Учебное пособие 2113

.pdf

Russian Journal of Building Construction and Architecture

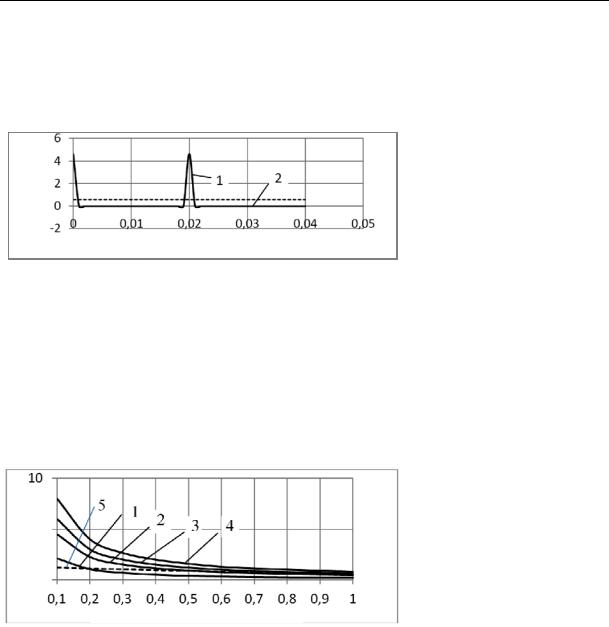

According to the data in Fig.10, as the stresses in the contact zone of the tire with the surface increase, so does the deformation of the laid material, which is the reason for a decrease in the compaction coefficient.

Deformation, mm

1 is the total deformation;

2 is the elastic deformation

Time of the cycle, s

Fig. 9. Deformations of the mix in the surfacing pothole under the tire load

As the machine with a reduced load passes again and again, the mix is compacted, which enhances its ability to resist external load, i.e., to increase the stiffness coefficient of the mix. An increase in the stiffness of the mix is characterized by an increase in the density, compaction coefficient, deformation modulus and elastic modulus of pavement.

Deformation, mm

Coefficient of stiffness, N/mm

1 is 0,21 МPа;

2 is 0,45;

3 is 0,6;

4 is 0,8;

5 is the elastic deformation

Fig. 10. Dependence of the deformation on the stiffness coefficient of the mix under varying stresses in the contact zone with the surfacing

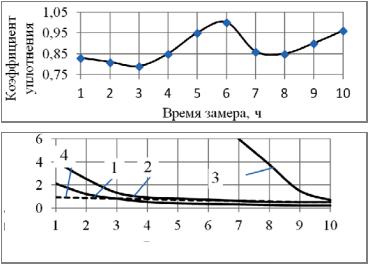

Fig. 11 shows combined graphs of changes in the coefficient of compaction of the roadway surfacing material and the deformation of the layer of the mix with different axial loads when vehicles move in time.

Fig. 11 shows that as the stress in the contact zone of the tire with the surface of the pothole increases, so does the deformation in the mix layer. When vehicles with an axial load exceeding the permissible limit in the tire contact zone with the pothole surface in the traffic stream, stresses occur that exceed the tensile strength of the material and thus decomposition of the laid material occurs, which causes the compaction coefficient to decrease.

50

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

The softening of the structure of the material (destruction) will take place under the following condition:

к , |

(10) |

where σк are the contact stresses under a pneumatic tire, МPа; [σ] is the strength limit of the compacted material, МPа.

Compaction |

|

|

|

coefficient |

|

|

|

|

|

|

1 is 0,21 МPа; |

|

|

Measurement time, h |

2 is 0,45 МPа; |

|

|

||

|

|

|

|

Deformation, |

|

3 is 0,6 МPа; |

|

|

4 is the elastic deformation, mm |

||

mm |

|

||

|

|

||

Measurement time, h

Fig. 11. Deformation of the mix layer under the axial load as vehicles move

When traffic flows with different axial loads move, given the formation of the structure of the bitumen-mineral mix, the deformation of the layer of the mix will depend on the load on the top layer of the pothole, which affects the value of the compression coefficient. The change in the coefficient of compaction of the layer of the mix will occur until the structure of asphalt is finally formed that is caused by complete removal of moisture from the layer of the mix.

Depending on the properties of the material in the surfacing pothole laid by means of the je- t-injection method and the transmitted load from vehicles, the development of elastic, plastic or elastic-visco-plastic deformations is possible, which characterizes the process of compaction of the laid material or its decompression. The condition for the development of deformations under the load from vehicles on the laid material in the surfacing pothole can be represented in the form of the following dependencies:

–– у |

|

у конт |

is the elastic deformation, |

|

||

–– конт |

у у |

is the plastic deformation, |

|

|||

–– у |

у 0,9 1,0 |

пр |

is the compaction, |

(11) |

||

|

|

|

|

|

|

|

–– х |

х [ сд] is the shift of the particles in relation to each other, |

|

||||

51

Russian Journal of Building Construction and Architecture

where [τсд] is the shear strength limit of the material, МPа; [σ] пр is the compressive strength of the material, МPа; σконт are the stresses in the contact zone of the tire and the material particle, МPа; σу and τу are the stresses in the material layer under the transport load.

Looking into the process of the contact of the particles of the mix with each other as they are being laid into the surfacing pothole under the transport load, we obtain analytical dependences that enable us to determine the stresses in the zone of contact of the particles [4, 5, 7]. The table shows the numerical values of the stresses in the zone of contact of the particles under the load from the vehicle tire considering the particle diameter of the mineral component of the bitumen-mineral mix.

Таble

Stresses in the zone of contact of the particles under the load of the vehicle tire

Diameter of the |

|

|

|

|

Stresses under the vehicle tire, МPа |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.21 |

|

0.45 |

|

0.6 |

|

0.8 |

|

1.0 |

||||||

particle, mm |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

σх |

|

σу |

σх |

σу |

σх |

|

σу |

σх |

|

σу |

σх |

|

σу |

|

|

|

|

|

|

||||||||||

2.5 |

−0.02 |

|

0.6 |

−0.05 |

1.2 |

−0.06 |

|

1.6 |

−0.09 |

|

2.7 |

−0.11 |

|

2.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.0 |

−0.04 |

|

0.8 |

−0.08 |

1.6 |

−0.10 |

|

2.2 |

−0.15 |

|

2.9 |

−0.18 |

|

3.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10.0 |

−0.05 |

|

1.1 |

−0.11 |

2.3 |

−0.15 |

|

3.1 |

−0.20 |

|

4.2 |

−0.25 |

|

5.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15.0 |

−0.12 |

|

1.3 |

−0.26 |

2.8 |

−0.35 |

|

3.7 |

−0.46 |

|

4.9 |

−0.58 |

|

6.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20.0 |

−0.11 |

|

1.5 |

−0.25 |

3.2 |

−0.33 |

|

4.3 |

−0.45 |

|

5.8 |

−0.56 |

|

7.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

According to the data presented in the table, as the load on the pavement increases, so do the stresses in the contact zone of the layer particles, which is in agreement with the results of modeling and experimental studies.

Conclusions

1.The results of the study are contrary to the current view that the use of the jet-injection method does not require additional compaction for laying material into a pothole.

2.The density and coefficient of compaction of the mix in the jet-injection method is ensured by the vertical deformation of the particles of the layer as the shear stresses do not ensure the movement of particles in the horizontal plane (τ < [τsd]). The compaction coefficients and water saturation of the samples do not meet the requirements of the regulatory guidelines (Ку = 0.81––0.82; water saturation of more than 10 %), which is confirmed by simulation results and experimental studies.

3.When vehicles are moving with a pavement load of up to 0.5 MPa, the process of compaction of the bitumen-mineral mix of the 5––10 mm fraction in the surfacing pothole following the laying by means of the jet-injection method is ensured.

52

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

4.The movement of vehicles with a load on pavement of more than 0.5 MPa results in the development of plastic deformations in the mix layer of the surfacing pothole that affects the compaction coefficient. Plastic deformation of the material in the pothole occurs due to compressive and shear stresses, they are sufficient to overcome the adhesion forces between the particles.

5.When laying bitumen-mineral mixes with 5––15 and 5––20 mm fractions, an increase in the density occurs during traffic with a load on pavement up to 0.35 MPa. With a further increase in the load on the surface of the pothole, plastic deformations occur in the mix layer, as the contact stresses between the particles are beyond the tensile strength of the material (σк > [σпр] and τ > τсд).

6.To ensure the required quality of repairs by means of the jet-injection method following the

laying of the mix, it is necessary to limit the axial load of vehicles on the mix layer in the surfacing pothole while the material structure is being formed.

References

1.Alferov V. I. Dorozhnye materialy na osnove bitumnykh emul'sii [Road materials based on bituminous emulsions]. Voronezh, Izd-vo Voronezh. gos. un-ta, 2003. 146 p.

2.Apestin V. K. O raskhozhdenii proektnykh i normativnykh srokov sluzhby dorozhnykh odezhd [About discrepancy of design and standard service life of road clothes]. Nauka i tekhnika v dorozhnoi otrasli, 2011, no. 1, pp. 18—20.

3.Gezentsvei L. B., Gorelyshev N. V., Boguslavskii A. M., Korolev I. V. Dorozhnyi asfal'tobeton. Izd-e vtoroe [Road asphalt concrete. 2ed]. Moscow, Transport Publ., 1985. 350 p.

4.Zubkov A. F. Analiz metodov razrabotki tekhnologicheskikh protsessov uplotneniya dorozhnykh pokrytii iz goryachikh asfal'tobetonnykh smesei [Analysis of methods for developing technological processes for compacting road surfaces from hot asphalt concrete mixtures]. Vestnik Tambovskogo gosudarstvennogo tekhnicheskogo universiteta, 2006, vol. 12, no. 4—2, pp. 1158—1161.

5.Zubkov A. F. Opredelenie vozmozhnoi prodolzhitel'nosti uplotneniya pokrytii nezhestkogo tipa pri stroitel'stve avtomobil'nykh dorog [Determination of the possible duration of compaction of non-rigid coatings in the construction of roads]. Vestnik Tambovskogo gosudarstvennogo tekhnicheskogo universiteta, 2006, vol. 12, no. 3—2, pp. 806—817.

6.Zubkov A. F., Andrianov K. A., Piletskii M. E. Raschet kontaktnykh napryazhenii pri ukladke i uplotnenii bitumomineral'nykh smesei pri remonte dorozhnykh pokrytii [Calculation of contact stresses when laying and compacting bituminous mixtures when repairing road surfaces]. Privolzhskii nauchnyi zhurnal, 2018, no. 1, pp. 64—71.

7.Zubkov A. F., Odnol'ko V. G. Tekhnologiya stroitel'stva asfal'tobetonnykh pokrytii avtomobil'nykh dorog

[Technology of construction of asphalt concrete road surfaces]. Moscow, Mashinostroenie Publ., 2009. 223 p.

8.Ivantsov V. A. [Physical and mechanical properties of mineral materials treated with emulsions]. Trudy SoyuzdorNII. Vyp. 34. Issledovaniya organicheskikh vyazhushchikh materialov i bitumomineral'nykh smesei dlya

53

Russian Journal of Building Construction and Architecture

dorozhnogo stroitel'stva [The Works Of Soyuzdornii. Vol. 34. Research of organic binders and bituminous mixtures for road construction], 1969, pp. 91—102.

9.Piletskii M. E., Zubkov A. F. Analiz sostoyaniya avtomobil'nykh dorog Tambovskoi oblasti i vybor tekhnologii dlya remonta vyboin na pokrytiyakh nezhestkogo tipa [Analysis of the state of roads in the Tambov region and the choice of technology for repairing potholes on non-rigid surfaces]. Nauchnyi vestnik Voronezhskogo GASU. Stroitel'stvo i arkhitektura, 2016, no. 1 (41), pp. 74—82.

10.Piletskii M. E., Zubkov A. F., Andrianov K. A., Didrikh I. V. Primenenie bitumomineral'nykh smesei pri remonte vyboin dorozhnykh pokrytii [The use of bituminous mixtures in the repair of potholes of road surfaces].

Privolzhskii nauchnyi zhurnal, 2017, no. 3 (43), pp. 50—57.

11.Piletskii M. E., Didrikh I. V., Zubkov A. F., Tugolukov E. N. Yamochnyi remont pokrytii nezhestkogo tipa in"ektsionno-struinym metodom [Patching of non-rigid coatings by injection-jet method]. Nauchnyi zhurnal stroitel'stva i arkhitektury, 2018, no. 1 (49), pp. 80—88.

12.Piletskii M. E., Zubkov A. F., Andrianov K. A., Makarov A. M. Svidetel'stvo o gosudarstvennoi registratsii programmy dlya EVM № 2017663676. Raschet deformatsii materiala pri deistvii dinamicheskoi nagruzki [Certificate of state registration of the computer program no. 2017663676. Calculation of deformation of a material under the action of dynamic load]. Data gos. registratsii v Reestre programm dlya EVM 08.12.2017.

13.Buza E., Omanovic S., Huseinovic A. Pothole Detection with Image Processing and Spectral Cluste-

ring. Proceedings of the 2nd International Conference on Information Technology and Computer Networks (ICTN '13). Antalya, Turkey, 2013. Р. 48—53.

14. Evaluation of Winter Pothole Patching Methods Repor. Final Report. Prepared by: Munir D. Nazzal, P. E. Sang-Soo Kim; The Ohio Department of Transportation, Office of Statewide Planning & Research State Job, 2014, no. 134724, pp. 13—17.

15.Griffith А. Improved Winter Pothole Patching. State Planing and Research Project, 1998, no. 538, pp. 11—13.

16.Hot Mix Asphalt Repair. Sitemap Pavement Resources Inc. Available at: http://pavementresources.com/hot- mix-asphalt-repair

17.Jones K. M. Wet Weather Pothole Repair. Edition Tehnical Quarterly of the Texas State Department of Highways and Public Transportation, 1988, February, pp. 1—4.

18.Plewa A., Belyaev P. S., Andrianov K. A., Zubkov A. F., Frolov V. A. The effect of modifying additives

on the consistency and properties of bitumen binders. Advanced Materials and Technologies, 2016, no. 4, pp. 35—40.

19.Villiers R. L. Maintenance engineering standards to fulfil the legal duty of road authorities towards saferoads. Dissertation presented for the Degree of Doctor of Philosophy (Stellenbosch University), March 2016.

246p. Available at: https://scholar.sun.ac.za

20.Wang P., Hu Y., Dai Y., and Tian M. Asphalt Pavement Pothole Detection and Segmentation Based on Wavelet Energy Field. Journal Mathematical Problems in Engineering, 2017, vol. 2017. 13 p. Available at: https://doi.org/10.1155/2017/1604130

54

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

DOI 10.25987/VSTU.2020.45.1.005

UDC 625.768.5

T. V. Samodurova 1, O. V. Gladysheva 2, N. Yu. Alimova 3, V. N. Peregudova 4

MONITORING OF SNOWFILLING ROADS SECTIONS —

INFORMATION MODELING

Voronezh State Technical University 1, 2, 3

Russia, Voronezh

Branch of Voronezh State Technical University in Borisoglebsk 4

Russia, Borisoglebsk

1 D. Sc. in Engineering, Prof. of the Dept. of Design of Highways and Bridges, tel.: +7 (743) 271-52-02, e-mail: samodurova@vgasu.vrn.ru

2 PhD in Engineering, Assoc. Prof. of the Dept. of Design of Highways and Bridges, e-mail: ov-glad@ya.ru 3 PhD in Engineering, Assoc. Prof. of the Dept. of Design of Highways and Bridges,

e-mail: natalimowa@ya.ru

4 PhD student of the Dept. of Design of Highways and Bridges, e-mail: lapusia2@yandex.ru

Statement of the problem. The problems of information modeling for monitoring of skidding road sections in winter season are discussed.

Results. As a skidding section, the road section in a ditch has been considered. The information model substantiation describing the geometrical parameters of a skidding road section is designed. Information resources characterizing the state of an external environment are described. Computational and analytical component of the information model is represented by means of the algorithm of obtaining about skidding road sections and need for snow removal.

Conclusions. It was concluded that information models could be designed that can be used at the maintenance stage of the road life cycle for organizing the operational management of snow removal.

Keywords: winter road maintenance, skidding section, monitoring, information modeling, level of development.

Introduction. According to the decree by the President of the Russian Federation, a list of new national projects up to 2024 has been defined in 12 strategically important directions, one of which is the “Safe and High-Quality Roads”. The national project proposes measures for improving traffic safety, preventing traffic accidents and reducing casualties. This is going to be achieved by means of developing information technology on highways –– intelligent transport systems, digitalization of road management.

© Samodurova T. V., Gladysheva O. V., Alimova N. Yu., Peregudova V. N., 2020

55

Russian Journal of Building Construction and Architecture

One of the priority areas for information technologies in the road sector is introducing the concept of information modeling providing an information model of a road object that functions as a common resource for obtaining information about it for making optimal decisions at all stages of its life cycle [12, 13].

The winter season is considered the most challenging in terms of traffic safety. Snow-covered sections of roads are particularly dangerous due to low coupling qualities of a road surface [4]. According to the regulatory documents, excavations are classified as highly prone to skidding [17]. Constant monitoring of such sections, predicting of snow drifts and timely snow removal is an urgent task serving to improve road safety.

The purpose of the study is to analyze and justify the information resources necessary to manage winter maintenance of snow-covered road sections from the point of view of information modeling. The objective of the investigation is a section of a road with a ditch.

1. Theoretical justification of information resources for monitoring snow-covered areas.

Technical monitoring of roads at the maintenance stage is aimed at systematic monitoring of their condition in order to timely detect current changes, preventing negative processes from happening as well as eliminating their consequences. In this case, the state of the object is predicted considered a mutual influence of an object and an environment.

The Russian national standards impose rigid requirements on winter maintenance of roads and regulate the thickness of snow deposits and time of their clearing following snowfalls and blizzards [16]. In order to ensure the best properties of roads in wintertime, it is the duty of road maintenance services to conduct work to combat snow deposits. The necessary material and technical resources such as road special equipment, time of commencement of work and its amount can be calculated using a quantitative assessment of snow deposits on a surface.

The authors previously conducted studies to identify the amount of snow accumulations in road ditches and of snow deposits in a roadway [7]. As during the winter season the amount of snow deposits within a road subgrade is constantly changing, studies were conducted on the dynamics of snow accumulation during this period [10, 20]. The growth of volumes blown during snowstorms and snowfalls, snow removed from the carriageway and roadsides during patrolling snow removal, and a decrease in periods in between blizzards due to weather factors, i.e., compaction and melting of snow, were calculated.

The viability of the models set forth by the authors was tested on snow-covered sections of roads of the Voronezh and Oryol regions through the course of experimental studies [9]. A comparison of the data obtained during snow measurements and the results of numerical modeling employing the models set forth by the authors showed that their convergence is over 85 %.

56

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

Thus, it was concluded that these models could be employed in order to investigate the dynamics of snow accumulation on roads during the winter season. However, currently considering the availability of technical tools, communications and computer technology in road maintenance units, it is possible to address practical problems at the stage of road maintenance based on the results of continuous monitoring of the operational status of ditches in wintertime [5].

A viable dynamic mathematical model describing snow accumulation on a snow-covered section of a roadway enables its operational status to be monitored in the winter on the condition that that there is information support, algorithms and models for processing and analyzing the information needed for making decisions.

The information model allows us to identify the operational state of a skidding area, to predict its likelihood in the future as well as to select a snow removal technology. The main objective of managing transport objects at the maintenance stage can be defined as providing the safety and efficiency of a road and road structures and maintaining their transport and operational condition in compliance with the requirements under the conditions of ensuring continuity and road safety in any period of a year. In winter maintenance of roads, due to an impact of an external environment, it is vital to consider management from the perspective of information provision. In this case, a generalized control scheme can be presented in the form that reflects the interaction of a few subsystems [8]: information-measuring, information-reference and telecommunication (communication systems). The scheme of the interaction of the subsystems is given in Fig. 1.

Communication system

|

|

Information-reference |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Management program |

||||||||||||||||

|

|

|

|

|

|

|

|

|

Management subject |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Executive |

|

|

|

|

|

|

|

|

|

Managing |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

Equipment, |

|

Developing |

||||||||

|

|

|

|

|

|

|

|

technology, |

|

|

a management |

|

||||||

|

|

|

|

|

|

|

|

|

resources |

|

|

effort |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

Information-measuring |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

External effects |

|

|

|

|

|

Management object |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control

Fig. 1. Major subsystems for managing roads at the maintenance stage (informational aspect)

57

Russian Journal of Building Construction and Architecture

To obtain the information on the external influences and the actual state of the control object (transport structure), an information-measuring subsystem is required. For winter maintenance of roads to run effectively, it is necessary to obtain operational information on weather parameters in the vicinity to the roads and information on the state of the road surface. The measurement of these parameters does not only describe the actual situation in the control object, but under certain conditions it also allows its change to be predicted.

An information and reference subsystem contains information on the regulatory state of the control object as prescribed in the national standards. It was previously assumed that the same subsystem should include digital databases describing the control object, i.e., the road and available resources (not shown in the diagram) [8]. However, at the current stage of development of information technologies, information on the control object should be its information model [12], some of its aspects are discussed in the article.

A control subsystem based on the analysis of the incoming information provides the choice of optimal control actions. Effective organization of work is not possible without reliable communication. This subsystem provides transfer of information from measuring devices and sensors to the processing center, allows recommendations on the choice of a particular technology to be transferred, the progress of their implementation to be monitored and the result to be recorded based on feedback.

Let us look at the implementation of the suggested scheme using the example of the organization of maintenance of a snow-covered road section with a ditch.

The dynamics of changes in the amount of snow deposits on slopes and road ditches at any time t was generally described by means of a dynamic model [10]:

|

|

, |

(1) |

Qотл(t) f Qснп(t); Qмет(t); Qуб (t); Qпот (t); t |

|||

where Qснп is the amount of snow during snowfalls, m3/m; Qмет is the amount of snow during blizzards, m3/m; Qуб is the amount of snow moved from the roadway and ditches during machine snow clearance, m3/m; Qпот is the amount of snow loss under the effect of weather conditions, m3/m; t is the time, h.

Each of the components of the model depends on multiple factors and is calculated depending on particular values [10].

A dynamic mathematical model that is sufficiently indicative of snow accumulation in a ditch allows for monitoring of the operational state of the skidding area in the wintertime on the condition that there is information support, algorithms and models for processing and analyzing the information needed for making decisions.

58

Issue № 1 (45), 2020 |

ISSN 2542-0526 |

All the factors affecting the operational state of the skidding area can be divided into internal (road) and external ones (describing the state of the environment) [8].

According to the functional purpose for the task of monitoring skidding of information modeling, it can consist of the following parts:

––object, which will include a description of a snow-covered road section;

––weather and climate, containing an actual description of and external environment and predictions of its changes;

––computational and analytical including calculations, analysis of results, predicting the condition of an object, selection of recommendations and technologies for prevention or elimination of snow drifts.

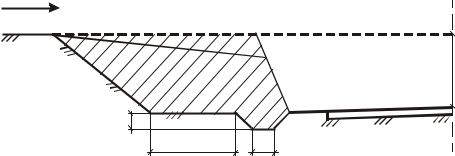

2. A geometric model of a snow-covered road section in a ditch. Skidding during snowstorms is determined by physical processes of a snow and wind flow around a transverse profile of the subgrade.

In order to monitor snow accumulation in ditches, geometric models describing a transverse profile of the subgrade can be employed [3, 22]. A design scheme with the geometric parameters of an uncovered ditch is shown in Fig. 2.

Depending on the relationship between the amount of snow and snow capacity of the uncovered ditch, two calculation schemes are employed. The first one is employed for snowfall volumes not exceeding the snow capacity of a ditch, and its upper surface of snow deposits is limited by the line AB with a slope in the direction of the road axis 1 : 8 [3]. The second design scheme is employed when the amount of snowfall exceeds the snow capacity of a ditch according to the first design scheme. In this case, the area of snow deposits on the slope and in the ditch is limited by a shaded polygon.

Vп

A

|

1:8 |

B |

|

|

|

H |

|

1:m1 |

|

1:0,5 |

|

|

|

||

h |

1:m3 |

1:m2 |

|

l2 |

|

l1 |

|

Fig. 2. Calculation scheme for identifying skidding of a road ditch

H is the depth of a ditch, m; m1, m2 and m3 are the coefficients of the ditch slopes;

l1 is the width of the ditch slope, m; l2 is the width of the bottom of the ditch, m; h is the depth of the ditch, m

59