Статьи на перевод PVDF_P(VDF-TrFE) / Optimization of Annealing Temperature for PVDF-TrFE

.pdfAdvanced Materials Research Vol. 626 (2013) pp 721-726 Online available since 2012/Dec/27 at www.scientific.net © (2013) Trans Tech Publications, Switzerland doi:10.4028/www.scientific.net/AMR.626.721

Optimization of Annealing Temperature for PVDF-TrFE (70:30 mol %) Thin Film

Mohamad Hafiz Mohd Wahid1, a, Rozana Mohd Dahan1, b, Siti Zaleha Sa’ad1,

Adillah Nurashikin Arshad1, Muhamad Naiman Sarip1,

Mohamad Rusop Mahmood2 and Wan Haliza Abd Majid3

1Faculty of Applied Sciences, Universiti Teknologi MARA, 40450 Shah Alam, Selangor, Malaysia. 2Faculty of Electrical Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor, Malaysia.

3Low Dimensional Research Centre, Faculty of Science, Universiti Malaya, 50603 Kuala Lumpur,

Malaysia. ahafizwahid87@gmail.com, brozanadahan@salam.uitm.edu.my

Keywords: PVDF-TrFE, Dielectric, Morphology, Annealing, Crystallinity.

Abstract. The annealing temperature of 250nm PVDF-TrFE (70:30 mol%) spin coated thin films were optimized. The annealing temperature were varies starting from solvent evaporation (Ts), Curie’s transition (Tc), up to melting temperature (Tm). The result shows that the dielectric constant increases with the increasing of annealing temperature. Supported with the XRD observation indicating there were an improvement in crystallinity consistently with the increasing of the annealing temperature. Morphological properties of the annealed PVDF-TrFE thin films were observed by utilizing Field Emission Scanning Electron Microscope (FESEM) at 100k magnification. It can be found that, the annealing temperature promotes the development of elongated crystallite structure which known as ferroelectric crystal. However, the presence of nanoscale cracks on the thin film annealed at 160˚C (AN160, over Tm) suggesting high possibility to posed defects while in device applications.

Introduction

Over last three decades, lots of intensive researches were conducted on Polyvinylidenefluoride-Trifluoroethylene (PVDF-TrFE) when Kawai firstly found the piezoelectricity of PVDF in 1969 [1], followed by Bergman [2] and Nakamura, who discovered the pyroelectric property; and soon, Furukawa found its ferroelectricity [3]. PVDF-TrFE were largely contribute to the races for multifunctional device’s miniaturization such as capacitors, transistors, electromechanicals and memory devices [4-13] owing to their flexibility, ease in processing and most important most important, high dielectric and ferroelectric.

Researches continued to optimize involved parameters in order to produced high dielectricity which contributes to the increment in ferro-, piezoand pyroelectricity of the polymers. Furukawa have found that the PVDF-TrFE with 50-80% of VDF content produced high dielectric and ferroelectric characteristic due to its switchable dipole moment and consist of β-phase crystallite structure [14]. Furthermore, PVDF-TrFE have the ability to achieve favourable dielectric constant in by performing additional treatment such as annealing [15-18], stretching [9, 19-20], fillers incorporations [21-22] and other advance methods [20, 23]. Annealing process had been widely used due to its simplicity. Previous study reported that, annealing process at slightly above the first Curie’s temperature (during heating) but below the melting temperature resulting improved its crystallinity, hence its dielectrical properties [14]. Apparently, this condition is suitable as C-F molecules in PVDF-TrFE are loose and able to orient its structure in the polarized conformation. This will increase the dipole moment, hence increase the dielectrical properties of PVDF-TrFE [9].

In this experiment, a batch of PVDF-TrFE spin coated thin films of approximately 250nm thick were annealed at different temperatures starting from the solvent evaporation temperature (Ts), Curie’s transition temperature (Tc) and up to its melting temperature (Tm). The dielectric constant of

All rights reserved. No part of contents of this paper may be reproduced or transmitted in any form or by any means without the written permission of TTP, www.ttp.net. (ID: 130.236.83.211-24/02/13,19:38:28)

722 |

Advanced Materials Engineering and Technology |

|

|

the thin films was successfully improved by increasing the annealing temperature to a certain extent. The crystallinity and morphology of these thin films were observed and discussed in relation to the annealing process.

Experimental

PVDF-TrFE thin film preparation. PVDF-TrFE (70:30mol%) manufactured by PiezoTech, France were fabricated using spin coating method on Aluminium (Al) coated glass, which was prepared by thermal evaporation of Al (Edwards AUTO 306) with the thickness of 30nm.

Before fabrication of the thin films, PVDF-TrFE (70:30mol%) pallets were dissolved in methyl ethyl ketone (MEK) (MERCK, UK) with concentration of 30g/L. The solution was stirred for 24hours, then sonicated for one hour using ultrasonic water bath (Hwasin Technology Powersonic 420, 40 kHz).

Prior spin coating, the solution was heated at 50˚C. The PVDF-TrFE solution was spin coated to form approximately 250nm thick samples.

Annealing Process. Table 1 shows the sample name and annealing temperature for each thin film. These temperatures were selected based on the solvent evaporation (MEK, evaporate at ~79˚C) and transition temperatures (Table 2) obtained from DSC observation (Netzsch DSC 200 F3 Maia®). All samples were heated to the selected temperature and held isothermally for two hours. All thin films were allowed to cool to ambient temperature before removal from the oven.

Table 1 Annealing process of the PVDF-TrFE thin films.

Sample |

Annealing temperature |

Note |

UN |

Un-annealed |

Without treatment |

AN80 |

80°C |

Solvent evaporation temperature |

AN100 |

100°C |

Below Tc |

AN120 |

120°C |

Over Tc |

AN140 |

140°C |

Before Tm |

AN160 |

160°C |

Over Tm |

Table 2 Transition temperatures of PVDF-TrFE (70-30mol %) obtained from DSC Netzsch 200 F3 Maia®.

|

Phase Transition |

|

Temperature (˚C) |

|

|

Curie’s (TC) |

|

113 |

|

|

Melting (Tm) |

154 |

|

|

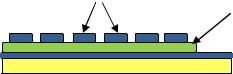

Measurements. The morphological study of the thin films were observed using Field Emission Scanning Electron Microscopy, (FE-SEM) (JOEL JSM-7600F). The crystallinity of the thin films was detected by means of XRD (PANanalytical X’Pert) with nickel filter (Kα=1.54Ȧ) at 45kV and 20mA. In order to measure the dielectric properties of the thin films, metal-insulator-metal (MIM) capacitor configuration was fabricated by depositing 30nm thick Al acting as the top contact with area of 9mm2 for each contact point (Fig. 2). Dielectric properties were measured from 1×102Hz to 1×106Hz using high range frequency impedance analyzer (Solartron Analytical 1062A) with

ZView® software for data acquisition.

Al |

PVDF-TrFE Spin Coated |

|

Film |

Al-coated Glass |

|

Fig. 1 MIM Configuration consist Al-deposited bottom and top of the PVDF-TrFE spin coated film.

Advanced Materials Research Vol. 626 |

723 |

|

|

Results and Discussions

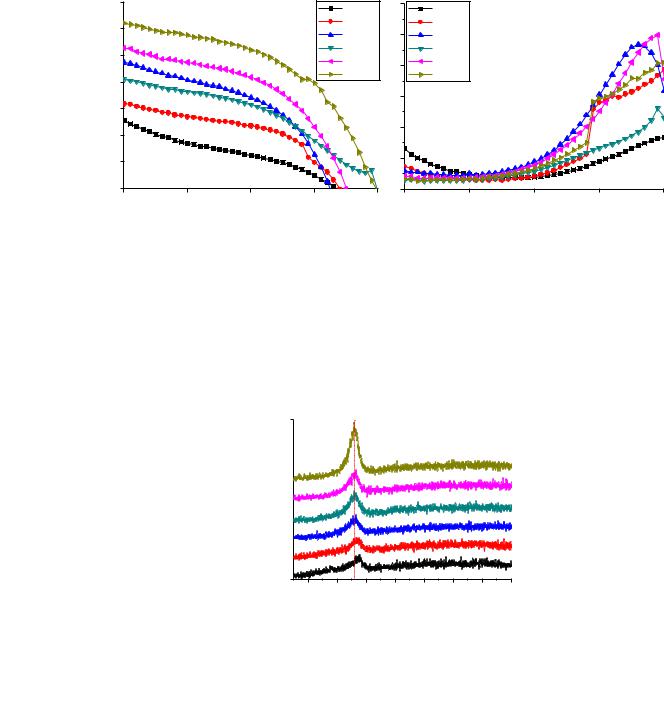

Fig. 2 shows the frequency dependence dielectric constant, ε’ and dielectric loss, ε’’ of annealed

PVDF-TrFE thin film. At the frequency of 1×105Hz and above, inconsistency followed by small noise of ε’ and ε’’ graph can be observed. Thus, the dielectric constant from frequency 102Hz to 105Hz were taken as the results in this experiment. From the plots, it can be observed that the ε’ of the thin films were increased with the increasing in annealing temperatures. The untreated sample (UN) which was not subjected to annealing showed the lowest value of ε’ (~9.2) at 104Hz compared to annealed thin films. The ε’ was increased from ~9.2 to ~10.3 at the same frequency for the sample annealed at the Ts (AN80). This may due to the elimination of solvent promoting packing of crystallite in the thin films (supported by FESEM). However, as the thin film annealed at 100°C (AN100), the ε’ value was higher than the thin film annealed at 120°C (AN120). This may due to the rotational motion of PVDF-TrFE chain structure started to occur at 100°C in which promoting the reorganization of polymer chain to form more packed structure [24]. The ε’ continuously increased upon the increment of annealing temperature with AN160 thin film showed the highest ε’ (~13.2 at

104Hz) with fairly low ε’’ (~0.68) generated at the same frequency.

|

15 |

|

|

|

UN |

6 |

|

|

|

|

|

|

|

|

14 |

|

|

|

AN80 |

|

|

|

|

|

AN100 |

5 |

|

|

|

|

|

|

||

|

13 |

|

|

|

AN120 |

|

|

|

|

|

AN140 |

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

12 |

|

|

|

AN160 |

|

|

|

|

|

|

|

|

' |

|

|

|

|

|

3 |

11 |

|

|

|

'' |

|

|

|

|

|

|

|

|

2 |

|

10 |

|

|

|

|

|

|

9 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

0 |

|

102 |

103 |

104 |

105 |

106 |

|

Frequency (Hz)

|

UN |

|

|

|

|

AN80 |

|

|

|

|

AN100 |

|

|

|

|

AN120 |

|

|

|

|

AN140 |

|

|

|

|

AN160 |

|

|

|

102 |

103 |

104 |

105 |

106 |

|

|

Frequency (Hz) |

|

|

Fig. 2 Dielectric constant, ε’ and dielectric loss, ε’’ of PVDF-TrFE thin film samples with different annealing temperature.

Fig. 4 shows the XRD pattern for annealed PVDF-TrFE thin films. It can be observed that, the peak of (200) + (110) 2θ ~19.2˚ shows gradually increment for UN and annealed samples especially at 160°C (AN160). This proved that the rises in the crystallinity of PVDF-TrFE for annealed thin films, contribute to an increment of ε’ consistently [14]. It can be observed that, AN160 produced the highest crystallinity among others. Moreover, the increase in the intensity peak indicated an improvement of structural orientation and development for the annealed PVDF-TrFE thin films which will be discussed below [24].

|

|

|

|

|

(200)+(110) |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

2 = 19.2o |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AN160 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AN140 |

|

cps (a.u.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

AN120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AN100 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AN80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UN |

|

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

|

|

|

|

|

|

o2Theta |

|

|

|

|

|

|

|

|

Fig. 3 XRD diffraction pattern for the PVDF-TrFE thin film samples annealed at different temperature.

724 |

Advanced Materials Engineering and Technology |

|

|

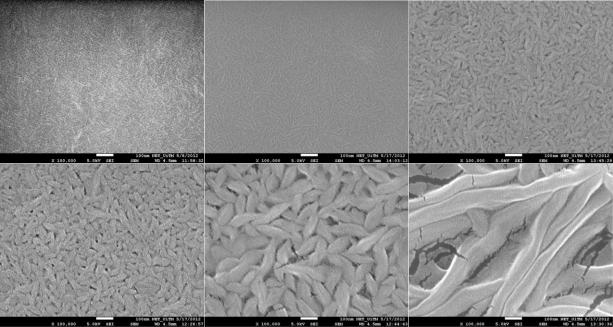

Fig. 4 shows the morphology of UN and annealed PVDF-TrFE (70:30 mol %) thin films observed by using FE-SEM at 100k magnification. Significant development of elongated crystallite structure was observed in AN100 (Fig. 4c) in comparison to the UN and AN80 with undefined crystallite structure. From Fig. 4(c) to 4(e), clearly shows that the crystallite size gradually increased in length and width as the annealing temperature were increased. Consistent with the dielectric and XRD measurement discussed earlier, the formation of elongated crystallite structure assisting in the increment of the dielectric constant and crystallinity properties of PVDF-TrFE thin films. Moreover, elongated crystallite structure also shows an evident that these annealed PVDF-TrFE thin films exhibit the ferroelectric crystal structure [25]. However, different FESEM micrographs were observed when the thin film was annealed over Tm (AN160). A fibrous-like structure with presence of cracks was observed for AN160 as shown in Fig. 4(f). This may due to the re-crystallization of the AN160 thin film after melted over Tm. During melting, thermal energy initiated the mobility and flow of the polymer molecules which demolish the crystal structure in PVDF-TrFE. Upon cooling, recrystallization by the reorganization of crystallite and at the same time the formation of fibrous-like structure attributed to the contraction on the film surface, hence formation of cracks. Moreover, it can be observed that, the absence of crystallite at the area of the cracks may due to the fusion of neighboring crystallite which then forming long to fibrous-like crystallite structure. It can be conclude that, even though AN160 produced the highest ε’ and crystallinity, the presence of cracks on the surface will not be preferable as they may posed defects such as leakage current and parasitic capacitance in device fabrications [26]. Further characterizations need to be carried out in measuring the performance of these thin films before the device fabrication.

a |

|

b |

|

c |

|

|

|

|

|

d |

|

e |

|

f |

|

|

|

|

|

Fig. 4 FE-SEM micrograph at 100K magnification for sample of (a) UN, (b) AN80, (c) AN100,

(d) AN120, (e) AN140 and (f) AN160.

Summary

The effect of annealed PVDF-TrFE thin films on the dielectric characteristic, crystallinity and morphology were discussed. Thin film annealed at 160°C (AN160) was found to have the optimized temperature by producing the highest ε’ (~13.2 at 104Hz) with fairly low loss (~0.68 at 104Hz). However, the presence of nanoscale cracks on AN160 suggesting high possibility to posed defects while in device applications. Further characterizations were suggested to investigate the performance of these thin films for device applications.

Advanced Materials Research Vol. 626 |

725 |

|

|

Acknowledgements

This research was fully supported by Fundamental Research Grant Scheme from Ministry of Higher Education, Faculty of Applied Sciences, NanoSciTech, Institute of Science and Nano-ElecTronic Centre (NET), Faculty of Electrical Engineering, Universiti Teknologi MARA, Malaysia. Our highest appreciation goes to Microwave Technology Centre, Faculty of Electrical Engineering, Universiti Teknologi MARA for their assistance in sample preparation. Our special thanks goes to Fellowship Scheme, Universiti Teknologi MARA Malaysia for the funding this study

References

[1]H. Kawai, "The Piezoelectricity of Poly (vinylidene Fluoride)," Japanese Journal of Applied Physics, vol. 8, p. 2, (1969).

[2]J. J. G. Bergman, McFee, J. H., and Crane, G. R., "Pyroelectricity and Optical Second Harmonic Generation in Polyvinylidene Fluoride Films," Applied Physics Letters, vol. 18, pp. 203-205, (1971).

[3]M. Tamura, Ogasawara, Kiyohide, Ono, Nobuyuki, and Hagiwara, Sumio, "Piezoelectricity in uniaxially stretched poly(vinylidene fluoride)," Journal of Applied Physics, vol. 45, pp. 3768-3771, (1974).

[4]X. Zhou, Chu, B., Wang, Y. and Zhang, Q., "Polyvinylidene fluoride based polymeric dielectrics for high energy density capacitor application," in 2009 IEEE 9th International Conference on the Properties and Applications of Dielectric Materials, Harbin, pp. 15-19 (2009).

[5]I. Bae, Kang, Seok Ju, Park, Youn Jung, Furukawa, T. and Park, Cheolmin, "Organic ferroelectric field-effect transistor with P(VDF-TrFE)/PMMA blend thin films for non-volatile memory applications," Current Applied Physics, vol. 10, pp. e54-e57, (2010).

[6]Q.-D. Ling, Liaw, Der-Jang, Zhu, Chunxiang, Chan, Daniel Siu-Hung, Kang, En-Tang and Neoh, Koon-Gee, "Polymer electronic memories: Materials, devices and mechanisms," Progress in Polymer Science, vol. 33, pp. 917-978. (2008).

[7]K. Müller, Henkel, Karsten, Paloumpa, Ioanna and Schmeier, Dieter, "Organic field effect transistors with ferroelectric hysteresis," Thin Solid Films, vol. 515, pp. 7683-7687.(2007).

[8]C. A. Nguyen, Lee, P. S. and Mhaisalkar, S. G., "Investigation of turn-on voltage shift in organic ferroelectric transistor with high polarity gate dielectric," Organic Electronics, vol. 8, pp. 415-422. (2007).

[9]C. A. Nguyen, Mhaisalkar, S. G., Ma, J. and Lee, P. S., "Enhanced organic ferroelectric field effect transistor characteristics with strained poly(vinylidene fluoride-trifluoroethylene) dielectric," Organic Electronics, vol. 9, pp. 1087-1092. (2008).

[10]A. Rusu, Salvatore, Giovanni and Ionescu, Adrian, "An experimental investigation of the surface potential in ferroelectric P(VDF-TrFE) FETs," Microelectronic Engineering, vol. 87, pp. 1607-1609. (2010).

[11]A. M. Vinogradov, Hugo Schmidt, V., Tuthill, George F. and Bohannan, Gary W., "Damping and electromechanical energy losses in the piezoelectric polymer PVDF," Mechanics of Materials, vol. 36, pp. 1007-1016. (2004).

[12]Q. Q. Zhang, et al., "Dielectric and pyroelectric properties of PCaT/P(VDF-TrFE) 0-3 composite thin films," Journal of Non-Crystalline Solids, vol. 254, pp. 118-122. (1999).

[13]M. D. Rozana, Reece, M.J., Famiza, L., Wahid, M.H., Arshad, A.N. and Sarip, M.N., "Effect of PTFE and OTS on the Ferroelectric Properties of PVDF-TrFE Thin Films," World Appl. Sci. J., vol. 16, pp. 1196-1202. (2012).

[14]T. Furukawa, "Structure and functional properties of ferroelectric polymers," Advances in Colloid and Interface Science, vol. 71-72, pp. 183-208. (1997).

[15]M. A. Barique and H. Ohigashi, "Annealing effects on the Curie transition temperature and melting temperature of poly(vinylidene fluoride/trifluoroethylene) single crystalline films," Polymer, vol. 42, pp. 4981-4987. (2001).

726Advanced Materials Engineering and Technology

[16]J. S. Lee, Prabu, Arun Anand and Kim, Kap Jin, "Annealing effect upon chain orientation, crystalline morphology, and polarizability of ultra-thin P(VDF-TrFE) film for nonvolatile polymer memory device," Polymer, vol. 51, pp. 6319-6333. (2010).

[17]R. Tanaka, Tashiro, Kohji and Kobayashi, Masamichi, "Annealing effect on the ferroelectric phase transition behavior and domain structure of vinylidene fluoride (VDF)-trifluoroethylene copolymers: a comparison between uniaxially oriented VDF 73 and 65% copolymers," Polymer, vol. 40, pp. 3855-3865. (1999).

[18]W. Li, Zhu, Yuejin, Hua, Dayin, Wang, Peiqing, Chen, Xiaorong and Shen, Jie, "Crystalline morphologies of P(VDF-TrFE) (70/30) copolymer films above melting point," Applied Surface Science, vol. 254, pp. 7321-7325. (2008).

[19]V. Sencadas, et al., "Effect of the mechanical stretching on the ferroelectric properties of a (VDF/TrFE) (75/25) copolymer film," Solid State Communications, vol. 129, pp. 5-8, 2004.

[20]R. M. Dahan, S.I. Ismail, Famiza Latif, M.N. Sarip, M.H. Wahid and A.N. Arshad, "Dielectric Properties of Collagen on Plasma Modified Polyvinylidene Fluoride," Am. J. Applied Sci., vol. 9, pp. 694-699. (2012).

[21]D. R. Dillon, Tenneti, Kishore K., Li, Christopher Y., Ko, Frank K., Sics, Igors and Hsiao, Benjamin S., "On the structure and morphology of polyvinylidene fluoride-nanoclay nanocomposites," Polymer, vol. 47, pp. 1678-1688. (2006).

[22]P. Cebe and J. Runt, "P(VDF-TrFE)-layered silicate nanocomposites. Part 1. X-ray scattering and thermal analysis studies," Polymer, vol. 45, pp. 1923-1932. (2004).

[23]W. Y. Kim, Ka, Du Youn, Kwon, Il Woong, Kim, Dong Soo, Lee, Yong Soo, Kim, Sang Youl and Lee, Hee Chul, "Patterning of ferroelectric poly(vinylidene fluoride-trifluoroethylene) film for nonvolatile memory devices," Current Applied Physics, vol. 11, pp. s341-s344. (2011).

[24]Y. W. Yuxiang Li, Qingpu Wang and Chunlei Ma, "Effects of annealing on the optical and electronic properties of Poly(vinylidene fluoride-trifluoroethylene) copolymer thin films " Advanced Materials Research vol. 79-82, pp. 919-922. (2009).

[25]K. J. K. a. A. A. P. Jong Soon Lee, "Ferroelectric P(VDF/TrFE) Ultrathin Film for SPM-based Data Storage Devices " Solid State Phenomena, vol. 124-126, pp. 303-306. (2007).

[26]N. N. H. N. M. Lyly Nyl Ismail, Muhamad Salleh Shamsudin, Habibah Zulkefle, Mohd Hanapiah Abdullah, Sukreen Hana Herman and Mohamad Rusop, "Effect of Solvent on the Dielectric Properties of Nanocomposite Poly(methyl methacrylate)-Doped Titanium Dioxide Dielectric Films," Japanese Journal of Applied Physics vol. 51, p. 06FG09. (2012).

Advanced Materials Engineering and Technology

10.4028/www.scientific.net/AMR.626

Optimization of Annealing Temperature for PVDF-TrFE (70:30 mol %) Thin Film

10.4028/www.scientific.net/AMR.626.721