɤɢɜ |

ɳɢɬɚɦɢɩɚɧɟɥɢ. ȼɧɭɬɪɟɧɧɹɹɫɬɨɪɨɧɚ |

|

ɥɸɛɨɦɫɟɱɟɧɢɢɩɚɧɟɥɢ. |

ɥɢɰɟɜɨɝɨɫɬɚɥɶɧɨɝɨɥɢɫɬɚ ɩɨɤɪɵɜɚɟɬɫɹ |

(4) |

ɇɟɫɤɨɥɶɤɨɫɥɨɟɜɝɪɭɧɬɨɜɤɢɞɥɹ |

ɧɟɫɤɨɥɶɤɢɦɢɫɥɨɹɦɢɝɪɭɧɬɨɜɤɢ, ɞɥɹ |

|

ɨɛɟɫɩɟɱɟɧɢɹɫɰɟɩɥɟɧɢɹɦɟɠɞɭ |

ɨɛɟɫɩɟɱɟɧɢɹɧɚɞɟɠɧɨɝɨɫɰɟɩɥɟɧɢɟ |

|

ɤɥɟɟɦɢɨɰɢɧɤɨɜɚɧɧɵɦɫɬɚɥɶɧɵɦ |

ɦɟɠɞɭɤɥɟɟɦɢɨɰɢɧɤɨɜɤɨɣɫɬɚɥɶɧɨɝɨ |

|

ɥɢɫɬɨɦ. |

ɥɢɫɬɚ. ɋɢɥɚɫɰɟɩɥɟɧɢɹɜɩɚɧɟɥɹɯParoc |

(5) |

ɋɬɵɤɩɨɠɚɪɨɛɟɡɨɩɚɫɧɨɣ |

ɩɪɟɜɨɫɯɨɞɢɬɤɪɢɬɢɱɟɫɤɨɟɡɧɚɱɟɧɢɟ, |

|

ɤɨɧɫɬɪɭɤɰɢɢ, ɨɛɟɫɩɟɱɢɜɚɸɳɢɣ |

ɭɫɬɚɧɨɜɥɟɧɧɨɟɫɬɚɧɞɚɪɬɨɦAST - 100 |

|

ɧɟɩɪɨɧɢɰɚɟɦɨɫɬɶɩɚɧɟɥɢɞɥɹ |

ɤɇ/ɦ2. |

|

ɝɨɪɹɱɢɯɝɚɡɨɜɢɩɥɚɦɟɧɢ. |

Ƚɨɬɨɜɚɹ ɩɨɜɟɪɯɧɨɫɬɶ |

Ⱥɜɬɨɦɚɬɢɡɢɪɨɜɚɧɧɨɟɩɪɨɢɡɜɨɞɫɬɜɨ |

ɈɛɵɱɧɨɩɚɧɟɥɢParoc ɨɤɪɚɲɟɧɵ ɢ |

ɈɝɧɟɫɬɨɣɤɢɟɩɚɧɟɥɢParoc |

ɢɦɟɸɬɪɚɫɰɜɟɬɤɭɫɨɛɟɢɯɫɬɨɪɨɧ. |

ɢɡɝɨɬɚɜɥɢɜɚɸɬɫɹɩɨ |

ɉɨɜɟɪɯɧɨɫɬɢ ɫɬɚɥɶɧɵɯɥɢɫɬɨɜ |

ɜɵɫɨɤɨɩɪɨɢɡɜɨɞɢɬɟɥɶɧɨɣ |

ɩɨɤɪɵɜɚɸɬɫɹɤɨɦɩɨɡɢɬɧɨɣ ɫɦɟɫɶɸ. |

ɚɜɬɨɦɚɬɢɱɟɫɤɨɣɬɟɯɧɨɥɨɝɢɢɜ |

ɉɨɜɟɪɯɧɨɫɬɢɫɨɬɞɟɥɤɨɣɧɟɧɭɠɞɚɸɬɫɹ |

ɫɨɨɬɜɟɬɫɬɜɢɢɫɨɫɬɚɧɞɚɪɬɨɦɤɚɱɟɫɬɜɚ |

ɜɞɨɩɨɥɧɢɬɟɥɶɧɨɣɨɛɪɚɛɨɬɤɟ. ɉɪɢ |

ISO 9001. ȼɟɫɶɩɪɨɢɡɜɨɞɫɬɜɟɧɧɵɣ |

ɧɟɨɛɯɨɞɢɦɨɫɬɢ, ɜɨɡɦɨɠɧɚɩɨɫɬɚɜɤɚ |

ɩɪɨɰɟɫɫɨɬɧɚɱɚɥɚɞɨɤɨɧɰɚ |

ɩɚɧɟɥɟɣɫɩɪɢɦɟɧɟɧɢɟɦɧɟɪɠɚɜɟɸɳɟɣ |

ɧɟɩɪɟɪɵɜɧɨɤɨɧɬɪɨɥɢɪɭɟɬɫɹ |

ɫɬɚɥɢ. |

ɨɮɢɰɢɚɥɶɧɵɦɢɨɪɝɚɧɚɦɢɤɨɧɬɪɨɥɹ |

Ɍɢɩɵɩɨɤɪɵɬɢɣɦɨɝɭɬɥɟɝɤɨɦɟɧɹɬɶɫɹ |

ɤɚɱɟɫɬɜɚ, ɚɬɚɤɠɟɫɥɭɠɛɨɣɜɧɭɬɪɟɧɧɟɝɨ |

ɤɚɤɩɨɰɜɟɬɨɜɨɣɝɚɦɦɟ, ɬɚɤɢɩɨ |

ɤɨɧɬɪɨɥɹɤɚɱɟɫɬɜɚParoc Panel System, |

ɧɚɡɧɚɱɟɧɢɸ. |

ɞɥɹɫɨɛɥɸɞɟɧɢɹɬɪɟɛɨɜɚɧɢɣɤɤɚɱɟɫɬɜɭ |

ȼɡɚɜɢɫɢɦɨɫɬɢɨɬɨɛɥɚɫɬɢɢɯ |

ɩɪɨɞɭɤɰɢɢ, ɩɪɨɢɡɜɟɞɟɧɧɨɣ ɩɨ |

ɩɪɢɦɟɧɟɧɢɹ– ɜɧɭɬɪɟɧɧɢɟɢɥɢ |

ɬɟɯɧɨɥɨɝɢɢ(AST). ɋɵɪɶɟ, ɩɚɧɟɥɢɢ |

ɜɧɟɲɧɢɟɤɨɧɫɬɪɭɤɰɢɢ– ɩɨɤɪɵɬɢɹ |

ɬɟɯɧɨɥɨɝɢɹɩɪɨɢɡɜɨɞɫɬɜɚɨɯɪɚɧɹɸɬɫɹ |

ɦɨɝɭɬɜɵɛɢɪɚɬɶɫɹɜɫɨɨɬɜɟɬɫɬɜɢɢɫ |

ɦɧɨɝɨɱɢɫɥɟɧɧɵɦɢɩɚɬɟɧɬɚɦɢ. |

ɭɫɥɨɜɢɹɦɢ, ɜɤɨɬɨɪɵɯɨɧɢɛɭɞɭɬ |

|

ɷɤɫɩɥɭɚɬɢɪɨɜɚɬɶɫɹ. |

|

4 |

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: AST® , ɐɜɟɬɚ ɢ ɩɨɤɪɵɬɢɹ |

ɇɚɪɭɠɧɵɟ ɫɬɟɧɵ

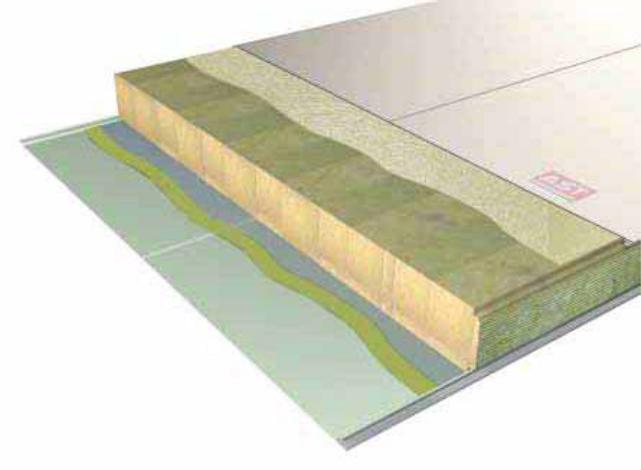

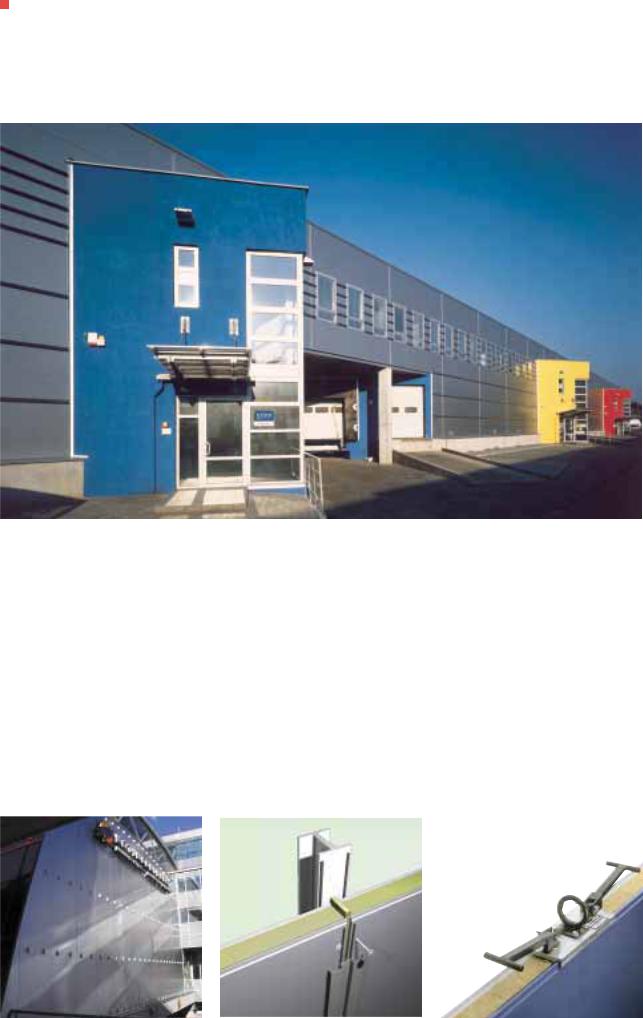

ɇɟɫɝɨɪɚɟɦɵɟ ɫɷɧɞɜɢɱ-ɩɚɧɟɥɢ Paroc ɩɪɟɞɫɬɚɜɥɹɸɬ ɫɨɛɨɣ ɤɨɦɩɥɟɤɫɧɨɟ ɪɟɲɟɧɢɟ ɩɨ ɭɫɬɪɨɣɫɬɜɭ ɧɚɪɭɠɧɵɯ ɫɬɟɧɨɜɵɯ ɨɝɪɚɠɞɟɧɢɣ, ɨɛɟɫɩɟɱɢɜɚɸɳɟɟ ɬɟɩɥɨɢɡɨɥɹɰɢɸ, ɨɝɧɟɫɬɨɣɤɨɫɬɶ, ɧɚɞɟɠɧɭɸ ɩɚɪɨɢɡɨɥɹɰɢɸ ɢ ɨɬɞɟɥɤɭ ɤɚɤ ɫ ɜɧɟɲɧɟɣ, ɬɚɤ ɢ ɫ ɜɧɭɬɪɟɧɧɟɣ ɫɬɨɪɨɧɵ. ɒɢɪɨɤɢɣ ɚɫɫɨɪɬɢɦɟɧɬ ɩɚɧɟɥɟɣ ɞɚɟɬ ɧɟɨɝɪɚɧɢɱɟɧɧɵɟ ɚɪɯɢɬɟɤɬɭɪɧɵɟ ɜɨɡɦɨɠɧɨɫɬɢ ɢ ɢɧɞɢɜɢɞɭɚɥɶɧɨɫɬɶ ɨɮɨɪɦɥɟɧɢɹ ɮɚɫɚɞɚ. ɉɪɢ ɭɫɬɪɨɣɫɬɜɟ ɧɚɪɭɠɧɵɯ ɫɬɟɧ, ɩɚɧɟɥɢ ɦɨɝɭɬ ɭɫɬɚɧɚɜɥɢɜɚɬɶɫɹ ɝɨɪɢɡɨɧɬɚɥɶɧɨ, ɜɟɪɬɢɤɚɥɶɧɨ ɢɥɢ ɩɨ ɞɢɚɝɨɧɚɥɢ.

ɈɌ ɉȺɇȿɅȿɃ Ʉ ɋɂɋɌȿɆȺɆ

ɉɨɠɚɪɧɚɹ ɛɟɡɨɩɚɫɧɨɫɬɶ

ȼɧɭɬɪɟɧɧɢɟ ɫɬɟɧɵ |

ɉɨɬɨɥɤɢ |

Ɋɚɰɢɨɧɚɥɶɧɚɹ ɫɢɫɬɟɦɚ ɨɛɟɫɩɟɱɢɜɚɟɬ |

ɉɨɬɨɥɨɱɧɵɟ ɫɢɫɬɟɦɵ Paroc |

ɭɫɬɪɨɣɫɬɜɨ ɛɟɡɨɩɚɫɧɵɯ ɢ ɥɟɝɤɢɯ |

ɭɧɢɜɟɪɫɚɥɶɧɵ ɜ ɩɪɢɦɟɧɟɧɢɢ. ȼ |

ɜɧɭɬɪɟɧɧɢɯ ɩɟɪɟɝɨɪɨɞɨɤ ɫ |

ɡɚɜɢɫɢɦɨɫɬɢ ɨɬ ɜɵɛɪɚɧɧɨɝɨ ɫɨɱɟɬɚɧɢɹ |

ɨɬɞɟɥɚɧɧɵɦɢ ɝɥɚɞɤɢɦɢ ɩɨɜɟɪɯɧɨɫɬɹɦɢ |

ɧɚɝɪɭɡɨɤɢ ɨɩɪɟɞɟɥɟɧɢɢ ɩɪɨɱɧɨɫɬɧɵɯ |

ɫ ɨɛɟɢɯ ɫɬɨɪɨɧ. ɋɬɟɧɚ, ɢɡɝɨɬɨɜɥɟɧɧɚɹ |

ɯɚɪɚɤɬɟɪɢɫɬɢɤ ɫɢɫɬɟɦɵ, ɤɨɧɫɬɪɭɤɰɢɢ |

ɢɡ ɩɚɧɟɥɟɣ Paroc, ɨɬɥɢɱɚɟɬɫɹ ɯɨɪɨɲɢɦɢ |

ɦɨɝɭɬ ɪɚɛɨɬɚɬɶ ɤɚɤ ɧɚɝɪɭɠɚɟɦɵɟ, ɬɚɤ |

ɩɨɤɚɡɚɬɟɥɹɦɢ ɬɟɩɥɨɢɡɨɥɹɰɢɢ ɢ |

ɢ ɧɟɧɚɝɪɭɠɚɟɦɵɟ ɩɨɬɨɥɤɢ. ɉɪɢ |

ɝɟɪɦɟɬɢɱɧɨɫɬɢ. ɉɪɢ ɧɟɨɛɯɨɞɢɦɨɫɬɢ, |

ɭɫɬɪɨɣɫɬɜɟ ɩɨɞɜɟɫɧɵɯ ɩɨɬɨɥɤɨɜ, |

ɩɟɪɟɝɨɪɨɞɤɢ ɢɡ ɩɚɧɟɥɟɣ Paroc ɦɨɝɭɬ |

ɩɚɧɟɥɢ ɩɪɨɫɬɨ ɤɪɟɩɹɬɫɹ ɤ ɧɟɫɭɳɢɦ |

ɨɛɟɫɩɟɱɢɬɶ ɨɝɧɟɫɬɨɣɤɨɫɬɶ ɞɨ 3 ɱɚɫɨɜ. |

ɩɪɨɮɢɥɹɦ, ɢ ɞɚɥɟɟ ɤ ɨɫɧɨɜɧɵɦ |

ɋɩɟɰɢɚɥɶɧɚɹ ɦɧɨɝɨɫɥɨɣɧɚɹ |

ɤɨɧɫɬɪɭɤɰɢɹɦ ɡɞɚɧɢɹ. |

ɤɨɧɫɬɪɭɤɰɢɹ ɩɪɢɞɚɟɬ ɩɚɧɟɥɹɦ |

ȼɟɧɬɢɥɹɰɢɨɧɧɵɟ ɭɫɬɪɨɣɫɬɜɚ ɢ ɩɪɨɱɢɟ |

ɩɪɨɱɧɨɫɬɶ, ɧɟɨɛɯɨɞɢɦɭɸ ɞɥɹ |

ɷɥɟɦɟɧɬɵ ɬɟɯɧɢɱɟɫɤɨɝɨ ɨɫɧɚɳɟɧɢɹ |

ɛɨɥɶɲɟɩɪɨɥɟɬɧɵɯ ɜɧɭɬɪɟɧɧɢɯ ɫɬɟɧ. |

ɦɨɝɭɬ ɪɚɫɩɨɥɚɝɚɬɶɫɹ ɡɚ ɩɨɞɜɟɫɧɵɦɢ |

Ⱦɥɹ ɩɨɦɟɳɟɧɢɣ ɫ ɜɵɫɨɤɢɦɢ ɩɨɬɨɥɤɚɦɢ, |

ɩɨɬɨɥɤɚɦɢ. ɋɜɟɬɨɜɵɟ ɩɪɢɛɨɪɵ, |

ɩɪɚɤɬɢɱɧɵɦ ɢ ɷɤɨɧɨɦɢɱɟɫɤɢ |

ɤɨɦɦɭɧɢɤɚɰɢɢ, ɬɪɭɛɨɩɪɨɜɨɞɵ ɢ |

ɨɩɪɚɜɞɚɧɧɵɦ ɪɟɲɟɧɢɟɦ ɹɜɥɹɟɬɫɹ |

ɤɚɛɟɥɢ ɬɚɤɠɟ ɨɛɵɱɧɨ ɤɪɟɩɹɬɫɹ ɤ |

ɜɟɪɬɢɤɚɥɶɧɚɹ ɭɫɬɚɧɨɜɤɚ ɩɚɧɟɥɟɣ ɬɚɦ, |

ɨɫɧɨɜɧɵɦ ɤɨɧɫɬɪɭɤɰɢɹɦ. Ʉɪɨɦɟ ɷɬɨɝɨ, |

ɝɞɟ ɨɧɢ ɩɨɞɯɨɞɹɬ ɩɨ ɜɵɫɨɬɟ ɩɪɨɥɟɬɚ. |

ɩɚɧɟɥɢ ɦɨɝɭɬ ɛɵɬɶ ɡɚɤɪɟɩɥɟɧɵ |

Ɉɞɧɚɤɨ ɩɚɧɟɥɢ ɦɨɝɭɬ ɭɫɬɚɧɚɜɥɢɜɚɬɶɫɹ |

ɧɚɩɪɹɦɭɸ ɤ ɤɨɧɫɬɪɭɤɰɢɹɦ ɤɪɨɜɥɢ. |

ɢ ɝɨɪɢɡɨɧɬɚɥɶɧɨ, ɧɚɩɪɢɦɟɪ, ɦɟɠɞɭ |

|

ɤɨɥɨɧɧɚɦɢ. |

|

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: AST® |

5 |

ɈɌ ɉȺɇȿɅȿɃ Ʉ ɋɂɋɌȿɆȺɆ

ɈɌ ɉȺɇȿɅȿɃ Ʉ ɋɂɋɌȿɆȺɆ

ɗɤɨɧɨɦɧɵɟ ɫɢɫɬɟɦɵ

Ʉɨɦɩɥɟɤɫɧɵɣɩɨɞɯɨɞ

Ɉɝɧɟɫɬɨɣɤɢɟɫɷɧɞɜɢɱ-ɩɚɧɟɥɢParoc ɜ ɤɨɦɩɥɟɤɬɟɫɨɜɫɟɦɢɨɫɬɚɥɶɧɵɦɢ ɤɨɦɩɨɧɟɧɬɚɦɢ, ɧɟɨɛɯɨɞɢɦɵɦɢɞɥɹ ɡɚɜɟɪɲɟɧɢɹɤɨɧɫɬɪɭɤɰɢɢ– ɭɝɥɨɜɵɦɢ ɩɚɧɟɥɹɦɢ, ɤɪɟɩɟɠɧɵɦɢɦɚɬɟɪɢɚɥɚɦɢ, ɝɢɞɪɨɢɡɨɥɹɰɢɟɣɫɬɵɤɨɜ, ɩɪɨɮɢɥɹɦɢ, ɭɩɥɨɬɧɟɧɢɹɦɢ, ɩɨɞɴɟɦɧɵɦ ɨɛɨɪɭɞɨɜɚɧɢɟɦ, ɚɬɚɤɠɟ ɩɟɪɜɨɤɥɚɫɫɧɨɣɬɟɯɧɢɱɟɫɤɨɣ ɩɨɞɞɟɪɠɤɨɣɨɬParoc Panel System –

ɩɪɟɞɫɬɚɜɥɹɸɬɫɨɛɨɣɫɢɫɬɟɦɭ, ɞɥɹ ɤɨɬɨɪɨɣɧɟɫɭɳɟɫɬɜɭɟɬɨɝɪɚɧɢɱɟɧɢɣ, ɤɪɨɦɟɜɨɨɛɪɚɠɟɧɢɹ. ɗɬɚɫɨɜɪɟɦɟɧɧɚɹ ɫɬɪɨɢɬɟɥɶɧɚɹɫɢɫɬɟɦɚɨɬɜɟɱɚɟɬ ɬɟɯɧɢɱɟɫɤɢɦ, ɷɫɬɟɬɢɱɟɫɤɢɦɢ ɛɸɞɠɟɬɧɵɦɬɪɟɛɨɜɚɧɢɹɦɜɫɟɯ ɭɱɚɫɬɧɢɤɨɜɫɬɪɨɢɬɟɥɶɧɨɝɨɩɪɨɟɤɬɚ.

ɉɨɠɚɪɧɚɹɛɟɡɨɩɚɫɧɨɫɬɶ |

ɞɟɬɚɥɟɣ, ɨɛɟɫɩɟɱɢɜɚɟɦɵɟɮɢɪɦɟɧɧɨɣ |

Ɂɚɳɢɬɚɠɢɡɧɢɢɢɦɭɳɟɫɬɜɚ ɜ |

ɫɥɭɠɛɨɣɬɟɯɧɢɱɟɫɤɨɣɩɨɞɞɟɪɠɤɢ, |

ɫɨɜɪɟɦɟɧɧɨɦɦɢɪɟɢɦɟɟɬɨɝɪɨɦɧɨɟ |

ɭɫɤɨɪɹɸɬɩɪɨɟɤɬɢɪɨɜɚɧɢɟɢɦɨɧɬɚɠ. |

ɡɧɚɱɟɧɢɟ. Ɉɝɧɟɫɬɨɣɤɢɟɫɷɧɞɜɢɱ- |

ɗɤɨɧɨɦɢɱɧɨɫɬɶɢɧɚɞɟɠɧɨɫɬɶ |

ɩɚɧɟɥɢParoc, ɫɨɡɞɚɧɧɵɟɫ |

ɂɫɩɨɥɶɡɨɜɚɧɢɟ ɫɬɪɨɢɬɟɥɶɧɵɯɩɚɧɟɥɟɣ, |

|

|

ɢɫɩɨɥɶɡɨɜɚɧɢɟɦɧɟɝɨɪɸɱɟɝɨ |

|

|

ɢɡɝɨɬɚɜɥɢɜɚɟɦɵɯɜɤɨɧɬɪɨɥɢɪɭɟɦɵɯ |

ɧɚɩɨɥɧɢɬɟɥɹɫɨɬɞɟɥɤɨɣɢɡɥɢɫɬɨɜɨɣ |

|

|

ɭɫɥɨɜɢɹɯɩɨɫɬɚɧɞɚɪɬɚɦɬɟɯɧɨɥɨɝɢɢ |

ɫɬɚɥɢ, ɨɛɟɫɩɟɱɚɬɩɚɫɫɢɜɧɭɸ |

AST, ɜɫɨɱɟɬɚɧɢɢɫɜɵɛɪɚɧɧɵɦɢ |

|

|

ɩɪɨɬɢɜɨɩɨɠɚɪɧɭɸɡɚɳɢɬɭɜɬɟɱɟɧɢɟ |

|

|

ɤɨɧɫɬɪɭɤɰɢɹɦɢ ɢɮɭɧɤɰɢɨɧɚɥɶɧɵɦɢ |

ɜɫɟɝɨɫɪɨɤɚɫɥɭɠɛɵ ɡɞɚɧɢɹ. |

ɪɟɲɟɧɢɹɦɢɭɡɥɨɜ, ɫɜɨɞɢɬɤɦɢɧɢɦɭɦɭ |

|

|

Ɋɚɰɢɨɧɚɥɶɧɨɫɬɶ |

ɨɲɢɛɤɢɩɪɢɫɬɪɨɢɬɟɥɶɫɬɜɟɨɛɴɟɤɬɨɜ. |

ɉɚɧɟɥɢParoc ɫɨɱɟɬɚɸɬɮɭɧɤɰɢɢ |

ɇɚɞɟɠɧɵɟɦɚɬɟɪɢɚɥɵɢɤɨɧɫɬɪɭɤɰɢɢ, |

ɬɟɩɥɨɢɡɨɥɹɰɢɢ, ɩɨɠɚɪɧɨɣɡɚɳɢɬɵ, ɚ |

ɬɨɱɧɨɟɫɨɛɥɸɞɟɧɢɟɝɪɚɮɢɤɚɩɨɫɬɚɜɨɤɢ |

|

|

|

ɦɢɧɢɦɚɥɶɧɵɟɫɪɨɤɢ ɦɨɧɬɚɠɚ |

ɬɚɤɠɟɭɧɢɤɚɥɶɧɵɟɤɨɧɫɬɪɭɤɬɢɜɧɵɟ |

|

|

ɡɧɚɱɢɬɟɥɶɧɨɝɨɫɧɢɠɚɸɬɨɛɴɟɦɵɨɛɳɢɯ |

ɯɚɪɚɤɬɟɪɢɫɬɢɤɢɥɟɝɤɢɯɫɛɨɪɧɵɯ |

ɡɚɬɪɚɬɢɩɨɜɵɲɚɸɬɤɚɱɟɫɬɜɨɪɚɛɨɬ. |

ɷɥɟɦɟɧɬɨɜ ɤɨɬɨɪɵɟɥɟɝɤɨɢɛɵɫɬɪɨ |

|

, |

|

ɦɨɧɬɢɪɭɸɬɫɹ. ɉɪɟɞɥɚɝɚɟɦɵɟ |

|

ɜɚɪɢɚɧɬɵ ɢɫɩɨɥɧɟɧɢɹɨɬɞɟɥɶɧɵɯ |

|

6 |

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ⱥɫɫɨɪɬɢɦɟɧɬ ɩɪɨɞɭɤɰɢɢ |

ɈɌ ɉȺɇȿɅȿɃ Ʉ ɋɂɋɌȿɆȺɆ

ɋɢɫɬɟɦɚɬɢɡɚɰɢɹ

Ɇɨɞɟɥɶɧɵɟɫɢɫɬɟɦɵ

ɫɨɡɞɚɧɧɵɟɜɫɨɨɬɜɟɬɫɬɜɢɢɫ

ɤɨɧɤɪɟɬɧɵɦɢɬɪɟɛɨɜɚɧɢɹɦɢ Ʉɚɠɞɚɹɦɨɞɟɥɧɚɹɫɢɫɬɟɦɚɫɨɫɬɨɢɬɢɡ ɩɨɥɧɨɝɨɧɚɛɨɪɚɩɚɧɟɥɟɣParoc, ɨɩɪɟɞɟɥɟɧɧɨɜɵɩɨɥɧɟɧɧɚɹ, ɨɬɞɟɥɨɱɧɨɝɨɩɨɤɪɵɬɢɹɢɬɢɩɚ ɜɚɬɧɨɝɨɧɚɩɨɥɧɢɬɟɥɹ, ɚɬɚɤɠɟ ɫɨɨɬɜɟɬɫɬɜɭɸɳɚɹɷɤɫɩɥɭɚɬɚɰɢɨɧɧɵɦ ɬɪɟɛɨɜɚɧɢɹɦ, ɤɪɟɩɟɠɧɵɟɷɥɟɦɟɧɬɵ, ɨɛɟɫɩɟɱɟɧɧɚɦɟɬɚɥɥɢɱɟɫɤɢɦɢ ɩɪɨɮɢɥɹɦɢ ɢɝɢɞɪɨɢɡɨɥɹɰɢɟɣɞɥɹ ɫɬɵɤɨɜ. ɇɚɪɹɞɭɫɩɚɧɟɥɹɦɢɢ ɩɪɢɧɚɞɥɟɠɧɨɫɬɹɦɢ, ɡɚɤɚɡɱɢɤɭ ɩɪɟɞɨɫɬɚɜɥɹɸɬɫɹɬɚɤɠɟ ɨɩɬɢɦɚɥɶɧɵɟɜɚɪɢɚɧɬɵɢɫɩɨɥɧɟɧɢɹ ɭɡɥɨɜ, ɨɬɜɟɱɚɸɳɢɟɬɟɯɧɢɱɟɫɤɢɦɢ ɷɫɬɟɬɢɱɟɫɤɢɦɩɨɬɪɟɛɧɨɫɬɹɦɫɢɫɬɟɦɵ.

Ȼɚɡɨɜɚɹɫɢɫɬɟɦɚ

ɫɨɫɬɨɢɬɢɡ

ɩɚɧɟɥɟɣɞɥɹ

ɭɫɬɪɨɣɫɬɜɚ

ɨɛɵɱɧɵɯ

ɧɚɪɭɠɧɵɯɢ ɜɧɭɬɪɟɧɧɢɯɫɬɟɧ, ɢɩɨɬɨɥɨɱɧɵɯ

ɩɟɪɟɤɪɵɬɢɣ, ɤɤɨɬɨɪɵɦɧɟ ɩɪɟɞɴɹɜɥɹɸɬɫɹɤɚɤɢɟ-ɥɢɛɨɨɫɨɛɵɟ ɬɪɟɛɨɜɚɧɢɹ, ɚɬɚɤɠɟɨɩɪɚɜɞɚɧɧɵɯɢ ɮɭɧɤɰɢɨɧɚɥɶɧɵɯɪɟɲɟɧɢɣ ɫɬɚɧɞɚɪɬɧɵɯɷɥɟɦɟɧɬɨɜ.

Ɏɚɫɚɞɧɚɹ

ɫɢɫɬɟɦɚ

ɩɪɟɞɥɚɝɚɟɬ

ɧɟɨɝɪɚɧɢɱɟɧɧɵɟ

ɚɪɯɢɬɟɤɬɭɪɧɵɟ

ɜɨɡɦɨɠɧɨɫɬɢɞɥɹ

ɮɨɪɦɢɪɨɜɚɧɢɹ

ɢɧɞɢɜɢɞɭɚɥɶɧɨɝɨ

ɨɛɥɢɤɚ ɡɞɚɧɢɹ. ɋɩɟɰɢɚɥɶɧɨ ɪɚɡɪɚɛɨɬɚɧɧɵɟ ɨɝɧɟɫɬɨɣɤɢɟɩɚɧɟɥɢ

Paroc ɢɝɢɞɪɨɢɡɨɥɹɰɢɹɫɬɵɤɨɜ, ɚ ɬɚɤɠɟɞɨɩɨɥɧɢɬɟɥɶɧɵɟɷɥɟɦɟɧɬɵ ɨɮɨɪɦɥɟɧɢɹɹɜɥɹɸɬɫɹɨɬɥɢɱɧɵɦ ɫɪɟɞɫɬɜɨɦɫɨɡɞɚɧɢɹɮɚɫɚɞɨɜ.

ɉɪɨɬɢɜɨɩɨɠɚɪɧɚɹ ɫɢɫɬɟɦɚ

ɫɨɫɬɨɢɬ ɢɡ ɨɝɧɟɫɬɨɣɤɢɯ ɩɟɪɟɝɨɪɨɞɨɤ, ɩɨɬɨɥɨɱɧɵɯ ɩɟɪɟɤɪɵɬɢɣ ɢ ɩɚɧɟɥɟɣ ɫɬɟɧɨɜɨɝɨ ɨɝɪɚɠɞɟɧɢɹ. ɉɚɧɟɥɢ ɢɡ ɧɟɝɨɪɸɱɢɯ ɦɚɬɟɪɢɚɥɨɜ,

ɫɟɪɬɢɮɢɰɢɪɨɜɚɧɧɵɟ ɤɨɧɫɬɪɭɤɰɢɢ ɢ ɫɩɟɰɢɚɥɶɧɵɟ ɪɚɡɪɚɛɨɬɤɢ ɹɜɥɹɸɬɫɹ ɝɚɪɚɧɬɢɟɣ ɛɟɡɨɩɚɫɧɨɫɬɢ ȼɚɲɟɝɨ ɡɞɚɧɢɹ ɢ ɭɩɪɨɳɚɸɬ ɩɪɨɟɤɬɢɪɨɜɚɧɢɟ.

Ƚɢɝɢɟɧɢɱɟɫɤɚɹ ɫɢɫɬɟɦɚ

ɪɚɡɪɚɛɨɬɚɧɚ ɞɥɹ ɫɨɡɞɚɧɢɹ ɩɨɦɟɳɟɧɢɣ, ɜ ɤɨɬɨɪɵɯ ɞɟɣɫɬɜɭɸɬ ɫɬɪɨɝɢɟ ɬɪɟɛɨɜɚɧɢɹ ɝɢɝɢɟɧɵ, ɧɚɩɪɢɦɟɪ, ɜɩɢɳɟɜɨɣ ɢɥɢ

ɷɥɟɤɬɪɨɬɟɯɧɢɱɟɫɤɨɣ ɩɪɨɦɵɲɥɟɧɧɨɫɬɢ. Ƚɥɚɞɤɢɟ ɩɨɜɟɪɯɧɨɫɬɢ, ɩɢɳɟɜɨɟ ɩɨɤɪɵɬɢɟ FoodSafe, ɩɥɨɬɧɵɟ ɫɬɵɤɢ ɢ ɫɩɟɰɢɚɥɶɧɨ ɪɚɡɪɚɛɨɬɚɧɧɵɟ ɞɟɬɚɥɢ ɹɜɥɹɸɬɫɹ ɨɫɧɨɜɨɣ ɫɨɡɞɚɧɢɹ ɩɟɪɟɝɨɪɨɞɨɤ, ɩɨɬɨɥɤɨɜ ɢ ɜɧɟɲɧɢɯ ɫɬɟɧ, ɫɨɨɬɜɟɬɫɬɜɭɸɳɢɯ ɠɟɫɬɤɢɦ ɝɢɝɢɟɧɢɱɟɫɤɢɦ ɧɨɪɦɚɦ.

Ⱥɤɭɫɬɢɱɟɫɤɚɹ

ɫɢɫɬɟɦɚ

ɹɜɥɹɟɬɫɹ ɨɩɬɢɦɚɥɶɧɵɦ ɪɟɲɟɧɢɟɦ ɩɪɢ ɫɬɪɨɢɬɟɥɶɫɬɜɟ ɩɪɟɞɩɪɢɹɬɢɣ ɩɪɨɦɵɲɥɟɧɧɨɝɨ

ɧɚɡɧɚɱɟɧɢɹ. ɋɢɫɬɟɦɚ ɤɨɦɩɥɟɤɬɭɟɬɫɹ ɩɟɪɮɨɪɢɪɨɜɚɧɧɵɦɢ ɩɚɧɟɥɹɦɢ Paroc.

|

ɇɚɪɭɠɧɵɟ ɫɬɟɧɵ |

ȼɧɭɬɪɟɧɧɢɟ ɩɟɪɟɝɨɪɨɞɤɢ |

ɉɨɬɨɥɨɱɧɵɟ ɩɚɧɟɥɢ |

Ȼɚɡɨɜɚɹ ɫɢɫɬɟɦɚ |

Paroc Original-E |

Paroc Original-I |

Paroc Original-C |

Ɏɚɫɚɞɧɚɹ ɫɢɫɬɟɦɚ |

Paroc Micro-E |

|

|

|

Paroc Smooth 600-E |

|

|

|

Paroc Smooth-E |

|

|

|

Paroc Shadowline-E |

|

|

ɉɪɨɬɢɜɨɩɨɠɚɪɧɚɹ ɫɢɫɬɟɦɚ |

Paroc Fire-E |

Paroc Fire-I |

Paroc Fire-C |

Ƚɢɝɢɟɧɢɱɟɫɤɚɹ ɫɢɫɬɟɦɚ |

Paroc Hygiene-E |

Paroc Hygiene-I |

Paroc Hygiene-C |

Ⱥɤɭɫɬɢɱɟɫɤɚɹ ɫɢɫɬɟɦɚ |

|

Paroc Acoustic-I |

Paroc Acoustic-C |

ɈɛɨɡɧɚɱɟɧɢɟE:- ɇɚɪɭɠɧɚɹ ɫɬɟɧɚ / I:- ɉɟɪɟɝɨɪɨɞɤɚ / ɋ:- ɉɨɬɨɥɨɱɧɚɹ ɩɚɧɟɥɶ

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ⱥɫɫɨɪɬɢɦɟɧɬ ɩɪɨɞɭɤɰɢɢ |

7 |

ȻȺɁɈȼȺə ɋɂɋɌȿɆȺ

ȻȺɁɈȼȺə ɋɂɋɌȿɆȺ

Ɋɚɰɢɨɧɚɥɶɧɨɫɬɶ ɢ ɮɭɧɤɰɢɨɧɚɥɶɧɨɫɬɶ

Ȼɚɡɨɜɚɹ ɩɚɧɟɥɶ Paroc Original ɫ ɤɚɧɟɥɸɪɚɦɢ ɲɚɝɨɦ 200 ɦɦ

8

Ɉɛɥɚɫɬɶɩɪɢɦɟɧɟɧɢɹ

ȻɚɡɨɜɚɹɫɢɫɬɟɦɚParoc ɩɪɢɦɟɧɹɟɬɫɹ ɩɪɢɫɨɨɪɭɠɟɧɢɢɮɚɫɚɞɨɜɬɚɦ, ɝɞɟ ɨɫɧɨɜɧɨɟɜɧɢɦɚɧɢɟɭɞɟɥɹɟɬɫɹ ɮɭɧɤɰɢɨɧɚɥɶɧɨɫɬɢɢɪɚɰɢɨɧɚɥɶɧɨɫɬɢ, ɝɞɟɷɤɨɧɨɦɢɱɟɫɤɢɟɫɨɨɛɪɚɠɟɧɢɹ ɩɪɟɜɚɥɢɪɭɸɬɧɚɞɷɫɬɟɬɢɱɟɫɤɢɦɢ, ɧɚɩɪɢɦɟɪ, ɩɪɢɫɬɪɨɢɬɟɥɶɫɬɜɟ ɩɪɨɦɵɲɥɟɧɧɵɯɢɫɩɨɪɬɢɜɧɵɯ ɨɛɴɟɤɬɨɜ. ɋɢɫɬɟɦɚɬɚɤɠɟɜɤɥɸɱɚɟɬ ɩɪɨɱɧɵɟɧɟɫɝɨɪɚɟɦɵɟɩɚɧɟɥɢɞɥɹ ɭɫɬɪɨɣɫɬɜɚɜɧɭɬɪɟɧɧɢɯɩɟɪɟɝɨɪɨɞɨɤɢ ɩɨɬɨɥɨɱɧɵɯɩɟɪɟɤɪɵɬɢɣɜ ɩɨɦɟɳɟɧɢɹɯɨɛɳɟɝɨɧɚɡɧɚɱɟɧɢɹ, ɤ ɤɨɬɨɪɵɦɧɟɩɪɟɞɴɹɜɥɹɸɬɫɹɨɫɨɛɵɟ ɬɪɟɛɨɜɚɧɢɹɩɨɨɝɧɟɫɬɨɣɤɨɫɬɢ, ɝɢɝɢɟɧɢɱɟɫɤɢɦɢɚɤɭɫɬɢɱɟɫɤɢɦ ɫɜɨɣɫɬɜɚɦ.

Ⱥɫɫɨɪɬɢɦɟɧɬɩɚɧɟɥɟɣ

ȼɫɨɫɬɚɜȻɚɡɨɜɨɣɫɢɫɬɟɦɵɜɯɨɞɹɬ ɩɚɧɟɥɢɫɬɚɧɞɚɪɬɧɨɣɤɨɧɫɬɪɭɤɰɢɢ: ɩɚɧɟɥɢParoc Original ɫɤɚɧɟɥɸɪɚɦɢ, ɪɚɫɩɨɥɨɠɟɧɧɵɦɢɫɲɚɝɨɦ200 ɦɦ. Ɂɚɜɨɞɫɤɚɹɨɬɞɟɥɤɚɩɨɜɟɪɯɧɨɫɬɟɣ ɩɚɧɟɥɟɣɩɨɡɜɨɥɹɟɬɛɵɫɬɪɨɡɚɩɭɫɬɢɬɶ ɡɞɚɧɢɟɜɷɤɫɩɥɭɚɬɚɰɢɸ. ɋɬɚɧɞɚɪɬɧɵɦ ɩɨɤɪɵɬɢɟɦɜɧɟɲɧɢɯɩɨɜɟɪɯɧɨɫɬɟɣ ɨɪɢɝɢɧɚɥɶɧɵɯɩɚɧɟɥɟɣɹɜɥɹɟɬɫɹ ɩɨɥɢɜɢɧɢɥɢɞɟɧɮɬɨɪɢɞ(ɉȼȾɎ), ɜɧɭɬɪɟɧɧɢɟɩɨɜɟɪɯɧɨɫɬɢɩɨɤɪɵɜɚɸɬɫɹ ɫɥɨɟɦɩɨɥɢɷɮɢɪɚ.

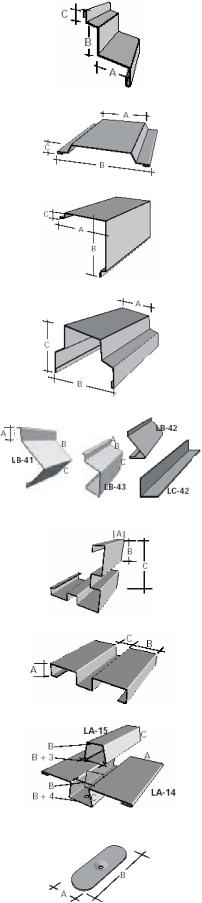

Ɋɚɰɢɨɧɚɥɶɧɵɟ ɢ ɮɭɧɤɰɢɨɧɚɥɶɧɵɟ ɞɟɬɚɥɢ

Ⱦɟɬɚɥɶ ɨɤɧɚ

Ɉɝɧɟɫɬɨɣɤɨɫɬɶ

ɄɨɧɫɬɪɭɤɰɢɨɧɧɚɹɤɚɦɟɧɧɚɹɜɚɬɚParoc ɤɥɚɫɫɢɮɢɰɢɪɭɟɬɫɹɤɚɤɧɟɝɨɪɸɱɢɣ ɦɚɬɟɪɢɚɥ. Ȼɥɚɝɨɞɚɪɹɩɪɢɦɟɧɟɧɢɸ ɧɟɝɨɪɸɱɢɯɦɚɬɟɪɢɚɥɨɜ, ɫɨɤɪɚɳɚɟɬɫɹ ɩɨɠɚɪɧɚɹɧɚɝɪɭɡɤɚɧɚɡɞɚɧɢɟ ɢ ɫɧɢɠɚɟɬɫɹɭɪɨɜɟɧɶɩɨɠɚɪɧɨɣ ɨɩɚɫɧɨɫɬɢ. ɉɪɢɢɫɩɨɥɶɡɨɜɚɧɢɢ ɨɝɧɟɭɩɨɪɧɵɯɩɚɧɟɥɟɣParoc, ɦɨɝɭɬ ɫɨɤɪɚɬɢɬɶɫɹɢɡɚɬɪɚɬɵɧɚɫɬɪɚɯɨɜɤɭ.

Ƚɟɪɦɟɬɢɱɧɨɫɬɶ

ɋɬɵɤɢɦɟɠɞɭ ɩɚɧɟɥɹɦɢParoc ɧɟɩɪɨɧɢɰɚɟɦɵɞɥɹɜɨɡɞɭɯɚɢɜɨɞɵ. ȼ ɫɥɭɱɚɹɯ, ɟɫɥɢɫɩɟɰɢɮɢɤɚɰɢɹ ɨɩɪɟɞɟɥɹɟɬɧɚɥɢɱɢɟɭɩɥɨɬɧɟɧɢɹ ɬɨɥɶɤɨɜɨɞɧɨɦɫɬɵɤɟ, ɷɬɨɬɫɬɵɤ ɞɨɥɠɟɧɪɚɫɩɨɥɚɝɚɬɶɫɹɫɨɫɬɨɪɨɧɵ ɩɨɜɟɪɯɧɨɫɬɢ, ɨɛɪɚɳɟɧɧɨɣ ɜɛɨɥɟɟ ɬɟɩɥɭɸɫɬɨɪɨɧɭɡɞɚɧɢɹ. ɄɨɧɫɬɪɭɤɰɢɨɧɧɚɹɤɚɦɟɧɧɚɹɜɚɬɚParoc ɫɚɦɚɩɨɫɟɛɟɧɟɱɭɜɫɬɜɢɬɟɥɶɧɚɤ ɜɨɡɞɟɣɫɬɜɢɸɜɥɚɝɢ, ɩɨɫɤɨɥɶɤɭɧɟ ɢɦɟɟɬɷɮɮɟɤɬɚɤɚɩɢɥɥɹɪɧɨɝɨ ɜɩɢɬɵɜɚɧɢɹ. ɉɪɢɫɨɨɪɭɠɟɧɢɢ ɜɵɫɨɬɧɵɯɡɞɚɧɢɣ, ɧɟɨɛɯɨɞɢɦɨɭɞɟɥɹɬɶ ɩɨɜɵɲɟɧɧɨɟɜɧɢɦɚɧɢɟɜɨɩɪɨɫɚɦ ɩɪɨɧɢɤɚɟɦɦɨɫɬɢɜɨɡɞɭɯɚɉɚɧɟɥɢ ɜɵɫɨɬɧɵɯɮɚɫɚɞɨɜɢɜɟɪɬɢɤɚɥɶɧɨ ɭɫɬɚɧɨɜɥɟɧɧɵɟɩɚɧɟɥɢɞɨɥɠɧɵ

ɋɬɵɤ cɬɟɧɚ\ɤɪɨɜɥɹ

ɋɬɵɤ ɫɬɟɧɚ/ɮɭɧɞɚɦɟɧ

ȻȺɁɈȼȺə ɋɂɋɌȿɆȺ

ɫɧɚɛɠɚɬɶɫɹɭɩɥɨɬɧɟɧɢɟɦɜɨɛɟɢɯ ɤɚɧɚɜɤɚɯɫɬɵɤɚ. Ɉɤɨɧɧɵɟɢɞɜɟɪɧɵɟ ɩɪɨɟɦɵ, ɚɬɚɤɠɟɢɧɵɟɧɟɨɛɯɨɞɢɦɵɟ ɨɬɜɟɪɫɬɢɹ, ɢɦɟɸɳɢɟɫɹɩɨɩɪɨɟɤɬɭɜ ɩɚɧɟɥɹɯ, ɞɨɥɠɧɵɢɦɟɬɶɞɨɫɬɚɬɨɱɧɨɟ ɭɩɥɨɬɧɟɧɢɟ.

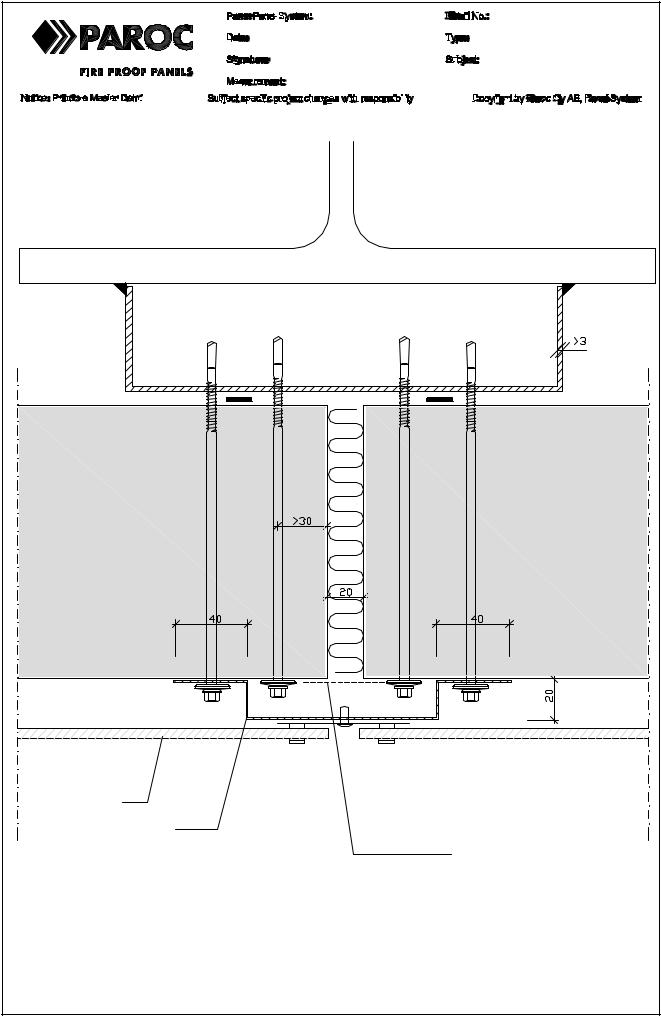

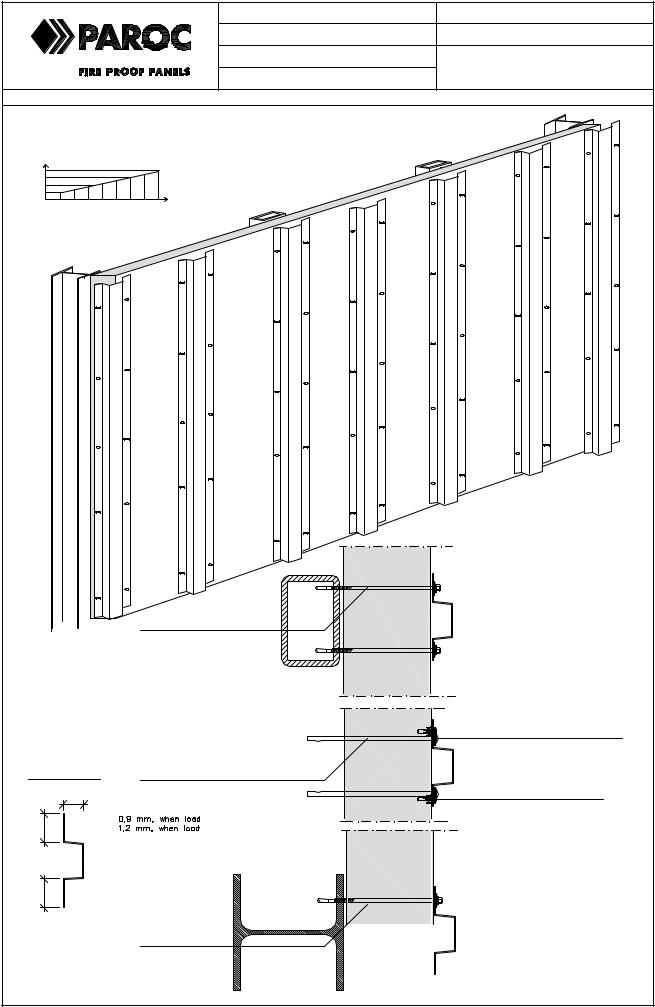

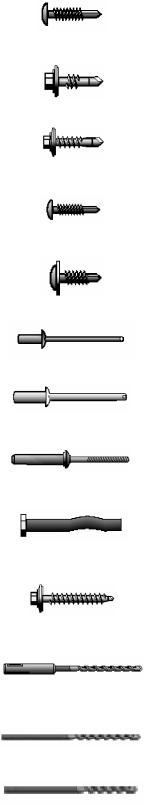

Ʉɪɟɩɥɟɧɢɟɩɚɧɟɥɟɣ

Ɉɛɵɱɧɵɣɫɩɨɫɨɛɤɪɟɩɥɟɧɢɹɩɚɧɟɥɟɣ

ɩɪɟɞɭɫɦɚɬɪɢɜɚɟɬɢɫɩɨɥɶɡɨɜɚɧɢɟ ɫɤɜɨɡɧɨɝɨɤɪɟɩɟɠɚ, ɜɟɪɬɢɤɚɥɶɧɵɟ ɩɚɧɟɥɢɜɧɭɬɪɟɧɧɢɯɩɟɪɟɝɨɪɨɞɨɤ ɤɪɟɩɹɬɫɹɩɪɢɩɨɦɨɳɢɩɪɨɮɢɥɟɣ. ɉɨɬɨɥɨɱɧɵɟɩɚɧɟɥɢɤɪɟɩɹɬɫɹɧɚ ɧɟɫɭɳɢɯɤɨɧɫɬɪɭɤɰɢɹɯɩɪɢɩɨɦɨɳɢ ɬɪɚɩɟɰɢɟɜɢɞɧɵɯɩɪɨɮɢɥɟɣɢɚɧɤɟɪɧɵɯ ɛɨɥɬɨɜ. ɉɚɧɟɥɢɤɪɟɩɹɬɫɹɤ ɬɪɚɩɟɰɢɟɜɢɞɧɵɦɩɪɨɮɢɥɹɦɲɭɪɭɩɚɦɢ. ȼɟɪɯɧɢɟɩɨɜɟɪɯɧɨɫɬɢɩɚɧɟɥɟɣɞɨɥɠɧɵ ɛɵɬɶɫɤɪɟɩɥɟɧɵɞɪɭɝɫɞɪɭɝɨɦ. ɂɧɮɨɪɦɚɰɢɹɨɩɪɚɜɢɥɶɧɨɦɬɢɩɟɢ ɚɪɦɢɪɨɜɚɧɢɢɤɪɟɩɟɠɧɵɯɞɟɬɚɥɟɣ ɩɪɟɞɫɬɚɜɥɟɧɚɜɪɚɫɱɟɬɧɵɯɞɨɤɭɦɟɧɬɚɯ. ɋɬɨɢɦɨɫɬɶɦɚɬɟɪɢɚɥɨɜȻɚɡɨɜɨɣ ɫɢɫɬɟɦɵɫɜɟɞɟɧɚɤɦɢɧɢɦɭɦɭ ɡɚɫɱɟɬ ɩɪɢɦɟɧɟɧɢɹɨɬɤɪɵɬɨɝɨɤɪɟɩɟɠɚ, ɩɪɢɤɥɟɩɚɧɧɵɯɮɚɪɬɭɤɨɜ ɝɢɞɪɨɢɡɨɥɹɰɢɢɢɩɪɨɫɬɨɬɵ ɤɨɦɩɨɧɟɧɬɨɜ.

Ƚɨɪɢɡɨɧɬɚɥɶɧɵɣ ɫɬɵɤ ɫɬɟɧɨɜɵɯ ɩɚɧɟɥɟɣ

ɇɚɪɭɠɧɵɣ ɭɝɥɨɜɨɣ ɫɬɵɤ

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ⱥɫɫɨɪɬɢɦɟɧɬ ɩɪɨɞɭɤɰɢɢ, ɐɜɟɬɚ ɢ ɩɨɤɪɵɬɢɹ, Ɍɟɯɧɢɱɟɫɤɨɟ ɨɩɢɫɚɧɢɟ, Ⱦɟɬɚɥɢ ɫɢɫɬɟɦɵ |

9 |

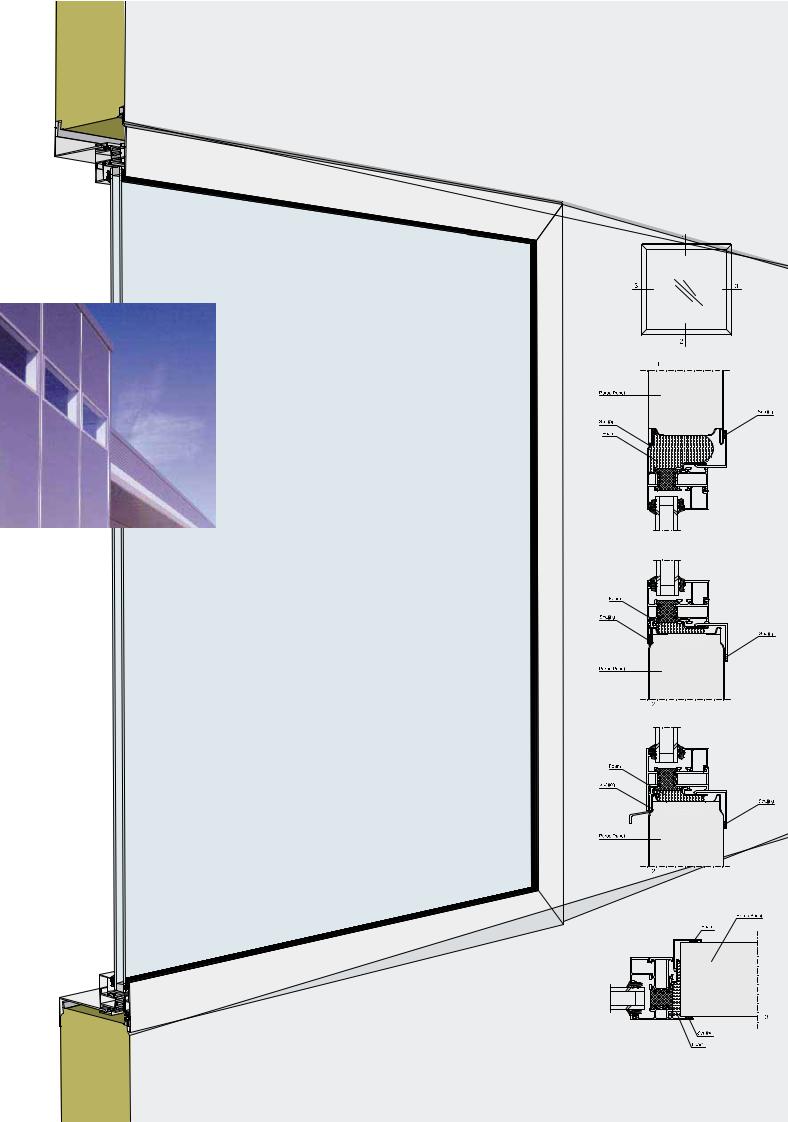

ɋɂɋɌȿɆȺ ɎȺɋȺȾȺ

ɋɂɋɌȿɆȺ ɎȺɋȺȾȺ

Ⱥɪɯɢɬɟɤɬɭɪɧɵɟ ɪɟɲɟɧɢɹ

Ƚɨɬɨɜɚɹ ɭɝɥɨɜɚɹ ɩɚɧɟɥɶ

Paroc Smooth 600

Paroc Shadow

Paroc Smooth

Paroc Micro

10

Ɉɛɥɚɫɬɶ ɩɪɢɦɟɧɟɧɢɹ

Ⱥɪɯɢɬɟɤɬɭɪɚɡɞɚɧɢɹɹɜɥɹɟɬɫɹ ɨɬɪɚɠɟɧɢɟɦɯɚɪɚɤɬɟɪɚɟɝɨɨɛɢɬɚɬɟɥɹ: ɤɥɚɫɫɢɤɚɢɥɢɦɨɞɟɪɧ, ɷɮɮɟɤɬɧɨɫɬɶɢɥɢ ɧɟɩɪɢɬɹɡɚɬɟɥɶɧɨɫɬɶ. ɋɢɫɬɟɦɚɮɚɫɚɞɚ Paroc ɩɪɟɞɨɫɬɚɜɥɹɟɬɡɚɤɚɡɱɢɤɭɲɢɪɨɤɢɟ ɚɪɯɢɬɟɤɬɭɪɧɵɟɜɨɡɦɨɠɧɨɫɬɢɞɥɹ ɜɵɪɚɠɟɧɢɹɟɝɨɢɧɞɢɜɢɞɭɚɥɶɧɨɫɬɢ. Ɋɚɡɥɢɱɧɵɟɜɚɪɢɚɧɬɵɢɫɩɨɥɧɟɧɢɹ ɩɨɜɟɪɯɧɨɫɬɟɣ, ɲɢɪɨɤɢɣɜɵɛɨɪɰɜɟɬɨɜɢ ɞɟɤɨɪɚɬɢɜɧɵɟɷɥɟɦɟɧɬɵɨɮɨɪɦɥɟɧɢɹ ɫɬɵɤɨɜɩɨɡɜɨɥɹɸɬɜɩɨɥɧɨɣɦɟɪɟ ɜɵɪɚɡɢɬɶɫɚɦɵɟɫɦɟɥɵɟɡɚɦɵɫɥɵ ɚɪɯɢɬɟɤɬɨɪɚ. ɋɢɫɬɟɦɚɮɚɫɚɞɚ ɩɪɢɦɟɧɹɟɬɫɹɜɩɪɨɟɤɬɚɯ, ɜɤɨɬɨɪɵɯ ɛɨɥɶɲɨɟɡɧɚɱɟɧɢɟɩɪɢɞɚɟɬɫɹ ɷɫɬɟɬɢɱɟɫɤɨɣɫɬɨɪɨɧɟɚɪɯɢɬɟɤɬɭɪɧɨɝɨ ɪɟɲɟɧɢɹ. ɗɬɚɫɨɜɪɟɦɟɧɧɚɹ, ɥɟɝɤɚɹɢ ɜɵɫɨɤɨɬɟɯɧɨɥɨɝɢɱɧɚɹɫɢɫɬɟɦɚɹɜɥɹɟɬɫɹ ɨɱɟɜɢɞɧɵɦɜɵɛɨɪɨɦɞɥɹɡɞɚɧɢɣ ɞɟɥɨɜɨɝɨɢɨɛɳɟɫɬɜɟɧɧɨɝɨɧɚɡɧɚɱɟɧɢɹ.

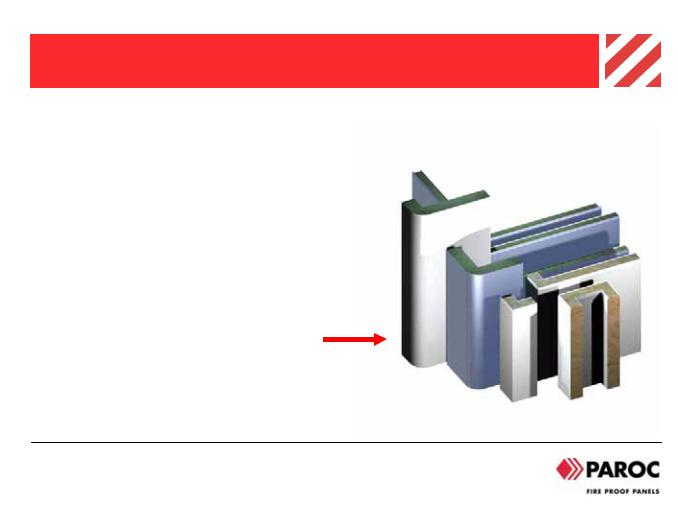

Ⱥɫɫɨɪɬɢɦɟɧɬ ɩɚɧɟɥɟɣ

ɋɢɫɬɟɦɚɮɚɫɚɞɚɩɪɟɞɫɬɚɜɥɟɧɚɲɢɪɨɤɢɦ ɜɵɛɨɪɨɦɬɢɩɨɜɩɨɜɟɪɯɧɨɫɬɟɣ: Smooth (ɝɥɚɞɤɚɹ) ɞɥɹɫɨɡɞɚɧɢɹɷɮɮɟɤɬɚ ɥɚɤɨɧɢɱɧɨɣɩɪɨɫɬɨɬɵ, Smooth 600 ɞɥɹ ɩɨɥɭɱɟɧɢɹɩɨɜɟɪɯɧɨɫɬɢ, ɨɬɦɟɱɟɧɧɨɣ ɪɢɬɦɢɱɟɫɤɢɦɪɢɫɭɧɤɨɦ, Micro ɞɥɹɬɨɝɨ, ɱɬɨɛɵɩɨɞɱɟɪɤɧɭɬɶɧɸɚɧɫɵɢɧɨɜɚɹ ɦɚɪɤɚShadow ɞɥɹɢɝɪɵɫɭɡɨɪɨɦɬɟɧɟɣ. ȼɧɟɲɧɹɹɩɨɜɟɪɯɧɨɫɬɶɩɚɧɟɥɟɣɜɫɟɯ ɬɢɩɨɜɢɦɟɟɬɩɨɤɪɵɬɢɟɢɡ PVDF, ɱɬɨ ɝɚɪɚɧɬɢɪɭɟɬɩɪɟɤɪɚɫɧɵɣɜɧɟɲɧɢɣɜɢɞ ɮɚɫɚɞɚɧɚɦɧɨɝɢɟɝɨɞɵ.

Ƚɨɬɨɜɵɟ ɭɝɥɨɜɵɟ ɩɚɧɟɥɢ

Ƚɨɬɨɜɵɟɭɝɥɨɜɵɟɩɚɧɟɥɢɨɛɟɫɩɟɱɢɜɚɸɬ

ɝɢɛɤɨɫɬɶɜɩɪɨɟɤɬɢɪɨɜɚɧɢɢɮɚɫɚɞɧɵɯ ɤɨɧɫɬɪɭɤɰɢɣ. ɗɬɢɫɛɨɪɧɵɟɭɝɥɨɜɵɟ ɦɨɞɭɥɢɢɡɝɨɬɚɜɥɢɜɚɸɬɫɹɢɡɩɚɧɟɥɟɣ

Paroc

ɫɩɨɜɟɪɯɧɨɫɬɶɸ, ɩɨɜɬɨɪɹɸɳɟɣɨɬɞɟɥɤɭ ɨɛɵɱɧɵɯɩɚɧɟɥɟɣ. ɋɬɟɯɧɢɱɟɫɤɨɣɬɨɱɤɢ ɡɪɟɧɢɹ, ɭɝɥɨɜɵɟɦɨɞɭɥɢɢɦɟɸɬɬɟɠɟ ɯɚɪɚɤɬɟɪɢɫɬɢɤɢ, ɱɬɨɢ ɨɫɧɨɜɧɵɟ ɧɚɢɦɟɧɨɜɚɧɢɹɩɚɧɟɥɟɣParoc. ɍɝɥɨɜɵɟ ɩɚɧɟɥɢ ɦɨɧɬɢɪɭɸɬɫɹɜɝɨɪɢɡɨɧɬɚɥɶɧɨɣɢ ɜɜɟɪɬɢɤɚɥɶɧɨɣɤɨɧɮɢɝɭɪɚɰɢɹɯ.

ɋɜɨɛɨɞɚ ɜɵɛɨɪɚ ɧɚɩɪɚɜɥɟɧɢɹ ɭɫɬɚɧɨɜɤɢ

ɉɚɧɟɥɢParoc ɩɪɟɞɨɫɬɚɜɥɹɸɬɩɨɥɧɭɸ ɫɜɨɛɨɞɭɜɵɛɨɪɚɧɚɩɪɚɜɥɟɧɢɹɭɫɬɚɧɨɜɤɢ. Ƚɨɪɢɡɨɧɬɚɥɶɧɚɹɭɫɬɚɧɨɜɤɚɫɨɡɞɚɟɬ ɜɩɟɱɚɬɥɟɧɢɟɨɛɬɟɤɚɟɦɨɫɬɢɢɦɨɳɢ, ɜɷɬɨɦ ɫɥɭɱɚɟɞɢɡɚɣɧɝɧɚɤɥɚɞɧɵɯɩɪɨɮɢɥɟɣ ɢɝɪɚɟɬ ɪɟɲɚɸɳɭɸɪɨɥɶ. ɉɚɧɟɥɢ, ɤɚɤ ɩɪɚɜɢɥɨ, ɹɜɥɹɸɬɫɹɨɞɧɨɩɪɨɥɟɬɧɵɦɢ ɤɨɧɫɬɪɭɤɰɢɹɦɢɢɢɫɤɥɸɱɢɬɟɥɶɧɨɩɪɨɫɬɵ ɜɦɨɧɬɚɠɟ, ɨɞɧɚɤɨɦɧɨɝɨɩɪɨɥɟɬɧɵɟ ɤɨɧɮɢ-ɝɭɪɚɰɢɢɬɚɤɠɟɜɨɡɦɨɠɧɵ. ȼɟɪɬɢɤɚɥɶɧɚɹɭɫɬɚɧɨɜɤɚɩɪɢɞɚɟɬ ɭɧɢɮɢɰɢɪɨɜɚɧɧɵɦɮɚɫɚɞɚɦɪɢɬɦɢɱɟɫɤɢɣɭɡɨɪ.

ɂɧɞɢɜɢɞɭɚɥɶɧɵɣ ɞɢɡɚɣɧ ɞɟɤɨɪɚɬɢɜɧɵɯ ɧɚɤɥɚɞɨɤ

Ⱦɟɤɨɪɚɬɢɜɧɵɟɧɚɤɥɚɞɤɢɫɨɡɞɚɸɬ

ɞɨɩɨɥɧɢɬɟɥɶɧɵɣɞɟɤɨɪɚɬɢɜɧɵɣɷɮɮɟɤɬɜ ɨɮɨɪɦɥɟɧɢɢɮɚɫɚɞɚ. Ɋɚɡɥɢɱɧɵɟ ɤɨɧɫɬɪɭɤɰɢɢɮɚɪɬɭɤɨɜɩɨɦɨɝɚɸɬɫɨɡɞɚɬɶ ɢɧɞɢɜɢɞɭɚɥɶɧɵɟɷɮɮɟɤɬɵɢɢɝɪɭɬɟɧɟɣ. ɉɪɢɩɪɨɟɤɬɢɪɨɜɚɧɢɢɮɚɪɬɭɤɨɜ, ɧɟɨɛɯɨɞɢɦɨɭɱɢɬɵɜɚɬɶɜɵɫɨɬɭɤɪɟɩɟɠɚ ɩɚɧɟɥɟɣ. Ɏɚɪɬɭɤɢɢɡɝɨɬɚɜɥɢɜɚɸɬɫɹɢɡ ɥɢɫɬɨɜɨɣɫɬɚɥɢɫPVDF ɩɨɤɪɵɬɢɟɦɜ ɲɢɪɨɤɨɦɚɫɫɨɪɬɢɦɟɧɬɟ. Ɋɟɤɨɦɟɧɞɭɟɦɚɹ ɬɨɥɳɢɧɚ0,6 – 0,7 ɦɦ. ɋɬɚɧɞɚɪɬɧɵɟɢ ɜɵɩɨɥɧɟɧɧɵɟɩɨɢɧɞɢɜɢɞɭɚɥɶɧɨɦɭ ɩɪɨɟɤɬɭɮɚɪɬɭɤɢɦɨɝɭɬɛɵɬɶɡɚɤɚɡɚɧɵɜ ɦɟɫɬɧɨɦ ɨɮɢɫɟɩɪɨɞɚɠ.

ɋɂɋɌȿɆȺ ɎȺɋȺȾȺ

Ⱦɟɤɨɪɚɬɢɜɧɵɟ ɞɟɬɚɥɢ

Ɍɳɚɬɟɥɶɧɨɪɚɡɪɚɛɨɬɚɧɧɵɟɞɟɤɨɪɚɬɢɜɧɵɟɞɟɬɚɥɢ ɡɚɜɟɪɲɚɸɬɨɛɥɢɤɮɚɫɚɞɧɨɣɫɢɫɬɟɦɵ. Paroc Panel System ɪɚɫɩɨɥɚɝɚɟɬɧɚɛɨɪɨɦɫɬɚɧɞɚɪɬɧɵɯ ɞɟɬɚɥɟɣɞɥɹɫɨɡɞɚɧɢɹɷɮɮɟɤɬɧɵɯɮɚɫɚɞɨɜ.

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹɢɧɮɨɪɦɚɰɢɹ: Ⱥɫɫɨɪɬɢɦɟɧɬɩɪɨɞɭɤɰɢɢ, ɐɜɟɬɚɢɩɨɤɪɵɬɢɹ, Ɍɟɯɧɢɱɟɫɤɨɟɨɩɢɫɚɧɢɟ, Ⱦɟɬɚɥɢɫɢɫɬɟɦɵ, ȾɟɬɚɥɶɫɬɵɤɚShadow |

11 |

ɉɊɈɌɂȼɈɉɈɀȺɊɇȺə ɋɂɋɌȿɆȺ

ɉɊɈɌɂȼɈɉɈɀȺɊɇȺə ɋɂɋɌȿɆȺ

Ɂɚɳɢɬɚ ɠɢɡɧɢ ɢ ɢɦɭɳɟɫɬɜɚ

Ɉɛɥɚɫɬɶɩɪɢɦɟɧɟɧɢɹ |

Ʉɪɟɩɥɟɧɢɟɩɚɧɟɥɟɣ |

x Ʌɢɰɟɜɵɟɱɚɫɬɢɩɨɬɨɥɨɱɧɵɯ |

|

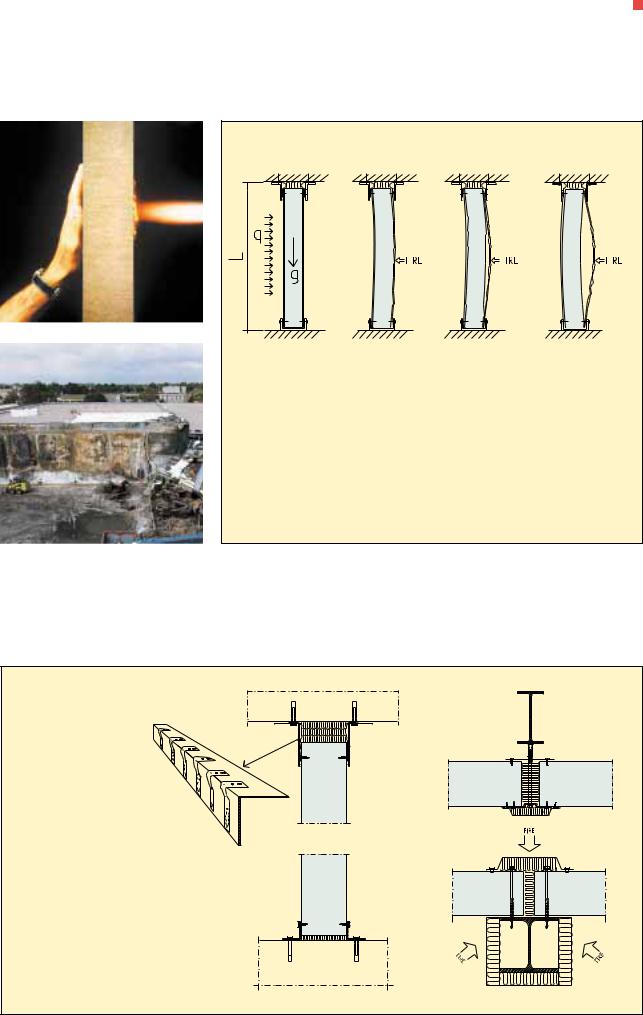

ɉɪɨɬɢɜɨɩɨɠɚɪɧɚɹɫɢɫɬɟɦɚ– ɷɬɨ |

Ⱦɥɹɬɨɝɨ, ɱɬɨɛɵɨɛɟɫɩɟɱɢɬɶ |

ɩɚɧɟɥɟɣɭɤɪɟɩɥɹɸɬɫɹɧɚ |

|

ɧɚɞɟɠɧɵɣ ɜɵɛɨɪɞɥɹɫɨɨɪɭɠɟɧɢɹ |

ɩɪɚɜɢɥɶɧɭɸɪɚɛɨɬɭ ɨɝɧɟɫɬɨɣɤɨɣ |

ɩɨɞɞɟɪɠɢɜɚɸɳɟɦɩɪɨɮɢɥɟɬɚɤɢɦ |

|

ɨɝɧɟɫɬɨɣɤɢɯɤɨɧɫɬɪɭɤɰɢɣ. ɗɬɚɫɢɫɬɟɦɚ |

ɫɬɟɧɨɜɨɣɢɥɢɩɨɬɨɥɨɱɧɨɣɩɚɧɟɥɢɜ |

ɨɛɪɚɡɨɦ, ɱɬɨɛɵɫɨɡɞɚɜɚɥɫɹɷɮɮɟɤɬ |

|

ɩɪɟɞɫɬɚɜɥɹɟɬɫɨɛɨɣɤɨɦɩɥɟɤɫɧɨɟ |

ɫɥɭɱɚɟɩɨɠɚɪɚ, ɱɪɟɡɜɵɱɚɣɧɨɜɚɠɧɨ |

«ɰɟɩɨɱɤɢ» ɦɟɠɞɭɩɚɧɟɥɹɦɢ. |

|

ɪɟɲɟɧɢɟɞɥɹɫɬɪɨɢɬɟɥɶɫɬɜɚɡɞɚɧɢɣɢ |

ɩɪɚɜɢɥɶɧɨɮɢɤɫɢɪɨɜɚɬɶɟɺɬɚɤɢɦ |

Ƚɟɪɦɟɬɢɱɧɨɫɬɶ |

|

ɭɫɬɪɨɣɫɬɜɚɢɧɬɟɪɶɟɪɨɜɫ |

ɨɛɪɚɡɨɦ, ɱɬɨɛɵɨɧɚɧɟɨɛɪɭɲɢɥɚɫɶɩɪɢ |

Ɉɝɧɟɫɬɨɣɤɢɟɫɬɟɧɨɜɵɟɩɚɧɟɥɢ |

|

ɢɫɩɨɥɶɡɨɜɚɧɢɟɦ ɨɝɧɟɫɬɨɣɤɢɯɩɚɧɟɥɟɣ |

ɩɨɬɟɪɟɩɪɨɱɧɨɫɬɢ. Ʉɪɟɩɟɠɧɵɟ |

ɩɨɫɬɚɜɥɹɸɬɫɹɛɟɡɞɨɩɨɥɧɢɬɟɥɶɧɨɝɨ |

|

ɢɫɩɟɰɢɚɥɶɧɨɪɚɡɪɚɛɨɬɚɧɧɵɯɞɥɹɷɬɨɣ |

ɷɥɟɦɟɧɬɵɞɨɥɠɧɵɧɚɞɟɠɧɨ |

ɭɩɥɨɬɧɟɧɢɹɫɬɵɤɨɜ. ɋɬɵɤɢɩɚɧɟɥɟɣ |

|

ɰɟɥɢɞɟɬɚɥɟɣɢɚɤɫɟɫɫɭɚɪɨɜ. ɉɚɧɟɥɢ |

ɭɞɟɪɠɢɜɚɬɶɩɚɧɟɥɶɧɚɦɟɫɬɟɢɢɦɟɬɶ |

ɞɨɫɬɚɬɨɱɧɨɩɥɨɬɧɵɟ, ɱɬɨɛɵ |

|

Paroc ɨɬɜɟɱɚɸɬɬɪɟɛɨɜɚɧɢɹɦ |

ɡɚɩɚɫɩɪɨɱɧɨɫɬɢ, ɫɨɨɬɜɟɬɫɬɜɭɸɳɢɣ |

ɩɪɨɬɢɜɨɫɬɨɹɬɶɩɪɨɧɢɤɧɨɜɟɧɢɸ |

|

ɨɝɧɟɫɬɨɣɤɨɫɬɢɞɨ3 ɱɚɫɨɜɞɥɹɫɬɟɧɢɞɨ |

ɧɚɝɪɭɡɤɚɦɜɫɥɭɱɚɟɩɨɠɚɪɚ. Ɂɚɤɥɟɩɤɢɢ |

ɝɨɪɹɱɢɯɞɵɦɨɜɵɯɝɚɡɨɜ. Ⱦɥɹ |

|

1 ɱɚɫɚɞɥɹɩɨɬɨɥɨɱɧɵɯɤɨɧɫɬɪɭɤɰɢɣ. |

ɲɭɪɭɩɵɤɪɟɩɥɟɧɢɣɜɵɩɨɥɧɹɸɬɫɹɢɡ |

ɭɩɥɨɬɧɟɧɢɹɨɬɜɟɪɫɬɢɣɢɲɜɨɜɜ |

|

Ⱥɫɫɨɪɬɢɦɟɧɬɩɚɧɟɥɟɣ |

ɫɬɚɥɢ, ɬɚɤɤɚɤɚɥɸɦɢɧɢɟɜɵɟ |

ɩɚɧɟɥɹɯParoc ɢɫɩɨɥɶɡɭɟɬɫɹɧɟɝɨɪɸɱɚɹ |

|

ȼɉɪɨɬɢɜɨɩɨɠɚɪɧɨɣɫɢɫɬɟɦɟ |

ɤɪɟɩɟɠɧɵɟɷɥɟɦɟɧɬɵɧɟɜɵɞɟɪɠɢɜɚɸɬ |

ɤɚɦɟɧɧɚɹɜɚɬɚ. |

|

ɩɪɢɦɟɧɹɸɬɫɹɩɚɧɟɥɢParoc ɫɜɵɫɨɤɢɦɢ |

ɬɟɦɩɟɪɚɬɭɪɧɵɯɧɚɝɪɭɡɨɤ. |

Ɉɬɜɟɪɫɬɢɹ |

|

ɩɪɟɞɟɥɚɦɢɨɝɧɟɫɬɨɣɤɨɫɬɢ. |

Ʉɪɟɩɥɟɧɢɟɜɵɩɨɥɧɹɟɬɫɹɫɥɟɞɭɸɳɢɦ |

Ɉɬɜɟɪɫɬɢɹɜɩɟɪɟɝɨɪɨɞɤɚɯɞɨɥɠɧɵ |

|

ɉɨɜɟɪɯɧɨɫɬɶɪɟɛɪɢɫɬɚɹɫɲɚɝɨɦ200 |

ɨɛɪɚɡɨɦ: |

ɢɦɟɬɶɬɚɤɢɟɠɟɩɪɟɞɟɥɵ |

|

ɦɦ. Ɍɢɩɫɟɪɞɟɱɧɢɤɚ50F ɢɥɢ75F |

x |

Ƚɨɪɢɡɨɧɬɚɥɶɧɨɭɫɬɚɧɚɜɥɢɜɚɟɦɵɟ |

ɨɝɧɟɫɬɨɣɤɨɫɬɢ, ɤɚɤɢɫɚɦɢ |

ɜɵɛɢɪɚɟɬɫɹɜɫɨɨɬɜɟɬɫɬɜɢɢɫ |

|

ɫɬɟɧɨɜɵɟɩɚɧɟɥɢɤɪɟɩɹɬɫɹɤ |

ɤɨɧɫɬɪɭɤɰɢɢɩɟɪɟɝɨɪɨɞɤɢ. ɗɬɢɦɟɫɬɚ |

ɧɟɨɛɯɨɞɢɦɵɦɩɪɨɥɟɬɨɦ. |

|

ɩɪɨɮɢɥɹɦɩɪɢɩɨɦɨɳɢ |

ɞɨɥɠɧɵɛɵɬɶɞɨɫɬɚɬɨɱɧɨɭɩɥɨɬɧɟɧɵ, |

|

|

ɩɪɨɧɢɤɚɸɳɢɯɲɭɪɭɩɨɜ |

ɱɬɨɛɵɧɟɞɨɩɭɫɬɢɬɶɩɟɪɟɞɚɱɢɬɟɩɥɚɫ |

|

x |

ȼɟɪɬɢɤɚɥɶɧɵɟɫɬɟɧɨɜɵɟɩɚɧɟɥɢ |

ɝɨɪɹɱɟɣɫɬɨɪɨɧɵɫɬɟɧɵɤɯɨɥɨɞɧɨɣ. |

|

|

ɤɪɟɩɹɬɫɹɩɪɢɩɨɦɨɳɢ |

ɂɡɨɥɹɰɢɹɨɬɜɟɪɫɬɢɣɜɵɩɨɥɧɹɟɬɫɹɩɪɢ |

|

|

ɩɪɨɧɢɤɚɸɳɢɯɲɭɪɭɩɨɜɥɢɛɨ |

ɩɨɦɨɳɢɧɟɝɨɪɸɱɟɣɤɚɦɟɧɧɨɣɜɚɬɵ. |

|

|

ɝɢɛɤɨɝɨɩɪɨɬɢɜɨɩɨɠɚɪɧɨɝɨ |

|

|

|

ɩɪɨɮɢɥɹParoc |

|

12

ɉɊɈɌɂȼɈɉɈɀȺɊɇȺə ɋɂɋɌȿɆȺ

ɑɬɨ ɩɪɨɢɫɯɨɞɢɬ ɜ ɫɥɭɱɚɟ ɩɨɠɚɪɚ

Ʉɚɱɟɫɬɜɨɩɚɫɫɢɜɧɨɣɛɟɡɨɩɚɫɧɨɫɬɢ Paroc Panel System ɪɚɛɨɬɚɟɬɩɨɩɪɢɧɰɢɩɭɰɟɩɨɱɤɢ. ɉɨɷɬɨɦɭ, ɩɪɢɩɪɨɟɤɬɢɪɨɜɚɧɢɢɢ ɩɚɧɟɥɶɧɨɣɫɢɫɬɟɦɵParoc ɩɪɨɹɜɢɥɨɫɶ ɦɨɧɬɚɠɟɨɝɧɟɫɬɨɣɤɢɯɤɨɧɫɬɪɭɤɰɢɣ, ɱɪɟɡɜɵɱɚɣɧɨɜɚɠɧɨɨɛɟɫɩɟɱɢɬɶɩɪɚɜɢɥɶɧɨɟ ɜɩɨɥɧɨɣɦɟɪɟɜɨɜɪɟɦɹɫɢɥɶɧɨɝɨ ɜɵɩɨɥɧɟɧɢɟɤɨɧɫɬɪɭɤɬɢɜɧɵɯɞɟɬɚɥɟɣ, ɱɬɨɛɵɫɢɫɬɟɦɚɜɰɟɥɨɦɨɬɜɟɱɚɥɚɬɪɟɛɨɜɚɩɨɠɚɪɚ, ɤɨɬɨɪɵɟɩɪɨɢɡɨɲɟɥɧɚɬɟɪɧɢɹɦɜɨɬɧɨɲɟɧɢɢɭɫɬɨɣɱɢɜɨɫɬɢ, ɢɡɨɥɹɰɢɢɢɝɟɪɦɟɬɢɱɧɨɫɬɢ. ɪɢɬɨɪɢɢɩɪɨɢɡɜɨɞɫɬɜɟɧɧɨ-ɫɤɥɚɞ- ɫɤɨɝɨɤɨɦɩɥɟɤɫɚɜɇɢɞɟɪɥɚɧɞɚɯ.

ɋɬɟɧɚɩɨɱɬɢ9-ɦɟɬɪɨɜɨɣɜɵɫɨɬɵ, ɜɵɩɨɥɧɟɧɧɚɹɢɡɨɝɧɟɫɬɨɣɤɢɯɩɚɧɟɥɟɣ Paroc, ɩɨɦɟɲɚɥɚɨɝɧɸɩɟɪɟɤɢɧɭɬɶɫɹ ɜɞɪɭɝɨɣɤɨɧɟɰɡɞɚɧɢɹ.

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ⱥɫɫɨɪɬɢɦɟɧɬ ɩɪɨɞɭɤɰɢɢ, ɐɜɟɬɚ ɢ ɩɨɤɪɵɬɢɹ, Ɍɟɯɧɢɱɟɫɤɨɟ ɨɩɢɫɚɧɢɟ, Ⱦɟɬɚɥɢ ɫɢɫɬɟɦɵ |

13 |

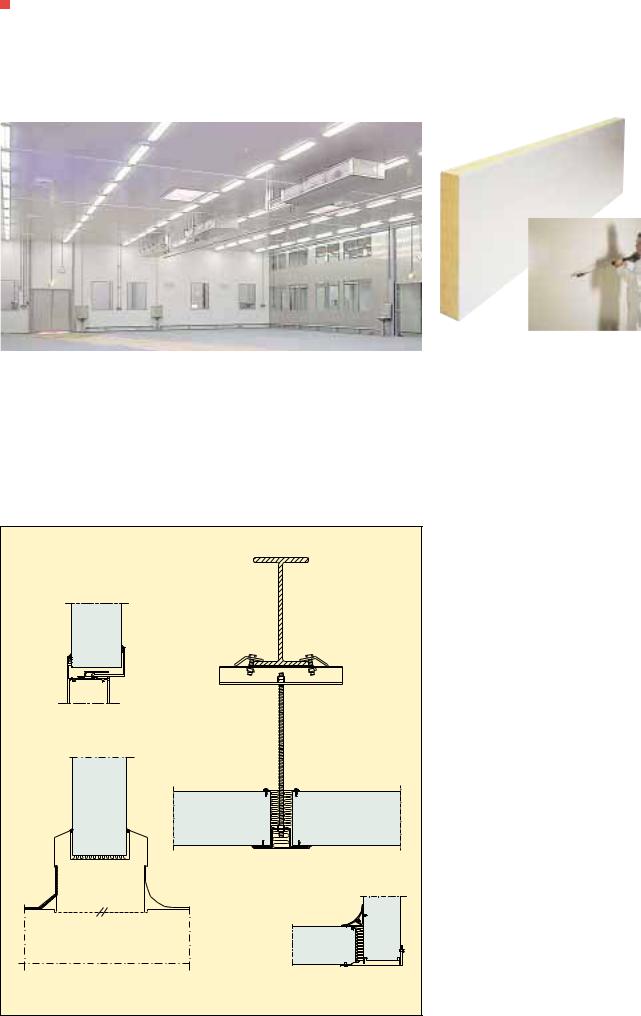

ȽɂȽɂȿɇɂɑȿɋɄȺə ɋɂɋɌȿɆȺ

ȽɂȽɂȿɇɂɑȿɋɄȺə ɋɂɋɌȿɆȺ

ɉɚɧɟɥɢ ɞɥɹ “ɱɢɫɬɵɯ” ɩɪɨɢɡɜɨɞɫɬɜ

Ɉɛɥɚɫɬɶɩɪɢɦɟɧɟɧɢɹ

Ȼɥɚɝɨɞɚɪɹ ɝɟɪɦɟɬɢɱɧɨɣɫɬɪɭɤɬɭɪɟ, ɫɩɟɰɢɚɥɶɧɨɦɭɩɨɤɪɵɬɢɸFoodSafe ɢ ɝɥɚɞɤɨɣɩɨɜɟɪɯɧɨɫɬɢ, ɩɚɧɟɥɢParoc ɲɢɪɨɤɨɩɪɢɦɟɧɹɸɬɫɹɧɚ ɩɪɟɞɩɪɢɹɬɢɹɯɩɢɳɟɜɨɣɢ ɷɥɟɤɬɪɨɬɟɯɧɢɱɟɫɤɨɣ ɩɪɨɦɵɲɥɟɧɧɨɫɬɢɫɢɯɱɪɟɡɜɵɱɚɣɧɨ ɜɵɫɨɤɢɦɢɬɪɟɛɨɜɚɧɢɹɦɢ ɩɪɨɦɵɲɥɟɧɧɨɣɝɢɝɢɟɧɵ. ɇɚɢɛɨɥɟɟ ɱɚɫɬɨɩɚɧɟɥɢParoc ɢɫɩɨɥɶɡɭɸɬɫɹɩɪɢ ɫɬɪɨɢɬɟɥɶɫɬɜɟɩɢɳɟɜɵɯɰɟɯɨɜ, ɫɤɥɚɞɫɤɢɯɩɨɦɟɳɟɧɢɣ, ɫɤɥɚɞɨɜ ɡɚɦɨɪɨɠɟɧɧɨɣɩɪɨɞɭɤɰɢɢ, ɯɨɥɨɞɢɥɶɧɵɯɤɚɦɟɪɢ ɦɚɝɚɡɢɧɨɜ.

Ⱥɫɫɨɪɬɢɦɟɧɬɩɚɧɟɥɟɣ

ɉɚɧɟɥɢParoc, ɹɜɥɹɸɳɢɟɫɹɱɚɫɬɶɸ Ƚɢɝɢɟɧɢɱɟɫɤɨɣɫɢɫɬɟɦɵ, ɢɦɟɸɬ ɫɨɜɟɪɲɟɧɧɨɝɥɚɞɤɭɸɩɨɜɟɪɯɧɨɫɬɶ. Ɍɚɤɢɟɩɚɧɟɥɢɩɨɫɬɚɜɥɹɸɬɫɹɞɥɹ ɭɫɬɪɨɣɫɬɜɚɫɬɟɧɢɩɨɬɨɥɤɨɜ, ɥɟɝɤɨ ɦɨɸɬɫɹɢɢɦɟɸɬɩɪɨɱɧɨɟɜɧɟɲɧɟɟ ɩɨɤɪɵɬɢɟ. ȼɧɭɬɪɟɧɧɟɟɩɨɤɪɵɬɢɟ ɩɚɧɟɥɟɣ– FoodSafe ɢɥɢɩɨɥɢɷɮɢɪ, ɩɨɤɪɵɬɢɟɧɚɪɭɠɧɵɯɫɬɟɧɨɜɵɯ ɨɝɪɚɠɞɟɧɢɣ– ɉȼȾɎ. ɉɨ ɫɩɟɰɢɚɥɶɧɨɦɭɡɚɤɚɡɭɜɵɩɭɫɤɚɸɬɫɹ ɩɚɧɟɥɢc ɩɨɤɪɢɬɢɟɦɢɡɧɟɪɠɚɜɟɸɳɟɣ ɫɬɚɥɢ.

ɉɨɤɪɵɬɢɟFoodSafe

ɉɪɢɬɪɚɧɫɩɨɪɬɢɪɨɜɤɟ, ɩɟɪɟɪɚɛɨɬɤɟ, ɭɩɚɤɨɜɤɟɢɯɪɚɧɟɧɢɢɩɢɳɟɜɵɯɩɪɨɞɭɤɬɨɜ ɞɨɥɠɧɵɫɨɛɥɸɞɚɬɶɫɹɬɪɟɛɨɜɚɧɢɹ ɝɢɝɢɟɧɵ. Ƚɥɚɞɤɢɟɩɨɜɟɪɯɧɨɫɬɢɢɩɥɨɬɧɵɟ ɫɬɵɤɢ, ɧɟɢɦɟɸɳɢɟɩɨɬɟɧɰɢɚɥɶɧɵɯɦɟɫɬ ɫɤɨɩɥɟɧɢɹɝɪɹɡɢ, ɡɧɚɱɢɬɟɥɶɧɨɨɛɥɟɝɱɚɸɬ ɢɭɫɤɨɪɹɸɬɦɨɣɤɭ«ɩɢɳɟɜɵɯ» ɩɚɧɟɥɟɣ Paroc. Ȼɥɚɝɨɞɚɪɹɩɪɨɱɧɨɣɦɧɨɝɨɫɥɨɣɧɨɣ ɤɨɧɫɬɪɭɤɰɢɢɩɚɧɟɥɟɣ, ɞɨɩɭɫɤɚɟɬɫɹ ɢɫɩɨɥɶɡɨɜɚɧɢɟɞɥɢɧɧɵɯɩɪɨɥɟɬɨɜɤɚɤɜ ɝɨɪɢɡɨɧɬɚɥɶɧɵɯ, ɬɚɤɢɜɜɟɪɬɢɤɚɥɶɧɵɯ ɤɨɧɫɬɪɭɤɰɢɹɯ. ȼɰɟɯɚɯɫɩɨɜɵɲɟɧɧɵɦɢ ɝɢɝɢɟɧɢɱɟɫɤɢɦɢɬɪɟɛɨɜɚɧɢɹɦɢɥɟɝɤɢɣɜ ɨɛɫɥɭɠɢɜɚɧɢɢɢɩɪɨɫɬɨɪɧɵɣɢɧɬɟɪɶɟɪ ɦɨɠɧɨɫɨɡɞɚɬɶ, ɩɪɢɦɟɧɢɜɜɧɟɲɧɸɸ ɧɟɫɭɳɭɸɪɚɦɭ.

ɉɪɨɫɬɨɬɚɨɛɫɥɭɠɢɜɚɧɢɹ

ɗɤɨɧɨɦɢɱɟɫɤɚɹɷɮɮɟɤɬɢɜɧɨɫɬɶɩɪɨɟɤɬɚ

ɨɩɪɟɞɟɥɹɟɬɫɹɫɨɱɟɬɚɧɢɟɦɡɚɬɪɚɬɧɚ ɫɬɪɨɢɬɟɥɶɫɬɜɨɢɨɛɫɥɭɠɢɜɚɧɢɟ. ɉɚɧɟɥɢ Paroc ɫɝɢɝɢɟɧɢɱɟɫɤɢɦɩɨɤɪɵɬɢɟɦɥɟɝɤɨ ɦɨɧɬɢɪɭɸɬɫɹɫɢɫɩɨɥɶɡɨɜɚɧɢɟɦɫɚɦɨɝɨ ɩɪɨɫɬɨɝɨɨɛɨɪɭɞɨɜɚɧɢɹ. Ⱥɢɯ ɨɛɫɥɭɠɢɜɚɧɢɟɜɨɫɨɛɟɧɧɨɫɬɢɦɨɣɤɚɜ ɩɢɳɟɜɨɣɩɪɨɦɵɲɥɟɧɧɨɫɬɢ, ɧɟ ɩɪɟɞɫɬɚɜɥɹɟɬɫɥɨɠɧɨɫɬɢ. ɂɫɩɨɥɶɡɨɜɚɧɢɟ ɨɝɧɟɫɬɨɣɤɢɯɩɚɧɟɥɟɣParoc ɦɨɠɟɬ, ɤɬɨɦɭ ɠɟ, ɫɬɚɬɶɮɚɤɬɨɪɨɦɫɧɢɠɟɧɢɹɡɚɬɪɚɬɧɚ ɫɬɪɚɯɨɜɤɭ.

ɋɩɟɰɢɚɥɶɧɵɟɷɥɟɦɟɧɬɵ

ɉɨɦɟɳɟɧɢɹɫɨɫɨɛɵɦɢɫɬɚɧɞɚɪɬɚɦɢ

ɱɢɫɬɨɬɵɬɪɟɛɭɸɬɩɪɢɦɟɧɟɧɢɹ ɫɩɟɰɢɚɥɶɧɵɯɤɨɧɫɬɪɭɤɬɢɜɧɵɯɪɟɲɟɧɢɣ. Paroc Panel System ɩɪɟɞɥɚɝɚɟɬɧɚɛɨɪ ɫɬɚɧɞɚɪɬɧɵɯɞɟɬɚɥɟɣ, ɨɛɟɫɩɟɱɢɜɚɸɳɢɯ ɫɨɨɬɜɟɬɫɬɜɢɟɫɚɦɵɦɠɟɫɬɤɢɦ ɬɪɟɛɨɜɚɧɢɹɦ, ɱɬɨɨɫɨɛɟɧɧɨɜɚɠɧɨɞɥɹ ɩɪɟɞɩɪɢɹɬɢɣɩɢɳɟɜɨɣɩɪɨɦɵɲɥɟɧɧɨɫɬɢ. ɇɟɨɛɯɨɞɢɦɨ, ɱɬɨɛɵɜɫɟɩɨɜɟɪɯɧɨɫɬɢ, ɷɥɟɦɟɧɬɵɤɪɟɩɥɟɧɢɹɢɞɟɬɚɥɢɢɦɟɥɢ ɦɚɤɫɢɦɚɥɶɧɨɩɥɨɬɧɨɟɩɪɢɥɟɝɚɧɢɟɢɛɵɥɢ ɝɥɚɞɤɢɦɢ, ɱɬɨɛɵɢɡɛɟɠɚɬɶɫɤɨɩɥɟɧɢɣ ɝɪɹɡɢɜɳɟɥɹɯɢɧɚɩɨɜɟɪɯɧɨɫɬɹɯ ɤɨɧɫɬɪɭɤɰɢɣ.

14 |

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ⱥɫɫɨɪɬɢɦɟɧɬ ɩɪɨɞɭɤɰɢɢ, ɐɜɟɬɚ ɢ ɩɨɤɪɵɬɢɹ, Ɍɟɯɧɢɱɟɫɤɨɟ ɨɩɢɫɚɧɢɟ, Ⱦɟɬɚɥɢ ɫɢɫɬɟɦɵ |

ȺɄɍɋɌɂɑȿɋɄȺə ɋɂɋɌȿɆȺ

Ɂɜɭɤɨɢɡɨɥɹɰɢɹ ɢ ɡɜɭɤɨɩɨɝɥɨɳɟɧɢɟ

Ɉɛɥɚɫɬɶɩɪɢɦɟɧɟɧɢɹ

Ⱥɤɭɫɬɢɱɟɫɤɚɹɫɢɫɬɟɦɚɪɚɡɪɚɛɨɬɚɧɚɞɥɹ ɭɫɬɪɨɣɫɬɜɚɩɟɪɟɝɨɪɨɞɨɤɢɩɨɬɨɥɤɨɜɜ ɩɨɦɟɳɟɧɢɹɯɩɪɨɦɵɲɥɟɧɧɨɝɨ ɧɚɡɧɚɱɟɧɢɹ, ɝɞɟɧɟɨɛɯɨɞɢɦɵ ɭɥɭɱɲɟɧɧɵɟɯɚɪɚɤɬɟɪɢɫɬɢɤɢ ɡɜɭɤɨɢɡɨɥɹɰɢɢɢɡɜɭɤɨɩɨɝɥɨɳɟɧɢɹ. ɍɪɨɜɟɧɶɲɭɦɚ, ɫɨɡɞɚɜɚɟɦɵɣɫɬɚɧɤɚɦɢ ɢɦɟɯɚɧɢɡɦɚɦɢɜɪɚɛɨɱɢɯɰɟɯɚɯ, ɦɨɠɟɬɞɨɫɬɢɝɚɬɶɡɧɚɱɟɧɢɣ, ɩɪɟɜɵɲɚɸɳɢɯɞɨɩɭɫɬɢɦɵɟɧɨɪɦɵ, ɩɪɢɷɬɨɦ, ɟɫɥɢɧɟɩɪɢɧɹɬɶ ɫɨɨɬɜɟɬɫɬɜɭɸɳɢɯɦɟɪ, ɦɨɝɭɬ ɨɬɦɟɱɚɬɶɫɹɞɚɠɟɧɚɪɭɲɟɧɢɹɫɥɭɯɚɭ ɪɚɛɨɬɚɸɳɢɯ. ɇɚɢɛɨɥɟɟɪɚɰɢɨɧɚɥɶɧɵɦ ɪɟɲɟɧɢɟɦɜɷɬɨɦɫɥɭɱɚɟɹɜɥɹɟɬɫɹ ɨɬɞɟɥɟɧɢɟɦɚɲɢɧɨɬɥɸɞɟɣ ɡɜɭɤɨɢɡɨɥɢɪɨɜɚɧɧɵɦɢɩɟɪɟɝɨɪɨɞɤɚɦɢ ɥɢɛɨɫɨɡɞɚɧɢɟɨɬɞɟɥɶɧɵɯɦɚɲɢɧɧɵɯ ɩɨɦɟɳɟɧɢɣɢɨɩɟɪɚɬɨɪɧɵɯɫ ɢɫɩɨɥɶɡɨɜɚɧɢɟɦɫɩɟɰɢɚɥɶɧɵɯ ɡɜɭɤɨɩɨɝɥɨɳɚɸɳɢɯɷɤɪɚɧɨɜ.

Ⱥɫɫɨɪɬɢɦɟɧɬɩɪɨɞɭɤɰɢɢ

ȼɚɤɭɫɬɢɱɟɫɤɢɯɤɨɧɫɬɪɭɤɰɢɹɯ ɩɪɢɦɟɧɹɸɬɫɹɤɚɤɛɚɡɨɜɵɟ, ɬɚɤɢ ɩɟɪɮɨɪɢɪɨɜɚɧɧɵɟɩɚɧɟɥɢParoc.

ɋɩɟɰɢɚɥɶɧɵɟɚɤɭɫɬɢɱɟɫɤɢɟɩɚɧɟɥɢ ɢɦɟɸɬɨɞɧɨɫɬɨɪɨɧɧɸɸɩɟɪɮɨɪɚɰɢɸ, ɨɛɟɫɩɟɱɢɜɚɸɳɭɸɭɥɭɱɲɟɧɧɨɟ ɡɜɭɤɨɩɨɝɥɨɳɟɧɢɟ. ɉɟɪɮɨɪɢɪɨɜɚɧɧɵɟ ɩɚɧɟɥɢɦɨɝɭɬɩɪɢɦɟɧɹɬɶɫɹɜɜɧɭɬɪɢ ɩɨɦɟɳɟɧɢɣɫɧɨɪɦɚɥɶɧɵɦɫɭɯɢɦ ɤɥɢɦɚɬɨɦ.

Ɂɜɭɤɨɢɡɨɥɹɰɢɹ

Ʉɨɷɮɮɢɰɢɟɧɬɡɜɭɤɨɢɡɨɥɹɰɢɢɩɚɧɟɥɟɣ Rw ɪɚɜɟɧ31 ɞȻ. ɉɪɢɜɟɞɟɧɧɵɣɧɢɠɟ ɝɪɚɮɢɤɢɥɥɸɫɬɪɢɪɭɟɬɤɨɷɮɮɢɰɢɟɧɬ ɡɜɭɤɨɢɡɨɥɹɰɢɢɞɥɹɨɛɵɱɧɵɯɩɚɧɟɥɟɣ ɬɨɥɳɢɧɨɣ80 ɦɦɢ150 ɦɦɢɞɥɹ ɩɟɪɮɨɪɢɪɨɜɚɧɧɵɯɩɚɧɟɥɟɣɬɨɥɳɢɧɨɣ 100 ɦɦ. ȼɫɥɭɱɚɟ, ɟɫɥɢɧɟɨɛɯɨɞɢɦɵ ɛɨɥɟɟɜɵɫɨɤɢɟɩɨɤɚɡɚɬɟɥɢ ɡɜɭɤɨɢɡɨɥɹɰɢɢ, ɜɨɡɦɨɠɧɨɩɪɢɦɟɧɟɧɢɟ ɫɞɜɨɟɧɧɵɯɤɨɧɫɬɪɭɤɰɢɣɢɡɩɚɧɟɥɟɣ Paroc ɥɢɛɨɢɫɩɨɥɶɡɨɜɚɧɢɟ ɞɨɩɨɥɧɢɬɟɥɶɧɵɯɦɟɪ.

Ɂɜɭɤɨɩɨɝɥɨɳɟɧɢɟ

ɉɟɪɮɨɪɢɪɨɜɚɧɧɵɟɩɚɧɟɥɢParoc ɢɦɟɸɬ ɨɞɧɨɫɬɨɪɨɧɧɸɸɩɟɪɮɨɪɚɰɢɸ, ɱɬɨ ɭɥɭɱɲɚɟɬɡɜɭɤɨɩɨɝɥɨɳɚɸɳɢɟɫɜɨɣɫɬɜɚ ɩɚɧɟɥɢ. Ⱦɥɹɭɥɭɱɲɟɧɢɹ ɡɜɭɤɨɩɨɝɥɨɳɚɸɳɢɯɫɜɨɣɫɬɜɛɚɡɨɜɵɯ ɩɚɧɟɥɟɣParoc ɩɪɢɦɟɧɹɸɬɫɹ ɞɨɩɨɥɧɢɬɟɥɶɧɵɟɡɜɭɤɨɩɨɝɥɨɳɚɸɳɢɟ ɦɚɬɟɪɢɚɥɵɜɮɨɪɦɟɚɤɭɫɬɢɱɟɫɤɢɯ ɜɚɬɧɵɯɩɚɧɟɥɟɣ.

ɂɧɞɟɤɫ ɡɜɭɤɨɢɡɨɥɹɰɢɢ ɞɥɹ ɩɚɧɟɥɟɣ ɬɨɥɳɢɧɨɣ 80 ɦɦ ɢ |

ɉɪɚɤɬɢɱɟɫɤɢɣ ɤɨɷɮɮɢɰɢɟɧɬ ɡɜɭɤɨɩɨɝɥɨɳɟɧɢɹ Įɪ ɞɥɹ |

150 ɦɦ ɢ ɩɟɪɮɨɪɢɪɨɜɚɧɧɵɯ ɩɚɧɟɥɟɣ ɬɨɥɳɢɧɨɣ 100 ɦɦ. |

ɩɟɪɮɨɪɢɪɨɜɚɧɧɵɯ ɩɚɧɟɥɟɣ Paroc ɬɨɥɳɢɧɨɣ 100 ɦɦ. |

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ⱥɫɫɨɪɬɢɦɟɧɬ ɩɪɨɞɭɤɰɢɢ, ɐɜɟɬɚ ɢ ɩɨɤɪɵɬɢɹ, Ɍɟɯɧɢɱɟɫɤɨɟ ɨɩɢɫɚɧɢɟ, Ⱦɟɬɚɥɢ ɫɢɫɬɟɦɵ |

15 |

ɌȿɏɇɂɑȿɋɄɂȿ ɏȺɊȺɄɌȿɊɂɋɌɂɄɂ

ɗɤɫɩɥɭɚɬɚɰɢɨɧɧɵɟ ɫɜɨɣɫɬɜɚ ɩɚɧɟɥɟɣ

|

|

|

|

|

|

|

|

|

|

|

|

|

ȺɫɫɨɪɬɢɦɟɧɬɩɚɧɟɥɟɣParoc |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

ɇɚɡɧɚɱɟɧɢɟ |

|

|

Ɍɢɩ |

|

|

ɇɨɦɢɧ. |

|

|

Ɏɚɤɬɢɱ. |

|

|

|

ɒɢɪɢɧɚ1) |

|

|

|

Ⱦɥɢɧɚ2) |

|

|

|

Ɇɚɫɫɚ3) |

|

|

|

ɉɪɟɞɟɥ |

|

|

|

Ɂɧɚɱɟɧɢɟ-U |

5) |

|

|

Ʉɨɷɮɮ. |

|

|

|

|

|

ɫɟɪɞɟɱ- |

|

ɬɨɥɳɢɧɚ |

|

|

ɬɨɥɳɢɧɚ |

|

|

|

ɦɦ |

|

|

|

ɦɦ |

|

|

|

ɤɝ/ɦ2 |

|

|

|

ɨɝɧɟɫɬɨɣ- |

|

|

|

W/m2K |

|

|

|

ɡɜɭɤɨɢɡɨɥɹɰɢɢ |

|

|

|

|

|

|

ɧɢɤɚ |

|

ɦɦ |

|

|

ɦɦ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ɤɨɫɬɢ4) ɦɢɧ |

. |

|

|

|

|

|

|

RwdB |

|

|

|

ɇɚɪɭɠɧɵɟ |

|

|

50ɋ |

|

|

50 |

|

|

53 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

15 |

|

|

|

- |

|

|

|

0,72 |

|

|

|

30 |

|

|

ɫɬɟɧɵ |

|

|

50ɋ |

|

|

80 |

|

|

79 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

17 |

|

|

|

- |

|

|

|

0.47 |

|

|

|

31 |

|

|

ȼɧɭɬɪɟɧɧɢɟ |

|

|

50ɋ |

|

|

100 |

|

|

99 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

19 |

|

|

|

EI 60 |

|

|

|

0,38 |

|

|

|

31 |

|

|

ɩɟɪɟɝɨɪɨɞɤɢ |

|

|

50ɋ |

|

|

120 |

|

|

120 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

20 |

|

|

|

EI 60 |

|

|

|

0,32 |

|

|

|

31 |

|

|

|

|

|

50ɋ |

|

|

150 |

|

|

151 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

23 |

|

|

|

EI 90 |

|

|

|

0,26 |

|

|

|

31 |

|

|

|

|

|

50ɋ |

|

|

200 |

|

|

202 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

27 |

|

|

|

EI 180 |

|

|

|

0,20 |

|

|

|

31 |

|

|

|

|

|

50ɋ |

|

|

240 |

|

|

243 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

31 |

|

|

|

EI 180 |

|

|

|

0,16 |

|

|

|

31 |

|

|

ȼɧɭɬɪɟɧɧɢɟ |

|

|

50F |

|

|

50 |

|

|

53 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

16 |

|

|

|

- |

|

|

|

0,78 |

|

|

|

30 |

|

|

ɩɟɪɟɝɨɪɨɞɤɢ |

|

|

50F |

|

|

80 |

|

|

79 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

19 |

|

|

|

EI 60 |

|

|

|

0,51 |

|

|

|

31 |

|

|

|

|

|

50F |

|

|

100 |

|

|

99 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

21 |

|

|

|

EI 120 |

|

|

|

0,42 |

|

|

|

31 |

|

|

|

|

|

50F |

|

|

120 |

|

|

120 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

23 |

|

|

|

EI 120 |

|

|

|

0,35 |

|

|

|

31 |

|

|

|

|

|

50F |

|

|

150 |

|

|

151 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

27 |

|

|

|

EI 180 |

|

|

|

0,28 |

|

|

|

31 |

|

|

|

|

|

50F |

|

|

200 |

|

|

202 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

33 |

|

|

|

EI 180 |

|

|

|

0,22 |

|

|

|

31 |

|

|

|

|

|

50F |

|

|

240 |

|

|

243 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

38 |

|

|

|

EI 180 |

|

|

|

0,18 |

|

|

|

31 |

|

|

ɇɚɪɭɠɧɵɟ |

|

|

75C |

|

|

80 |

|

|

79 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

20 |

|

|

|

- |

|

|

|

0,51 |

|

|

|

31 |

|

|

ɫɬɟɧɵ |

|

|

75C |

|

|

100 |

|

|

99 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

22 |

|

|

|

EI 606) |

|

|

|

0,42 |

|

|

|

31 |

|

|

ɩɨɬɨɥɨɱɧɵɟ |

|

|

75C |

|

|

120 |

|

|

120 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

25 |

|

|

|

EI 606) |

|

|

|

0,35 |

|

|

|

31 |

|

|

ɉɟɪɟɤɪɵɬɢɹ |

|

|

75C |

|

|

150 |

|

|

151 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

29 |

|

|

|

EI 906) |

|

|

|

0,28 |

|

|

|

31 |

|

|

|

|

|

75C |

|

|

200 |

|

|

202 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

35 |

|

|

|

EI 1806) |

|

|

|

0,22 |

|

|

|

31 |

|

|

|

|

|

75C |

|

|

240 |

|

|

243 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

40 |

|

|

|

EI 1806) |

|

|

|

0,18 |

|

|

|

31 |

|

|

ɉɨɬɨɥɨɱɧɵɟ |

|

|

75F |

|

|

80 |

|

|

79 |

|

|

1200 |

|

|

12,0 |

|

|

20 |

|

|

- |

|

|

0,51 |

|

|

31 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

ɩɟɪɟɤɪɵɬɢɹ |

|

|

75F |

|

|

100 |

|

|

99 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

22 |

|

|

|

EI 60 |

|

|

|

0,42 |

|

|

|

31 |

|

|

|

|

|

75F |

|

|

120 |

|

|

120 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

25 |

|

|

|

EI 60 |

|

|

|

0,35 |

|

|

|

31 |

|

|

|

|

|

75F |

|

|

150 |

|

|

151 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

29 |

|

|

|

EI 60 |

|

|

|

0,28 |

|

|

|

31 |

|

|

|

|

|

75F |

|

|

200 |

|

|

202 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

35 |

|

|

|

EI 60 |

|

|

|

0,22 |

|

|

|

31 |

|

|

|

|

|

75F |

|

|

240 |

|

|

243 |

|

|

|

1200 |

|

|

|

12,0 |

|

|

|

40 |

|

|

|

EI 60 |

|

|

|

0,18 |

|

|

|

31 |

|

ɇɟɨɛɯɨɞɢɦɨ ɭɱɢɬɵɜɚɬɶ, ɱɬɨ ɜ ɪɚɡɦɟɪɚɯ ɩɚɧɟɥɟɣ ɢ ɤɚɪɤɚɫɧɵɯ ɤɨɧɫɬɪɭɤɰɢɣ ɦɨɝɭɬ ɢɦɟɬɶɫɹ ɩɨɝɪɟɲɧɨɫɬɢ.

1)ɒɢɪɢɧɚ ɦɨɞɭɥɹ.

2)Ⱦɥɢɧɚ ɩɚɧɟɥɟɣ ɬɨɥɳɢɧɨɣ 50, 80, 100 ɢ 120 ɦɦ ɦɨɠɟɬ ɛɵɬɶ ɨɝɪɚɧɢɱɟɧɚ ɞɥɹ ɨɛɟɫɩɟɱɟɧɢɹ ɛɟɡɨɩɚɫɧɨɝɨ ɩɟɪɟɦɟɳɟɧɢɹ

3)ɉɚɧɟɥɢ ɫɨ ɫɬɚɧɞɚɪɬɧɵɦ ɬɢɩɨɦ ɩɨɜɟɪɯɧɨɫɬɢ.

4)ɉɪɟɞɟɥɵ ɨɝɧɟɫɬɨɣɤɨɫɬɢ ɷɤɜɢɜɚɥɟɧɬɧɵ ɤɥɚɫɫɭ EI (ɢɡɨɥɹɰɢɹ, ɰɟɥɨɫɬɧɨɫɬɶ). Ɂɧɚɱɟɧɢɹ ɬɪɟɛɨɜɚɧɢɣ ɝɨɫɭɞɚɪɫɬɜɟɧɧɵɯ ɫɬɚɧɞɚɪɬɨɜ ɦɨɝɭɬ ɨɬɥɢɱɚɬɶɫɹ ɨɬ ɭɤɚɡɚɧɧɵɯ ɜ ɞɚɧɧɨɦ ɦɚɬɟɪɢɚɥɟ. ɉɪɨɬɢɜɨɩɨɠɚɪɧɵɟ ɩɨɬɨɥɤɢ ɧɟ ɹɜɥɹɸɬɫɹ ɧɟɫɭɳɢɦɢ.

5)Ɂɧɚɱɟɧɢɹ-U, ɜɤɥɸɱɚɹ ɫɨɩɪɨɬɢɜɥɟɧɢɟ ɩɨɜɟɪɯɧɨɫɬɢ, Rsi + Rse = 0,17 m2K/W. ɗɬɢ ɡɧɚɱɟɧɢɹ-U ɨɫɧɨɜɚɧɵ ɧɚ lambra-ɡɧɚɱɟɧɢɹɯ ɥɚɦɟɥɟɣ ɢɡ ɤɚɦɟɧɧɨɣ ɜɚɬɵ ɫ ɜɟɪɬɢɤɚɥɶɧɵɦ ɪɚɫɩɨɥɨɠɟɧɢɟɦ ɜɨɥɨɤɨɧ. ɉɪɢ ɫɪɚɜɧɟɧɢɢ ɫ ɡɧɚɱɟɧɢɹɦɢ lambda ɬɪɚɞɢɰɢɨɧɧɵɯ ɜɚɬɧɵɯ ɩɥɢɬ, ɜɵɹɜɥɹɸɬɫɹ ɡɧɚɱɢɬɟɥɶɧɨ ɥɭɱɲɢɟ ɩɨɤɚɡɚɬɟɥɢ ɡɧɚɱɟɧɢɣ-U. Ɍɟɦ ɧɟ ɦɟɧɟɟ, ɡɧɚɱɟɧɢɹ, ɜɟɪɧɵɟ ɞɥɹ ɬɪɚɞɢɰɢɨɧɧɵɯ ɩɥɢɬ, ɧɟ ɜɟɪɧɵ ɞɥɹ ɩɚɧɟɥɟɣ, ɢɡɝɨɬɨɜɥɟɧɧɵɯ ɢɡ ɥɚɦɟɥɟɣ.

6)Ɍɨɥɶɤɨ ɞɥɹ ɜɧɟɲɧɢɯ ɫɬɟɧ.

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ⱥɫɫɨɪɬɢɦɟɧɬ ɩɪɨɞɭɤɰɢɢ |

17 |

ɌȿɏɇɂɑȿɋɄɂȿ ɏȺɊȺɄɌȿɊɂɋɌɂɄɂ

ɌȿɏɇɂɑȿɋɄɂȿ ɏȺɊȺɄɌȿɊɂɋɌɂɄɂ

Ɋɚɫɱɟɬ ɞɥɢɧɧɵɯ ɩɪɨɥɟɬɨɜ

|

Ɋɚɫɱɟɬɧɵɟɤɪɢɬɟɪɢɢ |

ɫɬɚɥɶɧɨɣɨɛɨɥɨɱɤɢ. Ɇɚɤɫɢɦɚɥɶɧɚɹ |

|

|

ɋɬɟɧɵɪɚɫɫɱɢɬɵɜɚɸɬɫɹɜ |

ɜɟɥɢɱɢɧɚɩɪɨɝɢɛɚɨɝɪɚɧɢɱɟɧɚ |

|

|

ɫɨɨɬɜɟɬɫɬɜɢɢɫɨɡɧɚɱɟɧɢɹɦɢ |

ɩɪɨɥɟɬ/100 ɞɥɹɧɚɪɭɠɧɵɯɫɬɟɧ, |

|

|

ɜɟɬɪɨɜɨɣɧɚɝɪɭɡɤɢɢɜɫɚɫɵɜɚɧɢɹ, |

ɩɪɨɥɟɬ/150 ɞɥɹɜɧɭɬɪɟɧɧɢɯ |

|

|

ɨɩɪɟɞɟɥɹɟɦɵɦɢɦɟɫɬɧɵɦɢ |

ɩɟɪɟɝɨɪɨɞɨɤɢɩɪɨɥɟɬ/250 ɞɥɹ |

|

|

ɧɨɪɦɚɬɢɜɧɵɦɢɞɨɤɭɦɟɧɬɚɦɢ. Ⱦɥɹ |

ɩɨɬɨɥɨɱɧɵɯɤɨɧɫɬɪɭɤɰɢɣ. ɉɚɧɟɥɢɧɟ |

|

|

ɧɟɧɚɝɪɭɠɚɟɦɵɯɩɟɪɟɤɪɵɬɢɣ, |

ɩɟɪɟɞɚɸɬɜɟɪɬɢɤɚɥɶɧɵɯɧɚɝɪɭɡɨɤɨɬ |

|

|

ɩɪɨɱɧɨɫɬɶɩɚɧɟɥɟɣɞɨɥɠɧɚɛɵɬɶ |

ɤɨɧɫɬɪɭɤɰɢɣɤɪɨɜɥɢɤɮɭɧɞɚɦɟɧɬɭ, |

|

|

ɞɨɫɬɚɬɨɱɧɨɣɞɥɹɩɨɞɞɟɪɠɚɧɢɹɜɟɫɚ |

ɫɨɨɬɜɟɬɫɬɜɟɧɧɨ, ɞɥɹɛɨɥɶɲɢɯɩɪɨɟɦɨɜ |

|

|

ɫɚɦɢɯɤɨɧɫɬɪɭɤɰɢɣ. ɇɚɝɪɭɠɚɟɦɵɟ |

ɧɟɨɛɯɨɞɢɦɨɢɫɩɨɥɶɡɨɜɚɬɶ |

|

|

ɩɟɪɟɤɪɵɬɢɹɪɚɫɫɱɢɬɵɜɚɸɬɫɹɧɚ |

ɞɨɩɨɥɧɢɬɟɥɶɧɵɣɤɚɪɤɚɫɩɨɜɫɟɦɭ |

|

|

ɧɚɝɪɭɡɤɭɨɬɜɟɫɚɫɚɦɢɯɤɨɧɫɬɪɭɤɰɢɣ |

ɩɟɪɢɦɟɬɪɭ. |

|

|

ɩɟɪɟɤɪɵɬɢɹ, ɪɚɛɨɱɭɸɧɚɝɪɭɡɤɭɢ |

|

|

|

|

Ɋɚɫɱɟɬɧɚɪɭɠɧɵɯɫɬɟɧ |

|

|

ɞɨɩɨɥɧɢɬɟɥɶɧɭɸɩɟɪɢɨɞɢɱɟɫɤɭɸ |

|

|

|

ɧɚɝɪɭɡɤɭ, ɫɨɡɞɚɜɚɟɦɭɸɥɸɞɶɦɢ, |

Ʉɨɧɫɬɪɭɤɰɢɹɡɞɚɧɢɹɜɛɨɥɶɲɢɧɫɬɜɟ |

|

|

ɫɥɭɱɚɟɜɨɩɪɟɞɟɥɹɟɬɫɹɮɨɪɦɨɣɤɚɪɤɚɫɚ. |

||

|

ɧɚɯɨɞɹɳɢɦɢɫɹɧɚɞɩɟɪɟɤɪɵɬɢɹɦɢ, ɜ |

||

|

|

ɍɩɪɨɟɤɬɢɪɨɜɳɢɤɚɢɦɟɟɬɫɹ |

|

Ɉɫɧɨɜɧɚɹ ɤɪɢɜɚɹ ɞɥɢɧɵ ɩɪɨɥɟɬɚ ɫ |

|

|

|

|

ɫɨɨɬɜɟɬɫɬɜɢɢɫȻɪɢɬɚɧɫɤɢɦ |

|

|

ɪɚɡɦɟɪɧɵɦɢ ɯɚɪɚɤɬɟɪɢɫɬɢɤɚɦɢ. |

ɋɬɚɧɞɚɪɬɨɦBS6399, Ƚɥɚɜɚ1. |

ɜɨɡɦɨɠɧɨɫɬɶɨɩɬɢɦɢɡɢɪɨɜɚɬɶ |

|

ɤɨɧɫɬɪɭɤɰɢɢɡɞɚɧɢɹ, ɢɫɩɨɥɶɡɭɹ |

|||

|

|||

ɉɪɨɱɧɨɫɬɶɢɪɚɫɱɟɬɧɚɝɪɭɡɨɤ |

|

||

ɉɪɟɜɨɫɯɨɞɧɵɟɦɚɬɟɪɢɚɥɵɢɬɟɯɧɨɥɨɝɢɹ |

ȼɟɥɢɱɢɧɵɩɪɨɝɢɛɨɜɩɪɨɥɟɬɚ |

ɩɪɨɱɧɨɫɬɶɫɚɦɢɯɩɚɧɟɥɟɣParoc, |

|

– AST ɞɟɥɚɸɬɩɚɧɟɥɢParoc |

ɪɚɫɫɱɢɬɵɜɚɸɬɫɹɞɥɹɞɨɩɭɫɬɢɦɵɯ |

ɧɚɩɪɢɦɟɪ, ɩɪɢɩɨɦɨɳɢɭɫɬɪɨɣɫɬɜɚ |

|

ɧɚɝɪɭɡɨɤ, ɜɤɥɸɱɚɹɤɨɷɮɮɢɰɢɟɧɬ |

|||

ɞɥɢɧɧɵɯɩɪɨɥɟɬɨɜ. ɉɚɧɟɥɢParoc |

|||

ɱɪɟɡɜɵɱɚɣɧɨɩɪɨɱɧɵɦɢɢɠɟɫɬɤɢɦɢ, |

|||

ɧɚɞɟɠɧɨɫɬɢɞɥɹɧɚɝɪɭɡɤɢȖq = 1,5 ɢ |

|||

|

|||

|

|

||

|

ɡɚɩɚɫɩɪɨɱɧɨɫɬɢɞɥɹɦɚɬɟɪɢɚɥɚȖm = |

ɨɛɵɱɧɨɦɨɧɬɢɪɭɸɬɫɹɜɤɨɧɫɬɪɭɤɰɢɹɯɫ |

|

ɫɩɨɫɨɛɧɵɦɢɩɪɨɬɢɜɨɫɬɨɹɬɶɤɚɤ |

|

||

ɩɨɥɨɠɢɬɟɥɶɧɨɣ, ɬɚɤɢɨɬɪɢɰɚɬɟɥɶɧɨɣ |

ɨɞɧɢɦɩɪɨɥɟɬɨɦ, ɨɞɧɚɤɨɜɨɡɦɨɠɧɵ |

||

1,25, ɫɨɝɥɚɫɧɨɪɟɤɨɦɟɧɞɚɰɢɹɦCIB |

|

||

ɜɟɬɪɨɜɨɣɧɚɝɪɭɡɤɟ. Ⱦɥɹɫɬɪɨɢɬɟɥɹɷɬɨ |

|

||

ɞɥɹɥɟɝɤɢɯɫɷɧɞɜɢɱ-ɩɚɧɟɥɟɣ. Ɍɢɩ |

ɤɨɧɫɬɪɭɤɰɢɢɫɧɟɫɤɨɥɶɤɢɦɢ |

||

ɩɪɨɥɟɬɚɦɢ. ȼɦɧɨɝɨɩɪɨɥɟɬɧɵɯ |

|||

|

|||

ɨɡɧɚɱɚɟɬɜɨɡɦɨɠɧɨɫɬɶɩɨɤɪɵɜɚɬɶ |

|

||

ɞɥɢɧɧɵɟɩɪɨɥɟɬɵ– ɤɥɸɱɟɜɨɟ |

ɫɟɪɞɟɱɧɢɤɚɜɵɛɢɪɚɟɬɫɹɜ |

|

|

|

ɤɨɧɫɬɪɭɤɰɢɹɯɧɟɨɛɯɨɞɢɦɨɭɱɢɬɵɜɚɬɶ |

||

|

|

||

|

ɡɚɜɢɫɢɦɨɫɬɢɨɬɬɪɟɛɭɟɦɨɣɜɟɥɢɱɢɧɵ |

ɬɟɦɩɟɪɚɬɭɪɧɵɣɝɪɚɞɢɟɧɬɩɨɬɨɥɳɢɧɟ |

|

ɩɪɟɢɦɭɳɟɫɬɜɨɜɫɨɜɪɟɦɟɧɧɨɦ |

ɩɪɨɥɟɬɚ. |

|

|

ɫɬɪɨɢɬɟɥɶɧɨɦɩɪɨɰɟɫɫɟ. |

ɩɚɧɟɥɢ. |

||

|

|||

|

|

||

|

Ⱦɥɹɞɥɢɧɧɵɯɩɪɨɥɟɬɨɜɜɨɡɦɨɠɧɨ |

|

|

|

ɭɜɟɥɢɱɟɧɢɟɬɨɥɳɢɧɵɫɥɨɟɜ |

|

|

|

ɧɚɪɭɠɧɨɣ |

|

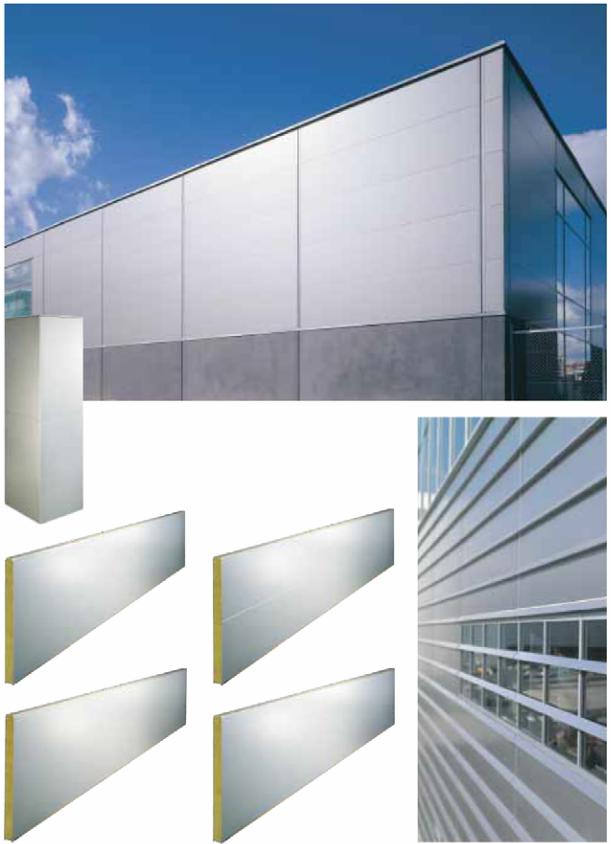

Ɇɚɤɫɢɦɚɥɶɧɵɟ ɪɚɡɦɟɪɵ ɩɪɨɥɟɬɨɜ ɞɥɹ ɩɚɧɟɥɟɣ Paroc ɜ ɨɞɧɨɩɪɨɥɟɬɧɵɯ ɧɚɪɭɠɧɵɯ ɫɬɟɧɚɯ

ɉɚɧɟɥɢ Paroc ɫ ɨɛɨɥɨɱɤɨɣ ɢɡ ɫɬɚɥɶɧɨɝɨ ɥɢɫɬɚ 0,6 ɦɦ.

Ɍɟɦɩɟɪɚɬɭɪɧɵɣ ɝɪɚɞɢɟɧɬ ɦɟɠɞɭ ɩɪɨɬɢɜɨɩɨɥɨɠɧɵɦɢ ɩɨɜɟɪɯɧɨɫɬɹɦɢ ɩɚɧɟɥɢ 55ɨɋ, ɦɚɤɫɢɦɚɥɶɧɵɣ ɩɪɨɝɢɛ L/100.

18

Ɋɚɫɱɟɬɩɟɪɟɝɨɪɨɞɨɤ |

ɪɚɫɫɱɢɬɚɧɵɧɚɬɨ, ɱɬɨɛɵ |

ɉɪɢɩɨɦɨɳɢɩɚɧɟɥɟɣParoc |

ɜɵɞɟɪɠɢɜɚɬɶɧɚɝɪɭɡɤɭɢ |

ɦɨɠɧɨɥɟɝɤɨɪɚɡɞɟɥɢɬɶ |

ɞɢɧɚɦɢɱɟɫɤɭɸɧɚɝɪɭɡɤɭɨɬ |

ɩɨɦɟɳɟɧɢɟɦɟɠɞɭɭɠɟ |

ɱɟɥɨɜɟɤɚ. Ⱦɥɹɨɛɫɥɭɠɵɜɚɧɢɹɡɨɧɵ |

ɢɦɟɸɳɢɦɢɫɹɷɥɟɦɟɧɬɚɦɢɡɞɚɧɢɹ |

ɩɪɨɯɨɞɚɢɩɪɢɥɨɠɟɧɢɹɫɢɥ |

ɢɥɢɨɬɞɟɥɶɧɨɝɨɤɚɪɤɚɫɚ. ȼɫɥɭɱɚɟ |

ɧɚɝɪɭɠɚɟɦɵɯɩɨɬɨɥɤɨɜɞɨɥɠɧɵ |

ɫɜɧɭɬɪɟɧɧɢɦɢɩɟɪɟɝɨɪɨɞɤɚɦɢ, |

ɛɵɬɶɞɨɩɨɥɧɢɬɟɥɶɧɨɭɤɪɟɩɥɟɧɵɢ |

ɧɚɝɪɭɡɤɢɞɨɫɬɢɝɚɸɬ |

ɡɚɳɢɳɟɧɵɮɚɧɟɪɧɵɦɢɷɥɟɦɟɧɬɚɦɢ |

ɦɚɤɫɢɦɚɥɶɧɵɯɡɧɚɱɟɧɢɣɧɚɷɬɚɩɟ |

ɪɚɫɩɪɟɞɟɥɟɧɢɹɧɚɝɪɭɡɤɢ. ȼɦɟɫɬɚɯ |

ɫɬɪɨɢɬɟɥɶɫɬɜɚ, ɤɨɝɞɚɭɫɬɚɧɨɜɤɚ |

ɢɧɬɟɧɫɢɜɧɨɝɨɩɟɲɟɯɨɞɧɨɝɨ |

ɜɧɟɲɧɢɯɫɬɟɧ, ɨɤɨɧɧɵɯɢ |

ɞɜɢɠɟɧɢɹ, ɧɚɩɪɢɦɟɪ, ɪɹɞɨɦɫ |

ɞɜɟɪɧɵɯɛɥɨɤɨɜɟɳɟɧɟ |

ɥɟɫɬɧɢɰɚɦɢ, ɞɜɟɪɶɦɢɢɦɟɫɬɚɦɢ |

ɡɚɜɟɪɲɟɧɚ. Ɇɢɧɢɦɚɥɶɧɚɹ |

ɭɫɬɚɧɨɜɤɢɦɟɯɚɧɢɡɦɨɜ, ɩɚɧɟɥɢ |

ɪɚɫɱɟɬɧɚɹɧɚɝɪɭɡɤɚɞɥɹ |

ɩɟɪɟɤɪɵɬɢɣɞɨɥɠɧɵɛɵɬɶɭɫɢɥɟɧɵ |

ɩɟɪɟɝɨɪɨɞɨɤɫɨɫɬɚɜɥɹɟɬ0,3 ɤɇ/ɦ2. |

ɳɢɬɚɦɢɪɚɫɩɪɟɞɟɥɟɧɢɹɧɚɝɪɭɡɤɢ |

|

ɩɨɜɟɪɯɠɟɫɬɤɢɯɩɥɢɬɢɡ |

Ɋɚɫɱɟɬɩɨɬɨɥɤɨɜ |

ɩɪɟɫɫɨɜɚɧɧɨɣɤɚɦɟɧɧɨɣɜɚɬɵ. ȼɨ |

|

|

ɉɪɨɱɧɨɫɬɶɩɨɬɨɥɨɱɧɵɯ |

ɜɫɟɯɫɥɭɱɚɹɯ, ɧɟɨɛɯɨɞɢɦɨɢɡɛɟɝɚɬɶ |

|

|

ɤɨɧɫɬɪɭɤɰɢɣɪɚɫɫɱɢɬɵɜɚɟɬɫɹɜ |

|

|

ɯɨɠɞɟɧɢɹɩɨɩɥɢɬɚɦɩɟɪɟɤɪɵɬɢɣ |

ɡɚɜɢɫɢɦɨɫɬɢɨɬɢɯɜɚɪɢɚɧɬɚ |

ɜɛɥɢɡɢɜɵɪɟɡɨɜɜɩɚɧɟɥɹɯ. |

ɩɪɟɞɩɨɥɚɝɚɟɦɨɝɨɢɫɩɨɥɶɡɨɜɚɧɢɹ. |

|

ɇɟɧɚɝɪɭɠɚɟɦɵɟɩɨɬɨɥɤɢɧɟ |

|

ɌȿɏɇɂɑȿɋɄɂȿ ɏȺɊȺɄɌȿɊɂɋɌɂɄɂ

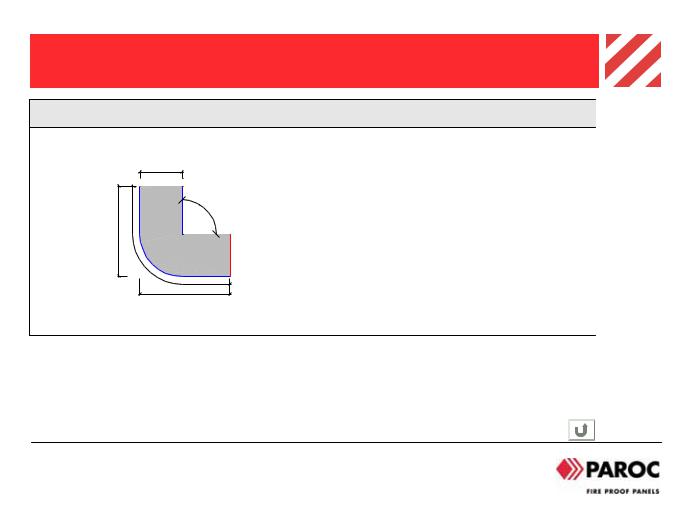

ɉɪɨɟɦɵ

ɉɪɨɟɦɵɜɩɚɧɟɥɹɯParoc ɥɟɝɤɨɢɷɤɨɧɨɦɢɱɧɨ ɩɪɨɞɟɥɵɜɚɸɬɫɹɩɪɹɦɨɧɚɦɟɫɬɟɭɫɬɚɧɨɜɤɢ. Ɉɬɞɟɥɶɧɵɟɧɟɛɨɥɶɲɢɟɨɬɜɟɪɫɬɢɹɦɨɝɭɬ ɩɪɨɪɟɡɚɬɶɫɹɜɥɸɛɨɦɦɟɫɬɟɩɚɧɟɥɢ. Ʉɪɭɩɧɵɟ ɩɪɨɟɦɵɫɧɢɠɚɸɬɩɪɨɱɧɨɫɬɶɩɚɧɟɥɶɧɨɝɨ ɷɥɟɦɟɧɬɚ. ɂɦɟɟɬɡɧɚɱɟɧɢɟɪɚɡɦɟɪɢ ɪɚɫɩɨɥɨɠɟɧɢɟɨɬɜɟɪɫɬɢɹ. ɉɪɢɧɟɨɛɯɨɞɢɦɨɫɬɢ, ɧɚɝɪɭɡɤɢɞɨɥɠɧɵɛɵɬɶɩɟɪɟɪɚɫɩɪɟɞɟɥɟɧɵɧɚ ɨɩɨɪɧɵɟɤɨɧɫɬɪɭɤɰɢɢ.

Ɇɚɤɫɢɦɚɥɶɧɵɣ ɪɚɡɦɟɪ ɩɪɨɥɟɬɚ ɞɥɹ ɧɟɧɚɝɪɭɠɚɟɦɵɯ ɢ ɧɚɝɪɭɠɚɟɦɵɯ ɩɨɬɨɥɤɨɜ ɢɡ ɩɚɧɟɥɟɣ

Paroc 75C/F

Ɍɨɥɳɢɧɚ |

ɇɟɧɚɝɪɭɠɚɟɦɵɟ |

ɇɚɝɪɭɠɚɟɦɵɟ |

ɩɚɧɟɥɢ |

ɩɨɬɨɥɤɢ |

ɩɨɬɨɥɤɢ |

(ɦɦ) |

|

|

50 |

4,3 |

3,5 |

80 |

6,0 |

4,8 |

100 |

7,0 |

5,7 |

120 |

8,0 |

6,5 |

150 |

9,3 |

7,6 |

200 |

10,8 |

9,1 |

240 |

11,9 |

10,0 |

ɉɚɧɟɥɢParoc ɫɜɟɪɯɧɟɣɨɛɨɥɨɱɤɨɣɢɡɫɬɚɥɶɧɨɝɨ ɥɢɫɬɚ0,6 ɦɦɢɧɢɠɧɟɣɨɛɨɥɨɱɤɨɣ0,5 ɦɦ. ɒɢɪɢɧɚɨɩɨɪ40 ɦɦ. Ɍɟɦɩɟɪɚɬɭɪɧɵɣɝɪɚɞɢɟɧɬɦɟɠɞɭɩɪɨɬɢɜɨɩɨɥɨɠɧɵɦɢɩɨɜɟɪɯɧɨɫɬɹɦɢɩɚɧɟɥɢ0ɨɋ. ɆɚɤɫɢɦɚɥɶɧɵɣɩɪɨɝɢɛL/240. ɇɚɝɪɭɡɤɚɞɥɹɧɟɧɚɝɪɭɠɚɟɦɵɯɩɨɬɨɥɤɨɜ: ɫɨɛɫɬɜɟɧɧɵɣɜɟɫɩɚɧɟɥɢ. ɇɚɝɪɭɡɤɚɞɥɹɧɚɝɪɭɠɚɟɦɵɯɩɨɬɨɥɤɨɜ: ɫɨɛɫɬɜɟɧɧɵɣɜɟɫɩɚɧɟɥɢ, ɫɨɫɪɟɞɨɬɨɱɟɧɧɚɹ ɧɚɝɪɭɡɤɚ0,9 ɤɇɢɪɚɜɧɨɦɟɪɧɚɹɪɚɛɨɱɚɹɧɚɝɪɭɡɤɚ

0,25 ɤɇ/ɦ2.

Ⱦɥɹɪɚɫɱɟɬɚɨɫɨɛɵɯɭɫɥɨɜɢɣɧɚɝɪɭɡɤɢ, ɩɪɨɫɶɛɚ ɫɜɹɡɚɬɶɫɹɫParoc Panel System.

ɉɚɧɟɥɢParoc ɫɨɛɨɥɨɱɤɨɣɢɡɫɬɚɥɶɧɨɝɨɥɢɫɬɚ0,5 ɦɦ. ɒɢɪɢɧɚɨɩɨɪɵ40 ɦɦɞɥɹɩɚɧɟɥɟɣɬɨɥɳɢɧɨɣ50 - 240 ɦɦ. Ɍɟɦɩɟɪɚɬɭɪɧɵɣɝɪɚɞɢɟɧɬɦɟɠɞɭɩɪɨɬɢɜɨɩɨɥɨɠɧɵɦɢɩɨɜɟɪɯɧɨɫɬɹɦɢ ɩɚɧɟɥɢ0ɨɋ, ɦɚɤɫɢɦɚɥɶɧɵɣɩɪɨɝɢɛL/150, ɧɚɝɪɭɡɤɚ0,3 ɤɇ/ɦ2.

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ɍɟɯɧɢɱɟɫɤɨɟ ɨɩɢɫɚɧɢɟ |

19 |

ɌȿɏɇɂɑȿɋɄɂȿ ɏȺɊȺɄɌȿɊɂɋɌɂɄɂ

ɌȿɏɇɂɑȿɋɄɂȿ ɏȺɊȺɄɌȿɊɂɋɌɂɄɂ

ȼɵɫɨɤɢɟ ɤɚɱɟɫɬɜɟɧɧɵɟ ɯɚɪɚɤɬɟɪɢɫɬɢɤɢ

ɉɪɢɦɟɪ ɢɫɩɵɬɚɧɢɹ ɩɚɧɟɥɢ Paroc ɬɢɩɚ 50F 150ɦɦ ɧɚɨɝɧɟɫɬɨɣɤɨɫɬɶ: ɩɨ ɢɫɬɟɱɟɧɢɢ ɬɪɟɯ ɱɚɫɨɜ ɬɟɦɩɟɪɚɬɭɪɚ ɩɨɜɟɪɯɧɨɫɬɢ, ɨɬɤɪɵɬɨɣ ɜɨɡɞɟɣɫɬɜɢɸ ɨɝɧɹ, ɫɨɫɬɚɜɥɹɥɚ ɫɜɵɲɟ 1100ɨɋ, ɜ ɬɨ ɜɪɟɦɹ ɤɚɤ ɩɨɜɵɲɟɧɢɟ ɬɟɦɩɟɪɚɬɭɪɵ ɩɪɨɬɢɜɨɩɨɥɨɠɧɨɣ ɩɨɜɟɪɯɧɨɫɬɢ ɫɨɫɬɚɜɢɥɨ ɦɟɧɟɟ 135ɨɋ.

20 |

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: ɐɜɟɬɚ ɢ ɩɨɤɪɵɬɢɹ |

ɌȿɏɇɂɑȿɋɄɂȿ ɏȺɊȺɄɌȿɊɂɋɌɂɄɂ |

|

|

Ɍɟɩɥɨɢɡɨɥɹɰɢɨɧɧɵɟ |

ɱɭɜɫɬɜɢɬɟɥɟɧɤɜɨɞɟ, ɬɚɤɤɚɤɢɦɟɟɬ |

|

ɯɚɪɚɤɬɟɪɢɫɬɢɤɢ |

ɧɭɥɟɜɨɣɤɨɷɮɮɢɰɢɟɧɬɤɚɩɢɥɥɹɪɧɨɝɨ |

|

ɋɢɫɬɟɦɚParoc ɨɛɥɚɞɚɟɬɜɵɫɨɤɢɦɢ |

ɜɩɢɬɵɜɚɧɢɹ. Ɏɚɤɬɢɱɟɫɤɢɣɭɪɨɜɟɧɶ |

|

ɬɟɩɥɨɢɡɨɥɹɰɢɨɧɧɵɦɢ |

ɝɟɪɦɟɬɢɱɧɨɫɬɢɫɬɵɤɨɜ, ɞɨɫɬɢɠɢɦɵɣ |

|

ɯɚɪɚɤɬɟɪɢɫɬɢɤɚɦɢ ɛɥɚɝɨɞɚɪɹ |

ɧɚɩɪɚɤɬɢɤɟ, ɨɛɟɫɩɟɱɢɜɚɟɬ |

|

ɝɟɪɦɟɬɢɱɧɵɦɫɬɵɤɚɦ, ɦɚɥɨɦɭ |

ɞɨɫɬɚɬɨɱɧɵɣɭɪɨɜɟɧɶɡɚɳɢɬɵɨɬ |

|

ɡɧɚɱɟɧɢɸɥɹɦɛɞɚ, ɧɟɩɪɟɪɵɜɧɨɦɭɢ |

ɩɪɨɧɢɤɧɨɜɟɧɢɹɜɨɡɞɭɯɚɢɜɥɚɝɢɚ |

|

ɨɞɧɨɪɨɞɧɨɦɭɢɡɨɥɹɰɢɨɧɧɨɦɭɫɥɨɸ, ɧɟ |

ɬɚɤɠɟɢ ɬɟɪɦɨɢɡɨɥɹɰɢɨɧɧɵɟɤɚɱɟɫɬɜɚ |

|

ɢɦɟɸɳɟɦɭɬɟɩɥɨɜɵɯɦɨɫɬɢɤɨɜ. |

ɩɚɧɟɥɶɧɵɯɤɨɧɫɬɪɭɤɰɢɣ. |

|

ɇɟɡɧɚɱɢɬɟɥɶɧɵɟɜɚɪɢɚɰɢɢɡɧɚɱɟɧɢɹ-U |

Ɂɜɭɤɨɢɡɨɥɹɰɢɹ |

|

ɦɨɝɭɬɢɦɟɬɶɦɟɫɬɨɜɡɚɜɢɫɢɦɨɫɬɢɨɬ |

Ɂɧɚɱɟɧɢɟɢɧɞɟɤɫɚɡɜɭɤɨɢɡɨɥɹɰɢɢ |

|

ɬɪɟɛɨɜɚɧɢɣ ɦɟɫɬɧɵɯɧɨɪɦ. |

ɩɚɧɟɥɟɣRw ɪɚɜɧɨ31 ɞȻ. ɉɪɢ |

|

Ɂɚɳɢɬɚɨɬɩɪɨɧɢɤɧɨɜɟɧɢɹɜɨɡɞɭɯɚ, |

ɧɟɨɛɯɨɞɢɦɨɫɬɢ, ɡɧɚɱɟɧɢɟ |

|

ɢɫɩɚɪɟɧɢɣɢɨɫɚɞɤɨɜ |

ɡɜɭɤɨɢɡɨɥɹɰɢɢɦɨɠɟɬɛɵɬɶɭɜɟɥɢɱɟɧɨ |

|

ɋɩɟɰɢɚɥɶɧɵɣɫɬɵɤJointSeal |

ɩɪɢɩɨɦɨɳɢɞɨɩɨɥɧɢɬɟɥɶɧɵɯ |

|

ɨɛɨɪɭɞɨɜɚɧɭɩɥɨɬɧɟɧɢɟɦ, |

ɤɨɧɫɬɪɭɤɰɢɣ, ɡɚɤɪɟɩɥɟɧɧɵɯɧɚ |

|

ɭɫɬɚɧɚɜɥɢɜɚɟɦɵɦɧɚɷɬɚɩɟ |

ɩɚɧɟɥɹɯ. |

|

ɢɡɝɨɬɨɜɥɟɧɢɹɩɚɧɟɥɟɣɧɚɡɚɜɨɞɟ. Ɍɚɤɨɣ |

«ɋɭɯɚɹ» ɫɬɪɨɢɬɟɥɶɧɚɹɬɟɯɧɨɥɨɝɢɹ |

|

ɫɬɵɤɧɚɞɟɠɧɨɩɟɪɟɤɪɵɜɚɟɬɞɨɫɬɭɩ |

Paroc Panel System – ɷɬɨ«ɫɭɯɚɹ» |

|

ɜɨɞɵɢɢɫɩɚɪɟɧɢɣɜɧɭɬɪɶɩɚɧɟɥɢɤɟɺ |

ɫɬɪɨɢɬɟɥɶɧɚɹɬɟɯɧɨɥɨɝɢɹ, ɩɨɫɥɟ |

|

ɫɟɪɞɟɱɧɢɤɭ. ɋɚɦɢɩɨɜɟɪɯɧɨɫɬɢ |

ɩɪɢɦɟɧɟɧɢɹɤɨɬɨɪɨɣɧɚɫɬɪɨɢɬɟɥɶɧɨɣ |

|

ɩɚɧɟɥɟɣɬɚɤɠɟɧɟɩɪɨɩɭɫɤɚɸɬɜɨɡɞɭɯɢ |

ɩɥɨɳɚɞɤɟɧɟɨɫɬɚɟɬɫɹɫɵɪɨɫɬɢɢ ɡɨɧ |

|

ɜɥɚɝɭ. Ɇɚɬɟɪɢɚɥɫɟɪɞɟɱɧɢɤɚɩɚɧɟɥɢ– |

ɩɨɜɵɲɟɧɧɨɣɜɥɚɠɧɨɫɬɢ. Ɂɞɚɧɢɟ |

|

ɤɚɦɟɧɧɚɹɜɚɬɚParoc – ɧɟ |

ɝɨɬɨɜɨɤ ɷɤɫɩɥɭɚɬɚɰɢɢɫɪɚɡɭɩɨɫɥɟ |

|

|

ɨɤɨɧɱɚɧɢɹɦɨɧɬɚɠɚ. |

|

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ɍɟɯɧɢɱɟɫɤɨɟ ɨɩɢɫɚɧɢɟ |

21 |

ɍɋɅɍȽɂ

ɍɋɅɍȽɂ

Ɇɢɧɢɦɢɡɚɰɢɹ ɤɚɩɢɬɚɥɶɧɵɯ ɡɚɬɪɚɬ ɡɚ ɫɱɟɬ ɛɨɝɚɬɨɝɨ ɨɩɵɬɚ ɢ ɷɮɮɟɤɬɢɜɧɨɝɨ ɨɛɫɥɭɠɢɜɚɧɢɹ

ȼɞɨɩɨɥɧɟɧɢɟɤɩɚɧɟɥɹɦɢɚɤɫɟɫɫɭɚɪɚɦ, |

ɬɨɝɨ, ɱɬɨɛɵɨɛɟɫɩɟɱɢɬɶɟɝɨɭɫɩɟɯɜɨɜɫɟɯ |

ɞɨɫɬɭɩɧɵɜɰɢɮɪɨɜɨɦɜɢɞɟɜɮɨɪɦɚɬɟ |

|

Paroc Panel System ɩɪɟɞɥɚɝɚɟɬɭɧɢɤɚɥɶɧɵɣ |

ɞɟɬɚɥɹɯ. |

AutoCAD. |

|

ɩɚɤɟɬɭɫɥɭɝ, ɨɛɥɟɝɱɚɸɳɢɣɡɚɤɚɡɱɢɤɭ |

|

ɇɟɬɨɥɶɤɨɩɚɧɟɥɢ, ɧɨɢɚɤɫɟɫɫɭɚɪɵ |

|

|

Ɍɟɯɧɢɱɟɫɤɚɹɩɨɞɞɟɪɠɤɚɢɨɪɝɚɧɢɡɚɰɢɹ |

||

ɭɩɪɚɜɥɟɧɢɟɨɛɴɟɤɬɚɦɢɫɬɪɨɢɬɟɥɶɫɬɜɚɫ |

|

Ʉɪɟɩɟɠɧɵɟɜɢɧɬɵ, ɭɩɥɨɬɧɢɬɟɥɢɢɝɧɭɬɵɟ |

|

ɢɫɩɨɥɶɡɨɜɚɧɢɟɦɫɢɫɬɟɦParoc ɧɚɜɫɟɯ |

ɫɛɵɬɚ |

||

Paroc Panel System ɩɪɟɞɨɫɬɚɜɥɹɟɬ |

ɩɪɨɮɢɥɹ, ɮɢɝɭɪɢɪɭɸɳɢɟɜɱɟɪɬɟɠɚɯ |

||

|

|||

ɷɬɚɩɚɯɪɚɛɨɬɨɬɧɚɱɚɥɚɩɪɨɟɤɬɢɪɨɜɚɧɢɹɞɨ |

ɢɧɫɬɪɭɤɰɢɢɩɨɪɚɫɱɟɬɭɩɚɧɟɥɶɧɵɯɫɢɫɬɟɦɢ |

ɞɟɬɚɥɟɣ, ɫɟɪɬɢɮɢɰɢɪɨɜɚɧɵɞɥɹ |

|

ɡɚɜɟɪɲɟɧɢɹɦɨɧɬɚɠɚ. Ⱦɚɧɧɵɣɩɚɤɟɬ |

ɩɪɨɥɟɬɨɜ, ɨɫɧɨɜɚɧɧɵɟɧɚɢɦɟɸɳɢɯɫɹɭɧɚɫ |

ɢɫɩɨɥɶɡɨɜɚɧɢɹ ɜɫɢɫɬɟɦɟɫ Paroc Panel |

|

ɜɤɥɸɱɚɟɬɩɨɥɧɵɣɧɚɛɨɪɭɫɥɭɝɩɨɞɞɟɪɠɤɢ, |

|||

ɧɨɭ-ɯɚɭɜɢɡɝɨɬɨɜɥɟɧɢɢɢɩɪɨɟɤɬɢɪɨɜɚɧɢɢ |

System. ȼɫɟɚɤɫɟɫɫɭɚɪɵɢɩɪɢɧɚɞɥɟɠɧɨɫɬɢ |

||

ɨɛɟɫɩɟɱɢɜɚɸɳɢɯɭɫɩɟɲɧɨɟ |

ɤɨɧɫɬɪɭɤɰɢɣɢɡɫɷɧɞɜɢɱ-ɩɚɧɟɥɟɣ. ɉɪɢ |

|

|

|

ɦɨɝɭɬɛɵɬɶɡɚɤɚɡɚɧɵɢɩɨɫɬɚɜɥɟɧɵɜɦɟɫɬɟɫ |

||

ɩɪɨɟɤɬɢɪɨɜɚɧɢɟɢɱɟɬɤɨɟɨɫɭɳɟɫɬɜɥɟɧɢɟ |

ɫɨɨɬɜɟɬɫɬɜɭɸɳɟɣɞɨɝɨɜɨɪɟɧɧɨɫɬɢ, Paroc |

ɩɚɧɟɥɹɦɢ. |

|

ɝɪɚɮɢɤɚɩɨɫɬɚɜɨɤɢɦɨɧɬɚɠɧɵɯɪɚɛɨɬ. |

|||

Panel System ɦɨɠɟɬɜɵɩɨɥɧɢɬɶɫɬɚɬɢɱɟɫɤɢɟ |

|

||

Ɉɛɳɢɟɡɚɬɪɚɬɵ, ɬɚɤɢɦɨɛɪɚɡɨɦ, ɛɭɞɭɬ |

ɉɨɪɹɞɨɤ ɦɨɧɬɚɠɚɩɚɧɟɥɟɣ |

||

ɪɚɫɱɟɬɵɜɟɬɪɨɜɨɣɧɚɝɪɭɡɤɢ, |

ɇɚɨɫɧɨɜɚɧɢɢɚɪɯɢɬɟɤɬɭɪɧɵɯɱɟɪɬɟɠɟɣ, |

||

ɫɜɟɞɟɧɵɤɦɢɧɢɦɭɦɭ. |

|||

|

|||

|

Paroc ɜɵɩɨɥɧɹɟɬɢɩɪɟɞɫɬɚɜɥɹɟɬɡɚɤɚɡɱɢɤɭ |

||

|

ɫɨɨɬɜɟɬɫɬɜɭɸɳɢɟɬɢɩɨɜɵɦɫɬɚɧɞɚɪɬɚɦ |

||

|

|

||

Ɉɩɵɬɧɵɣɩɟɪɫɨɧɚɥ |

ɫɬɪɚɧɵɡɚɤɚɡɱɢɤɚɢȿɜɪɨɩɟɣɫɤɢɦɢ |

|

|

ɈɩɵɬɧɵɟɫɨɬɪɭɞɧɢɤɢɨɮɢɫɨɜɩɪɨɞɚɠParoc |

ɪɟɤɨɦɟɧɞɚɰɢɹɦCIB. |

ɦɨɧɬɚɠɧɵɟɱɟɪɬɟɠɵ ɞɥɹɩɪɨɷɤɬɚ ɜɫɟɯ |

|

ɩɚɧɟɥɟɣɫɭɤɚɡɚɧɢɟɦɧɟɨɛɯɨɞɢɦɵɯɞɥɢɧ. |

|||

Panel System ɨɤɚɠɭɬɧɚɲɢɦɤɥɢɟɧɬɚɦ |

|

||

Ʉɨɦɩɚɧɢɹɩɪɟɞɥɚɝɚɟɬɭɫɥɭɝɢɨɩɵɬɧɵɯ |

|

||

|

|

ȼɬɨɠɟɜɪɟɦɹɝɨɬɨɜɹɬɫɹɧɟɨɛɯɨɞɢɦɵɟ |

|

ɩɨɦɨɳɶɜɜɵɪɚɛɨɬɤɟɨɩɬɢɦɚɥɶɧɵɯ |

ɬɟɯɧɢɱɟɫɤɢɯɫɩɟɰɢɚɥɢɫɬɨɜɞɥɹɜɵɪɚɛɨɬɤɢ |

|

|

|

|

ɭɫɬɚɧɨɜɨɱɧɵɟɱɟɪɬɟɠɵ ɤɨɧɫɬɪɭɤɰɢɣɜ |

|

ɪɟɲɟɧɢɣɜɩɪɨɰɟɫɫɟɧɟɩɨɫɪɟɞɫɬɜɟɧɧɨɣ |

ɚɪɯɢɬɟɤɬɭɪɧɵɯɢɢɧɠɟɧɟɪɧɵɯɪɟɲɟɧɢɣɢ |

ɫɛɨɪɟ, ɫɨɞɟɪɠɚɳɢɟɢɧɮɨɪɦɚɰɢɸɨɩɨɪɹɞɤɟ |

|

ɫɨɜɦɟɫɬɧɨɣɪɚɛɨɬɵ. ɉɨɫɥɟɩɨɞɩɢɫɚɧɢɹ |

|

||

ɪɟɤɨɦɟɧɞɚɰɢɣɩɨɨɬɞɟɥɶɧɵɦɭɡɥɚɦ |

ɦɨɧɬɚɠɚɤɚɠɞɨɣɩɚɧɟɥɢ. ɋɩɟɰɢɚɥɶɧɚɹ |

||

ɞɨɝɨɜɨɪɚ, ɧɚɲɵ ɢɧɠɟɧɟɪɵɩɪɨɞɨɥɠɚɬ |

ɩɚɧɟɥɶɧɵɯɤɨɧɫɬɪɭɤɰɢɣ. ɑɟɪɬɟɠɢ |

||

|

|||

|

|

ɪɟɡɤɚɩɚɧɟɥɟɣɜɫɨɨɬɜɟɬɫɬɜɢɢɫɱɟɪɬɟɠɚɦɢ |

|

ɩɪɚɤɬɢɱɟɫɤɭɸɪɚɛɨɬɭɧɚɞɩɪɨɟɤɬɨɦɞɥɹ |

ɫɬɚɧɞɚɪɬɧɵɯɢɫɩɟɰɢɚɥɶɧɵɯɞɟɬɚɥɟɣ |

|

|

|

|

ɦɨɠɟɬɛɵɬɶɜɵɩɨɥɧɟɧɚɧɚɡɚɜɨɞɟɩɨ |

|

|

|

ɨɬɞɟɥɶɧɨɦɭɡɚɤɚɡɭ. |

22 |

Ⱦɨɩɨɥɧɢɬɟɥɶɧɚɹ ɢɧɮɨɪɦɚɰɢɹ: Ɋɭɤɨɜɨɞɫɬɜɨ ɩɨ ɦɨɧɬɚɠɭ, Ɋɭɤɨɜɨɞɫɬɜɨ ɩɨ ɷɤɫɩɥɭɚɬɚɰɢɢ ɢ ɨɛɫɥɭɠɢɜɚɧɢɸ |

ɍɋɅɍȽɂ

ɉɪɨɱɧɚɹɭɩɚɤɨɜɤɚ |

|

|

|

ɉɚɧɟɥɢParoc ɩɨɫɬɚɜɥɹɸɬɫɹ |

|

|

|

ɩɨɤɭɩɚɬɟɥɸɜɩɪɨɱɧɨɣɭɩɚɤɨɜɤɟ, |

|

|

|

ɫɨɨɬɜɟɬɫɬɜɭɸɳɟɣɭɫɥɨɜɢɹɦ |

ɦɨɧɬɚɠɭ, ɫɩɟɰɢɚɥɶɧɵɟɤɪɟɩɟɠɧɵɟ |

|

|

ɬɪɚɧɫɩɨɪɬɢɪɨɜɤɢ. ɋɨɞɟɪɠɢɦɨɟ |

ɉɚɪɬɧɟɪɵɩɨɦɨɧɬɚɠɭ |

||

|

ȼɨɮɢɫɚɯɩɪɨɞɚɠɦɚɬɟɪɢɚɥɨɜParoc ȼɚɦ |

||

|

ɦɚɬɟɪɢɚɥɵɢɨɛɭɱɟɧɢɟɩɟɪɫɨɧɚɥɚ |

||

|

|

||

ɤɚɠɞɨɝɨɩɚɤɟɬɚɢɦɟɫɬɨ ɤɚɠɞɨɣ |

|

|

|

|

ɦɨɧɬɚɠɧɢɤɨɜɩɪɹɦɨɧɚɦɟɫɬɟ |

|

|

|

|

ɦɨɝɭɬɩɨɪɟɤɨɦɟɧɞɨɜɚɬɶɦɨɧɬɚɠɧɵɟ |

|

ɩɚɧɟɥɢɩɨɨɩɢɫɚɧɨɜɭɩɚɤɨɜɨɱɧɨɦ |

ɩɨɦɨɝɚɸɬɭɫɤɨɪɢɬɶɩɪɨɰɟɫɫ. |

|

|

ɥɢɫɬɟ. ɉɨɫɥɟɩɨɥɭɱɟɧɢɹɝɪɭɡɚ, ɤɚɠɞɚɹ |

ɨɪɝɚɧɢɡɚɰɢɢ, ɩɟɪɫɨɧɚɥɤɨɬɨɪɵɯɩɪɨɲɟɥ |

||

Ɇɨɧɬɚɠɫɷɧɞɜɢɱ-ɩɚɧɟɥɟɣParoc |

|||

|

|||

|

|

ɫɩɟɰɢɚɥɶɧɨɟɨɛɭɱɟɧɢɟɢɢɦɟɟɬ |

|

ɭɩɚɤɨɜɤɚɞɨɥɠɧɚɛɵɬɶɩɪɨɜɟɪɟɧɚɧɚ |

ɜɨɡɦɨɠɟɧɜɥɸɛɭɸɩɨɝɨɞɭ. |

|

|

|

|

||

|

|

ɞɥɢɬɟɥɶɧɵɣɩɪɚɤɬɢɱɟɫɤɢɣɨɩɵɬɜ |

|

ɫɨɨɬɜɟɬɫɬɜɢɟɫɨɞɟɪɠɢɦɨɝɨ |

|

|

|

|

ɉɪɚɤɬɢɱɧɨɟɢɫɩɨɥɧɟɧɢɟɢɥɟɝɤɢɣ |

ɦɨɧɬɚɠɟɫɷɧɞɜɢɱ-ɩɚɧɟɥɟɣParoc. |

|

|

|

||

ɭɩɚɤɨɜɨɱɧɨɦɭɥɢɫɬɭɢɨɬɫɭɬɫɬɜɢɟ |

|

|

|

|

ɜɟɫɩɚɧɟɥɟɣɟɳɟɛɨɥɟɟɭɩɪɨɳɚɸɬ |

|

|

ɞɟɮɟɤɬɨɜ. |

ɡɚɞɚɱɭ. ɉɚɧɟɥɢɩɨɫɬɚɜɥɹɸɬɫɹɫ |

|

|

|

|

||

|

|

Ɉɛɫɥɭɠɢɜɚɧɢɟɤɨɧɫɬɪɭɤɰɢɣɢɡɩɚɧɟɥɟɣ |

|

Ɍɨɱɧɨɟɫɨɛɥɸɞɟɧɢɟɫɪɨɤɨɜɩɨɫɬɚɜɤɢ |

ɝɨɬɨɜɨɣɨɬɞɟɥɤɨɣ, ɩɨɷɬɨɦɭɩɨɫɥɟɢɯ |

Paroc |

|

Ⱦɥɹɤɚɠɞɨɝɨɤɨɧɤɪɟɬɧɨɝɨɩɪɨɟɤɬɚ |

ɦɨɧɬɚɠɚɨɬɩɚɞɚɟɬɧɟɨɛɯɨɞɢɦɨɫɬɶɜ |

ɂɧɫɬɪɭɤɰɢɢɩɨɨɛɫɥɭɠɢɜɚɧɢɸ |

|

ɩɨɫɬɚɜɤɢɦɚɬɟɪɢɚɥɨɜɧɚɨɛɴɟɤɬ |

ɩɪɢɦɟɧɟɧɢɢɬɟɯɧɨɥɨɝɢɣɜɥɚɠɧɨɣ |

ɤɨɧɫɬɪɭɤɰɢɣɢɡɫɷɧɞɜɢɱ-ɩɚɧɟɥɟɣParoc ɜ |

|

|

ɨɬɞɟɥɤɢ. |

||

ɨɪɝɚɧɢɡɭɸɬɫɹɜɬɨɱɧɨɦɫɨɨɬɜɟɬɫɬɜɢɢɫ |

|

||

|

|

ɬɟɱɟɧɢɟɫɪɨɤɚɢɯɫɥɭɠɛɵɩɪɢɜɨɞɹɬɫɹɜ |

|

ɫɨɝɥɚɫɨɜɚɧɧɵɦɝɪɚɮɢɤɨɦ. |

|

«Ɋɭɤɨɜɨɞɫɬɜɟɩɨɷɤɫɩɥɭɚɬɚɰɢɢɢ |

|

ɍɩɚɤɨɜɚɧɧɵɟɩɚɧɟɥɢ, ɞɨɫɬɚɜɥɟɧɧɵɟɧɚ |

Ɇɨɧɬɚɠɧɨɟɨɛɨɪɭɞɨɜɚɧɢɟ |

||

Ȼɟɡɨɩɚɫɧɨɟɢɢɫɩɵɬɚɧɧɨɟ |

ɨɛɫɥɭɠɢɜɚɧɢɸ». ȼɨɡɦɨɠɧɨɩɨɜɬɨɪɧɨɟ |

||

ɫɬɪɨɣɩɥɨɳɚɞɤɭ, ɦɨɝɭɬɪɚɡɝɪɭɠɚɬɶɫɹ |

ɦɨɧɬɚɠɧɨɟɨɛɨɪɭɞɨɜɚɧɢɟ, ɤɨɬɨɪɨɟ |

|

|

|

ɢɫɩɨɥɶɡɨɜɚɧɢɟɢɜɬɨɪɢɱɧɚɹɩɟɪɟɪɚɛɨɬɤɚ |

||

ɧɟɩɨɫɪɟɞɫɬɜɟɧɧɨɜɦɟɫɬɟɢɯɛɭɞɭɳɟɣ |

ɦɨɠɧɨɚɪɟɧɞɨɜɚɬɶɧɚɜɪɟɦɹ |

ɩɚɧɟɥɟɣ. |

|

ɭɫɬɚɧɨɜɤɢ, ɫɨɝɥɚɫɧɨɩɥɚɧɭɦɨɧɬɚɠɚ. |

ɜɵɩɨɥɧɟɧɢɹɦɨɧɬɚɠɧɵɯɪɚɛɨɬ, |

|

|

|

|

||

ɉɪɨɫɬɨɬɚɭɫɬɚɧɨɜɤɢ |

ɩɨɡɜɨɥɢɬɭɜɟɥɢɱɢɬɶ |

|

|

ɍɫɬɚɧɨɜɨɱɧɵɟɱɟɪɬɟɠɢɫ |

ɷɮɮɟɤɬɢɜɧɨɫɬɶ. ɉɪɢɩɨɦɨɳɢ |

|

|

ɤɨɞɢɪɨɜɚɧɧɵɦɢɨɛɨɡɧɚɱɟɧɢɹɦɢ |

ɫɩɟɰɢɚɥɶɧɵɯɢɧɫɬɪɭɦɟɧɬɨɜɩɚɧɟɥɢ |

|

|

ɩɚɧɟɥɟɣɢɦɟɫɬɢɯɪɚɫɩɨɥɨɠɟɧɢɹɜ |

ɥɟɝɤɨɭɫɬɚɧɚɜɥɢɜɚɸɬɫɹɜ |

|

|

ɭɩɚɤɨɜɤɟɡɧɚɱɢɬɟɥɶɧɨɭɩɪɨɳɚɸɬ |

ɝɨɪɢɡɨɧɬɚɥɶɧɨɟɢɜɟɪɬɢɤɚɥɶɧɨɟ |

|

|

ɩɪɨɰɟɞɭɪɭɩɥɚɧɢɪɨɜɚɧɢɹɪɚɛɨɬɧɚ |

ɩɨɥɨɠɟɧɢɟɢɩɪɢɦɟɧɢɦɵɞɥɹ |

|

|

ɨɛɴɟɤɬɟ. ɉɨɞɪɨɛɧɵɟɢɧɫɬɪɭɤɰɢɢɩɨ |

ɦɨɧɬɚɠɚ ɩɨɬɨɥɨɱɧɵɯɩɟɪɟɤɪɵɬɢɣ. |

|

23

Paroc Group ɩɪɨɢɡɜɨɞɢɬɢɪɟɚɥɢɡɭɟɬɲɢɪɨɤɢɣɚɫɫɨɪɬɢɦɟɧɬɧɟɝɨɪɸɱɢɯ ɢɡɨɥɹɰɢɨɧɧɵɯɦɚɬɟɪɢɚɥɨɜɢɬɟɯɧɨɥɨɝɢɣɞɥɹɫɬɪɨɢɬɟɥɶɧɨɝɨɢɩɪɨɦɵɲɥɟɧɧɨɝɨ ɩɪɢɦɟɧɟɧɢɹ, ɜɤɥɸɱɚɹɫɷɧɞɜɢɱ-ɩɚɧɟɥɢ. ȼɨɫɧɨɜɟɛɢɡɧɟɫɚɝɪɭɩɩɵɤɨɦɩɚɧɢɣParoc ɥɟɠɚɬɝɥɭɛɨɤɢɟɡɧɚɧɢɹɢɩɪɨɞɭɤɰɢɹɜɵɫɨɤɨɝɨɤɚɱɟɫɬɜɚ. Ƚɪɭɩɩɚɜɥɚɞɟɟɬ ɩɪɟɞɩɪɢɹɬɢɹɦɢɜɎɢɧɥɹɧɞɢɢ, ɒɜɟɰɢɢ, Ʌɢɬɜɟ, ɉɨɥɶɲɟɢȼɟɥɢɤɨɛɪɢɬɚɧɢɢɢɢɦɟɟɬ ɩɪɟɞɫɬɚɜɢɬɟɥɶɫɬɜɚɜ14 ɫɬɪɚɧɚɯȿɜɪɨɩɵ. ȽɨɥɨɜɧɨɣɨɮɢɫParoc Group Oy Ab ɪɚɫɩɨɥɨɠɟɧɜɎɢɧɥɹɧɞɢɢ.

ɋɬɪɨɢɬɟɥɶɧɚɹ ɢɡɨɥɹɰɢɹ

ɉɥɢɬɵ ɢɡ ɤɚɦɟɧɧɨɣ ɜɚɬɵ ɢ ɧɟɩɪɟɫɫɨɜɚɧɧɚɹ ɜɚɬɚ ɞɥɹ ɬɟɩɥɨɜɨɣ, ɡɜɭɤɨɜɨɣ ɢ ɩɨɠɚɪɧɨɣ ɢɡɨɥɹɰɢɢ ɠɢɥɵɯ ɢ ɨɛɳɟɫɬɜɟɧɧɵɯ ɡɞɚɧɢɣ, ɩɪɨɦɵɲɥɟɧɧɵɯ ɨɛɴɟɤɬɨɜ.

Ɍɟɯɧɢɱɟɫɤɚɹ ɢɡɨɥɹɰɢɹ

ɂɡɨɥɹɰɢɹ ɬɪɭɛɨɩɪɨɜɨɞɨɜ, ɩɥɟɬɟɧɵɟ ɦɚɬɵ, ɥɚɦɟɥɵ , ɧɟɩɪɟɫɫɨɜɚɧɧɚɹ ɜɚɬɚ ɢ ɜɵɫɨɤɨɬɟɦɩɟɪɚɬɭɪɧɵɟ ɩɥɢɬɵ ɞɥɹ ɬɟɩɥɨɜɨɣ, ɡɜɭɤɨɜɨɣ ɢ ɩɨɠɚɪɧɨɣ ɢɡɨɥɹɰɢɢ ɢ ɡɚɳɢɬɵ ɨɬ ɤɨɧɞɟɧɫɚɬɚ. ɗɬɢ ɢɡɞɟɥɢɹ ɜ ɨɫɧɨɜɧɨɦ ɩɪɢɦɟɧɹɸɬɫɹ ɜ ɫɢɫɬɟɦɚɯ ɨɬɨɩɥɟɧɢɹ, ɜɟɧɬɢɥɹɰɢɢ ɢ ɤɨɧɞɢɰɢɨɧɢɪɨɜɚɧɢɹ ɜɨɡɞɭɯɚ (HEVAC) ɢ ɩɪɨɢɡɜɨɞɢɬɟɥɹɦɢ ɤɨɦɩɥɟɤɫɧɨɝɨ ɨɛɨɪɭɞɨɜɚɧɢɹ (OEM), ɜ ɩɪɨɦɵɲɥɟɧɧɵɯ ɬɟɯɧɨɥɨɝɢɱɟɫɤɢɯ ɩɪɨɰɟɫɫɚɯ, ɫɭɞɨɜɵɯ ɫɢɫɬɟɦɚɯ.

ɋɢɫɬɟɦɚ ɩɚɧɟɥɟɣ

ȼɵɫɨɤɨɬɟɯɧɨɥɨɝɢɱɧɵɟ ɫɷɧɞɜɢɱ-ɩɚɧɟɥɢ ɧɚ ɨɫɧɨɜɟ ɥɚɦɟɥɢ ɢɡ ɤɚɦɟɧɧɨɣ ɜɚɬɵ ɉɚɪɨɤ ɋɬɪɭɤɬɭɪɚɥ . ɋɪɟɞɢ ɭɧɢɤɚɥɶɧɵɯ ɫɜɨɣɫɬɜ ɨɝɧɟɭɩɨɪɧɵɯ ɩɚɧɟɥɟɣ Paroc (Paroc Fire Proof Panels) ɜɵɫɨɤɢɟ ɩɨɤɚɡɚɬɟɥɢ ɨɝɧɟɫɬɨɣɤɨɫɬɢ, ɩɪɨɱɧɨɫɬɶ, ɧɢɡɤɢɣ ɜɟɫ ɢ ɧɟɩɪɟɜɡɨɣɞɟɧɧɵɟ ɬɟɩɥɨɢɡɨɥɹɰɢɨɧɧɵɟ ɤɚɱɟɫɬɜɚ. ɗɬɢ ɩɚɧɟɥɢ ɢɫɩɨɥɶɡɭɸɬɫɹ ɜ ɤɚɱɟɫɬɜɟ ɧɚɪɭɠɧɵɯ ɫɬɟɧɨɜɵɯ ɨɝɪɚɠɞɟɧɢɣ, ɜɧɭɬɪɟɧɧɢɯ ɩɟɪɟɝɨɪɨɞɨɤ ɢ ɩɟɪɟɤɪɵɬɢɣ. ɋɢɫɬɟɦɚ ɩɪɟɞɫɬɚɜɥɹɟɬ ɫɨɛɨɣ ɷɤɨɧɨɦɢɱɧɨɟ ɪɟɲɟɧɢɟ ɞɥɹ ɭɫɬɪɨɣɫɬɜɚ ɮɚɫɚɞɨɜ, ɩɨɦɟɳɟɧɢɣ ɫ ɨɫɨɛɵɦɢ ɝɢɝɢɟɧɢɱɟɫɤɢɦɢ, ɩɪɨɬɢɜɨɩɨɠɚɪɧɵɦɢ ɢ ɚɤɭɫɬɢɱɟɫɤɢɦɢ ɬɪɟɛɨɜɚɧɢɹɦɢ.

Paroc® Fire Proof Panels ɩɪɨɢɡɜɨɞɹɬɫɹ ɤɨɦɩɚɧɢɟɣ Paroc Oy Ab, Panel System,

ɹɜɥɹɸɳɟɣɫɹ ɱɥɟɧɨɦ ɝɪɭɩɩɵ Paroc Group, Ɏɢɧɥɹɧɞɢɹ. Paroc®, Paroc Structural®, AST® Advanced Structural Technology, JointSeal®, LiftAid®, FoodSafe® ɢ Shadowline® - ɡɚɪɟɝɢɫɬɪɢɪɨɜɚɧɧɵɟ ɬɨɪɝɨɜɵɟ ɦɚɪɤɢ Paroc Group.

PAROC OY AB

Panel System

FIN-21600 Parainen, Finland Ɍɟɥ. +358 20 455 6555 Ɏɚɤɫ +358 20 455 6523 www.paroc.com

ȼɏɈȾɂɌ ȼ ɋɈɋɌȺȼȽɊɍɉɉɕ ɄɈɆɉȺɇɂɃ PAROC

3001PPSEN0601

Panel System

2.00 INT

June 2001

Paroc Panel System

System Guide

1

I N T R O D U C T I O N

Paroc Panel System for your success

Leading manufacturer

Paroc Oy Ab, Panel System develops, manufactures, markets and distributes highly qualified prefabricated sandwich panels based on a core material of Paroc Structural stone wool to the building industry.

Paroc Panel System has reached a market leader position in the countries where it is present. Experience with deliveries to more than 30 countries has made Paroc Panel System a reliable and international partner.

Paroc Fire Proof Panels are manufactured in Finland and the UK and mainly distributed throughout Northern, Western and Eastern Europe and AsiaPacific.

Modern building method

The idea behind the Paroc Panel system was to create a rational product to match the demands of modern buildings: appearance, short construction time, fire safety, energy saving, a high degree of flexibility, and good overall economy. Together with the Finnish Technical Research Centre, Paroc Group developed Paroc Fire Proof Panels and their unique core material Paroc Structural stone wool primarily for industrial and storage

buildings, sports facilities and similar functions. But the architectural possibilities and significant advantages of this very light, modern and high-tech panel system make it an obvious choice also for commercial and public buildings as well as business premises.

Approvals covering our core markets

Paroc Fire Proof Panels have been type approved for fire resistance, strength and thermal insulation in several countries. Approved properties are subject to continual quality control by official bodies and by Paroc Panel’s internal quality control.

Paroc Panel System conforms to ISO 9001 Quality Standard. This means that the full chain from raw materials, through production and deliveries operates according to a certified quality system. Paroc Panel System is also certified by Det Norske Veritas and by the Loss Prevention Certification Board Limited (LPCB).

The Technical Research Centre of Finland has granted a certificate to Paroc Panels, Certificate No. 3/96, 30.9.1996.

The market for Paroc Fire Proof Panels is in strong growth as the advantages are obvious:

•reliable quality

•cost efficiency

•quick installation

Reliable quality

AST Advanced Structural Technology has been developed as a tool for the customer to ensure that the product he is buying meets the most demanding requirements for load-bearing sandwich panels. AST results in secure strength properties, reliable long-term durability and fire safety in Paroc Panels. The essential characteristics of the panels can not be identified visually, but they can still be measured and controlled in the manufacturing process. Paroc Fire Proof panels are manufactured according to AST technology.

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Further information: AST→ Advanced Structural Technology |

||||||

I N T R O D U C T I O N

Content

Paroc Fire Proof Panels |

4 |

Fire-safe applications |

5 |

Economical system |

6 |

Segmented systems |

7 |

Rationality and |

8 |

functionality |

|

Architectural solutions |

10 |

Protection of life |

12 |

and property |

|

Foodsafe environment |

14 |

Sound insulation |

15 |

and absorption |

|

High performance |

16 |

based on AST® |

|

Dimensioning |

18 |

long spans |

High-quality properties 20

Minimising building costs

by competence |

22 |

and service |

Responsibility

The technical data and recommendations included in |

Paroc Panel System is only responsible for the |

this literature are primarily based on the European |

properties of the panels included in this literature. Any |

Recommendations for Sandwich Panels, the Certificate |

other information submitted, e.g. on load assump- |

No. 3/96 issued by the Technical Research Centre |

tions, dimensioning, detail design and installation is to be |

of Finland and on practical experience. In countries |

considered as guiding information only. All rights reserved |

where Paroc Panel System has type approvals or where a |

including the rights to product development and other |

country has specific standards, panels and solutions are |

changes as well as changes related to this literature. |

designed in accordance therewith and deviations may be |

|

made from the information given here. |

|

3

FROM PANELS TO SYSTEMS

Paroc Fire Proof Panels

Paroc® Fire Proof Panels

Paroc Fire Proof Panels are highly advanced sandwich panels based on a core material of Paroc Structural stone wool. The steel sheet surfaces act compositely with the Paroc Structural wool core to form a high performance product with all the features needed for building sections. Fire ratings, strength, tightness and thermal insulation are among the unique performance characteristics of the panels when employed as external wall cladding, internal walls and ceilings. The superior qualities of Paroc Fire Proof Panels are based on the AST, Advanced Structural Technology.

Unique Paroc Structural→ core