Учебное пособие 2113

.pdf

Russian Journal of Building Construction and Architecture

According to Fig. 11, the required modulus of elasticity of the pavement depends on the group of an estimated load and a road category. A correlation between a road category and a minimum value of the elasticity modulus depending on a load group is identified. The numerical value of the required elasticity modulus of a road structure considering a load group for any road category can be given by the dependencies below, MPa:

–– according to the Industrial Road Guidelines (ОДН) 218.046-01:

the estimated load group А1:

Еупр 10К2 24К 215,

the estimated load group А2:

Еупр =-2.5К2 -10.5К +282, |

(16) |

the estimated load group А3:

Еупр =-2.5К2 -16.5К +327.5;

––Preliminary National Standards (ПНСТ) 265-2018:

Еупр =-13.75К2 +43.25К +298.75,

where К is a road category. The correlation coefficient of the equations is 0.98.

The analysis of the data in Fig. 11 and the dependencies (16) showed that regardless of the load, the required elasticity modulus of a road structure is governed by a general regularity (Fig. 12).

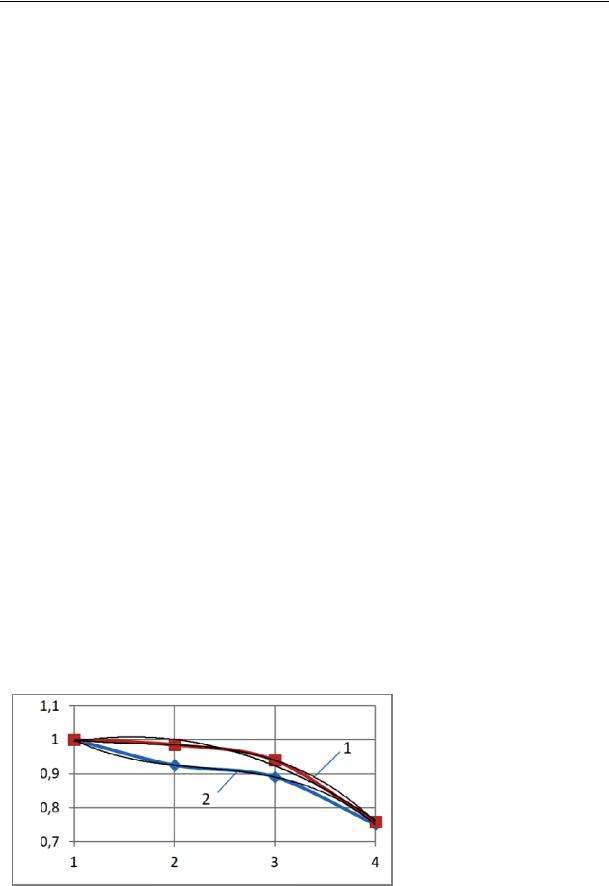

In order to obtain the general dependence of the required elasticity modulus of a road category, the dependences (17) are presented in relative values assuming the elasticity modulus of road category I as a unit. Let us denote the accepted value by the coefficient of an effect of a road category on the elasticity modulus Кк.

Coefficient, Kк

1 is the Preliminary National Standards (ПНСТ) 265-2018,

2 is the Industrial Road Guidelines (ОДН) 218.046-01

Road category

Fig. 12. Dependence of the coefficient of an effect of a road category on the elasticity modulus

80

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

The numerical value of the coefficient Кк can be given by the following dependencies: –– for the Industrial Road Guidelines (ОДН) 218.046-01:

Кк =-0.0242К3 +0.165К2 -0.4008К +1.26; |

(17) |

–– for the Preliminary National Standards (ПНСТ) 265-2018: |

|

Кк 0.0177К3 0.0908К2 0.164К 1.0909, |

(18) |

where К is a road category. The correlation coefficient of the equations is 0.98.

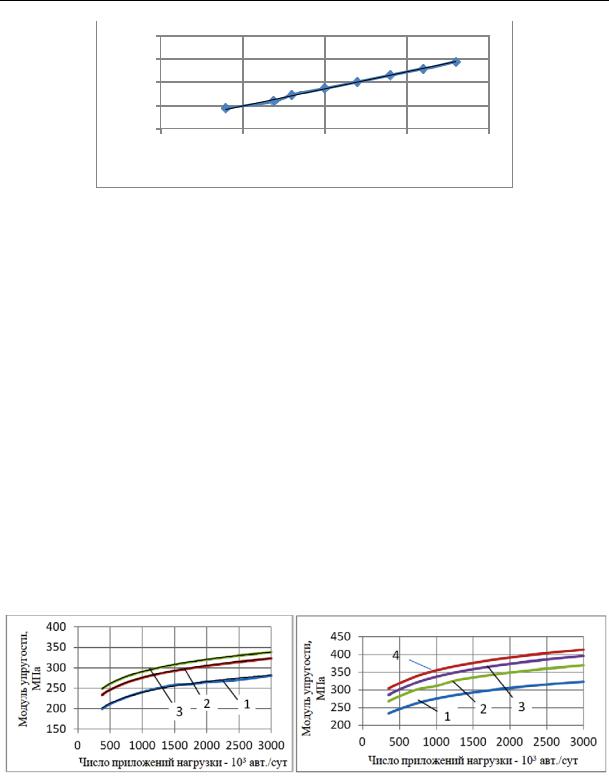

The thickness of a road surface affects the required elasticity modulus and depends on a transport load. The documents Preliminary National Standards (ПНСТ) 265-2018, Set of Guidelines (СП) 34.13330.2012 recommend laying non-rigid surfacing layers with the thickness of 0.10––0.12 m on the condition that the thickness of a structural layer must be at least twice the size of the largest fraction of a mineral material. Based on these recommendations, Fig. 13 shows the dependence of the required elasticity modulus Етр on the thickness of the upper surfacing layer.

Required elasticity modulus, MPa

Thickness of a surfacing layer, m

Fig. 13. Dependence of the required elasticity modulus Етр on the thickness of the upper surfacing layer

The numerical value of the required elasticity modulus considering the thickness of the upper surfacing layer is given by the following dependence:

Етр =171ln Нсл +609.7, |

(19) |

where Нсл is the thickness of an asphalt concrete surfacing layer, m. The correlation coefficient of the equations is 0.99.

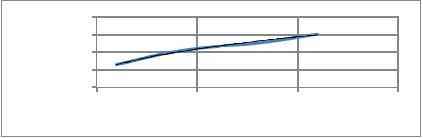

Let us represent this dependence in relative values assuming the required elasticity modulus in a surfacing layer with the thickness of 0.12 m per unit, it is denoted by Кн (Fig. 14).

According to Fig. 14, between the coefficient Кн and the thickness of a surfacing layer there is a directly proportional relationship which takes the following the form:

Кн =7.25Нсл +0.124, |

(20) |

where Нсл is the thickness of a surfacing layer, m. The correlation coefficient of the dependence is 0.999.

81

Russian Journal of Building Construction and Architecture

Coefficient, Kн

Thickness of a surfacing layer, m

Fig. 14. Dependence of the coefficient Кн on the thickness of a surfacing layer

Thus the dependence of the required elasticity modulus of a pavement on a traffic load considering the thickness of a pavement layer, road category, load group and traffic intensity can be given by the dependencies presented below, MPa:

–– according to the Industrial Road Guidelines (ОДН) 218.046-01:

Етр = 230 Кп Кгн Кн Кк КN , |

(21) |

–– according to the Preliminary National Standards (ПНСТ) 265-2018: |

|

Етр =320 Кп Кгн Кн Кк КN . |

(22) |

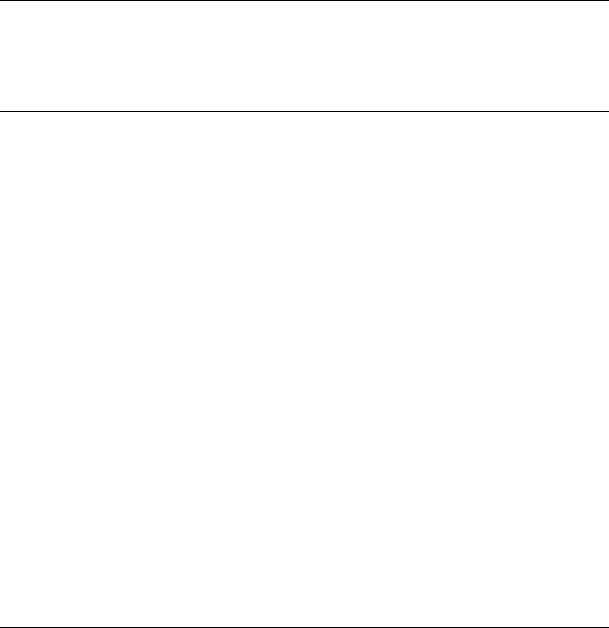

4. Results of the calculation of the required elasticity modulus of a pavement. Fig. 15 shows the dependencies of the minimum elasticity modulus of a pavement on the traffic intensity for road category II with a surfacing layer with the thickness of 0.12 m and different load groups calculated according to the dependencies (21), (22).

|

modulus, |

|

|

modulus, |

|

||

|

MPa |

|

|

MPa |

|

||

|

Elasticity |

|

|

Elasticity |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Number of the load applications, 103 cars/day |

||||

|

|

|

Number of the load applications, 103 cars/day |

|

|

|

|

|

|

|

a) |

|

|

|

b) |

Fig. 15. Dependence of the minimum elasticity modulus of a roadway surfacing for technical road category II on the number of load applications: а) for the loads А1; А2; А3 estimated according to the Industrial Road Guidelines (ОДН) 218.046-01; b) at the estimated load (pressure on a surfacing): 1 — 0,6; 2 — 0,8; 3 — 0,9; 4 — А3 estimated according to the Preliminary National Standards (ПНСТ) 265-2018

82

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

According to Fig. 15, regardless of the load group, the required elasticity modulus varies considerably in the range of traffic intensity from 500.000 to 1.000.000 load applications. An increase in the number of load applications for load group A1 from 500.000 to 1.000.000 requires that in the elastic modulus by 12.2 % and when the load on A2 and A3 changes, it is 12.3––13.8 % and 16.8––18.8 % respectively. As the number of load applications keeps growing, the elastic modulus varies from 3.5 to 4.7 %.

Conclusions

1.The analysis of the regulatory documents GOST (ГОСТ) 32960-2014 and the Preliminary National Standards (ПНСТ) 265-2018 showed that the axial load of more than 12 tons is not account for while calculating a permissible elastic deflection and this load is typical of modern heavy-duty vehicles.

2.The required elasticity modulus of a pavement depends on a pavement load and traffic intensity. An increase in the number of load applications for load group A1 from 500.000 to 1.000.000 requires an increase in еру module by 12.2 % and with a change in load to A2 and A3 —12.3––13.8 % and 16.8––18.8 % respectively.

3.The established dependencies (21) and (22) make it possible to perform an objective evaluation of the strength characteristics of pavement (the elasticity modulus of a pavement according to a permissible elastic deflection) while monitoring a road considering the traffic flow parameters, a road category and an overall pavement structure.

References

1.Babkov V. F. Avtomobil'nye dorogi. 3-e izd. pererab. i dop. [Motor road]. Moscow, Transport Publ., 1983. 280 p.

2.Zubkov A. F. Analiz metodov razrabotki tekhnologicheskikh protsessov uplotneniya dorozhnykh pokrytii iz goryachikh asfal'tobetonnykh smesei [Analysis of methods for developing technological processes for compacting road surfaces from hot asphalt concrete mixtures]. Vestnik Tambovskogo gosudarstvennogo tekhnicheskogo universiteta, 2006, vol. 12, no. 4—2, pp. 1158—1161.

3.Zubkov A. F. Opredelenie vozmozhnoi prodolzhitel'nosti uplotneniya pokrytii nezhestkogo tipa pri stroitel'stve avtomobil'nykh dorog [Determination of the possible duration of compaction of non-rigid coatings in the construction of roads]. Vestnik Tambovskogo gosudarstvennogo tekhnicheskogo universiteta, 2006, vol. 12, no. 3—2, pp. 806—817.

4.Zubkov A. F., Odnol'ko V. G. Tekhnologiya stroitel'stva asfal'tobetonnykh pokrytii avtomobil'nykh dorog

[Technology of construction of asphalt concrete road surfaces]. Moscow, Mashinostroenie Publ., 2009. 223 p.

5.Kiryukhin G. N. Garmonizatsiya standartov na shchebenochno-mastichnyi asfal'tobeton [Harmonization of standards for macadamized asphalt concrete]. Dorogi i mosty, 2011, no. 2 (26), pp. 311—323.

6.Kiryukhin G. N. K voprosu o sovershenstvovanii normativnykh trebovanii k asfal'tobetonu [On the issue of improving the regulatory requirements for asphalt concrete]. Dorogi i mosty, 2017, no. 1 (37), p. 18.

83

Russian Journal of Building Construction and Architecture

7.Kiryukhin G. N. [About preliminary national standards for asphalt concrete]. Sbornik statei i dokladov ezhegodnoi nauchnoi sessii «Assotsiatsiya issledovatelei asfal'tobetona» [Collection of articles and reports of the annual scientific session " Association of asphalt concrete researchers»]. Moscow, MADI Publ., 2018. P. 92—101.

8.Matvienko F. V., Kanishchev A. N., Volkov V. V. Modelirovanie deformatsii dorozhnoi konstruktsii ot vozdeistviya transportnogo potoka [Modeling of road structure deformation from the impact of traffic flow].

Nauchnyi vestnik Voronezhskogo GASU. Stroitel'stvo i arkhitektura, 2009, no. 3, pp. 67—72.

9.Matvienko F. V., Kanishchev A. N., Mel'kumov V. N., Volkov V. V. Prognozirovanie velichiny neobratimoi deformatsii dorozhnoi konstruktsii ot vozdeistviya transportnogo potoka [Forecasting the magnitude of irreversible deformation of road structures from the impact of traffic flow]. Nauchnyi vestnik Voronezhskogo GASU. Stroitel'stvo i arkhitektura, 2010, no. 3, pp. 81—92.

10.Radovskii B. S. Metody proektirovaniya sostava asfal'tobetonnykh smesei v SShA [Methods for designing the composition of asphalt concrete mixtures in the United States]. Dorozhnaya tekhnika, 2006, p. 68.

11.Radovskii B. S. Kontseptsiya vechnykh dorozhnykh odezhd [The concept of perpetual pavements].

Dorozhnaya tekhnika, 2011, no. 4, pp. 132.

12.Radovskii B. S., Merzlikin A. E. Otsenka pogreshnostei, voznikayushchikh pri raschete nezhestkikh dorozhnykh odezhd [Estimation of errors that occur when calculating non-rigid road surfaces]. Dorogi i mosty, 2016, no. 1 (35), p. 6.

13.Sal' A. O., Zolotarev V. A., Radovskii B. S., Il'ev E. B. Raschetnye kharakteristiki asfal'tobetonov primenitel'no k VSN 46-72 [Calculated characteristics of asphalt concrete in relation to BCH 46-72]. Avtomobil'nye dorogi, 1977, no. 5, p. 24.

14.Sil'yanov V. V., Domke E. R. Transportno-ekspluatatsionnye pokazateli gorodskikh dorog i ulits [Transport and operational indicators of urban roads and streets]. Modcow, Akademiya Publ., 2007. 352 p.

15.Chernyakov P. S., Zubkov A. F. [Regularities of changes in the main transport and operational characteristics of roads]. Trudy 5-i Mezhdunarodnoi nauchno-prakticheskoi konferentsii «Ustoichivoe razvitie regiona: arkhitektura, stroitel'stvo, transport» [Proc. of the 5th International scientific and practical conference "Sustainable development of the region: architecture, construction, transport"]. Tambov, Izd-vo Pershina R. V., 2018. P. 306—310.

16.Zubkov A. F., Ledenev V. I., Kupriyanov R. V. A Study of Temperature Modes and Strength Characteristics of Stone-Mastic Asphalt. Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture, 2014, no. 1 (21), pp. 54—64.

17.Zubkov A. F. Comparative Estimation of Parameters of Road Rollers of Static and Vibrating Action Subject to Effect of Compaction When Constructing Road Carpets of Nonrigid Type. Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture, 2009, no. 2 (2), pp. 43—53.

18.Kuprianow R., Andrianow K., Zubkow A., Plewa A. Analiza Zmian Temperatury Ukladanych Warstw Z Mieszanek Mineralno-Asfaltowych W Strefie Spoiny Podluznej. Budownictwa i Inzynierii Srodowiska, 2015, no. 3, pp. 113—117.

19.Kupriyanov R. V., Luzgachev V. A., Zubkov A. F. Determining the Temperature of the Asphalt Mix During the Construction of Asphalt Concrete Non-Rigid Pavement. Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture, 2016, no. 1 (29), pp. 63—74.

20.Plewa A., Belyaev P. S., Andrianov K. A., Zubkov A. F., Frolov V. A. The Effect of Modifying Additives on the Consistency and Properties of Bitumen Binders. Advanced Materials and Technologies, 2016, no. 4, pp. 35—40.

84

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

DOI 10.25987/VSTU.2020.45.1.007

UDC 625.711.84

Y. V. Shtefan 1, B. A. Bondarev 2

RISK MANAGEMENT IN REQUIREMENTS OFTHE ISO STANDARDS

IN RELATION TO LOGGING ROADS

Moscow Automobile and Road Construction State Technical University (MADI) 1

Russia, Moscow

Lipetsk State Technical University 2

Russia, Lipetsk

1 PhD in Engineering, Assoc. Prof., Department of Production and Maintenance of Automobile

and Road Building Machines Faculty of Road and Technological Machines, tel.: +7 (499) 155-03-86, e-mail: shtephan_y_v@mail.ru

2 D. Sc. in Engineering, Prof., Department of Construction Materials, tel.: +7 (474) 232-80-83, e-mail: ialex-86@mail.ru

Statement of the problem. The article considers the scientific bases for developing a system of assessing and standardizing risks in the construction and operation of logging roads within the framework of developing the existing logging road network in the Russian Federation. Regulatory documents in the sphere of managing and assessing technological and parametric risks are analyzed.

Results. The principles of standardizing the acceptable level of hazard are considered and approaches by different scientists and regulatory documents to risk calculation in the requirements on technical regulation are compared. A new approach is developed to standardize the acceptable quality parameters which nobody has ever used to assess parametric risks in relation to logging roads.

Conclusions. A scientifically based technology is proposed to calculate the acceptable risk level of a new or of an operating logging road and ways to compensate for residual risks. Ways are suggested of adequate risk reduction in assessing safety of the logging road design conditions with account of the probability of logging truck losing its stability. We are trying to improve the existing system of developing construction and reconstruction projects for existing logging roads thorough their conformity to international risk assessment requirements. That is why our conclusions include one on the front-end use of world-famous geographic information systems which are still scarcely used in domestic practice, particularly for logging roads. They will be instrumental in keeping track of different factors that could entail an increase in risks not considered in projects.

Keywords: risk-management, logging roads, risk assessment, risk theory, critical factors.

Introduction. According to the Constitution and International Agreements of the Russian Federation (Agreement on Technical Barriers to Trade in the WTO (Appendix 9); Protocol on Technical Regulation within the Eurasian Economic Union (EurAsEC) from 05.29.2014;

© Shtefan Y. V., Bondarev B. A., 2020

85

Russian Journal of Building Construction and Architecture

Treaty on the Establishment of EurAsEC; Decision of the Technical Commission of the Customs Union of April 7, 2011, no. 621), risk assessment is deemed as a service emerging from the enforcement of the Federal Law “On Accreditation in the National Accreditation System”. Presently, all the regulatory documents regarding technical regulation call for risk assessment techniques at all stages of a life cycle. The more similar this assessment is to the design stage, the lower will be costs of risk compensation during operation of a forest road. Thus approval and adoption of a forest road project is considered to be the most similar to designing a forest road, or in terms of technical regulation, time when of a forest road project is released. Therefore it is essential to develop a methodology for standardizing acceptable risk levels in order to decide as to whether a project complies with the requirements of technical regulations in terms of risks. However, there are currently no methods in both domestic and foreign practice [18, 19, 21, 22, 24, 27, 28] regarding risk assessment in forest road design, all sources of hazards and threats for forest roads are not identified, there are no experts in the field of identification, assessment and standardization of acceptable risk levels in relation to a forest road.

Hence risk assessment should be performed by specialists on risk hazard in technical regulation (TR) of construction, transport, forestry industry, road safety, building materials, geology, etc. It would be hugely beneficial if these specialists were trained risk assessment specialists or held PhD/doctoral degrees. It is only in this case that timely assessment with risk calculations could contribute to improving safety of forest roads and meet the requirements of Federal Law No. 184-FL (ФЗ) “On Technical Regulation”. In this paper the authors seeks to identify sources of hazards, to set forth a methodology for assessing and standardizing acceptable risk levels in relation to a forest road as well as to summarize the experience of risk management and bring to designers’ attention the identified sources of hazards for their timely consideration and due adjustments in forest road projects.

The probabilistic-theoretical approach to assessing technical and environmental risks relies on the probabilistic nature of the investigated parameters for TR objects. The known basic methodological principles for employing this approach to assessment and direct calculation of risks to all stages of a life cycle of forest roads and their structures are critical for quantitative calculation and risk analysis. Therefore according to the guidelines and regulations, the development of a scientifically based approach to assessing, calculating and standardizing technical risks for forest highways is an extremely relevant task facing modern scholars.

Based on the experience of foreign standards and national requirements for risk management, a methodology should be developed for calculating and standardizing acceptable residual

86

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

risks associated with logging in order to better cater for customers’ interests in design and reconstruction of existing forest highways. Hence we set out to analyze the requirements of regulatory documents of the Russian Federation and foreign risk researchers and apply them in design, construction and operation of forest highways. After key risks had been identified, the requirements for their standardization were established using the well-known scientific school by Prof. V. V. Stolyarov. The methods for improving reliability in design of forest highways were set forth using the terminology of the new standard ISO 31000-2018 [1].

1. Functional and Parametric Calculations of the Risk Theory. Studies of factors contributing to the operational properties of forest highways were carried out by such scholars as A. V. Skrypnikov, T. V. Skvortsova, V. V. Stolyarov, etc. According to [16], efficiency of a forest road is determined by a level of technical and operational condition to ensure reliable and safe operation of forest transport at optimal costs. Expertise and effective performance in repairs and maintenance is critical for a year-round, uninterrupted, safe and convenient traffic at specific speeds and loads. There is thus an opportunity to optimize a turnaround time of forest highways according to the coefficient of economic functionality given by the following formula:

Kf = 1 – Cr / Cv, (1) where Cr is the cost of repairs, Cv is the cost of restoration.

Funding decisions are made based on the results of optimization that is aimed at maximizing the economic effect of repairs and restoration: if Кf = 0.6...1.0, repairs of specific areas of a highway are carried out; 0.4...0.6, major repairs are performed; 0...0.4, a state of emergency occurs.

The scholars in [10] showed the dependence of the economics of repairs of forest highways on transportation costs of construction materials and proposed a model for identifying the boundaries of the zones of action of suppliers of materials to allow for the probabilistic nature of material costs. Thus while using local industrial waste, construction and repairing costs see a dramatic reduction.

Safety measures on forest highways entail a combination of measures taken by designers during the construction. A designer of A forest road has to:

––determine the type of a road (major, temporary) considering its prospective congestion, dimensions of timber trucks, travelling opportunities;

––identify hazards and assess risks;

––eliminate hazards and possibly limit risks;

––apply additional devices, pavement reinforcement, etc. for protection against residual risks;

87

Russian Journal of Building Construction and Architecture

––inform and warn the user on the remaining risks;

––take additional safety measures into consideration.

All measures that are taken at the designing stage are prioritized over those by the consumer (user). The latter’s responsibility in terms of the use of measures for reducing the remaining risks is not discussed. Nevertheless the existing system for assessing compliance with the TR requirements and its methodological base cannot guarantee the quality of incoming construction materials even considering the transition to a new system of standardizing quality indicators in the regulatory guidelines to TR TS 014/2011 [2]. For reliability and longevity of forest highways, it is essential that safety measures are simple and do not interfere with the main purpose of the road, i.e., do not restrict the movement of timber trucks at certain times of the year and do not interfere with movement of heavy-duty equipment at forest road intersections with public roads. They must timely and appropriately ensure the passage of such equipment that could be predicted at the risk assessment stage. Otherwise, this might lead to security measures being avoided in order to achieve a desired outcome, e.g., at night, when it is difficult to identify who was in violation of the restrictions and prohibitions on the movement of heavy-duty equipment. Failure to danger damage involves any malfunction of a road structure or interruptions in its timely maintenance resulting in an accident. Risk reduction means iterative (repetitive) and several sequentially repeated actions that are needed to reduce risks. Ideally, these principles call for knowledge of purposes of major forest roads, their condition and information on accidents, documentation on road conditions, existing technologies for their construction and risk reduction and territorial conditions when roads are operated. A lot of scholars in Russia and abroad with forest highways seem to agree [10, 13, 19, 24, 25]. Design and conditions of forest roads, which are acceptable at this time, might become unsatisfactory if technological advances make it possible to increase the load or speed of logging trucks with a lower risk of loss of stability of a logging truck and defects (potholes, ruts, etc.). According to the recommendation of the authors [13, 24], it is necessary to work closely on the development and implementation in organizations of transport construction standards of organizations in the framework of regional and climatic requirements. They should be in line with the safety requirements for structures in terms of strength and stability, preservation of the carrying capacity based on acceptable risks to human life, animals, environment as well as property, i.e., forestry equipment.

Over the past 25 years, the Saratov State Technical University has been working on mathematical and economic and mathematical models for risk assessment to humans and environment for roads considering vehicle speeds [9, 11]. Under the guidance of the school by

88

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

Prof. V. V. Stolyarov, 20 models (techniques) were designed [20]. Let us present those that seem most relevant for forest roads.

1.Risks of an accident when hitting an obstacle on a concave and convex curves as well as movement in limited visibility and loss of lateral stability of a car on a road curve.

2.Risks of failure of pavement, discontinuity in the monolithic layer, excessive saturation of the soil in relation to optimal humidity and environmental risks (these models were developed by N. E. Kokodeeva) [9].

3.Risks of hitting a vehicle moving in front during braking, risks of overcoming climbs at a specified speed difference.

4.Risks of loss of investment returns in construction of two-lane roads, risks of changing the technical category of a road due to inaccuracy in evaluating traffic intensity.

5.Risks of traffic congestions at a specified marking length prohibiting overtaking.

6.Risks of failure of surfacing due to heaving.

7.Risks of drivers losing relevant information.

8.Risks of soil degradation.

9.Risks of exceeding an estimated flow rate by a large one.

10.Risks of snow skidding on a road.

11.Risks of loss of stability of supports and local erosion at a bridge crossing.

12.Risks of loss of visibility of a road surface and oncoming car in severe weather conditions.

13.Road design considering accident risks.

The authors of [9, 17, 20] also came up with a road classification according to degree of responsibility in the framework of the Federal Law 384-FL (ФЗ). They are divided into categories from 1 to 5 in compliance with the Industry Road Guidelines (ОДН) 218.046-01 [14].

Using the normal distribution law for the risk theory, formulas for identifying critical risks [17] of a dangerous parameter are obtained:

1) in the first case when the value A > Acr, the formula (2) is used, it is graphically presented in Fig. 1:

|

|

А А |

|

|

|

r 0.5 Ф |

|

cr |

, |

(2) |

|

|

|

||||

t |

|

σ2 |

σ2 |

|

|

|

|

||||

|

|

А |

Аcr |

|

|

where A is the mathematical expectation of the calculated or actual parameter of a structure; Acr is the same for the critical (minimum) design parameter where a failure probability is 50 %; σА and σАcr are mean square deviations of the current values of the parameters; Ф is the Laplace integral function.

89