Статьи на перевод PVDF_P(VDF-TrFE) / Controlled Charge Transport by Polymer Blend

.pdf1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ACS Applied Materials & Interfaces |

Page 20 of 28 |

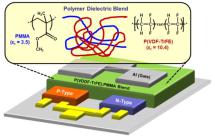

acid SAMs. In contrast, our methods for controlling the charge transport using fluorinated high-k

polymer dielectric blends can be utilized generally, regardless of the dielectric surface and on any other substrate, such as on glass or plastic. We believe that this approach would be a

promising methodology for the development of high-performance complementary metal oxide

semiconductor (CMOS)-based printed organic integrated circuits and can be used to broaden the applications of ambipolar materials in complementary-like circuits.

Conclusions

We have demonstrated high-performance TG/BC OFETs and their complementary electronic

circuits using inkjet-printed conjugated polymers and high-k polymer dielectric blends of

P(VDF-TrFE) and PMMA. The high-k polymer dielectric blends enable the fabrication of wellbalanced CMOS inverters with controlled hole and electron transport and low-voltage operation

due to the high dielectric constant. Both PC12TV12T (p-channel) and P(NDI2OD-T2) (n-

channel) inkjet-printed OFETs showed high µFET values, reaching 0.45 and 0.27 cm2/Vs,

respectively. Importantly, the p-type OFETs characteristics were gradually enhanced in

proportion to the P(VDF-TrFE) concentration in the dielectric blends, while n-type properties

were slightly degraded or not significantly changed. It was explained that the fluorinated dipole

(–C–F bonds) alignment of the P(VDF-TrFE) at the semiconductor-dielectric interface was more

favorable for hole accumulation and transport at the active channel rather than for electron accumulation and transport. Therefore, high, well-balanced electron and hole mobilities and

good VTh values were obtained at a 7:3 blend ratio between P(VDF-TrFE) and PMMA. When

the optimized blended dielectrics were used, high-performance complementary inverters were

ACS Paragon Plus Environment

20

Page 21 of 28 |

ACS Applied Materials & Interfaces |

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

demonstrated with a voltage gain of more than 25, an ideal inverting voltage (Vinv) near ½VDD, a

high noise immunity of ~75% of ½VDD, and low-voltage operation down to 2 V.

Experimental Methods

Field-Effect Transistor and Inverter Fabrication. Corning Eagle 2000 glass substrates were

cleaned sequentially in an ultrasonic bath with deionized water, acetone, and isopropanol for 10 min each. The Au/Ni (15 nm/3 nm thick) patterns used for the S/D electrodes were fabricated

using a conventional lift-off photolithography procedure. The p-type polymer semiconducting

material, PC12TV12T, was synthesized in our laboratory using a previously published

procedure,29 and P(NDI2OD-T2) (ActivInkTM N2200) was supplied by the Polyera Corporation

and used as received. PC12TV12T and P(NDI2OD-T2) were dissolved in anhydrous p-xylene to

obtain an approximately 5 mg/ml solution. The semiconductor inks were inkjet-printed using a piezoelectric-type single nozzle with an orifice 50 [m in diameter (Microfab, Inc.) and a custom-

built inkjet printing machine (UJ 200, Unijet, Inc.) in air. The inkjet-patterned semiconductor

films were thermally annealed at 200 °C for 30 min in a N2-purged glove box. PMMA (Aldrich,

MW = 120 kD) and P(VDF-TrFE) (Solvay, 70:30 molar ratio, random copolymer) were used as

dielectric materials without further purification. PMMA (70 mg/ml) and P(VDF-TrFE) (70 mg/ml) were dissolved in dimethyl sulphoxide (DMSO) and mixed with 5:5, 7:3, and 9:1 blend

ratios. The PMMA and P(VDF-TrFE):PMMA blend dielectric solutions were spin-coated at

~5000 rpm in a N2-purged glove box. After dielectric layer coating, the devices were baked at 80

°C for more than 2 hr in N2 to completely remove residual solvents. The transistors were

ACS Paragon Plus Environment

21

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ACS Applied Materials & Interfaces |

Page 22 of 28 |

completed by depositing the TG electrodes (Al) via thermal evaporation using a metal shadow

mask.

Thin Film and Device Characterization. The OFET electrical characteristics and the static

characteristics of the complementary inverters were measured using a Keithley 4200-SCS in a N2-filled glove box. The µFET and VTh values were calculated in the saturation region using the

gradual channel approximation equations.30 The C-F characteristics were measured using a built-

in Keithley 4200-SCS CV setup starting from 10 kHz to a 1 MHz frequency. The C-V

characteristics were measured using an Agilent 4284A precision LCR meter and a Keithley

4200-SCS at a frequency of 100 kHz. The surface profiles were measured using a surface profiler (Ambios, XP-1) after inkjet-printing of the P(NDI2OD-T2) and thermal annealing at 200

°C for 30 min, or after spin-coating and thermal baking of the gate dielectric layers. The surface

morphology of the gate dielectric films was investigated via tapping-mode AFM (Nanoscope III, Veeco Instruments, Inc.) at the Korea Basic Science Institute (KBSI).

Acknowledgements

This research was financially supported by a grant (code No. 2011-0031639) from the Center for

Advanced Soft Electronics under the Global Frontier Research Program of the Ministry of Education, Science and Technology, Korea, and a grant from the Basic Science Research

Program through the National Research Foundation of Korea (NRF), funded by the Ministry of

Education, Science and Technology (MEST) (2010-0023180).

ACS Paragon Plus Environment

22

Page 23 of 28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ACS Applied Materials & Interfaces

References

(1)Gelinck, G.; Heremans, P.; Nomoto, K.; Anthopoulos, T. D. Adv. Mater. 2010, 22, 3778-

3798.

(2)Chen, P.; Fu, Y.; Aminirad, R.; Wang, C.; Zhang, J.; Wang, K.; Galatsis, K.; Zhou, C.

Nano Lett. 2011, 11, 5301-5308.

(3)Usta, H.; Facchetti, A.; Marks, T. J. Acc. Chem. Res. 2011, 44, 501-510.

(4)Kim, S.-S.; Na, S.-I.; Jo, J.; Tae, G.; Kim, D.-Y. Adv. Mater. 2007, 19, 4410-4415.

(5)Baeg, K.-J.; Noh, Y.-Y.; Ghim, J.; Kang, S.-J.; Lee, H.; Kim, D.-Y. Adv. Mater. 2006, 18, 3179-3183.

(6)Baeg, K.-J.; Khim, D.; Kim, J.; Yang, B.-D.; Kang, M.; Jung, S.-W.; You, I.-K.; Kim, D.- Y.; Noh, Y.-Y. Adv. Funct. Mater. 2012, 22, 2915-2926.

(7)Kola, S.; Sinha, J.; Katz, H. E. J. Polym. Sci. B: Polym. Phys. 2012, 50, 1090-1120.

(8)Rabaey, J. M.; Chandrakasan, A.; Nikolić, B. In Digital Integrated Circuits 2nd ed.; Prentice Hall: New Jersey, 2003; Vol. 5, p 177.

(9)Baeg, K.-J.; Khim, D.; Kim, D.-Y.; Jung, S.-W.; Koo, J. B.; You, I.-K.; Yan, H.; Facchetti, A.; Noh, Y.-Y. J. Polym. Sci. B: Polym. Phys. 2011, 49, 62-67.

(10)Rogers, J. A.; Someya, T.; Huang, Y. Science 2010, 327, 1603-1607.

(11)Facchetti, A. Chem. Mater. 2011, 23, 733-758.

ACS Paragon Plus Environment

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ACS Applied Materials & Interfaces |

Page 24 of 28 |

(12)Katz, H. E. Chem. Mater. 2004, 16, 4748-4756.

(13)Klauk, H.; Zschieschang, U.; Pflaum, J.; Halik, M. Nature 2007, 445, 745-748.

(14)Crone, B.; Dodabalapur, A.; Lin, Y.-Y.; Filas, R. W.; Bao, Z.; LaDuca, A.; Sarpeshkar, R.; Katz, H. E.; Li, W. Nature 2000, 403, 521-523.

(15)Cho, J. H.; Lee, J.; Xia, Y.; Kim, B. S.; He, Y.; Renn, M. J.; Lodge, T. P.; Frisbie, C. D.

Nat. Mater. 2008, 7, 900-906.

(16)Fix, W.; Ullmann, A.; Ficker, J.; Clemens, W. Appl. Phys. Lett. 2002, 81, 1735-1737.

(17)Baeg, K.-J.; Kim, J.; Khim, D.; Caironi, M.; Kim, D.-Y.; You, I.-K.; Quinn, J. R.; Facchetti, A.; Noh, Y.-Y. ACS Appl. Mater. Interfaces 2011, 3, 3205-3214.

(18)Knobloch, A.; Manuelli, A.; Bernds, A.; Clemens, W. J. Appl. Phys. 2004, 96, 2286-2291.

(19)Ante, F.; Kälblein, D.; Zaki, T.; Zschieschang, U.; Takimiya, K.; Ikeda, M.; Sekitani, T.; Someya, T.; Burghartz, J. N.; Kern, K.; Klauk, H. Small 2012, 8, 73-79.

(20)Richards, T. J.; Sirringhaus, H. J. Appl. Phys. 2007, 102, 094510-1-094510-6.

(21)Noh, Y.-Y.; Zhao, N.; Caironi, M.; Sirringhaus ,H. Nat. Nanotechnol. 2007, 2, 784-789.

(22)Yunker, P. J.; Still, T.; Lohr, M. A.; Yodh, A. G. Nature 2011, 476, 308-311.

(23)Voigt, M. M.; Guite, A.; Chung, D.-Y.; Khan, R. U. A.; Campbell, A. J.; Bradley, D. D. C.; Meng, F.; Steinke, J. H. G.; Tierney, S.; McCulloch, I.; Penxten, H.; Lutsen, L.; Douheret, O.; Manca, J.; Brokmann, U.; Sönnichsen, K.; Hülsenberg, D.; Bock, W.; Barron, C.; Blanckaert, N.; Springer, S.; Grupp, J.; Mosley, A. Adv. Funct. Mater. 2010, 20, 239-246.

ACS Paragon Plus Environment

24

Page 25 of 28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ACS Applied Materials & Interfaces

(24)Lee, K. H.; Lee, G.; Lee, K.; Oh, M. S.; Im, S.; Yoon, S.-M. Adv. Mater. 2009, 21, 4287-

2491.

(25)Jung, S.-W.; Baeg, K.-J.; Yoon, S.-M.; You, I.-K.; Lee, J.-K.; Kim, Y.-S.; Noh, Y.-Y. J. Appl. Phys. 2010, 108, 102810-1-102810-5.

(26)Jung, S.-W.; Yoon, S.-M.; Kang, S. Y.; You, I.-K.; Koo, J. B.; Baeg, K.-J.; Noh, Y.-Y.

Curr. Appl. Phys. 2011, 11, S213-S218.

(27)Baeg, K.-J.; Khim, D.; Jung, S. W.; Kang, M.; You, I.-K.; Kim, D.-Y.; Facchetti, A.; Noh, Y.-Y. Adv. Mater. 2012, DOI: 10.1002/adma.201201464.

(28)Kobayashi, S.; Nishikawa, T.; Takenobu, T.; Mori, S.; Shimoda, T.; Mitani, T.; Shimotani, H.; Yoshimoto, N.; Ogawa, S.; Iwasa, Y. Nat. Mater. 2004, 3, 317-322.

(29)Kim, J.; Lim, B.; Baeg, K.-J.; Noh, Y.-Y.; Khim, D.; Jeong, H.-G.; Yun, J.-M.; Kim, D.- Y. Chem. Mater. 2011, 23, 4663-4665.

(30)Sze, S. M. In Physics of Semiconductor Devices, 2nd ed.; Wiely-Interscience: New Jersey, 1981; Vol. 8, p 438.

(31)Yan, H.; Chen, Z.; Zheng, Y.; Newman, C.; Quinn, J. R.; Dötz, F.; Kastler, M.; Facchetti, A. Nature 2009, 457, 679-686.

(32)Deegan, R. D.; Bakajin, O.; Dupont, T. F.; Huber, G.; Nagel, S. R.; Witten, T. A. Nature

1997, 389, 827-829.

(33)Sirringhaus, H.; Bird, M.; Zhao, N. Adv. Mater. 2010, 22, 3893-3898.

(34)Soltman, D.; Subramanian, V. Langmuir 2008, 24, 2224-2231.

ACS Paragon Plus Environment

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ACS Applied Materials & Interfaces |

Page 26 of 28 |

(35)Hu, H.; Larson, R. G. J. Phys. Chem. B 2006, 110, 7090-7094.

(36)Lim, J. A.; Lee, W. H.; Lee, H. S.; Lee, J. H.; Park, Y. D.; Cho, K. Adv. Funct. Mater.

2008, 18, 229-234.

(37) Park, Y. J.; Kang, S. J.; Lotz, B.; Brinkmann, M.; Thierry, A.; Kim, K. J.; Park, C.

Macromolecules 2008, 41, 8648-8654.

(38)Park, Y. J.; Kang, S. J.; Park, C.; Kim, K. J.; Lee, H. S.; Lee, M. S.; Chung, U-I.; Park, I. J. Appl. Phys. Lett. 2006, 88, 242908-1-242908-3.

(39)Livingston, J. D. In Electronic Properties of Engineering Materials; Wiely-Interscience: New York, 1999; Vol. 3, p 39.

(40)Chung, Y.; Verploegen, E.; Vailionis, A.; Sun, Y.; Nishi, Y.; Murmann, B.; Bao, Z. Nano Lett. 2011, 11, 1161-1165.

(41)Li, X.; van Breemen, A. J. J. M.; Khikhlovskyi, V.; Smits, E. C. P.; Kemerink, M.; Broer, D. J.; Gelinck, G. H. Org. Electron. 2012, 13, 1742-1749.

(42)Lovinger, A. J. Science 1983, 220, 1115-1121.

(43)Zirk, M.; Sawatdee, A.; Helbig, U.; Krause, M.; Scheipl, G.; Kraker, E.; Ersman, P. A.; Nilsson, D.; Platt, D.; Bodö, P.; Bauer, S.; Domann, G.; Stadlober, B. Adv. Mater. 2011, 23, 2069-2074.

(44)Naber, R. C. G.; Tanase, C.; Blom, P. W. M.; Gelinck, G. H.; Marsman, A. W.; Touwslager, F. J.; Setayesh, S.; Leeuw, D. M. Nat. Mater. 2005, 4, 243-248.

(45)Li, J.; Sun, Z.; Yan, F. Adv. Mater. 2012, 24, 88-93.

ACS Paragon Plus Environment

26

Page 27 of 28 |

ACS Applied Materials & Interfaces |

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

(46) Zschieschang, U.; Ante, F.; Schlörholz, M.; Schmidt, M.; Kern, K.; Klauk, H. Adv. Mater.

2010, 22, 4489-4493.

ACS Paragon Plus Environment

27

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ACS Applied Materials & Interfaces |

Page 28 of 28 |

Table of Contents (TOC) Graphic

ACS Paragon Plus Environment

28