- •INDUCTION MOTORS

- •How does an ordinary DC motor work?

- •DC motor invented by Michael Faraday in the 1820s

- •The Structure Of The

- •In fact, the asynchronous motor consists of three parts (from left to right):

- •Asynchronous Motor Stator

- •The asynchronous motor has three "pieces" of copper wire. Which are laid in

- •Asynchronous Motor Rotor

- •As you can see further, there are special slots in the rotor core.

- •Always remember that the rotor rotates in an asynchronous motor, not the stator.

- •Ways To Connect An Asynchronous

- •https://www.ruselectronic.com/induction-motor/

INDUCTION MOTORS

Vyacheslav Ivanov

Ruslan Munykin

Konstantin Nachichko

242-об(2)

How does an ordinary DC motor work?

In a DC motor, the magnet (and its magnetic field) is fixed in place and forms the outside, static part of the motor (the stator), while a coil of wire carrying the electric current forms the rotating part of the motor (the rotor).

The magnetic field comes from the stator, which is a permanent magnet, while you feed the electric power to the coil that makes up the rotor.

The interaction between the permanent magnetic field of the stator and the temporary magnetic field produced by the

DC motor invented by Michael Faraday in the 1820s

In the spring of 1889, M.O. Dolivo- Dobrovolsky built the first three-phase asynchronous motor with a power of about 100 watts. This motor was powered by a current from a three-phase single- core converter and showed quite satisfactory results during testing. Following the first single-core converter, a second, more powerful one was created, and then the manufacture of three-phase synchronous generators began.

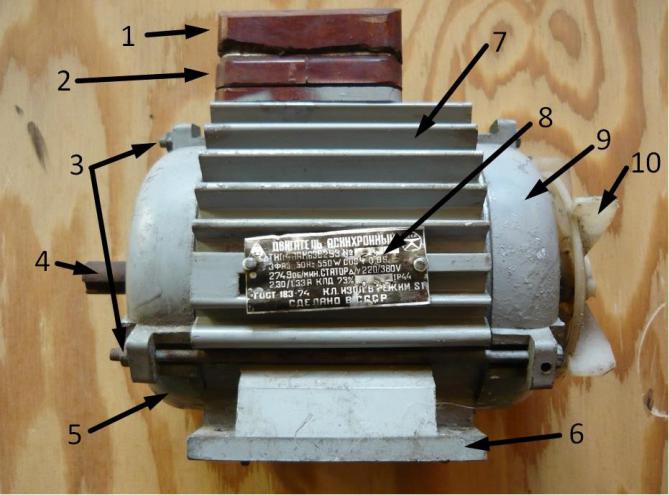

The Structure Of The

Asynchronous Motor

1 Terminal box cover.

2 Terminal box.

3 Body coupling bolts.

4 The rotor shaft.

5 The front cover of the case.

6 The base plate of the housing.

7 Housing with cooling fins.

8 Manufacturer's information plate

9 The back cover of the case.

10 Additional engine cooling fan ("turntable"). The "spinner" is not installed on all engines. If the intended place of work provides good air cooling, then the need for additional blowing is not required.

In fact, the asynchronous motor consists of three parts (from left to right): rotors, stators and housings, but the main parts are considered to be the rotor and stator, which we will talk about.

Asynchronous Motor Stator

•The stator of an asynchronous motor is a core consisting of plates of electrical steel and containing copper windings, which are laid in a certain way in the slots of the stator.

•As mentioned, the stator core consists of plates that are isolated from each other. There are slots on the inside of the stator which the insulation fits into.

•Next, a lacquered copper wire is wound into these grooves in a certain way, which consists of stator windings.

The asynchronous motor has three "pieces" of copper wire. Which are laid in a certain way in the slots of the stator at an angle of 120 degrees relative to each other.

All 6 ends of the winding wires are connected to the terminal box, which is located on the motor housing.

Asynchronous Motor Rotor

•Bearings are placed on the rotor shaft on both sides, which are attached to the front and rear covers and center the rotor exactly in the middle of the stator.

•Next comes a core made of sheets of special electrical steel, which are isolated from each other. By the way, network transformers are assembled from the same steel.

As you can see further, there are special slots in the rotor core.

Copper or aluminum rods are inserted into them, which close into a ring on both sides, forming a so-called "squirrel cage".

Always remember that the rotor rotates in an asynchronous motor, not the stator. The stator is the fixed part, and the rotor is the movable part of the electric motor.

In the operating state of the engine, there is always an air gap between the rotor and the stator. When the engine is running, the rotor must in no case touch the stator of the engine.