Учебное пособие 2112

.pdf

Issue № 1(29), 2016

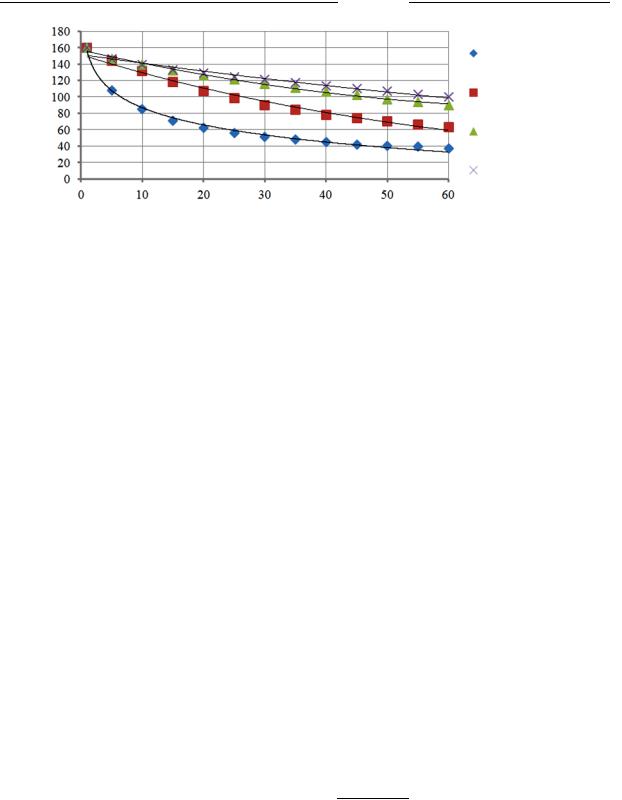

Temperature of the mix, ºС

Time, min

ISSN 2075-0811

Thickness of a layer 0,03 m

Thickness of a layer 0,05 m

Thickness of a layer 0,08 m

Thickness of a layer 0,1 m

Fig. 6. Distribu tion of the mix temperature in the depen dence on the thickness of a surfacing la er

The ab ve data su ggests that depending on the thic ness of a surfacing layer, the distribution of the t emperature varies. With the thick ness of a layer 0,03 m the cooling rate of the hot mix is faster, which is due to little heat per a surface unit. The heat ransfer is at its peak f ollowing the laying within 5 to 10 min utes (a non stationary heat mode). As the thickness of a layer in the asp halt concrete mix incr eases, there are identic al processe s but due to growing amounts

of heat per a mat rial unit |

they are m ore smooth and can be 10—20 inutes long. Table |

||

8 identifies the regression equations describing the distribution of temperature in time. |

|||

|

|

|

Table 8 |

Dependence for identifyin g the temper ture of the ho t mix in time |

|||

|

|

|

|

Thicknes s of a layer, m |

|

Regression equations |

Correlation coefficient |

|

|

|

|

0,03 |

|

tсм = -30,2lnτ + 156,3 |

0,9 9 |

0,05 |

|

tсм = 151,3е – 0,01τ |

0,9 9 |

0,08 |

|

tс м = 153,7е – 0 ,009τ |

0,9 9 |

0,1 |

|

tс м = 151,5е – 0 ,007τ |

0,9 7 |

The nu merical val ues of the temperature of the hot asphalt con crete mix |

n time is presented |

||||||||||

in Tabl e 9. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 9 |

Distribution of the temperature of the hot mix in time in different thicknesse |

of a layer |

|

|||||||||

|

|

|

|

|

Time, |

|

|

|

|

|

|

Thic kness of a layer, m |

|

|

|

min |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

0 |

5 |

10 |

|

20 |

|

30 |

40 |

50 |

60 |

||

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

0,03 |

160 |

108 |

85 |

|

62 |

|

51 |

45 |

40 |

37 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0,05 |

160 |

144 |

131 |

|

107 |

|

90 |

78 |

70 |

63 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0,08 |

160 |

146 |

139 |

|

126 |

|

116 |

10 6 |

97 |

90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0,10 |

160 |

146 |

139 |

|

129 |

|

121 |

11 3 |

107 |

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

71

Scientific Herald of t he Voronezh State University o f Architecture and Civil Engineering. Construction and Architecture

In orde |

to identify the general law of the |

effect of the thickness of a hot m ix layer on the dis- |

|||||||||||||

tribution of the te |

perature i |

|

time, let |

s present the data in |

able 9 in relative units (Table |

||||||||||

10). Let |

us denote the thickness of a surf cing layer Кн. |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 10 |

|

Distribution of the temperature of the hot mix in time in different thicknesse |

of a layer |

|

||||||||||||

|

|

|

|

|

|

(in relative units) |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Thick ness of a lay r, m |

|

|

|

|

|

|

Time, min |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

0 |

|

5 |

|

10 |

20 |

|

30 |

40 |

|

50 |

60 |

|||

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

0,58 |

|

|

|

|

|

|

|

0,03 |

|

|

1 |

|

0,75 |

|

0,65 |

|

0,57 |

0,5 7 |

|

0,57 |

0,58 |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

0,05 |

|

|

1 |

|

1 |

|

1 |

|

1 |

1 |

|

1 |

1 |

|

|

|

|

|

|

|

|

|

|

1,18 |

|

|

|

|

|

|

|

0,08 |

|

|

1 |

|

1,01 |

|

1,06 |

|

1,29 |

1,3 6 |

|

1,38 |

1,42 |

|

|

|

|

|

|

|

|

|

|

1,21 |

|

|

|

|

|

|

|

0,10 |

|

|

1 |

|

1,01 |

|

1,06 |

|

1,34 |

1,4 5 |

|

1,53 |

1,59 |

|

|

|

|

|

|

|

|

|

|

|

||||||

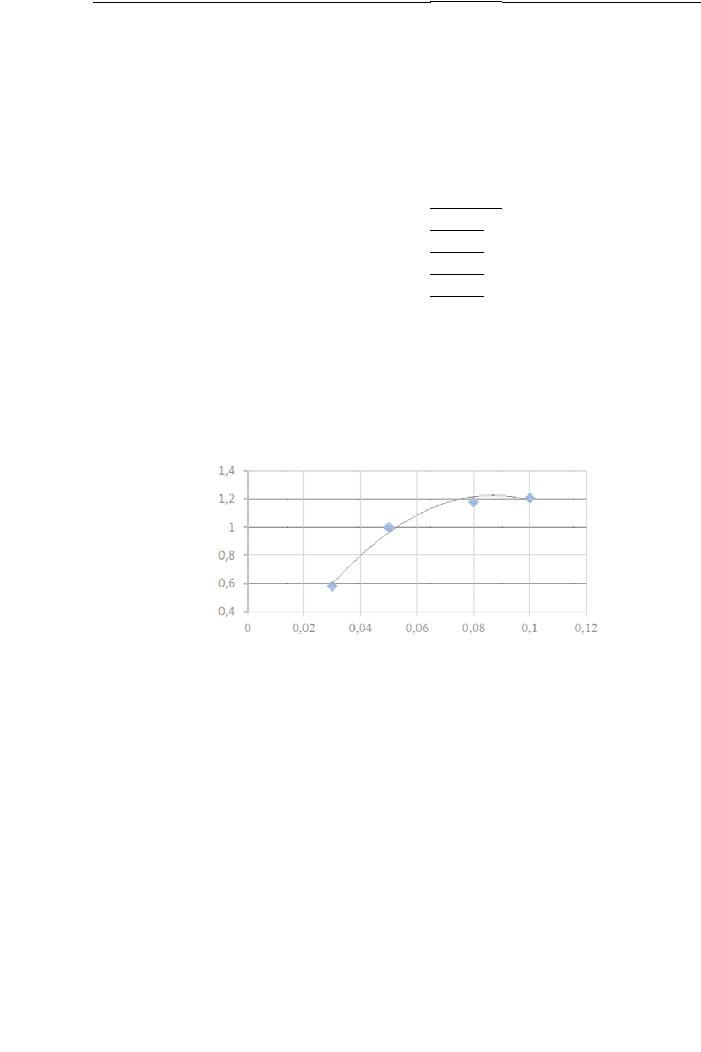

Taking into accou |

t the temp erature of t he mix in t |

e thicknes s of a layer 0,05 m per unit, let |

|||||||||||||

us ident ify the dependence of the effect o f the thick ness of a surfacing layer on the co oling of the hot asphalt concrete mix ( Fig. 7).

Coefficient КH

Thick ess of a surfacing layer, m

Fig. 7. Dependence КH on the thick ess of a surfa cing layer

The nu merical val ue of the coefficient of the effect of the thickness of a s rfacing layer Кн на on the d istribution of the temp erature in the hot asphalt concret mix is given by

Kh 195h2 |

33,88h 0,224, |

(6) |

|||||||

where h is the thic kness of a surfacing la yer; the cor relation coefficient is 0 ,99. |

|

||||||||

Generally the temperat re of the h ot asphalt concrete mix is deter mined using |

the ex- |

||||||||

pressio n |

|

|

|

|

|

|

|

|

|

t |

160K |

т |

K |

см |

K |

у |

K |

e 0,019 . |

(7) |

см |

|

|

|

н |

|

|

|||

72

Issue № 1(29), 2016 |

ISSN 2075-0811 |

Conclusions

1.According to the results of mathematical modeling of thermal processes in a non-rigid roadway surfacing layer, the factors contributing to the cooling rates of hot mixes were identified.

2.The effect of the thickness of a layer, air temperature, wind speed, temperature of the mix during laying on technological processes in paving non-rigid roadways.

3.An analytical dependence for the calculation of the temperature of the hot mix in time considering cooling rates, weather conditions, construction parameters of surfacing.

4.The obtained dependence in the calculation of the temperature of the hot mix considering a combination of different factors give insight into the effect of the temperature of the hot mix on technological processes of non-rigid roadway construction.

5.The use of this dependence allows high accuracy in determining the temperature of the mix at a certain point in paving considering weather and construction parameters of a roadway surfacing. Overall this facilitates laying and compaction of hot asphalt mixes from the temperature perspective.

References

1.Zubkov, A. F. Texnologiya ustrojstva dorozhnyx pokrytij s uchetom temperaturnyx rezhimov asfal'tobetonnyx smesej / A. F. Zubkov. — Tambov: Izd-vo Pershina R. V., 2006. — 151 s.

2.Texnologiya i organizaciya stroitel'stva avtomobil'nyx dorog: v 2 t. T. 2. Dorozhnye pokrytiya / V. P. Podol'skij [i dr.]; pod red. V. P. Podol'skogo. — M.: Akademiya, 2012. — 297 s.

3.Zubkov, A. F. Rekomendacii po razrabotke texnologicheskix processov stroitel'stva pokrytij iz goryachix asfal'tobetonnyx smesej / A. F. Zubkov, K. A. Andrianov // Ustojchivoe razvitie gorodov i novacii zhilishhno-kommunal'nogo kompleksa: sb. st. po materialam 5-oj Mezhdunar. nauch.-prakt. konf. — M., 2007. — S. 132—137.

4.Zubkov, A. F. Texnologiya stroitel'stva asfal'tobetonnyx pokrytij avtomobil'nyx dorog / A. F. Zubkov, V. G. Odnol'ko. — M.: Mashinostroenie, 2009. — 223 s.

5.Dorozhnyj asfal'tobeton / L. B. Gezencvej [i dr.]; pod red. L. B. Gezencveya. — M.: Transport, 1985. — 32 s.

6.SNiP 3.03.06-85. Avtomobil'nye dorogi. — Vved. 01-01-1986. — M.: Gosstroj SSSr, 1986. — 111 s.

7.GOST 9128-2009. Smesi asfal'tobetonnye dorozhnye, ae'rodromnye i asfal'tobeton. Texnicheskie usloviya. — Vved. 01-01-2011. — M.: Standartinform, 2010. — 20 s.

8.Ishhenko, I. S. Texnologiya ustrojstva i remonta asfal'tobetonnyx pokrytij / I. S. Ishhenko, T. N. Kalashnikova, D. A. Semenov. — M.: Air-ART, 2001. — 169 s.

9.Inozemcev, A. A. Bitumomineral'nye materialy / A. A. Inozemcev. — L.: Izd-vo literatury po stroitel'stvu, 1972. — 94 s.

73

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

10.Ladygin, B. I. Prochnost' i dolgovechnost' asfal'tobetona / B. I. Ladygin. –– Minsk: Nauka i texnika, 1972. — 187 c.

11.Zubkov, A. F. O nestacionarnoj teploperedache v processax stroitel'stva dorozhnyx pokrytij nezhestkogo tipa / A. F. Zubkov // Vestnik Tambov. gos. texn. un-ta. — 2007. — № 2. — S. 589—597.

12.Zubkov, A. F. Modelirovanie i raschet temperaturnyx rezhimov dorozhnyx odezhd nezhestkogo tipa v nestacionarnyx usloviyax: svidetel'stvo № 2006613129 o reg. programmy dlya E'VM, opubl. 5.09.2006.

13.SNiP 2.05.02-85*. Avtomobil'nye dorogi. — Vved. 01-01-1987. — M.: FGUP CPP, 2004. — 54 s.

74

Issue № 1(29), 2016 |

ISSN 2075-0811 |

UDC 691.168: 625.855

Vl. P. Podolsky1, Nguyen Van Long2, Nguyen Khac Hao3, Nguyen Duc Sy4

THE STUDY OF OPERATING CAPACITY OF ASPHALT CONCRETE

MODIFIED WITH AN ADDITIVE WETFIX BE

Voronezh State University of Architecture and Civil Engineering Russia, Voronezh, tel.: (473)236-18-89, e-mail: ecodor@bk.ru

1D. Sc. in Engineering, Head of Dept. of Сonstruction and Operation of Highways, Prof.

Ho Chi Minh City University of Transport

Vietnam, Ho Chi Minh, tel.: +8-490-869-44-84, e-mail: long_gtvt@mail.ru 2PhD in Engineering

3Engineer

University of Technology of the University of Danang

Vietnam, Danang, tel.: +8-490-562-79-17, e-mail: ducnguyensy@yahoo com 4PhD in Engineering

Statement of the problem. The problem of increasing the operating capacity of asphalt pavements is very urgent. The practice of road construction shows that after the start of the operation there is rut formation on an asphalt surface and various defects and deformations, one of the main reasons for that is unsatisfactory adhesion of bitumen with a paving stone. One of the applied solution methods is the introduction of various modified additives in organic astringent. This paper presents the results of the study of the main physical, mechanical and operational properties of bitumen and asphalt concrete modified using an adhesive additive Wetfix BE.

Results. The paper presents a theoretical review of ways to increase the deformation stability of asphalt surface in high temperatures suggested by the authors. The results of the experimental studies are shown according to the estimation of the influence of adhesive additive Wetfix BE to physical, mechanical and operational properties of the bitumen SRC 60/70 and hot thick asphalt concrete BTN C12,5.

Conclusions. The results of the experimental research allow one to make a conclusion that application of an adhesive additive Wetfix BE bitumen adhesion with paving stone improves, the deformation stability of asphalt surface in high temperatures increases. A significant positive effect was identified using an adhesive additive Wetfix BE in number of 0,2 % on the bitumen mass for an increasing the operating capacity of asphalt pavements.

Keywords: asphalt concrete, bitumen, deformation stability, defects, rutting, adhesive additive, Wetfix BE, adhesion with the aggregate.

© Podolsky Vl. P., Nguen Van Long, Nguyen Khac Hao, Nguyen Duc Sy, 2016

75

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

Introduction

One of the major problems facing road construction is improving the performance of asphalt concrete surfacings. Asphalt concrete is known to be a thermoplastic composite. Therefore one of the most important factors adversely affecting strength and deformation properties of materials of asphalt concrete layers of roadway surfacing is temperature [1]. One of the major signs of the quality of asphalt concrete is strength. In Vietnam strength indices at 50 and 20 ºС are implicitly used to indicate deflection and crack resistance of asphalt concrete. A capacity to resist accumulation of residual deformations and not to form cracks when summer temperatures drops considerably is indicative of the longevity of roadway asphalt concrete Asphalt concrete at the temperature of 50 оС and more is a viscoelastoplastic material subjected to plastic deformations. Previous studies [2, 3] showed that in summertime in Vietnam the temperature on the surface and inside asphalt concrete roadway surfacing can get as high as 70 оС and more, which is a lot higher than specified in the guidelines. In [1—3] it was found that at high temperatures of Vietnam the computed compression strength of asphalt concrete for 50 оС is not indicative of actual operating conditions of surfacings and does not make them sufficiently deformation resistant.

Besides there are a lot of heavy duty and multiaxle vehicles with the axle load a lot higher than specified in the guidelines [7].

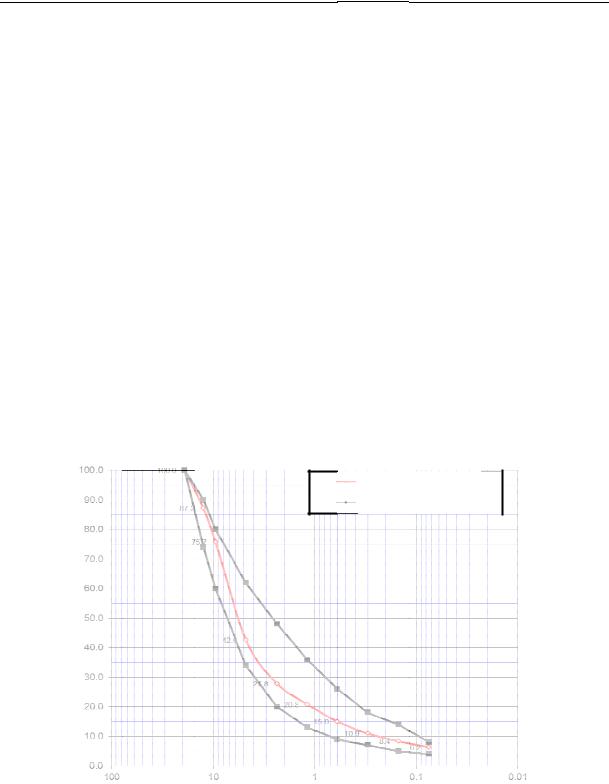

Due to the above there are not allowable deflection deformations accumulating in roadway surfacing (Fig. 1).

The formation of plastic deformations in asphalt concrete roadway surfacing compromises the travelling comfort and safety as well as damages the national economy. This is due to increasing transportation costs due to low demand as well as more frequent maintenances than specified in the guidelines. Therefore improving deformation resistance of asphalt concrete surfacing is a major concern these days [5, 12].

In [5] it was found that in order to provide the deformation resistance the construction of roadway surfacing should comply with transport and operational loads that are predicted for specific roadways considering their composition and trafficking. Materials with high strength characteristics and resistance to multiple loads should be used.

In [3, 5] the need is identified to carry out laboratory tests of physical and mechanical properties of asphalt concrete at the temperature of 60 °С to allow higher thermal resistance in the construction of roadway surfacings. Besides in [1, 4] the authors justify the need to compute the wheel resistance of the structure of a road surfacing at high summer temperatures of up to 60 оС.

76

Issue № 1(29), 2016 |

ISSN 2075-0811 |

Fig. 1. Plastic deformations on asphalt concrete surfacing of roadways of Vietnam

One of the major ways to address this is improving the structure and properties of a binder. The major characteristics of organic binders are the following [6]:

––adhesive properties providing the adhesion of binders with mineral materials;

––rheological properties determining operational and technological properties of deformation and strength of asphalt concrete;

––physical and chemical properties providing the resistance to climatic and operational conditions.

Organic binders must comply with a whole range of operational and technological requirements for the construction of asphalt concrete surfaces. Therefore adhesive additives must be introduced into organic binders to improve their adhesion with stone aggregates. As a result, there are fewer uncovered particles and the thickness of a mix is higher with less cracking caused by the operation of asphalt concrete surfacing. Hence the use of adhesive additives is cost-effective.

Presently in Vietnam different modified additives are used in organic binders, e.g., Wetfix BE, which is a liquid cation active adhesive additive specially designed for hot asphalt mixes that require high thermal stability.

The objective of the paper is to study operational properties of bitumen and asphalt concrete modified by means of Wetfix BE.

1. Experimental study to assess the effect of the adhesive additive Wetfix BE on the properties of modified asphalt concrete. In order to assess the effect of the adhesive additive Wetfix BE on the properties of modified asphalt concrete and its response to plastic deformations, an experimental study of the major properties of modified bitumen and asphalt

77

Scientific Herald of t he Voronezh State University o f Architecture and Civil Engineering. Construction and Architecture

concrete mix BTN C12,5 usin g the bind er SRC 60/70 was conducted in the Third laboratory of road ways and Laboratory C ompany B MT (Hoshi min).

The fol owing initial material were used in the tests:

––quarry limestone Socluk2 in Dong Nai Province;

––quarry sand fro m Phu Thinh in Dong Nai Provinc e;

––min ral powder from an asphalt concrete setup in km 42 of roadway 20;

––bitu men SRC 60/70;

––additive Wetfix BE by AKZO NOBE.

In orde r to investi gate the effect of the additive We fix BE a binder was m ade by int oducing

0,2 and 0,3 % of bitumen SRC |

60/70 in ass. |

Control mixes of the identical |

granular m etric composition (Fi . 2) were made using bitumen |

SRC 6 0/70. The ompositio s of the dense asphalt concrete BTN C12,5 were selected in complia nce with t he requirem ents TCV 8820-2011 [11]. Th binder co ntent in the investigated asphalt concrete mixes was select d according to the physical and chemical properties of the m ix SRC 60/70 and wa s 4,94 % per 100 % of a mineral skeleton.

Designed gra nular composition BTNC 12,5

Boundaries o the granular composition BTNC 1 ,5 по 858/QD-BG TVT

Fig. 2. |

ranular metric composition of a fine ag gregate asphalt concrete BT NC 12,5 |

|

Experim ental studi es of the w heel resista ce of asph alt concrete were carried out using |

a Ham- |

|

burg wh eel trackin |

HWTD (Fig. 3). The tests were c nducted using slabs of 320×260×5 |

0 mm at |

the tem perature of |

0 оС. The rut depth in the slabs was fixed after each 1500 loading cycles. |

|

78

Issue № 1(29), 2016 |

ISSN 2075-0811 |

Fig. 3. Hamburg wheel tracking test HWTD

2. Results of the experimental study. According to TCVN 7504-2005 [10], adhesion of the road bitumen with the aggregate is evaluated on five levels that are detailed in Table 1. According to 27/2014/TT-BGTVT [8], bitumen with the adhesion level of 3 can be applied in road construction.

Table 1

|

Major physical and mechanical properties of modified bitumen SRC 60/70 |

|

|

|

|

Level |

Adhesion level of bitumen with the aggregate |

|

|

|

|

5 |

Excellent: bitumen film is all over the aggregate surface and its thickness is identical throughout |

|

the entire aggregate surface |

||

|

||

|

|

|

4 |

Good: bitumen film is all over the aggregate surface but its thickness is not identical throughout |

|

entire aggregate surface |

||

|

||

|

|

|

3 |

Adequate: in some areas of the aggregate there is no bitumen film |

|

|

|

|

2 |

Bad: in some areas of the aggregate surface there is some bitumen but the bitumen film peels off |

|

its surface |

||

|

||

|

|

|

1 |

Poor: surface of the aggregate is clean |

|

|

|

The results of the experimental study of the major physical and mechanical properties of bitumen SRC 60/70 with and without the additive Wetfix BE are identified in Table 2.

The data in Table 2 suggests that while introducing 0,2 and 0,3 % of the adhesive additive Wetfix BE in mass into the road bitumen SRC 60/70 its level of adhesion with the aggregate rises from 3 to 4, the needs penetrates from 6,48 to 10,61 % deeper respectively, the softening temperature drops from 3,45 and 5,54 % respectively and the other properties change insignificantly and comply with the requirements specified in 27/2014/TT-BGTVT [8].

79

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

Therefore the introduction of the adhesive additive Wetfix BE into the road bitumen SRC 60/70 improves its adhesion with the aggregate to improve the operational properties of road asphalt concrete.

The results of the experimental studies of the physical and mechanical properties of asphalt concrete BTN C12,5 using bitumen SRC with and without the additive Wetfix BE are detailed in Table 3.

Table 2

Major physical and mechanical properties of bitumen SRC 60/70 with and without the additive Wetfix BE

|

|

Test results |

|

According |

|

Study variables |

|

|

|

||

0,0 % |

0,2 % |

0,3 % |

to [8] |

||

|

Wetfix BE |

Wetfix BE |

Wetfix BE |

||

|

|

||||

|

|

|

66,7 |

|

|

Depth of the needle at 25оC, 0,1 mm |

60,3 |

64,2 |

60 ÷ 70 |

||

Softening temperature along the circle and the |

48,06 |

46,40 |

45,4 |

≥ 46 |

|

ball, оС |

|||||

|

|

|

|

||

Dynamic viscosity at 600C, Pa·sec |

213 |

214 |

217 |

≥180 |

|

|

|

|

> 110 |

|

|

Flexibility at 25°С, сm |

> 110 |

> 110 |

≥ 100 |

||

|

|

|

1,88 |

|

|

Paraffin content, % |

1,86 |

1,87 |

≤ 2,2 |

||

|

|

|

318 |

|

|

Outburst temperature,оС |

320 |

320 |

≥ 232 |

||

|

|

|

99,50 |

|

|

Solubility in C2HCl3, % |

99,42 |

99,52 |

≥ 99 |

||

|

|

|

1,024 |

|

|

Specific weight at 25оC, g/сm3 |

1,025 |

1,025 |

1,0 ÷ 1,05 |

||

|

|

|

0,07 |

|

|

Weight loss, % |

0,06 |

0,07 |

≤ 0,5 |

||

|

|

|

4 |

|

|

Adhesion with the aggregate, level |

3 |

4 |

≥ 3 |

||

|

|

|

|

|

The data in Table 3 suggests that the use of 0,2 and 0,3 % of the adhesive additive Wetfix BE in mass of the bitumen into asphalt concrete BTN C12,5:

––the Marshall stability at 60оC increases by 5,34 and 8,08 % respectively;

––the Marshall stability at 60оC after 24 hours rises from 6,11 % and 11,5 % respectively;

––the Marshall stability at 60оC after 24 hours compared to the original one rises from 1,00 and 3,33 % respectively;

––the rut depth decreases by 36,79 and 32,28 % respectively;

––the other characteristics do not change considerably and meet the requirements in 858/QĐBGTVT [9] and TCVN 8820-2011 [11].

80