3505

.pdfIssue № 1(29), 2016 |

ISSN 2075-0811 |

The analysis of the obtained results of modeling is expressed via a dependency captured in Fig. 1 and shows that a 20 % increase in porosity causes smaller velocities due to changes in porous properties of a wave propagation medium. Nevertheless using differential methods of measurement, we can see this happening with a great degree of certainty, which allows fundamental insight into a dynamic nature of a medium presented in Fig. 2 and indicating influences of micropores on propagation of an elastic wave. This is not just a change in the velocity of its propagation but also of its absorption. Energy dissipation is expressed through component transformation of waves at the boundary between an elastic and gaseous medium of pores. Fig. 3 and 4 show dependencies of changes in the velocity of propagation of a longitudinal elastic wave in materials (both for solid cement and materials saturated with gas). Graphs have a linear dependence which shows elastic energy of waves is redistributed on concentrations of stresses and cracks. A dynamic modulus changes in the identical fashion except its sign which is also indicative of residual resources of a cement concrete pavement.

Conclusions

1.The authors suggest the use of the method of acoustic emission based on reading elastic wave signals arising as microdefects occur in the structure of a material under the impact of mechanical loads and allowing detection of defects as they emerge.

2.The designed graphs show that the velocity of propagation of an elastic acoustic wave decreases as a material becomes more porous and dynamic connections between the components of a medium increase. There is a dependency of the velocity of waves on the density за materials: an increase in the latter causes a decrease in the former.

3.The developed physical and mathematical model of the formation of elastic waves of acoustic emission as the microstructure of a cement concrete material fails, it allows one to address further performance and residual resource of an airfield pavement. The connection identified between the characteristics of propagation of elastic waves and physical and mechanical properties of a medium contributes to the accuracy of predicting possible failures.

References

1.Belyx, A. G. Rasprostranenie udarnyx voln v betonnyx pokrytiyax ae'rodroma pri silovom vozdejstvii kolesnyx opor vozdushnyx sudov. / A. G. Belyx, L. A. Kukarskix // Sb. st. Mezhdunar. nauch. in-ta Educatio. — 2014. — № 4. — S. 128—131.

2.Bykovcev, G. I. O rasprostranenii voln v uprugo-vyazko-plasticheskoj srede / G. I. Bykovcev, N. D. Vervejko // Inzhenernyj zhurnal MTT. — 1966. — № 4. — S. 111—123.

61

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

3.Vasil'ev, N. E. Ae'rodromnye pokrytiya: sovremennyj vzglyad / N. E. Vasil'ev, V. A. Kul'chickij, V. A. Mokogonov. — M.: Fiz.-mat. lit., 2002. — 528 s.

4.Grushko, I. M. Voprosy teorii struktury, prochnosti i razrusheniya betonov / I. M. Grushko, V. D. Altuxov // Texnologicheskaya mexanika betona: sb. nauch. tr. — Riga: Rizhskij politexnich. in-t, 1986. — S. 15—29.

5.Zajcev, Yu. V. Modelirovanie deformacii i prochnosti betona metodami mexaniki razrusheniya / Yu. V. Zajcev. — M.: Strojizdat, 1982. — 196 s.

6.Lange, Yu. V. Akusticheskie nizkochastotnye metody i sredstva kontrolya mnogoslojnyx konstrukcij / Yu. V. Lange. — M.: Mashinostroenie,1991. — 276 s.

7.Nigmatulin, R. I. Udarnye volny i fazovye prevrashheniya v zheleze / R. I. Nigmatulin // Prikladnaya mexanika i texnicheskaya fizika. — 1976. — № 5. — S. 128—135.

8.Rossixin, Yu. A. O rasprostranenii voln v uprugo-vyazko-plasticheskoj srede / Yu. A. Rossixin // Prikladnaya mexanika. — 1969. — T. V, vyp. 5. — S. 82—88.

9.Semashko, N. A. Akusticheskaya e'missiya v e'ksperimental'nom materialovedenii / N. A. Semashko, V. I. Shport. — M.: Mashinostroenie, 2002. — S. 32—36.

10.Tomas, T. Plasticheskoe techenie i razrushenie v tverdyx telax / T. Tomas. — M.: Mir, 1964. — 308 s.

11.Biot, M. A. Theory propagation of elastic waves in a fluid-saturated porous solid. I. Low-Frequency Range / M. A. Biot // Journal of the Acoustical Society of America. — 1956. — V. 28, N 2. — P. 168—178.

12. Hamstad, M. A. Effects of lateral dimensions on acoustic emission signals from dipole sources / M. A. Hamstad, A. O. Gallagher, J. Gary // Journal of acoustic emission. — 2007. — V. 19. — P. 258—274.

13.Krajcinovich, D. Statistical Damage Mechanics. Part I: Theory / D. Krajcinovich, A. Rinaldi // Applied Mechanics. — 2005. — V. 72, N 1. — P. 76—85.

14.Theobald, P. Velocity sensitivity calibration of AE sensors using the through wave method and laser interferometry [E'lektronnyj resurs] / P. Theobald, R. Pocklington // EWGAE—2010. — Vienna, 2010. — Rezhim dostupa: http://www.ndt.net/article/ewgae2010/papers/54_Theobald.pdf.

62

Issue № 1(29), 2016 |

ISSN 2075-0811 |

UDC 625.084

R. V. Kupriyanov1, V. A. Luzgachev2, A. F. Zubkov3

DETERMINING THE TEMPERATURE OF THE ASPHALT MIX

DURING THE CONSTRUCTION

OF ASPHALT CONCRETE NON-RIGID PAVEMENT

Tambov State Technical University

Russia, Tambov, tel.: (4752)63-09-20, e-mail: r.kupriyanoff@yandex.ru 1PhD student of Dept. of Urban Construction and Roadways

2PhD in Engineering, Assoc. Prof. of Dept. of Natural Resources and Environmental Protection 3D. Sc. in Engineering, Prof., Assoc. Prof. of Dept. of Urban Construction and Roadways

Statement of the problem. The lack of analytical expressions for calculating the temperature of the hot mix taking into account the simultaneous influence of various factors, does not allow one to specify the duration of technological processes of construction of road surfaces the non-rigid type. Therefore, for the proper organization of construction of laying of hot asphalt mixes and processes the laying and compaction within the specified temperature ranges, one must identify the dependency, which enables the determination of the temperature of the hot mixture taking into account the effect of all of these factors.

Results. In the article the mathematical dependence of the factors affecting the cooling rate of the hot asphalt mix, which resulted in the calculated dependence for determining the temperature of the hot asphalt mix at some point in time is identified. The influence of the thickness of a layer, air temperature, wind speed, temperature of the mix during a technological process in designing nonrigid road pavements is established. An analytical dependence to calculate the temperature of the hot mix considering the time of cooling, weather conditions and construction parameters of road pavement is obtained.

Conclusions. The dependence used to calculate the temperature of the mix, taking into account the temperature of the mixture, wind speed, thickness of the stacked layer, the air temperature at a specific point in time helps one to account for the influence of the time of technological processes on the construction of non-rigid road pavements.

Keywords: temperature, asphalt mix, thickness of the layer, wind speed.

Introduction

The quality of the construction of non-rigid pavements depends on the properties of a material and compliance to the requirements concerning industrial laying of hot asphalt mixes.

© Kupriyanov R. V., Luzgachev V. А., Zubkov А. F., 2016

63

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

The analysis of technologies employed in the construction of pavements showed that choice of machinery and their operation modes depend on the properties of a material that are characterized with the temperature of the hot mix [1—5]. The current guidelines and regulations specify the temperature of making, laying and compacting hot mixes in the construction of asphalt concrete pavements [6, 7].

The practice of construction of roadways shows that depending on specific working and weather conditions, the cooling rate of the hot mix layer in a pavement can vary, which affects times spent on laying, compaction and thus the output quality. Current regulations on the temperature of the hot mix depending on weather conditions and construction parameters of pavements are underpinned by experimental data and do not allow for the effects of the mix temperature at a certain point in the production affected by a number of specific weather and industrial factors [8].

1. Identifying factors influencing cooling of an asphalt concrete mix. Experimental studies show that cooling of a hot asphalt concrete mix of a pavement is exponential regardless of the composition, air temperature and wind speed [9]. Road pavements are known to heat due to solar radiation with their temperatures given by the formula [10]

tп 1,3tв 7, |

(1) |

where tв is the air temperature, °С.

This dependence allows one to determine the temperature of a paving surface. In their research B.I. Ladygin and N.V. Gorelysheva do so by introducing a coefficient allowing for effects of the temperature of the base course while paving is being laid [5, 10].

The construction time of non-rigid pavements considering the air temperature and thickness of a pavement layer is calculated [2]. The suggested construction times allow for a specific temperature of a mix when it is being laid notwithstanding that it may vary considerably on site as well as shortly after the work commences (Table 1).

|

|

|

|

|

|

|

|

|

Table 1 |

|

Effect of the air temperature and thickness of a paving on the laying times |

|

|||||||

|

|

|

|

|

|

|

|

|

|

Thickness of an |

|

|

Maximum time of laying and compaction at the wind speed of over |

||||||

asphalt concrete |

|

|

|

|

3—4 m/seс and air temperature, min |

|

|||

layer, сm |

|

|

|

|

|

|

|

|

|

|

0—2 ºС |

|

4—5 ºС |

|

8—10 ºС |

13—15 ºС |

18—20 ºС |

23—25 ºС |

|

|

|

|

|

|

|

|

|

|

|

3—4 |

|

13—15 |

|

16—18 |

|

19—21 |

22—24 |

25—27 |

30—32 |

|

|

|

|

|

|

|

|

|

|

5—6 |

|

18—22 |

|

24—27 |

|

28—30 |

32—35 |

37—40 |

42—45 |

|

|

|

|

|

|

|

|

|

|

8—10 |

|

43—46 |

|

52—58 |

|

63—68 |

71—77 |

80—90 |

95—110 |

|

|

|

|

|

|

|

|

|

|

64

Issue № 1(29), 2016 |

|

ISSN 2075-0811 |

The pre sented dat a allow for a whole r ange of factors contri buting to th e construction at a

specified air temp erature. In practice th e influenci |

g factors c an vary greatly, which would |

||

impact work times. No analytical depend ence in the |

calculatio n of the te |

perature of the hot |

|

mix co sidering a whole range of factor s makes it impossible to specify times of technologi- |

|||

cal processes of n on-rigid p avement surfacing. T |

erefore in order for |

the construction of |

|

roadway surfacing using hot |

sphalt con crete mixes as well as laying and compactio n in spe- |

||

cified t emperature ranges to run smoothly, it is nece ssary to determine the |

temperature of the |

||

hot mix considering all of the |

above fact ors. Gener ally the dep endence of |

the temperature of |

|

the hot mix on wea ther and industrial factors can be as follows |

|

||

|

|

|

tсм f (tсмн; tв; ; h; ), |

(2) |

where tв is the air temperatur , °С; tсмн i an initial temperatur of a mix, °С; τ is a |

measure- |

|||

ment ti me, min; h is the thick |

ess of the hot mix lay er, сm; ν is the wind sp eed, m/seс |

|

||

Cooling |

of hot mi |

es is found |

to be a non-stationary thermal process [11]. Heat transfer is at |

|

its peak just prior |

o the distribution of t he hot mix along the r oadway base due to heat trans- |

|||

fer from |

the middle of a layer |

due to a heat transfer coefficient. Heat losses are com pensated |

||

for with |

heat transfer from the middle of a layer res ulting in th e heat insi de the layer |

to redi- |

||

stribute and cooling of a surfacing layer being speedier. Works are performed at po sitive air tempera tures and t heir time de pend on the air tempe rature.

2. Ana ysis of the result of mathemat cal modeling. In ord er to identify laws co ncerning cooling of a hot as phalt concrete mix in the constr ction of road surfacin g and common dependencies of the temperature of the hot mix on a range of fa ctors, ther mal proces ses were modeled using a software developed at the Department of Urban Construction and Roadways of Tambov State Tech ical University [12]. Fig. 1 and Table 2 present the r esults of

modeli ng the temperature of t he hot mix considering times at different air |

temperatures. |

||||

|

|

|

|

|

|

|

Temperature, ºС |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Time, min |

|

|

|

|

|

|

|

|

|

Fig. 1. Change in the temperature of a hot asphalt conc ete mix in ti |

e, |

|||

air temperature, 0С: 1 — 10; 2 — 0; 3 — 5; 4 — 10; 5 — 20; 6 — 30; 7 — 4 0; 8 — 50

65

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

Table 2

Distribution of temperature during cooling of the hot mix in time at different air temperatures

|

Time, min |

0 |

5 |

10 |

20 |

30 |

40 |

50 |

60 |

Dependence |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

–10 |

160 |

142 |

126 |

99 |

79 |

64 |

53 |

45 |

t = 160e-0,022τ |

°С |

|

0 |

160 |

143 |

128 |

102 |

84 |

70 |

59 |

52 |

t = 160e-0,02τ |

|

5 |

160 |

143 |

129 |

104 |

86 |

73 |

63 |

55 |

t = 160e-0,019τ |

|

temperature, |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

160 |

144 |

130 |

106 |

88 |

75 |

66 |

58 |

t = 160e-0,018τ |

|

|

20 |

160 |

145 |

132 |

110 |

93 |

81 |

72 |

65 |

t = 160e-0,016τ |

|

|

30 |

160 |

146 |

134 |

113 |

98 |

86 |

78 |

72 |

t = 160e-0,0147τ |

|

Air |

|

|

|

|

|

|

|

|

|

|

|

|

40 |

160 |

147 |

136 |

117 |

102 |

92 |

84 |

78 |

t = 160e-0,0133τ |

|

|

|

||||||||||

|

|

50 |

160 |

148 |

138 |

120 |

107 |

97 |

90 |

84 |

t = 160e-0,0119τ |

The above data suggest that regardless of the air temperature, the distribution of the temperature in time conforms to general laws and can be described with an exponential dependence. A correlation coefficient for all the equations ranges from 0,98 to 0,99. In order to identify the general laws of the influence of the air temperature on the temperature of the hot mix we will represent the data from Table 2 in relative units. It was found experimentally that the temperature of the hot mix changes most considerably following the distribution along the base depending on the thickness of a layer within 5 to 10 minutes after it has been laid (Table 3).

Table 3

Distribution of the temperature during cooling of the hot mix in time at different air temperatures

|

Time, min |

0 |

5 |

10 |

20 |

30 |

40 |

50 |

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

–10 |

1,27 |

1,13 |

1 |

0,79 |

0,63 |

0,51 |

0,42 |

0,36 |

|

|

|

|

|

|

|

|

|

|

|

°С |

|

0 |

1,25 |

1,12 |

1 |

0,80 |

0,66 |

0,55 |

0,46 |

0,41 |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

1,24 |

1,11 |

1 |

0,81 |

0,67 |

0,57 |

0,49 |

0,43 |

|

temperature, |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

10 |

1,23 |

1,11 |

1 |

0,82 |

0,68 |

0,58 |

0,51 |

0,45 |

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

1,21 |

1,10 |

1 |

0,83 |

0,70 |

0,61 |

0,55 |

0,49 |

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

1,19 |

1,09 |

1 |

0,84 |

0,73 |

0,64 |

0,58 |

0,54 |

|

Air |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

40 |

1,18 |

1,08 |

1 |

0,86 |

0,75 |

0,68 |

0,62 |

0,57 |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

1,16 |

1,07 |

1 |

0,87 |

0,78 |

0,70 |

0,65 |

0,61 |

|

|

|

|

|

|

|

|

|

|

|

66

Issue № 1(29), 2016 |

|

|

ISSN 2075-0811 |

Let us denote the |

obtained coefficient of the effect of the air temperature on the temperature |

||

of the hot mix Кв. Fig. 2 sho s the dependence of the coeffici nt of the effect of the air temperatur on the tem perature of the hot mix with its numerical va lues given by

Кт 0,799e0,0018tв , |

(3) |

where т is the co efficient of the effect o f the air te mperature, dimensionl |

ss value; t he corre- |

lation coefficient i 0,99; tв is the temperature of the air, °С. |

|

The ab ove Figure suggests t at as the a ir tempera ure increas es, Кв has more effect, which causes the cooling rate of the hot mix to reduce. It was noted that depending on a type of a mix an bitumen l abel, the te mperature o f making and laying i specified in guideline s. However, de pending o how far a roadway i s, the temperature of an asphalt concrete mi x as it is delivere d on site can be minimum as sp ecified by the guidelines [6, 7]. umerical v alues of the temperature of a mix as it is being c ooled in time depending on the temperatur e as it is delivere d on site is in Table 4.

Coefficient Km

|

|

|

|

|

Air Tempe |

rature, ºС |

|

|

|

|

|

|

||

Fig. 2 . Dependenc |

|

|

|

|

|

|

|

|

|

|

||||

of the coefficient of the ef fect of the air temperature on the temper ature of the hot mix |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 4 |

|

D istribution of |

the temperature of the hot mix in time a t different mix temperature s during layi ng |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Time, min |

|

0 |

|

|

|

10 |

|

20 |

30 |

40 |

50 |

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

180 |

1 2 |

|

147 |

|

120 |

100 |

87 |

77 |

|

69 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature of a mix during |

160 |

1 4 |

|

131 |

|

107 |

90 |

78 |

70 |

|

63 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

140 |

1 6 |

|

115 |

|

95 |

80 |

70 |

63 |

|

57 |

||||

laying, 0С |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 |

1 9 |

|

99 |

|

82 |

70 |

62 |

55 |

|

51 |

|||

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

91 |

|

83 |

|

70 |

60 |

53 |

48 |

|

44 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

67

Scientific Herald of t he Voronezh State University o f Architecture and Civil Engineering. Construction and Architecture

In orde to identify the general law of th |

effect of the temperature of a mix delivered on site, |

let us i ntroduce the coefficie t Ксм allo |

ing for th temperature of the hot mix as it is deli- |

vered on site and p resent num erical values of the temperature in relative u nits. Let us assume

the temperature of the mix as it is delivered to be 160 0С per unit. The tem peratures of |

the mix |

||||||||||||

in relative units are identified in Table 5. |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

Table 5 |

|

Distribution of the temperature of the hot mix in time |

t different te mperatures of the mix durin g |

||||||||||||

|

|

|

|

(in relative units) |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Time, min |

|

0 |

5 |

|

10 |

|

20 |

30 |

40 |

50 |

60 |

|

Ʃ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

180 |

1,13 |

1,122 |

|

1,118 |

|

1 ,112 |

1,107 |

1,108 |

1,04 |

1,1 |

|

1,12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tempera ture of a mix |

160 |

1 |

1 |

|

1 |

|

1 |

1 |

1 |

1 |

1 |

|

1,0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

140 |

0,87 |

0,87 |

|

0,88 |

|

0,88 |

0,8 |

0,89 |

0,90 |

0,9 |

|

0,87 |

|

during laying, 0С |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 |

0,75 |

0,75 |

|

0,76 |

|

0 0,77 |

0,7 |

0,78 |

0,80 |

0,8 |

|

0,75 |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

0,63 |

0,63 |

|

0,64 |

|

0,65 |

0,6 |

0,64 |

0,65 |

0,6 5 |

|

0,62 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

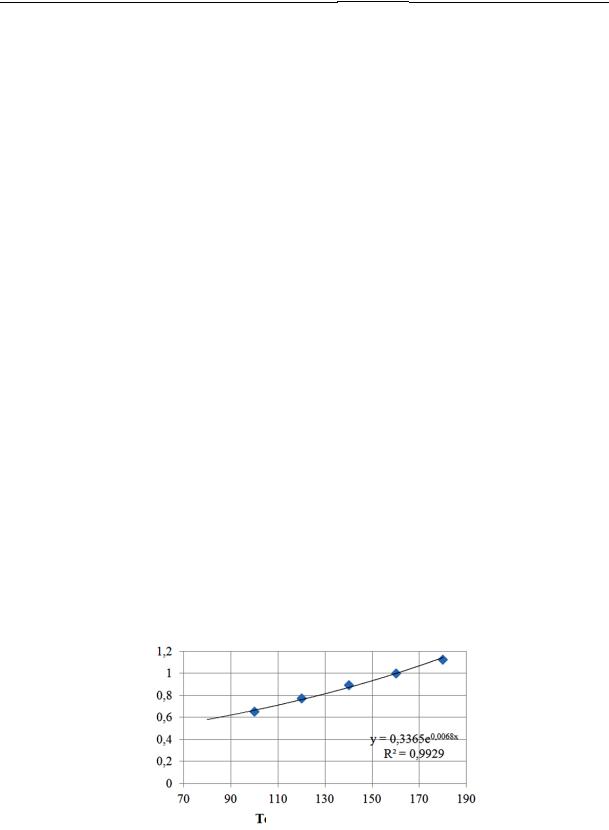

The ab ve data su ggests that regardless of the temperature of the mix deli vered on site, there is a gen eral law of cooling of the mix in time whic h can be accounted for by introdu cing the coefficient Ксм which is in Fig. 3. The numerical v lue of the coefficient Ксм is given by the followi ng

см 0,336e0,0068tсм , |

(4) |

where tсм is the tem perature o f the mix d ring laying; the correlation coefficient is 0,99.

KmCoefficient

Temperature of the mix, ºС

Temperature of the mix, ºС

Fig. 3. Dependence o f Ксм on the temperature o the mix as it is being distributed along a roadway ba e course

As asp |

alt concrete mixes ar e used, the cooling rate and thus the constru ction times depend |

on the |

wind speed. Current gu idelines specify restri tions on co nstruction times depe nding on |

68

Issue № 1(29), 2016 |

ISSN 2075-0811 |

the air temperature and the wind speed [8]. As the air temperature drops, current guidelines certify that the hot asphalt mix is paved onto the base course provided that the wind speed is not over than that as specified in Table 6 [6]. These restrictions depending on the wind speed are due to intensive heat transfer into the environment as the hot mix is distributed in a small layer on a large surfacing area which causes the cooling rate to increase and construction times to increase. The heat transfer coefficient is found to depend on the wind speed [9]. As a result of modeling of thermal processes in asphalt concrete mixes, the wind speed was found to influence the cooling rate of the mix considerably. Fig. 4 shows the cooling rate at different wind speeds and Table 6 –– the temperatures depending on time.

Temperature, ºС

0 m/sec 2–4 m/sec 3–8 m/sec 4–15 m/sec

Time, min

Fig. 4. Effect of the wind speed on the cooling rate of an asphalt concrete mix

Table 6

Change in the temperature of the hot mix in time at different wind speeds

Time, min |

|

0 |

5 |

10 |

20 |

30 |

40 |

50 |

60 |

|

|

|

|

|

|

|

|

|

|

|

0 |

160 |

127 |

115 |

95 |

80 |

70 |

63 |

57 |

|

|

|

|

|

|

|

|

|

|

|

2 |

160 |

122 |

110 |

89 |

75 |

65 |

58 |

53 |

|

|

|

|

|

|

|

|

|

|

|

4 |

160 |

117 |

105 |

85 |

71 |

61 |

54 |

49 |

Wind speed, m/sec |

|

|

|

|

|

|

|

|

|

6 |

160 |

113 |

100 |

80 |

67 |

58 |

51 |

46 |

|

|

|

|

|

|

|

|

|

|

|

|

8 |

160 |

109 |

96 |

76 |

63 |

55 |

48 |

44 |

|

|

|

|

|

|

|

|

|

|

|

10 |

160 |

106 |

92 |

73 |

60 |

52 |

46 |

42 |

|

|

|

|

|

|

|

|

|

|

|

15 |

160 |

98 |

84 |

66 |

54 |

46 |

41 |

38 |

|

|

|

|

|

|

|

|

|

|

In order to specify the effect of the wind speed on cooling of the hot asphalt concrete mix, let us introduce Table 6 in relative units (Table 7).

69

Scientific Herald of t he Voronezh State University o f Architecture and Civil Engineering. Construction and Architecture

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 7 |

|

Ch ange in the te mperature of the hot mix i n time at different wind speeds |

|

|

|||||||||||

|

|

|

|

|

(in relative units) |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ime, min |

|

|

0 |

5 |

10 |

20 |

|

30 |

40 |

50 |

|

60 |

Ʃ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

1 |

|

1 |

1 |

|

1 |

1 |

1 |

|

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

1 |

0,96 |

0, |

96 |

0,94 |

|

0,94 |

0 ,93 |

0,92 |

|

0,93 |

0,936 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

1 |

0,92 |

0, |

91 |

0,89 |

|

0,89 |

0 ,87 |

0,86 |

|

0,86 |

0,885 |

Wind speed, m/sec |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

1 |

0,89 |

0,87 |

0,85 |

|

0,84 |

0 ,83 |

0,81 |

|

0,81 |

0,84 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

1 |

0,86 |

0,83 |

0,8 |

|

0,79 |

0 ,79 |

0,76 |

|

0,77 |

0,795 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

1 |

0,83 |

0 |

,8 |

0,77 |

|

075 |

0 ,74 |

0,73 |

|

0,74 |

0,76 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

1 |

0,77 |

0, |

73 |

0,69 |

|

0,68 |

0 ,66 |

0,65 |

|

0,67 |

0,685 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The ab ve data su ggests that the wind sp eed influen ces the co ling rate of the hot mix and it increase s as does t he air mass displacement. Cooling complies ith an exp onential dep endence and is g eneral. Ta ing into account the temperature of the mix at the zero speed per unit, we obtain the depende nce of the w ind speed o n the cooli ng of the asphalt concr te mix (Fig. 5).

The nu merical val e of the coefficient is given by the equation

K |

0,984e 0,025v , |

(5) |

v |

|

|

where v is the win speed, m/ seс; the correlation coe fficient is 0 ,99.

Consid ring the specified stru cture of a oadway surfacing, the thickness of a layer can vary. According to the guidelines, a minimum thickness for the upper layer of a surfacing is 0,03 m and for the lower layer 0,08 [13]. Thus the cooli ng rate of t he hot mix and thereb y paving times a re different. Fig. 6 shows the dist ribution of the temper ture of the hot mix de pending on the thickness of a paved la yer at the mix tempera ure during laying 160 0С.

Coefficient Кv

Wind speed, /sec

Fig. 5. Co fficient Кv allowing for th effect of the wind speed

70