KEP_Product_240309

.pdf

www.kepital.com

Product Brochure

CONTENTS

1. |

General information |

|

1-1. |

KEPITAL Nomenclature |

03 |

1-2. |

Characteristics of KEPITAL |

04 |

1-3. |

Typical properties of KEPITAL |

06 |

2. |

Physical and mechanical properties |

|

2-1. |

Behavior under short-term stress |

10 |

2-2. |

Stress-Strain curve |

10 |

2-3. |

Temperature dependency on mechanical properties |

10 |

2-4. |

Impact strength |

11 |

2-5. |

Shear strength |

11 |

2-6. |

Specific volume |

11 |

2-7. |

Hardness |

12 |

2-8. |

Poisson’s ratio |

12 |

2-9. |

Behavior under long-term static stress |

13 |

2-10. |

Property to cyclic stress |

14 |

3. |

Thermal properties |

|

3-1. |

Melting point |

15 |

3-2. |

Specific heat |

15 |

3-3. |

Heat deflection temperature |

15 |

3-4. |

Coefficient of linear thermal expansion |

15 |

3-5. |

Thermal conductivity |

16 |

3-6. |

Heat ageing |

16 |

4. |

Tribological properties |

|

4-1. |

Friction |

17 |

4-2. |

Wear |

17 |

4-3. |

PV Limits |

17 |

5. |

Electrical properties |

|

5-1. |

Surface resistivity |

18 |

5-2. |

Volume resistivity |

18 |

5-3. |

Dielectric strength |

18 |

5-4. |

Dielectric constant |

18 |

5-5. |

Arc resistance |

18 |

6. |

Resistance to fuels and chemicals |

|

6-1. |

Fuel resistance |

19 |

6-2. |

Chemical resistance |

19 |

|

|

|

7. |

Resistance to light and weather |

|

7-1. |

Light resistance grade |

20 |

7-2. |

Weather resistance grade |

20 |

|

|

|

8. |

Processing of KEPITAL |

|

8-1. |

Equipment |

21 |

8-2. |

Injection molding |

21 |

8-3. |

Safety recommendation |

25 |

8-4. |

Troubleshooting guide |

25 |

|

|

|

9. |

UL approval |

27 |

|

|

|

10. |

Applications |

28 |

11. Quality, standard accreditation |

|

and environmental management system |

34 |

1. General Information

KEPITAL® is the trade name for the polyacetal copolymer products of Korean Engineering Plastics Co., Ltd. KEPITAL® has well balanced physical and mechanical properties with a good combination of highly crystalline and thermally stable structure. KEPITAL provides not only excellent mechanical and physical properties but also resistance to various chemicals and a wide processing window.

The characteristics of KEPITAL® are as follows:

·High mechanical properties

·High fatigue resistance

·Long-term dimensional stability

·Excellent fuel resistance

·Excellent creep resistance

·Superior friction resistance and wear resistance characteristics

·Superior chemical resistance and alkali resistance

KEPITAL’s product range, from standard unfilled grades to specialties, is well-balanced with inherent properties in order to meet both general purposes and particular requirements.

KEPITAL® is easily processed to manufacture the finished product through the typical processes of both injection molding and extrusion. Therefore, KEPITAL® has been widely used in products such as automotive, electronics, consumer goods, etc.

This brochure provides the physical and chemical properties of KEPITAL, processing information and diverse applications to help chose the right KEPITAL® grade.

1-1. KEPITAL Nomenclature

F xx - OO

1. Grade 2. Flowability 3. Characteristic

1.Grade

(1)Standard unfilled grades: F

(2)Reinforced & filled grades FG: Glass fiber reinforced MF: Milled glass fiber filled FB: Glass bead filled

FT: Whisker filled TC: Talcum filled

(3)Impact modified grades: TE

(4)Low friction and wear grades

FL: PTFE modified

FS, TS: Silicone modified

FM: MoS2 filled

TX, LO, TP: Special lubricant package formulated

2.Flowability

xxMelt Flow Rate (g/10 min)

10 |

|

3 |

|

15 |

|

6 |

|

20 |

|

9 |

|

25 |

|

13 |

|

30 |

|

28 |

|

40 |

|

52 |

|

3. Characteristics |

|

||

|

OO |

Characteristic |

|

|

|

|

|

03/33 Mold released / moderate toughness 03H Higher stiffness and strength than standard

unfilled grade

51UV-stabilized, Black color, outdoor

52UV-stabilized, Natural color, indoor

korea engineering plastics 3

1-2. Characteristic of KEPITAL

Standard unfilled grades

Grades |

|

|

|

|

|

Characteristics |

Application |

Melt Flow Rate |

|

||

Name |

|

||

(g/10min) |

|

||

|

|

|

|

3.0F10 High viscosity (low flow) grade with max Injection molding requiring toughness or extrusion-stock

|

|

toughness without modification |

shapes; rod, plate, tube and pipes |

|

|

|

|

6.0 |

F15 |

Intermediate flowability between F10 |

Injection molded parts or extruded rod, plate, tube and pipes |

|

|

and F20 |

|

|

|

|

|

9.0 |

F20 |

Medium viscosity grade for general |

Injection molded parts and extruded shapes with thinner wall |

|

|

purpose with well balanced properties |

section |

|

|

in demanding applications |

|

|

|

|

|

13 |

F25 |

General purpose with slightly higher |

Injection molded parts requiring better flow and less critical |

|

|

flow property |

demand on toughness |

|

|

|

|

28 |

F30 |

Low viscosity (high flow) grade |

Injection molded parts with geometrically long flow paths, thin |

|

|

|

wall or small shapes out of multi-cavities |

|

|

|

|

52 |

F40 |

Ultra high flow grade |

Very thin walled or small injection molded parts |

Reinforced · Filled grades

Grades |

|

Characteristics |

Application |

|

|

|

|||

Classification |

Name |

|||

|

|

|||

|

|

|

|

|

Glass fiber reinforced |

FG2025K |

High rigidity |

Parts where improved mechanical strength such as stiffness, fatigue & creep |

|

|

FG2015 |

stiffness |

resistance, high HDT etc. is required |

|

|

FG2025 |

|

|

|

|

|

|

|

|

Milled fiber filled |

MF3025 |

High stiffness |

Parts required of high stiffness with dimensional stability such as low warpage |

|

|

|

Low deformation |

|

|

|

|

|

|

|

Glass bead filled |

FB2030 |

High stiffness |

Appropriate molded parts requiring low deformation under elevated tempera- |

|

|

|

Low deformation |

ture environment |

|

|

|

|

|

|

Talcum filled |

TC3020 |

Dimensional |

Application requiring excellent dimensional stability |

|

|

|

stability |

|

|

|

|

|

|

|

Whisker filled |

FT2020 |

High rigidity |

Application requiring well balanced stiffness and dimensional stability |

|

|

|

Low strain |

|

|

|

|

|

|

Impact modified grades

Grades |

|

Characteristics |

Application |

|

|

|

|||

Classification |

Name |

|||

|

|

|||

|

|

|

|

|

Impact modified |

TE-21 |

Toughened |

General mechanical parts where moderately improved toughness |

|

|

TE-22 |

|

is required or highly stressed parts where super toughness is |

|

|

TE-23 |

|

needed. |

|

|

|

|

|

|

|

TE-24 |

Highly impact modified |

|

|

|

TE-25 |

|

|

|

|

|

|

|

|

|

TE-24S |

Super toughened |

|

|

|

|

|

|

4 korea engineering plastics

Low friction and wear grades

Grades |

Characteristics |

Application |

||

|

|

|||

Classification |

Name |

|||

|

|

|||

|

|

|

|

|

PTFE modified |

FL2010 |

Low friction and wear |

Injection and extruded parts where low friction coefficient and wear |

|

|

FL2020 |

|

volume are required such as bushes or conveyor belts etc |

|

|

|

|

|

|

Silicone modified |

FS2022 |

Low friction and wear |

Parts where reduced friction, wear and noise are needed. FS2022 and |

|

|

|

|

TS-22H are good for parts sliding against plastics |

|

|

TS-22H |

|

||

|

|

|

||

|

|

|

|

|

|

TS-25H |

|

Applications requiring extremely high sliding condition such as high speed, |

|

|

|

|

high load and high PV limits |

|

|

|

|

|

|

MoS2 filled |

FM2020 |

Low friction and wear |

Bushes and bearings |

|

|

FM2520S |

|

|

|

|

|

|

|

|

Special lubricant |

TP-20 |

Low friction and wear |

Gears, cams and bearings moving against same resin |

|

package |

|

against resin |

|

|

|

|

|

|

|

|

LO-21 |

Low friction and wear |

Gears, cams and bearings against metal |

|

|

|

to metal |

|

|

|

|

|

|

|

|

TX-11H |

Low friction and wear & |

Mechanical parts requiring noise reduction and low coefficient of friction |

|

|

TX-21 |

noise reduction |

against either plastics or metal under moderate moving condition |

|

|

TX-31 |

|

|

|

|

|

|

|

|

|

GR-30 |

Low friction and wear |

Mechanical parts where dimensional stability at elevated temperature as |

|

|

|

against metal |

well as low friction and wear against metal are needed |

|

|

|

|

|

|

UV-stabilized grades

Grades |

Characteristics |

Application |

||

|

|

|||

Classification |

Name |

|||

|

|

|||

|

|

|

|

|

Natural color |

F20-52 |

UV natural |

Parts where exposure to UV, such as automotive interiors |

|

|

F30-52 |

|

|

|

|

|

|

|

|

|

F20-52G |

Low gloss |

Parts requiring low surface gloss in addition to UV screen |

|

|

GD-52 |

|

|

|

|

|

|

|

|

Black color |

F20-51 |

UV black |

Parts exposed to UV for non-critical outdoor |

|

|

|

|

|

|

|

F20-51U |

UV black and |

Appropriate to use outdoors and in UV exposure environments, in particular |

|

|

|

improved impact |

for application with parts requiring improved impact |

|

|

|

|

|

|

Conductive, anti-static grades

Grades |

|

Characteristics |

Application |

|

|

|

|||

Classification |

Name |

|||

|

|

|||

|

|

|

|

|

Conductive |

ET-20S |

Conductive carbon |

Varied applications requiring conductive level of electrical property. |

|

|

ET-20A |

black powder filled |

ET-20A shows superior performance in fuel contact applications |

|

|

|

|

|

|

|

FA-20 |

High strength |

Parts requiring not only conductivity but also high strength |

|

|

|

|

|

|

Anti-static/ |

FV-30A |

Anti-static |

Parts in demanding applications for static electricity discharge |

|

static dissipative |

|

|

|

|

ED-10 |

Static dissipative |

Parts requiring suppression of static electricity generation and prevention of |

||

|

||||

|

ES-20 |

|

dust contamination and electrical noise generation |

|

|

|

|

|

korea engineering plastics 5

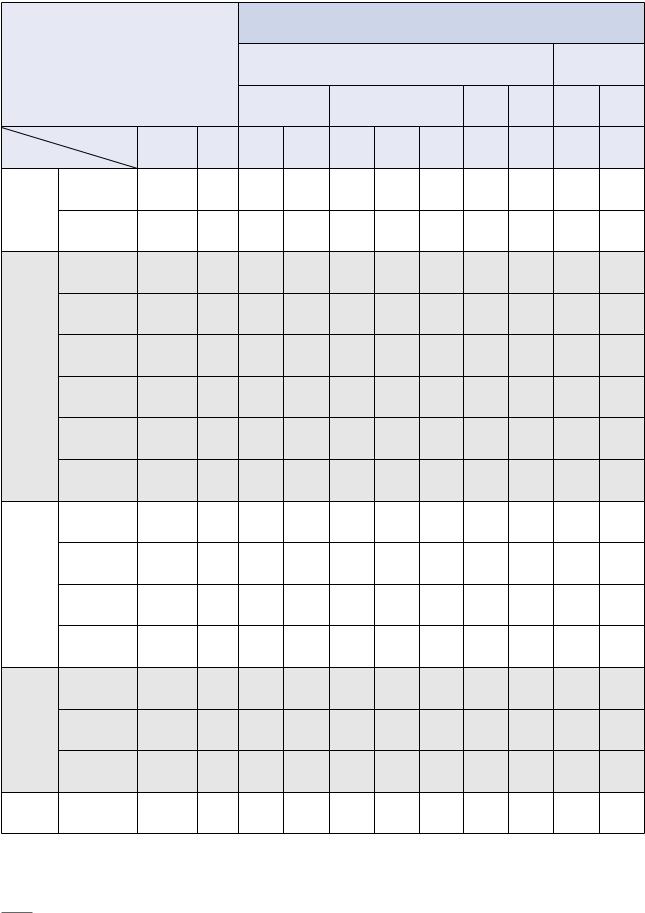

1-3. Typical properties of KEPITAL

|

|

|

|

|

|

|

Standard unfilled grades |

|

|

|

|||

|

Description |

|

|

|

|

General |

|

|

|

High rigidity |

|||

|

|

|

|

|

|

|

|

|

Low |

Extra |

High |

Medium |

|

|

|

|

|

High viscosity |

Medium viscosity |

low vis- |

|||||||

|

|

|

|

viscosity |

viscosity |

viscosity |

|||||||

|

|

|

|

|

|

|

|

|

cosity |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Grade |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test method |

Unit |

F10-01 |

F10-02 |

F15-33 |

F20-03 |

F25-03 |

F30-03 |

F40-03 |

F10-03H |

F25-03H |

|

Property |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Density |

ISO 1183 |

g/cm3 |

1.41 |

1.41 |

1.41 |

1.41 |

1.41 |

1.41 |

1.41 |

1.41 |

1.41 |

|

Physical |

|

|

|

|

|

|

|

|

|

|

|

|

|

properties |

Water |

|

|

|

|

|

|

|

|

|

|

|

|

|

ISO 62 |

% |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

||

|

Absorption |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Tensile strength |

ISO 527 |

MPa |

63 |

63 |

65 |

65 |

65 |

65 |

65 |

68 |

68 |

|

|

Elongation |

ISO 527 |

% |

10 |

10 |

10 |

10 |

9 |

8 |

8 |

12 |

10 |

|

|

at yield |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Nominal strain |

ISO 527 |

% |

40 |

40 |

35 |

35 |

33 |

25 |

20 |

40 |

32 |

|

|

at break |

||||||||||||

Mechanical |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

properties |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flexural strength |

ISO 178 |

MPa |

82 |

83 |

84 |

87 |

90 |

90 |

93 |

90 |

94 |

|

|

Flexural modulus |

ISO 178 |

MPa |

2350 |

2400 |

2450 |

2550 |

2650 |

2700 |

2750 |

2650 |

2800 |

|

|

Notched Charpy |

ISO 179 |

KJ/m2 |

7.0 |

7.0 |

7.0 |

6.5 |

6.0 |

5.5 |

5.0 |

7.0 |

6.5 |

|

|

impact strength |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Melt flow rate |

ISO 1133 |

g/10 min |

3 |

3 |

6 |

9 |

13 |

28 |

52 |

3 |

13 |

|

|

Melting point |

ISO 3146 |

°C |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

168 |

168 |

|

Thermal |

|

|

|

|

|

|

|

|

|

|

|

|

|

properties |

Heat Deflection |

|

|

|

|

|

|

|

|

|

|

|

|

|

temperature |

ISO 75 |

°C |

96 |

96 |

96 |

100 |

100 |

101 |

101 |

100 |

101 |

|

|

(1.8 MPa) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Coefficient of |

|

|

|

|

|

|

|

|

|

|

|

|

|

linear thermal |

ISO 11359 |

x10-5/°C |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

|

|

expansion |

|

|

|

|

|

|

|

|

|

|

|

|

|

Surface resistivity |

IEC 60093 |

Ω |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

|

Electrical |

Volume resistivity |

IEC 60093 |

Ω · cm |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

|

properties |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Dielectric strength |

IEC 60243 |

kV/mm |

19 |

19 |

19 |

19 |

19 |

19 |

19 |

19 |

19 |

|

Other |

Mold shrinkage |

KEP |

% |

2.2 |

2.2 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.2 |

2.0 |

|

(t3 mm, ø100 mm) |

(Flow direction) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

* The information contained in this data sheet is based on our current knowledge and experience, so it may change as new knowledge and experience become available. This information is based on only above-mentioned product produced in Korea Engineering Plastics Co., Ltd.(“KEP”) through relevant test methods and conditions and does not relate to any products made of this product with the inclusion of other additives, such as processing aids or colorants. This information should not be construed as a promise or guarantee of specific properties of this product described or its suitability for a particular application, so users make their own determination as to its suitability to their purpose prior to use this

product. It is the sole responsibility of the users to investigate whether any existing patents are infringed by the use of this product. This product is not intended for use in medical and dental implants and users should meet all safety and health standards. KEP makes no warranty and assumes no liability in connection with any use of this information.

6 korea engineering plastics

|

|

|

|

Reinforced & filled grade |

|

|

|

|

Low |

friction and wear grade |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Glass reinforced & filled |

|

|

|

|

|

Silicone modified |

|

|

Special |

||||||

|

|

|

|

|

|

|

Talcum |

Whisker |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PTFE modified |

|

|

|

|

MoS2 filled |

lubricant |

||||

|

|

|

|

|

|

|

filled |

filled |

|

|

|

|

|||||

|

|

|

|

|

Glass |

Milled |

|

|

|

|

|

|

|

|

package |

||

|

Glass Fiber |

|

|

|

|

|

General |

|

Specialty |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

Bead |

GF |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

FG2025K |

FG2015 |

FG2025 |

FB2030 |

MF3025 |

TC3020 |

FT2020 |

FL2010 |

FL2020 |

FS2022 |

|

TS-22H |

TS-25H |

FM2020 |

FM2520S |

TP-20 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.47 |

|

1.50 |

|

1.59 |

1.64 |

1.59 |

1.56 |

1.59 |

1.45 |

1.51 |

1.40 |

|

1.40 |

1.40 |

1.43 |

1.38 |

1.38 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.2 |

|

0.2 |

|

0.2 |

0.2 |

0.2 |

0.2 |

0.23 |

0.19 |

0.18 |

0.2 |

|

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

110 |

|

120 |

|

160 |

58 |

78 |

67 |

86 |

55 |

45 |

60 |

|

65 |

60 |

65 |

58 |

57 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

– |

|

– |

– |

– |

– |

– |

9.5 |

10 |

12 |

|

10.5 |

8.5 |

9.5 |

10 |

10.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.8 |

|

3.6 |

|

3.0 |

4.0 |

4.9 |

5.6 |

2.7 |

14 |

14.5 |

48 |

|

20 |

23 |

20 |

33 |

34 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

160 |

|

175 |

|

220 |

97 |

129 |

112 |

146 |

80 |

70 |

82 |

|

88 |

83 |

90 |

80 |

81 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4750 |

|

5200 |

|

8250 |

4050 |

5530 |

5290 |

6800 |

2400 |

2150 |

2400 |

|

2600 |

2550 |

2690 |

2400 |

2450 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.5 |

|

7.0 |

|

8.0 |

2.5 |

3.8 |

3.8 |

3.6 |

3.5 |

3.0 |

8.5 |

|

6.5 |

5.5 |

5.5 |

5.5 |

5.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

11.5 |

|

7 |

19 |

16 |

5 |

15 |

8 |

5 |

10 |

|

13 |

24 |

11 |

10.5 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

165 |

|

165 |

|

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

|

165 |

168 |

165 |

165 |

165 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

– |

|

162 |

– |

– |

– |

– |

– |

– |

– |

|

98 |

98 |

– |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

5 |

|

3 |

9 |

9 |

7 |

6 |

13 |

13 |

13 |

|

13 |

13 |

13 |

13 |

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1x1016 |

|

1x1016 |

|

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

|

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1x1014 |

|

1x1014 |

|

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

|

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

– |

|

23 |

20 |

– |

21 |

– |

16 |

16 |

– |

|

– |

– |

– |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.0 |

|

0.8 |

|

0.5 |

1.5 |

1.3 |

1.6 |

0.9 |

2.0 |

2.0 |

2.0 |

|

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

korea engineering plastics 7

|

|

|

|

|

Low friction and wear grade |

|

|

Impact modified grade |

|

||||

|

Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Special lubricant package |

|

|

High toughness |

|

||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Grade |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test method |

Unit |

LO-21 |

TX-11H |

TX-21 |

TX-31 |

GR-30 |

TE-21 |

TE-22 |

TE-23 |

|

TE-24 |

Property |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Density |

ISO 1183 |

g/cm3 |

1.39 |

1.40 |

1.39 |

1.39 |

1.43 |

1.39 |

1.37 |

1.36 |

|

1.35 |

Physical |

|

|

|

|

|

|

|

|

|

|

|

|

|

properties |

Water |

|

|

|

|

|

|

|

|

|

|

|

|

|

ISO 62 |

% |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.22 |

0.23 |

0.24 |

|

0.24 |

|

|

Absorption |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tensile strength |

ISO 527 |

MPa |

60 |

64 |

58 |

56 |

48 |

57 |

51 |

45 |

|

41 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Elongation |

ISO 527 |

% |

10 |

12 |

10 |

8 |

9 |

9 |

11 |

12 |

|

13 |

|

at yield |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nominal strain |

ISO 527 |

% |

26 |

40 |

33 |

35 |

40 |

40 |

>50 |

>50 |

|

>60 |

|

at break |

|

|||||||||||

Mechanical |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

properties |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flexural strength |

ISO 178 |

MPa |

81 |

86 |

79 |

80 |

66 |

76 |

68 |

60 |

|

53 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flexural modulus |

ISO 178 |

MPa |

2450 |

2550 |

2350 |

2400 |

2150 |

2150 |

1900 |

1650 |

|

1450 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notched Charpy |

ISO 179 |

KJ/m2 |

5.5 |

7.5 |

7.5 |

7.0 |

5.5 |

8.0 |

11.0 |

13.0 |

|

18.0 |

|

impact strength |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Melt flow rate |

ISO 1133 |

g/10 min |

9.5 |

5 |

16 |

30 |

20 |

11 |

8.5 |

8 |

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Melting point |

ISO 3146 |

°C |

165 |

168 |

165 |

165 |

165 |

165 |

165 |

165 |

|

165 |

Thermal |

|

|

|

|

|

|

|

|

|

|

|

|

|

properties |

Heat Deflection |

|

|

|

|

|

|

|

|

|

|

|

|

|

temperature |

ISO 75 |

°C |

95 |

97 |

– |

89 |

– |

84 |

76 |

76 |

|

66 |

|

(1.8 MPa) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Coefficient of |

|

|

|

|

|

|

|

|

|

|

|

|

|

linear thermal |

ISO 11359 |

x10-5/°C |

13 |

13 |

13 |

13 |

13 |

13 |

13 |

13 |

|

13 |

|

expansion |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Surface resistivity |

IEC 60093 |

Ω |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

|

1x1016 |

Electrical |

|

|

|

|

|

|

|

|

|

|

|

|

|

Volume resistivity |

IEC 60093 |

Ω · cm |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

|

1x1014 |

|

properties |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dielectric strength |

IEC 60243 |

kV/mm |

– |

– |

– |

18 |

– |

– |

– |

– |

|

21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other |

Mold shrinkage |

KEP |

% |

2.0 |

2.0 |

2.0 |

2.0 |

1.8 |

1.9 |

1.8 |

1.8 |

|

1.7 |

(t3 mm, ø100 mm) |

(Flow direction) |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

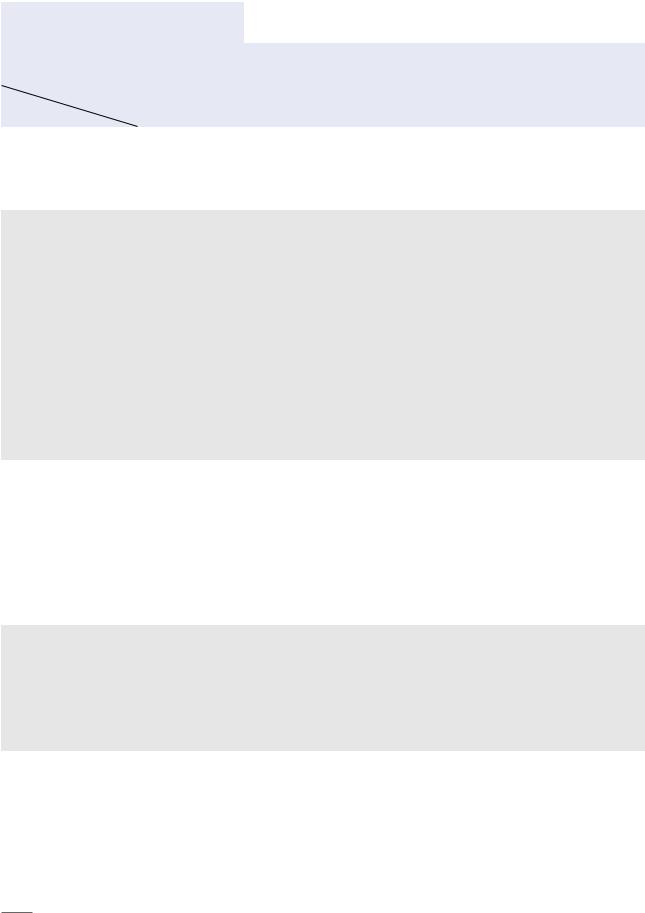

* The information contained in this data sheet is based on our current knowledge and experience, so it may change as new knowledge and experience become available. This information is based on only above-mentioned product produced in Korea Engineering Plastics Co., Ltd.(“KEP”) through relevant test methods and conditions and does not relate to any products made of this product with the inclusion of other additives, such as processing aids or colorants. This information should not be construed as a promise or guarantee of specific properties of this product described or its suitability for a particular application, so users make their own determination as to its suitability to their purpose prior to use this

product. It is the sole responsibility of the users to investigate whether any existing patents are infringed by the use of this product. This product is not intended for use in medical and dental implants and users should meet all safety and health standards. KEP makes no warranty and assumes no liability in connection with any use of this information.

8 korea engineering plastics

Impact modified |

|

|

UV-stabilized grade |

|

|

Conductive grade |

Anti-static/static dissipative |

|||||||

grade |

|

|

|

|

|

grade |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High |

General |

Black |

Low gloss |

Impact |

General |

High |

General |

Specialty |

||||||

toughness |

resistance |

stiffness |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TE-25 |

TE-24S |

F20-52 |

F30-52 |

F20-51 |

F30-51 |

F20-52G |

GD-52 |

F20-51U |

ET-20S |

ET-20A |

FA-20 |

FV-30A |

ED-10 |

ES-20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.34 |

1.32 |

1.41 |

1.41 |

1.41 |

1.41 |

1.41 |

1.41 |

1.38 |

1.38 |

1.39 |

1.43 |

1.41 |

1.32 |

1.36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

0.25 |

0.2 |

0.2 |

0.2 |

0.2 |

– |

0.2 |

0.2 |

– |

– |

– |

– |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

39 |

38 |

63 |

63 |

62 |

59 |

58 |

59 |

55 |

40 |

52 |

100 |

63 |

43 |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

23 |

10 |

9 |

9 |

8 |

11 |

7 |

10 |

4 |

8 |

2 |

8 |

18 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

>60 |

>100 |

35 |

37 |

25 |

35 |

40 |

14 |

40 |

12 |

8 |

2 |

25 |

90 |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

46 |

46 |

83 |

83 |

88 |

86 |

78 |

86 |

75 |

67 |

76 |

135 |

88 |

50 |

70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1250 |

1300 |

2350 |

2450 |

2650 |

2650 |

2350 |

2750 |

2250 |

2650 |

2450 |

7150 |

2580 |

1350 |

2000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21.0 |

28.0 |

6.0 |

6.0 |

7.0 |

7.0 |

6.0 |

4.0 |

8.5 |

4.0 |

5.5 |

4.0 |

5.0 |

16.0 |

12.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

2 |

10 |

28 |

10 |

25 |

10 |

25 |

10.5 |

11.5 |

1 |

3 |

29 |

<1 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

165 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

61 |

92 |

– |

– |

– |

– |

– |

89 |

88 |

92 |

160 |

97 |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

13 |

13 |

13 |

13 |

13 |

13 |

13 |

13 |

– |

– |

– |

– |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x1016 |

1x103 |

1x103 |

1x103 |

1x1015 |

1x109 |

1x1010 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

1x1014 |

– |

– |

– |

– |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

– |

19 |

19 |

19 |

19 |

19 |

19 |

19 |

– |

– |

– |

19 |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.6 |

1.5 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

– |

2.0 |

1.6 |

1.8 |

0.9 |

2,0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

korea engineering plastics 9

2. Physical and mechanical properties

The physical and mechanical properties measured by standard test methods should be the principle guideline to select material from an engineer’s stand point. It is also important to review both short-term (strength, modulus, elongation and impact strength etc) and long-term properties (creep, stress-relaxation and fatigue etc) in determining which material to use. This is because of the fact that plastic materials are affected by varied factors such as temperature, stress and time.

2-1. Behavior under short-term stress

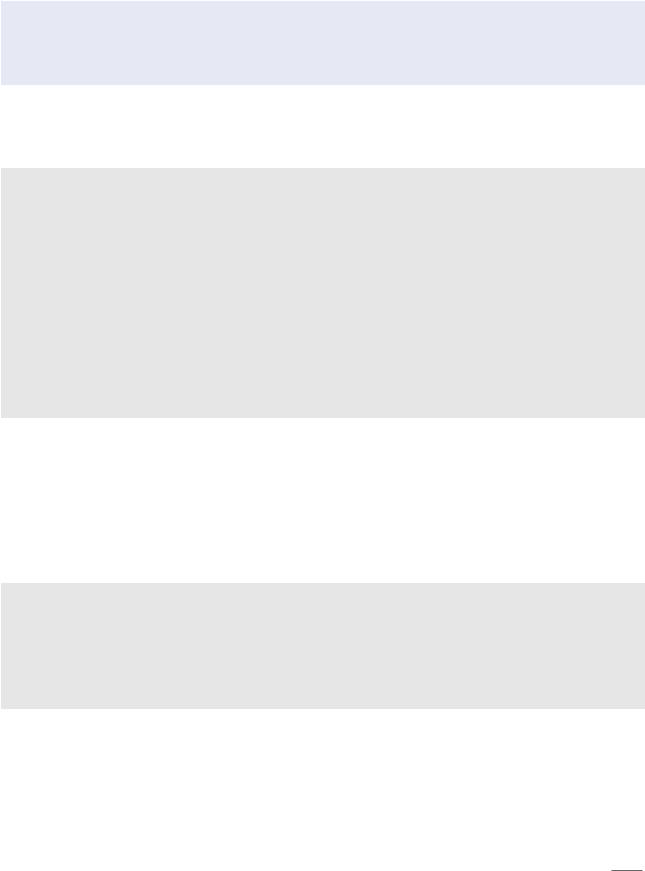

The short-term properties of plastics under a stress are determined by means of stress measurements in tensile/ flexural or sudden blow impact strength, depending on the materials’ characteristics, level of the stress, loading speed, temperature and chemical environment. However, long term properties show time dependent behavior. From the tensile test (ISO 527), such data like elastic Young’s modulus, strength, and elongation at yield and break point can be obtained. Those properties are determined from the stress and strain curve (S-S curves) that shows elastic and plastic behavior of a material under

a dynamic load. When the stresses are removed within the elastic limit, a thermoplastic is capable to recover its original shape. But on the other hand, if the stress is greater than the elastic limit, the material is deformed permanently after reduction of the stress.

Yield point A

Break point B

Stress (S)

Strain (e)

Figure 2-1. Tensile Stress-Strain curve

In the graph, A is the yield point and its yield stress represents the stress limit for elastic strain. B is the break point at which fracture occurs. Tensile strength notes the maximum stress ( max) in the stress-strain curve (S-S curve). Whereas, when fractured before the yield point, the maximum stress is called the tensile strength and there is no yield stress such as in some cases of reinforced and filled grades

10korea engineering plastics

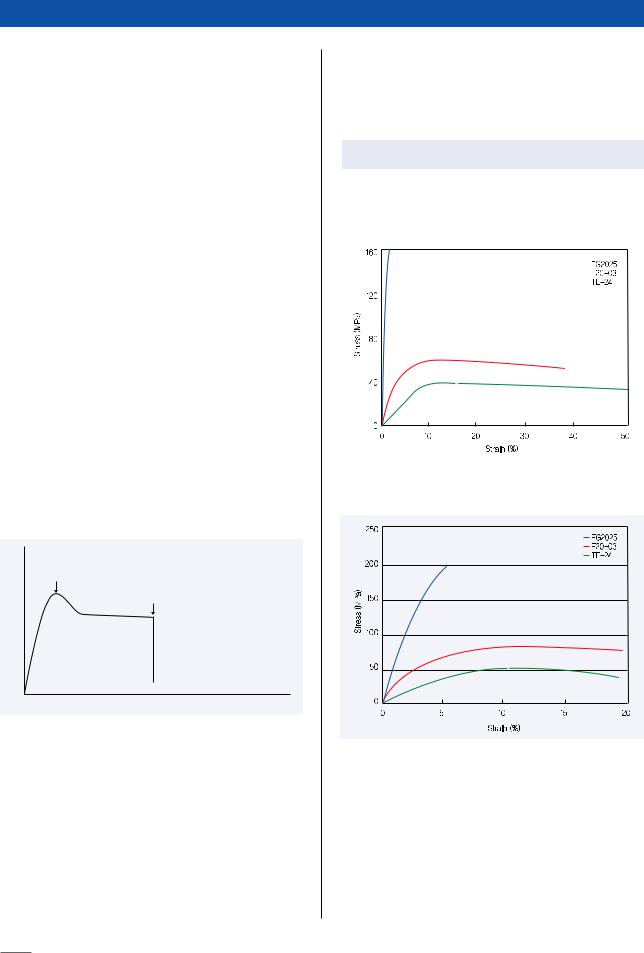

2-2. KEPITAL stress-strain curve

S-S curves of KEPITAL in tensile and maximum stress, representing tensile strength are shown in Figure 2-2 and in the following table.

|

|

|

|

(ISO 527, Temp. 23 °C) |

||||

|

Grade |

Tensile strength |

Testing speed |

|

||||

|

(MPa) |

(mm/min) |

|

|||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

F20-03 |

65 |

50 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

FG2025 |

160 |

50 |

|

|

|||

|

TE-24 |

41 |

50 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 2-2. .Tensile stress-strain curves for KEPITAL (ISO 527, Temp. 23 °C)

Figure 2-3. Flexural stress-strain curves for KEPITAL

(ISO 178, Temp. 23 °C, Testing speed 2.0 mm/min)

2-3. Temperature dependency on mechanical properties

KEPITAL maintains balanced physical and mechanical property characteristics over a wide range of temperatures. Figure 2-4 shows stress-strain curves of tensile tests at various temperatures, and Figure 2-5 shows dependence of the tensile strength on temperatures.