- •1. INTEGRATED AND AUTOMATED MANUFACTURING

- •1.1 INTRODUCTION

- •1.1.1 Why Integrate?

- •1.1.2 Why Automate?

- •1.2 THE BIG PICTURE

- •1.2.2 The Architecture of Integration

- •1.2.3 General Concepts

- •1.3 PRACTICE PROBLEMS

- •2. AN INTRODUCTION TO LINUX/UNIX

- •2.1 OVERVIEW

- •2.1.1 What is it?

- •2.1.2 A (Brief) History

- •2.1.3 Hardware required and supported

- •2.1.4 Applications and uses

- •2.1.5 Advantages and Disadvantages

- •2.1.6 Getting It

- •2.1.7 Distributions

- •2.1.8 Installing

- •2.2 USING LINUX

- •2.2.1 Some Terminology

- •2.2.2 File and directories

- •2.2.3 User accounts and root

- •2.2.4 Processes

- •2.3 NETWORKING

- •2.3.1 Security

- •2.4 INTERMEDIATE CONCEPTS

- •2.4.1 Shells

- •2.4.2 X-Windows

- •2.4.3 Configuring

- •2.4.4 Desktop Tools

- •2.5 LABORATORY - A LINUX SERVER

- •2.6 TUTORIAL - INSTALLING LINUX

- •2.7 TUTORIAL - USING LINUX

- •2.8 REFERENCES

- •3. AN INTRODUCTION TO C/C++ PROGRAMMING

- •3.1 INTRODUCTION

- •3.2 PROGRAM PARTS

- •3.3 CLASSES AND OVERLOADING

- •3.4 HOW A ‘C’ COMPILER WORKS

- •3.5 STRUCTURED ‘C’ CODE

- •3.6 COMPILING C PROGRAMS IN LINUX

- •3.6.1 Makefiles

- •3.7 ARCHITECTURE OF ‘C’ PROGRAMS (TOP-DOWN)

- •3.8 CREATING TOP DOWN PROGRAMS

- •3.9 CASE STUDY - THE BEAMCAD PROGRAM

- •3.9.1 Objectives:

- •3.9.2 Problem Definition:

- •3.9.3 User Interface:

- •3.9.3.1 - Screen Layout (also see figure):

- •3.9.3.2 - Input:

- •3.9.3.3 - Output:

- •3.9.3.4 - Help:

- •3.9.3.5 - Error Checking:

- •3.9.3.6 - Miscellaneous:

- •3.9.4 Flow Program:

- •3.9.5 Expand Program:

- •3.9.6 Testing and Debugging:

- •3.9.7 Documentation

- •3.9.7.1 - Users Manual:

- •3.9.7.2 - Programmers Manual:

- •3.9.8 Listing of BeamCAD Program.

- •3.10 PRACTICE PROBLEMS

- •3.11 LABORATORY - C PROGRAMMING

- •4. NETWORK COMMUNICATION

- •4.1 INTRODUCTION

- •4.2 NETWORKS

- •4.2.1 Topology

- •4.2.2 OSI Network Model

- •4.2.3 Networking Hardware

- •4.2.4 Control Network Issues

- •4.2.5 Ethernet

- •4.2.6 SLIP and PPP

- •4.3 INTERNET

- •4.3.1 Computer Addresses

- •4.3.2 Computer Ports

- •4.3.2.1 - Mail Transfer Protocols

- •4.3.2.2 - FTP - File Transfer Protocol

- •4.3.2.3 - HTTP - Hypertext Transfer Protocol

- •4.3.3 Security

- •4.3.3.1 - Firewalls and IP Masquerading

- •4.4 FORMATS

- •4.4.1 HTML

- •4.4.2 URLs

- •4.4.3 Encryption

- •4.4.4 Clients and Servers

- •4.4.5 Java

- •4.4.6 Javascript

- •4.5 NETWORKING IN LINUX

- •4.5.1 Network Programming in Linux

- •4.6 DESIGN CASES

- •4.7 SUMMARY

- •4.8 PRACTICE PROBLEMS

- •4.9 LABORATORY - NETWORKING

- •4.9.1 Prelab

- •4.9.2 Laboratory

- •5. DATABASES

- •5.1 SQL AND RELATIONAL DATABASES

- •5.2 DATABASE ISSUES

- •5.3 LABORATORY - SQL FOR DATABASE INTEGRATION

- •5.4 LABORATORY - USING C FOR DATABASE CALLS

- •6. COMMUNICATIONS

- •6.1 SERIAL COMMUNICATIONS

- •6.2 SERIAL COMMUNICATIONS UNDER LINUX

- •6.3 PARALLEL COMMUNICATIONS

- •6.4 LABORATORY - SERIAL INTERFACING AND PROGRAMMING

- •6.5 LABORATORY - STEPPER MOTOR CONTROLLER

- •7. PROGRAMMABLE LOGIC CONTROLLERS (PLCs)

- •7.1 BASIC LADDER LOGIC

- •7.2 WHAT DOES LADDER LOGIC DO?

- •7.2.1 Connecting A PLC To A Process

- •7.2.2 PLC Operation

- •7.3 LADDER LOGIC

- •7.3.1 Relay Terminology

- •7.3.2 Ladder Logic Inputs

- •7.3.3 Ladder Logic Outputs

- •7.4 LADDER DIAGRAMS

- •7.4.1 Ladder Logic Design

- •7.4.2 A More Complicated Example of Design

- •7.5 TIMERS/COUNTERS/LATCHES

- •7.6 LATCHES

- •7.7 TIMERS

- •7.8 COUNTERS

- •7.9 DESIGN AND SAFETY

- •7.9.1 FLOW CHARTS

- •7.10 SAFETY

- •7.10.1 Grounding

- •7.10.2 Programming/Wiring

- •7.10.3 PLC Safety Rules

- •7.10.4 Troubleshooting

- •7.11 DESIGN CASES

- •7.11.1 DEADMAN SWITCH

- •7.11.2 CONVEYOR

- •7.11.3 ACCEPT/REJECT SORTING

- •7.11.4 SHEAR PRESS

- •7.12 ADDRESSING

- •7.12.1 Data Files

- •7.12.1.1 - Inputs and Outputs

- •7.12.1.2 - User Numerical Memory

- •7.12.1.3 - Timer Counter Memory

- •7.12.1.4 - PLC Status Bits (for PLC-5s)

- •7.12.1.5 - User Function Memory

- •7.13 INSTRUCTION TYPES

- •7.13.1 Program Control Structures

- •7.13.2 Branching and Looping

- •7.13.2.1 - Immediate I/O Instructions

- •7.13.2.2 - Fault Detection and Interrupts

- •7.13.3 Basic Data Handling

- •7.13.3.1 - Move Functions

- •7.14 MATH FUNCTIONS

- •7.15 LOGICAL FUNCTIONS

- •7.15.1 Comparison of Values

- •7.16 BINARY FUNCTIONS

- •7.17 ADVANCED DATA HANDLING

- •7.17.1 Multiple Data Value Functions

- •7.17.2 Block Transfer Functions

- •7.18 COMPLEX FUNCTIONS

- •7.18.1 Shift Registers

- •7.18.2 Stacks

- •7.18.3 Sequencers

- •7.19 ASCII FUNCTIONS

- •7.20 DESIGN TECHNIQUES

- •7.20.1 State Diagrams

- •7.21 DESIGN CASES

- •7.21.1 If-Then

- •7.21.2 For-Next

- •7.21.3 Conveyor

- •7.22 IMPLEMENTATION

- •7.23 PLC WIRING

- •7.23.1 SWITCHED INPUTS AND OUTPUTS

- •7.23.1.1 - Input Modules

- •7.23.1.2 - Actuators

- •7.23.1.3 - Output Modules

- •7.24 THE PLC ENVIRONMENT

- •7.24.1 Electrical Wiring Diagrams

- •7.24.2 Wiring

- •7.24.3 Shielding and Grounding

- •7.24.4 PLC Environment

- •7.24.5 SPECIAL I/O MODULES

- •7.25 PRACTICE PROBLEMS

- •7.26 REFERENCES

- •7.27 LABORATORY - SERIAL INTERFACING TO A PLC

- •8. PLCS AND NETWORKING

- •8.1 OPEN NETWORK TYPES

- •8.1.1 Devicenet

- •8.1.2 CANbus

- •8.1.3 Controlnet

- •8.1.4 Profibus

- •8.2 PROPRIETARY NETWORKS

- •8.2.0.1 - Data Highway

- •8.3 PRACTICE PROBLEMS

- •8.4 LABORATORY - DEVICENET

- •8.5 TUTORIAL - SOFTPLC AND DEVICENET

- •9. INDUSTRIAL ROBOTICS

- •9.1 INTRODUCTION

- •9.1.1 Basic Terms

- •9.1.2 Positioning Concepts

- •9.1.2.1 - Accuracy and Repeatability

- •9.1.2.2 - Control Resolution

- •9.1.2.3 - Payload

- •9.2 ROBOT TYPES

- •9.2.1 Basic Robotic Systems

- •9.2.2 Types of Robots

- •9.2.2.1 - Robotic Arms

- •9.2.2.2 - Autonomous/Mobile Robots

- •9.2.2.2.1 - Automatic Guided Vehicles (AGVs)

- •9.3 MECHANISMS

- •9.4 ACTUATORS

- •9.5 A COMMERCIAL ROBOT

- •9.5.1 Mitsubishi RV-M1 Manipulator

- •9.5.2 Movemaster Programs

- •9.5.2.0.1 - Language Examples

- •9.5.3 Command Summary

- •9.6 PRACTICE PROBLEMS

- •9.7 LABORATORY - MITSUBISHI RV-M1 ROBOT

- •9.8 TUTORIAL - MITSUBISHI RV-M1

- •10. OTHER INDUSTRIAL ROBOTS

- •10.1 SEIKO RT 3000 MANIPULATOR

- •10.1.1 DARL Programs

- •10.1.1.1 - Language Examples

- •10.1.1.2 - Commands Summary

- •10.2 IBM 7535 MANIPULATOR

- •10.2.1 AML Programs

- •10.3 ASEA IRB-1000

- •10.4 UNIMATION PUMA (360, 550, 560 SERIES)

- •10.5 PRACTICE PROBLEMS

- •10.6 LABORATORY - SEIKO RT-3000 ROBOT

- •10.7 TUTORIAL - SEIKO RT-3000 ROBOT

- •10.8 LABORATORY - ASEA IRB-1000 ROBOT

- •10.9 TUTORIAL - ASEA IRB-1000 ROBOT

- •11. ROBOT APPLICATIONS

- •11.0.1 Overview

- •11.0.2 Spray Painting and Finishing

- •11.0.3 Welding

- •11.0.4 Assembly

- •11.0.5 Belt Based Material Transfer

- •11.1 END OF ARM TOOLING (EOAT)

- •11.1.1 EOAT Design

- •11.1.2 Gripper Mechanisms

- •11.1.2.1 - Vacuum grippers

- •11.1.3 Magnetic Grippers

- •11.1.3.1 - Adhesive Grippers

- •11.1.4 Expanding Grippers

- •11.1.5 Other Types Of Grippers

- •11.2 ADVANCED TOPICS

- •11.2.1 Simulation/Off-line Programming

- •11.3 INTERFACING

- •11.4 PRACTICE PROBLEMS

- •11.5 LABORATORY - ROBOT INTERFACING

- •11.6 LABORATORY - ROBOT WORKCELL INTEGRATION

- •12. SPATIAL KINEMATICS

- •12.1 BASICS

- •12.1.1 Degrees of Freedom

- •12.2 HOMOGENEOUS MATRICES

- •12.2.1 Denavit-Hartenberg Transformation (D-H)

- •12.2.2 Orientation

- •12.2.3 Inverse Kinematics

- •12.2.4 The Jacobian

- •12.3 SPATIAL DYNAMICS

- •12.3.1 Moments of Inertia About Arbitrary Axes

- •12.3.2 Euler’s Equations of Motion

- •12.3.3 Impulses and Momentum

- •12.3.3.1 - Linear Momentum

- •12.3.3.2 - Angular Momentum

- •12.4 DYNAMICS FOR KINEMATICS CHAINS

- •12.4.1 Euler-Lagrange

- •12.4.2 Newton-Euler

- •12.5 REFERENCES

- •12.6 PRACTICE PROBLEMS

- •13. MOTION CONTROL

- •13.1 KINEMATICS

- •13.1.1 Basic Terms

- •13.1.2 Kinematics

- •13.1.2.1 - Geometry Methods for Forward Kinematics

- •13.1.2.2 - Geometry Methods for Inverse Kinematics

- •13.1.3 Modeling the Robot

- •13.2 PATH PLANNING

- •13.2.1 Slew Motion

- •13.2.1.1 - Joint Interpolated Motion

- •13.2.1.2 - Straight-line motion

- •13.2.2 Computer Control of Robot Paths (Incremental Interpolation)

- •13.3 PRACTICE PROBLEMS

- •13.4 LABORATORY - AXIS AND MOTION CONTROL

- •14. CNC MACHINES

- •14.1 MACHINE AXES

- •14.2 NUMERICAL CONTROL (NC)

- •14.2.1 NC Tapes

- •14.2.2 Computer Numerical Control (CNC)

- •14.2.3 Direct/Distributed Numerical Control (DNC)

- •14.3 EXAMPLES OF EQUIPMENT

- •14.3.1 EMCO PC Turn 50

- •14.3.2 Light Machines Corp. proLIGHT Mill

- •14.4 PRACTICE PROBLEMS

- •14.5 TUTORIAL - EMCO MAIER PCTURN 50 LATHE (OLD)

- •14.6.1 LABORATORY - CNC MACHINING

- •15. CNC PROGRAMMING

- •15.1 G-CODES

- •15.3 PROPRIETARY NC CODES

- •15.4 GRAPHICAL PART PROGRAMMING

- •15.5 NC CUTTER PATHS

- •15.6 NC CONTROLLERS

- •15.7 PRACTICE PROBLEMS

- •15.8 LABORATORY - CNC INTEGRATION

- •16. DATA AQUISITION

- •16.1 INTRODUCTION

- •16.2 ANALOG INPUTS

- •16.3 ANALOG OUTPUTS

- •16.4 REAL-TIME PROCESSING

- •16.5 DISCRETE IO

- •16.6 COUNTERS AND TIMERS

- •16.7 ACCESSING DAQ CARDS FROM LINUX

- •16.8 SUMMARY

- •16.9 PRACTICE PROBLEMS

- •16.10 LABORATORY - INTERFACING TO A DAQ CARD

- •17. VISIONS SYSTEMS

- •17.1 OVERVIEW

- •17.2 APPLICATIONS

- •17.3 LIGHTING AND SCENE

- •17.4 CAMERAS

- •17.5 FRAME GRABBER

- •17.6 IMAGE PREPROCESSING

- •17.7 FILTERING

- •17.7.1 Thresholding

- •17.8 EDGE DETECTION

- •17.9 SEGMENTATION

- •17.9.1 Segment Mass Properties

- •17.10 RECOGNITION

- •17.10.1 Form Fitting

- •17.10.2 Decision Trees

- •17.11 PRACTICE PROBLEMS

- •17.12 TUTORIAL - LABVIEW BASED IMAQ VISION

- •17.13 LABORATORY - VISION SYSTEMS FOR INSPECTION

- •18. INTEGRATION ISSUES

- •18.1 CORPORATE STRUCTURES

- •18.2 CORPORATE COMMUNICATIONS

- •18.3 COMPUTER CONTROLLED BATCH PROCESSES

- •18.4 PRACTICE PROBLEMS

- •18.5 LABORATORY - WORKCELL INTEGRATION

- •19. MATERIAL HANDLING

- •19.1 INTRODUCTION

- •19.2 VIBRATORY FEEDERS

- •19.3 PRACTICE QUESTIONS

- •19.4 LABORATORY - MATERIAL HANDLING SYSTEM

- •19.4.1 System Assembly and Simple Controls

- •19.5 AN EXAMPLE OF AN FMS CELL

- •19.5.1 Overview

- •19.5.2 Workcell Specifications

- •19.5.3 Operation of The Cell

- •19.6 THE NEED FOR CONCURRENT PROCESSING

- •19.7 PRACTICE PROBLEMS

- •20. PETRI NETS

- •20.1 INTRODUCTION

- •20.2 A BRIEF OUTLINE OF PETRI NET THEORY

- •20.3 MORE REVIEW

- •20.4 USING THE SUBROUTINES

- •20.4.1 Basic Petri Net Simulation

- •20.4.2 Transitions With Inhibiting Inputs

- •20.4.3 An Exclusive OR Transition:

- •20.4.4 Colored Tokens

- •20.4.5 RELATIONAL NETS

- •20.5 C++ SOFTWARE

- •20.6 IMPLEMENTATION FOR A PLC

- •20.7 PRACTICE PROBLEMS

- •20.8 REFERENCES

- •21. PRODUCTION PLANNING AND CONTROL

- •21.1 OVERVIEW

- •21.2 SCHEDULING

- •21.2.1 Material Requirements Planning (MRP)

- •21.2.2 Capacity Planning

- •21.3 SHOP FLOOR CONTROL

- •21.3.1 Shop Floor Scheduling - Priority Scheduling

- •21.3.2 Shop Floor Monitoring

- •22. SIMULATION

- •22.1 MODEL BUILDING

- •22.2 ANALYSIS

- •22.3 DESIGN OF EXPERIMENTS

- •22.4 RUNNING THE SIMULATION

- •22.5 DECISION MAKING STRATEGY

- •23. PLANNING AND ANALYSIS

- •23.1 FACTORS TO CONSIDER

- •23.2 PROJECT COST ACCOUNTING

- •24. REFERENCES

- •25. APPENDIX A - PROJECTS

- •25.1 TOPIC SELECTION

- •25.1.1 Previous Project Topics

- •25.2 CURRENT PROJECT DESCRIPTIONS

- •26. APPENDIX B - COMMON REFERENCES

- •26.1 JIC ELECTRICAL SYMBOLS

- •26.2 NEMA ENCLOSURES

page 518

19. MATERIAL HANDLING

• Basic purpose is to provide automatic transfer of workparts between automated machines,

and interface with individual work stations.

19.1 INTRODUCTION

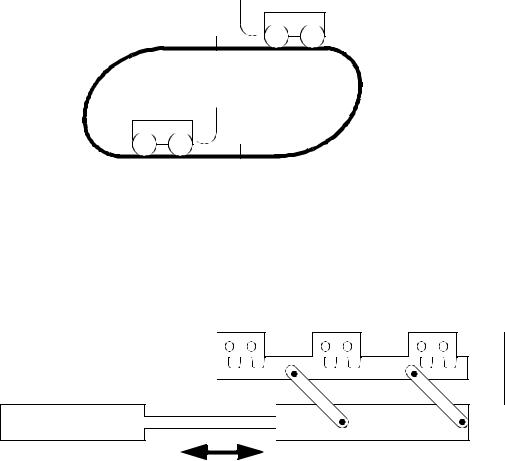

•Basic layouts for material handling include,

-lines - stations arranged along a fixed part transfer path.

-batch - stations are grouped by function and batches of raw materials/WIP are brought in batches

-job shop - individual parts are carried through one or more stages by one worker

-job site - equipment is brought to the work

•These transfer systems can also be categorized by their timing approach,

-synchronous - the entire line moves parts with a fixed period cycle. This is well suited to mass production of similar products.

-asynchronous - parts are moved as completed or needed. Often buffers are required, but this is more tolerant of problems than synchronous systems.

-continuous - the product flows by without stopping

•Basic Requirements,

•Random, independent movement of palletized workparts between workstations in the FMS

-pallets can flow from any station to any other

-parts are mounted in pallet fixtures

-pallets can move independently to avoid interference

•Temporary storage or banking of workparts

-queues allow parts to wait for machines, thus increasing efficiency

•Convenient access for loading and unloading workparts

-easy to do manual load/unload.

-automatic loading/unloading of parts at workstations

-can load/unload from either side of system

•Compatible with computer control

•Provision for future expansion

page 519

-modular extensions to system are desirable

•Adherence to all applicable industrial codes

-safety, noise, etc.

•Access to machine tools

-allow unobstructed floor level access to each workstation

•Operation in shop environment

-must be reliable when exposed to metal chips, cutting fluids, oil, dirt, etc.

•Common type of Material handling systems

- power roller conveyors

- power and free overhead conveyors

-shuttle conveyors

-floor “towline” systems

page 520

-robots (in a limited sense)

-indexing (geneva mechanism)

-walking beam

19.2 VIBRATORY FEEDERS

•When small parts are hard to orient we can dump them in a vibratory feeder.

•The vibrations cause parts to ‘hop’ forward.

•Various cutouts, tracks, etc are added to sort parts.