16.5 Process Control Tuning |

285 |

correction than in the optimum case. In many processes, this long delay or lag time is unacceptable.

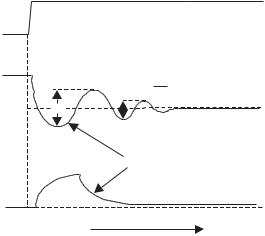

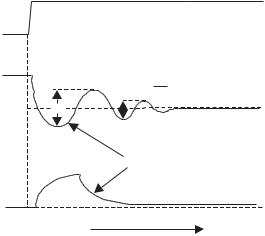

A criterion sometimes used for the optimum stable case for a damped cyclic response to a disturbance is that the overshoot decreases by one-quarter of its amplitude every successive cycle, as shown in Figure 16.16. This setting is a good compromise between minimum deviation and minimum duration. Further fine-tun- ing may be required to optimize a specific process.

16.5Process Control Tuning

The performance of a control loop depends on system design, loop implementation, and setup of the control functions. The factors affecting the quality of control are:

1.The accuracy and conditioning of the measuring and control devices;

2.Stability in the control loops;

3.The ability of the system to return a measured variable to its set point after a disturbance.

Tuning is the adjustment of P, I, and D in the correct combination to give the optimum performance of the process control loop. Idealized settings may not give optimum performance, since settings are application-dependent. There are several methods of tuning a control loop, but it is generally done automatically, manually, or through adjustments based on experience.

Loops can be tuned for:

1.Minimum area, which produces a longer lasting deviation from the set point, and is used where high peak values can be detrimental to the process;

2.Minimum cycling, which minimizes the number of disturbances and time duration, and gives better stability;

Change in load

|

Signal to |

|

H |

|

h |

= 4 |

|

actuator |

|

h |

|

|

H |

|

|

|

|

Optimum correction |

|

Variable |

|

|

|

|

|

Time |

Figure 16.16 Optimized gain settings.

3.Minimum deviation, which minimizes the deviation amplitude, but has cycling around the set point, and is the most commonly used process.

16.5.1Automatic Tuning

Programs are available from software and hardware suppliers that will include features to automatically set up and tune the control loops, although some final fine-tuning for optimum performance may still be required [6].

16.5.2Manual Tuning

Manual tuning requires a good understanding of the control loop being tuned, good engineering skills, and much patience. There are two basic methods of manual tun- ing—open loop tuning and closed loop tuning. Open loop tuning is typically used in applications that have long delays, such as in analysis and temperature loops. Closed loop tuning is used in applications with short time delays, such as in pressure, flow, and level loops.

Open loop requires the opening of the feedback loop at the output of the controller and applying a step change S (5% to 10%) to the actuator or valve. The following measurements from the feedback element are then made and recorded, as shown in Figure 16.17.

1.The reaction rate R = T/A.

2.Find the unit reaction rate RU = R/S.

3.Measure the lag L.

4.Set the controller PID values:

a.Gain KP = 1.2/(RU × L)

b.Integral TI = 2L (min)

c.Derivative TD = 0.5L (min)

Testing and fine-tuning may still be required.

Closed loop, also known as the Ziegler-Nichols closed loop method or ultimate cycle method, uses the following steps:

1.Use P only with set point at 50%, setting I and D to minimum.

2.Move the controller set point 10%, and hold a few minutes.

% Input |

Input |

|

|

or output |

S |

A |

|

step |

|

|

|

|

L |

T |

Time |

|

|

Minutes |

|

Figure 16.17 Reaction curve.

16.6 Implementation of Control Loops |

287 |

3.Return the set point to its 50% point.

4.Adjust the gain Gc until a stable continuous oscillation is obtained.

5.Measure period of cycle Tc.

6.Set the controller values for three-mode control, as follows:

a.Gain KP = 0.6Gc;

b.Integral TI = Tc/2 (min);

c.Derivative TD = 0.125Tc (min).

The system can now be tested and fine-tuned.

To give a quarter amplitude response, we set:

a.Integral TI = Tc/1.5;

b.Derivative TD = Tc/6;

c.Adjust the proportional gain for quarter amplitude response. Test and fine-tune as required.

Rules of thumb have been developed by experienced operators for values of P, I, and D. The controller is set up with these values, but since they are only approximations, the system will still require fine-tuning to obtain acceptable PID settings for a specific process. Typical rules of thumb are described in Table 16.1.

16.6Implementation of Control Loops

Implementation of the control loops can be achieved using pneumatic controllers, or analog or digital electronic controllers. The first process controllers were pneumatic. However, these are largely obsolete and in most cases have been replaced by electronic systems. Electronic systems have improved reliability, less maintenance, easier installation, easier adjustment, higher accuracy, lower cost, higher operating speeds, and they can be used with multiple variables.

16.6.1On/Off Action Pneumatic Controller

Figure 16.18 shows a pneumatic control system using a pneumatic On/Off controller. In this case, the transducer moves a flapper that controls the airflow from a nozzle. When the spring force on the flapper reaches the reference point, the transducer moves the flapper away from the nozzle, letting air flow from the nozzle, which allows the pressure to the actuator to drop. This reduction in pressure opens the valve. When the force from the transducer drops below the set level, the flapper

Table 16.1 Typical Rules of Thumb for PID Settings

Type of Loop |

Gain (KP) |

Tc (min) |

TD (min) |

Line pressure |

0.5 |

0.2 |

0 |

Tank pressure |

2.0 |

2.0 |

0.5 |

Temperature |

2.0 |

2.0 |

2.0 |

Flow |

0.7 |

0.05 |

0 |

Level |

1.7 |

5.0 |

0 |

Set reference point

Spring To transducer

Restriction

Flapper

Pivot

Flow

Figure 16.18 On/Off pneumatic controller.

moves, stopping the air flow from the nozzle increasing the air pressure to the valve, which in turn opens the actuator and closes the valve [7].

16.6.2Pneumatic Linear Controller

A force to pressure converter is shown in Figure 16.19. When the force F is increasing, the flapper pivots to close the nozzle. This in turn increases the pressure in the feedback bellows, which tries to rotate the flapper to open the nozzle and balance the force of the input. A balance condition occurs when the torque exerted by the force equals the torque exerted by the feedback bellows, giving:

(Pout − Po)A × t = F × d

solving for the output pressure

Pout |

= F × d + Po |

(16.10) |

|

A × t |

|

|

Flapper |

Set Po |

Force (F) |

|

|

|

|

Restriction |

|

Spring |

|

d |

|

|

|

Nozzle |

PSUPPLY |

Pivot |

t |

|

|

|

Feedback bellows |

|

Pout |

|

|

Figure 16.19 Linear pneumatic controller.

16.6 Implementation of Control Loops |

289 |

where, Pout is the output pressure, Po is the zero error pressure, A is the area of the bellows, t is the distance between the pivot and bellows, F is the applied force, and d is the distance from the force to the pivot.

For pressure transducers Po is normally 3 psi (20 kPa). Since d, A, and t are

fixed, there is a linear relation between Pout and F. The gain of the system is set by the ratio d/t, which is chosen so that when F is at its maximum, Pout = 15 psi (100 kPa).

16.6.3Pneumatic Proportional Mode Controller

Proportional mode control can be achieved with the setup shown in Figure 16.20. The operation is basically the same as in the force to pressure converter. The torque is produced by the error signal. The torque produced by the output balances the difference between the reference and input pressure (Pin), giving the following:

(Pout − Po)A × t = (Pin − Pref)Ain × d

solving for the output pressure

Pout = |

Ain × d |

(Pin − Pref ) + Po |

(16.11) |

A × t |

where Ain is the area of the input and reference bellows, and Pref is the reference pressure.

This gives a linear relation between Pin and Pout.

16.6.4PID Action Pneumatic Controller

Many configurations for PID pneumatic controllers have been developed over the years, have performed well, and are still in use in some older processing plants. With the advent of the requirements of modern processing and the development of electronic controllers, pneumatic controllers have achieved the distinction of becoming

Reference pressure |

|

Set Po |

|

Spring |

|

|

|

|

Restriction |

Flapper |

|

|

Pivot |

Nozzle |

PSUPPLY |

d |

t |

|

Feedback bellows |

|

|

|

|

POUT |

Pin |

|

|

Figure 16.20 Pneumatic On/Off furnace controller.

museum pieces. Figure 16.21 shows an example of a pneumatic PID controller. The pressure from the sensing device (Pin) is compared to a set or reference pressure (Pref) to generate a differential force (error signal) on the flapper, which moves the flapper in relation to the nozzle, giving an output pressure proportional to the difference between Pin and Pref. If the derivative restriction is removed, then the output pressure is fed back to the flapper via the proportional bellows, to oppose the error signal and to give proportional action. System gain is adjusted by moving the position of the bellows along the flapper arm (i.e., the closer the bellows is positioned to the pivot, the greater the movement of the flapper arm).

By putting a variable restriction between the pressure supply and the proportional bellows, a change in Pin causes a large change in Pout, since the feedback from the proportional bellows is delayed by the derivative restriction. This gives a pressure transient on Pout before the proportional bellows can react, thus giving derivative action. The size of the bellows and the setting of the restriction set the duration of the transient.

Integral action is achieved by the addition of the integral bellows and restriction, as shown. An increase in Pin moves the flapper towards the nozzle, causing an increase in output pressure. The increase in output pressure is fed to the integral bellows via the restriction, until the pressure in the integral bellows is sufficient to hold the flapper in the position set by the increase in Pin, creating integral action.

16.6.5PID Action Control Circuits

PID action can be performed using either analog or digital electronic circuits. This section discusses the use of analog circuits for proportional, derivative, and integral action. A large number of circuit variations can be used to perform these analog functions, but only the basic circuits used in control circuits are discussed.

Reference pressure

Flapper |

Nozzle |

Variable |

PSUPPLY |

|

restriction |

|

|

|

Restriction |

|

|

|

Proportional |

Derivative |

bellows |

control |

POUT

Pin

Figure 16.21 Pneumatic PID controller.

16.6 Implementation of Control Loops |

|

|

|

291 |

Vo |

R |

2 |

|

R |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

R |

Vin |

|

|

− |

|

R |

|

|

R1 |

+ |

|

− |

Vout |

|

|

|

|

|

|

|

|

|

|

|

+ |

|

Figure 16.22 Circuits used in PID action: (a) error generating circuit, and (b) proportional circuit.

The proportional mode, shown in Figure 16.22, is a circuit that can be used to generate an amplified voltage that is proportional to the error signal voltage. The proportional signal is given in (16.1). This is the equation of a summing amplifier, which, when used in a voltage amplifying circuit, can be modified to:

Vout = A × Vin + Vo |

(16.12) |

where Vout is p (16.1), A is gain or KP, Vin is eP, and Vo is po, or output voltage with zero error input; that is, the measured variable and the reference voltage are equal.

Proportional action is achieved by amplifying the error signal (Vin). The stage gain is the ratio of R2/R1, and the gain is adjusted by potentiometer (R1). In (16.1), po is the controller output with zero error, because the R2 input has unity gain. This input can be used to set the zero error output voltage Po, by making Vo = Po. The output is inverted to keep the signal positive.

The derivative mode is never used alone because it cannot provide a dc input to control the level of the output. Implementation of the action is shown so that it can be used to work with other modes. The circuit for derivative action is shown in Figure 16.23. The feedback resistor R2 can be replaced with a potentiometer to adjust the differentiation amplitude. The output signal of the differentiator is inverted, but is changed to a noninverted signal with an inverting amplifier stage. When using voltage amplifiers, (16.3) can be modified to:

Vout = R2C1(dVin/dt) |

(16.13) |

In practice, this circuit tends to be unstable due to high gain at high frequencies. Using ac analysis and impedances, the amplifier equation becomes:

where Xc = 1 2πfC1 , from which we get:

2πfC1 , from which we get:

Vout = −2 jπfC1R2 Vin

Because only magnitudes are of interest, the equation can be written:

|

Vout |

|

= 2πfR2 C1 |

|

Vin |

|

(16.14) |

|

|

|

|

R2

R1 C1

Vin

+

Figure 16.23 Derivative amplifier: (a) circuit, and (b) waveforms.

This equation shows the gain increasing linearly with frequency, and the possibility of instability at high frequencies. Resistor R1 is put in series with C1 to limit the gain of the amplifier at high frequencies, ensuring high frequency stability. The maximum frequency response fm of the system is estimated, for stability:

where C1 is found from the mode derivative gain requirements, and R2 then can be calculated.

The PD mode can be obtained by combining the circuits shown in Figures 16.22 and 16.23, as shown in Figure 16.24. Derivative action is obtained by the input capacitor C1 with R3, and proportional action is obtained by the ratio of the resistors R2 to R1 in series with R3. From analysis of the circuit and using (16.4), we get:

|

|

|

|

R |

2 |

|

|

|

|

|

R |

2 |

|

|

|

dV |

in |

+ V |

|

|

V |

|

= |

|

|

|

|

V |

|

+ |

|

|

|

|

R C |

|

|

(16.16) |

|

|

|

+ R |

|

|

|

|

+ R |

|

|

|

|

|

out |

R |

1 |

3 |

|

in |

R |

1 |

3 |

|

1 1 |

dt |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

where the proportional gain is R2/(R1 + R3), and the derivative gain is R1C1.

The integral mode can be obtained using the circuit shown in Figure 16.25. Capacitive feedback around the amplifier prevents the output from the amplifier from following the input change, giving integral action. The output changes slowly and linearly when there is a change in the measured variable (Vin). The feedback C1 and the input resistance R1, which can be adjusted, set the required integration time. Integral action is given by (16.5), which, when applied to the voltage amplifier in Figure 16.25, results in:

Vo |

|

R |

2 |

R |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

R1 |

|

− |

|

R |

|

|

|

|

|

|

Vin |

|

|

R3 |

|

− |

Vout |

|

|

|

+ |

|

|

|

|

C1 |

|

|

|

+ |

|

|

|

|

|

|

|

Figure 16.24 Proportional plus derivative amplifier: (a) circuit, and (b) waveforms.

16.6 Implementation of Control Loops |

|

|

293 |

|

C1 |

|

R |

|

|

|

Vin |

− |

R |

|

R1 |

+ |

− |

Vout |

|

+ |

|

|

|

|

|

Integrator |

|

|

Figure 16.25 Integrating amplifier: (a) circuit, and (b) waveforms.

|

|

1 |

1 |

|

Vout |

= |

|

|

Vin dt + V0 |

(16.17) |

R C |

|

|

|

1 |

∫0 |

|

|

|

1 |

|

|

The PI mode is a combination of the proportional mode and the integral mode. The resulting circuit is shown in Figure 10.26. Using circuit analysis and (16.7), results in:

V |

|

= |

R3 |

V |

|

+ |

R3 |

1 |

|

1 V |

|

dt + V |

|

(16.18) |

out |

|

in |

|

|

|

|

|

in |

0 |

|

|

R |

|

R R |

C |

|

∫0 |

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

1 |

|

|

1 |

3 |

|

|

|

|

|

|

16.6.6PID Electronic Controller

Figure 16.27 shows the block diagram of an analog PID controller. The measured variable from the sensor is compared to the set point in the summing circuit, and its output is the difference between the two signals. This is the error signal. This signal is fed to the integrator [8].

When there is a change in the measured variable, the error signal is seen by the proportional amplifier, the differentiator, and the integrator. The output from the amplifiers is combined in a summing circuit, amplified, and fed to the actuator motor to change the input variable. Although the integrator sees the error signal, it is slow to react, so its output does not change immediately, but starts to integrate the error signal. If the error signal is present for an extended period of time, then the integrator will supply the correction signal via the summing circuit to the actuator.

The circuit implementation of the PID controller is shown in Figure 16.28. Each of the amplifiers is shown doing a single function, and is only used as an example. In practice, there are a large number of circuit component combinations that can be used to produce PID action.

Vo |

R2 |

R3 |

C |

1 |

R |

|

|

|

|

|

|

|

|

|

|

R1 |

− |

|

R |

|

Vin |

|

|

|

|

+ |

|

− |

Vout |

|

|

|

|

|

|

|

|

|

+ |

|

Figure 16.26 Proportional integral amplifier.

294 |

|

|

|

|

Process Control |

Material |

|

|

|

|

Control |

out |

|

|

|

|

Sensor |

|

Process |

|

Material |

|

transducer |

|

input |

|

|

|

|

|

|

|

|

M |

|

|

|

Proportional |

|

Correction |

|

|

|

|

signal |

Set point |

|

|

|

|

|

|

|

|

Error |

Error |

|

Sum |

Amplifier |

|

signal |

Derivative |

|

detector |

|

|

|

|

|

|

Integral

Figure 16.27 Block schematic of a PID electronic controller.

A single amplifier also can be used to perform several functions, which would greatly reduce the circuit complexity. Such a circuit is shown in Figure 16.29, where the PD action circuit is combined with the integral circuit. This is only one of many alternatives [9].

In new designs, the PID action can be performed in the PLC processor using digital techniques, and by the processor in a smart sensor [10].

16.7Summary

This chapter discussed process control, the terminology used, and the various methods of implementation of the controller functions. The differences between sequential, On/Off feedback control, and continuous feedback control were given. Continuous feedback control can be broken down into proportional, derivative, and integral action. Other types of feedback control used in process control are cascade, ratio, and feed-forward. The stability of feedback control systems is discussed, and the various methods of tuning the system are given.

Pneumatic hardware for performing On/Off and PID control is described, and the operation of a typical controller is given. The use of digital electronics for

− Differentiator

+ Vout

+

Figure 16.28 Circuit of a PID action electronic controller.

2

2