PS-2020a / part17

.pdf

DICOM PS3.17 2020a - Explanatory Information |

Page 461 |

|

|

|

|

Treatment |

|

Treatment |

|

Machine |

User |

|

Archive |

|

Management |

|

Delivery |

|

Parameter |

|

|

|

|

System (TMS) |

|

System (TDS) |

|

Verifier |

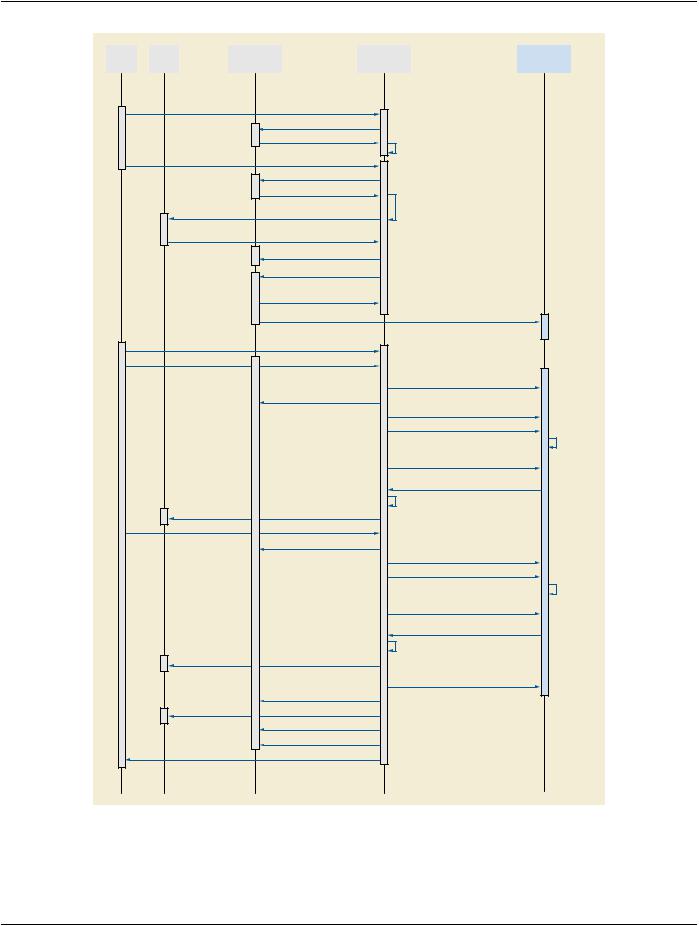

1. ‘List Procedures for Delivery’ on TDS console

2.Query UPS (C-FIND)

3.Receive 0-n UPS

Display list to User

4.‘Select Procedure’ on TDS console (optional, if only one procedure in list)

5.Get UPS details (C-GET)

Receive UPS details

Extract input UIDs from selected UPS

5a. Retrieve Archive Objects (C-MOVE)

RT Plan and any other required objects

(e.g., verification images, RT Beam Treatment Records)

6.Change UPS ‘IN PROCESS’ (N-ACTION with Transaction UID)

7.Retrieve TMS objects (C-MOVE)

RT Beams Delivery Instruction

RT Treatment Record Summary

RT Beams Treatment Rec (if not in 5)

7a. Communicate UPS and any required delivery data using a non-specified mechanism

8. ‘Start Treatment Session’ on TDS console

8a. ‘Deliver Beam 1’ on TDS console

8b. Create RT Conv. Machine Verification

(N-CREATE)

9. Set UPS 0% complete, Beam ‘1’ (N-SET)

9a. Set ‘Beam1’ RT Conv. Machine Verification (N-SET)

9b. Initiate verification (N-ACTION)

Verify

9c. Notify Verification Status (N-EVENT-REPORT,

Event-Type = ‘Done’, TVS = VERIFIED)

9d. Get RT-Conv. Machine Verification (N-GET)

- optional instruction

DELIVER RADIATION

9e. Store ‘Beam1’ RT Beams Treatment Record (C-STORE)

8a. ‘Deliver Beam 2’ on TDS console

9. Set UPS 50% complete, Beam ‘2’ (N-SET)

9a. Set ‘Beam2’ RT Conv. Machine Verification (N-SET)

9b. Initiate verification (N-ACTION)

Verify

9c. Notify Verification Status (N-EVENT-REPORT,

Event-Type = ‘Done’, TVS = VERIFIED)

9d. Get RT-Conv. Machine Verification (N-GET) - optional instruction

DELIVER RADIATION

9e. Store ‘Beam2’ RT Beams Treatment Record (C-STORE)

9f. Delete RT Conv. Machine Verification

(N-DELETE)

10.Set UPS 100% complete, (N-SET)

11.Store other result objects (C-STORE)

12.Set UPS to Final State (N-SET)

13.Change UPS ‘COMPLETED’ (N-ACTION)

14.Indicate ‘Treatment Session Completed on TDS Console’

Figure BBB.3.2.1-1. Treatment Delivery Normal Flow - External Verification Message Sequence

AftertheTDShassignaledtheUPScurrentReferencedBeamNumberandcompletionpercentageforagivenbeam(9),thefollowing sequence of steps is performed:

- Standard -

Page 462 |

DICOM PS3.17 2020a - Explanatory Information |

9a. Set 'Beam x' RT Conventional Machine Verification Instance

The TDS sets the RT Conventional Machine Verification SOP Instance to transfer the necessary verification parameters. This is conveyed using the N-SET primitive of the RT Conventional Machine Verification SOP Class. The Referenced Beam Number (300C,0006) Attribute is used to specify the beam to be delivered. It is the responsibility of the SCU to keep track of the verification parameters such that the complete list of required Attributes can be specified within the top-level sequence items.

9b. Initiate Verification

The TDS sets the RT Conventional Machine Verification SOP Instance to indicate that the TDS is ready for external verification to occur. This is conveyed using the N-ACTION primitive of the RT Conventional Machine Verification SOP Class.

9c. Verify Machine Parameters

The MPV then attempts to verify the treatment parameters for 'Beam x'. The MPV sends one or more N-EVENT-REPORT signals to the TDS during the verification process. The permissible event types for these signals in this context are 'Pending' (zero or more times, not shown in this use case), and 'Done' when the verification is complete (successful or otherwise).

9d. Get RT Conventional Machine Verification (optional step)

The TDS may then request Attributes of the RT Conventional Machine Verification instance. This is conveyed using the N-GET primitive of the RT Conventional Machine Verification SOP Class. If verification has occurred normally and the N-EVENT-REPORT containedaTreatmentVerificationStatusofVERIFIED(thisusecase),thenthisstepisnotnecessaryunlesstheTDSwishestorecord additional parameters associated with the verification process.

TheTDSthendeliversthetherapeuticradiation.Inthecurrentusecase,itisassumedthattheradiationcompletesnormally,delivering the entire scheduled fraction. Other use cases, such as voluntary interruption by the User, or interruption by the TDS or MPV, are not described here. If the delivery requires an override of additional information, a different message flow occurs. This is illustrated in the use case described in the next section.

9e. Store 'Beam x' RT Beams Treatment Record to Archive

TheTDSstoresanRTBeamsTreatmentRecordtotheArchive(orpotentiallytheTMSasdescribedinSectionBBB.3.1.2Transactions and Message Flow). The RT Beams Treatment Record is therefore not stored in Step 11 for the external verification case (since it has already been stored in the step on a per-beam basis).

For each subsequent beam in the sequence of beams being delivered, steps 8a (optional), 9, 9a, 9b, 9c, 9d (optional), and 9e are then repeated, i.e., N-SET, N-ACTION, and N-GET operations are performed on the same instance of the RT Conventional Machine Verification SOP Class, which persists throughout the beam session.

9f. Delete RT Conventional Machine Verification Instance

When all beams have been processed, the TDS deletes the RT Conventional Machine Verification SOP Instance to indicate to the MPVthatverificationisnolongerrequired.ThisisconveyedusingtheN-DELETEprimitiveoftheRTConventionalMachineVerification SOP Class.

BBB.3.3 Treatment-delivery With External Verification - Override Or Additional Info Required

BBB.3.3.1 Message Sequencing

Figure BBB.3.3.1-1 illustrates a message sequence example for the external verification model in the case where the Machine Parameter Verifier (MPV) either detects that an override is required, or requires additional information (such as a bar code) before authorizing treatment.

The steps in this use case replace Steps 8a to 9f in Use Case BBB.3.2, for the case where only a single beam is delivered.

- Standard -

|

|

DICOM PS3.17 2020a - Explanatory Information |

Page 463 |

||

|

|

Treatment |

Treatment |

|

Machine |

User |

Archive |

Management |

Delivery |

|

Parameter |

|

|

System (TMS) |

System (TDS) |

Verifier |

|

|

1. ‘Deliver Beam X’ on TDS console |

|

|

|

|

|

|

|

2. |

Create RT Conv. Machine Verification |

|

|

|

|

(N-CREATE) |

|

|

|

|

|

3. |

Set ‘BeamX’ RT Conv. Machine Verification (N-SET) |

|

|

|

|

4. |

Initiate verification (N-ACTION) |

|

|

|

|

|

|

Verify Failed |

|

|

|

5. |

Notify Verification Status (N-EVENT-REPORT, |

|

|

|

|

Event-Type = ‘Done’, TVS = NOT_VERIFIED) |

|

|

|

5a. Display override request or missing info message |

|

|

|

|

|

6. Supply override instruction or barcode |

|

|

|

|

|

|

|

7. |

Initiate verification (N-ACTION) |

|

|

|

|

|

|

Re-verify |

|

|

|

|

|

(succeeded) |

|

|

|

8. |

Notify Verification Status (N-EVENT-REPORT, |

|

|

|

|

Event-Type = ‘Done’, TVS = VERIFIED_OVR) |

|

|

|

|

|

9. |

Get RT-Conv. Machine Verification (N-GET) |

|

|

|

|

- optional instruction |

|

|

|

|

|

DELIVER RADIATION |

|

|

|

10. Store ‘BeamX’ RT Beams Treatment Record (C-STORE) |

|

|

|

|

|

|

|

11. Delete RT Conv. Machine Verification |

|

|

|

|

|

(N-DELETE) |

|

|

FigureBBB.3.3.1-1.TreatmentDeliveryMessageSequence-OverrideorAdditionalInformationRequired

BBB.3.3.2 Transactions and Message Flow

This section describes in detail the interactions illustrated in Figure BBB.3.3.1-1.

1.'Deliver Beam x' on TDS console (optional step)

See use case BBB.3.2.

2.Create RT Conventional Machine Verification Instance

See use case BBB.3.2.

3.Set 'Beam x' RT Conventional Machine Verification Instance

See use case BBB.3.2.

4.Initiate Machine Verification

See use case BBB.3.2.

5.Verify Machine Parameters

The MPV then attempts to verify the treatment parameters for 'Beam x'. The MPV determines that one or more treatment para- meters are out-of-tolerance, or that information such as a bar code is missing. It sends an N-EVENT-REPORT signal to the TDS with an Event Type of Done and an RT Machine Verification Status of NOT_VERIFIED. The MPV also shows the reason for the override/information request on its display (5a).

6.Supply Override Instruction or Bar Code

The User observes on the MPV console that an override or missing information is required, and supplies the override approval or missing information to the MPV via its user interface, or equivalent proxy.

- Standard -

Page 464 |

DICOM PS3.17 2020a - Explanatory Information |

7.Initiate Machine Verification

The TDS performs another N-ACTION on the RT Conventional Machine Verification SOP Instance to indicate that the TDS is once again ready for treatment verification. See use case BBB.3.2. This may be initiated by the user (as shown in this example), or may be initiated automatically by the TDS using a polling approach.

8.Re-verify Machine Parameters

The MPV verifies the treatment parameters, and determines that all parameters are now within tolerance and all required inform- ation is supplied. It sends an N-EVENT-REPORT signal to the TDS with an Event Type of Done and an RT Machine Verification Status of VERIFIED_OVR.

Note

If another verification failure occurs, the override cycle can be repeated as many times as necessary.

9.Get RT Conventional Machine Verification (optional step)

See use case BBB.3.2. If an N-GET is requested, the parameters that were overridden are available in Overridden Parameters Sequence (0074,104A).

The TDS then delivers the therapeutic radiation.

10.Store 'Beam x' RT Beams Treatment Record to Archive

See use case BBB.3.2. Overridden parameters are ultimately captured in the treatment record.

11.Delete RT Conventional Machine Verification Instance

See use case BBB.3.2.

BBB.3.4 Treatment-delivery With External Verification - Machine Adjustment Required

BBB.3.4.1 Message Sequencing

Figure BBB.3.4.1-1 illustrates a message sequence example for the external verification model in the case where the Machine Parameter Verifier (MPV) detects that one or more machine adjustments are required before authorizing treatment, and the TDS has been configured to retrieve the failure information and make the required adjustments.

The steps in this use case replace Steps 8a to 9f in Use Case BBB.3.2, for the case where only a single beam is delivered.

- Standard -

|

|

DICOM PS3.17 2020a - Explanatory Information |

Page 465 |

||

|

|

Treatment |

Treatment |

|

Machine |

User |

Archive |

Management |

Delivery |

|

Parameter |

|

|

System (TMS) |

System (TDS) |

Verifier |

|

|

1. ‘Deliver Beam X’ on TDS console |

|

|

|

|

|

|

|

2. |

Create RT Conv. Machine Verification |

|

|

|

|

(N-CREATE) |

|

|

|

|

|

3. |

Set ‘BeamX’ RT Conv. Machine Verification (N-SET) |

|

|

|

|

4. |

Initiate verification (N-ACTION) |

|

|

|

|

|

|

Verify Failed |

|

|

|

5. |

Notify Verification Status (N-EVENT-REPORT, |

|

|

|

|

Event-Type = ‘Done’, TVS = NOT_VERIFIED) |

|

|

|

5a. Display ‘verify failed’ message to user |

|

|

|

|

|

|

|

6. |

Get RT Conv. Machine Verification (N-GET) |

|

|

7. Request machine adjustment |

|

|

|

|

|

|

|

Machine adjusts |

|

|

|

|

|

8. |

Set ‘BeamX’ RT Conv. Machine Verification |

|

|

|

|

(N-SET) - modifications supplied |

|

|

|

|

|

9. |

Initiate verification (N-ACTION) |

|

|

|

|

9b. Notify Verification Status (N-EVENT-REPORT, |

Re-verify |

|

|

|

|

Event-Type = ‘Pending’) |

||

|

|

|

|

|

(succeeded) |

|

|

|

10. Notify Verification Status (N-EVENT-REPORT, |

|

|

|

|

|

Event-Type = ‘Done’, TVS = VERIFIED) |

|

|

|

|

|

11. Get RT-Conv. Machine Verification (N-GET) |

|

|

|

|

|

- optional instruction |

|

|

|

|

|

DELIVER RADIATION |

|

|

|

12. Store ‘BeamX’ RT Beams Treatment Record (C-STORE) |

|

|

|

|

|

|

|

13. Delete RT Conv. Machine Verification |

|

|

|

|

|

(N-DELETE) |

|

|

Figure BBB.3.4.1-1. Treatment Delivery Message Sequence - Machine Adjustment Required

BBB.3.4.2 Transactions and Message Flow

This section describe in detail the interactions illustrated in Figure BBB.3.4.1-1.

1.'Deliver Beam x' on TDS console (optional step)

See use case BBB.3.2.

2.Create RT Conventional Machine Verification Instance

See use case BBB.3.2.

3.Set 'Beam x' RT Conventional Machine Verification Instance

See use case BBB.3.2.

4.Initiate Machine Verification

See use case BBB.3.2.

5.Verify Machine Parameters

The MPV then attempts to verify the treatment parameters for 'Beam x'. The MPV determines that one or more treatment para- meters are out-of-tolerance. It sends an N-EVENT-REPORT signal to the TDS with an Event Type of Done and an RT Machine Verification Status of NOT_VERIFIED. It may also display the verification status and information to the user (5a).

6.Get RT Conventional Machine Verification

- Standard -

Page 466 |

DICOM PS3.17 2020a - Explanatory Information |

The TDS then requests the failed verification parameters of the verification process. This is conveyed using the N-GET primitive of the RT Conventional Machine Verification SOP Class. The MPV replies with an N-GET-RESPONSE having a Treatment Verification Status of NOT_VERIFIED. The reason(s) for the failure is encoded in the Failed Parameters Sequence (0074,1048) Attribute of the response.

7.Request machine adjustment

As illustrated in this example, some implementations may require that the User observes the failed verification parameters on the MPV console and manually request the required machine adjustment. In this case the User makes the request to the TDS via its user interface. In other implementations the TDS makes the adjustments automatically and request verification without User intervention.

8.Adjust TDS and Set 'Beam x' RT Conventional Machine Verification Instance

The TDS adjusts one or more of its parameters as requested, then sets the RT Conventional Machine Verification SOP Instance to indicate that the TDS is once again ready for treatment delivery. This is conveyed using the N-SET primitive of the RT Conven- tional Machine Verification SOP Class. The N-SET command provides values for all applicable parameters (not just those that have been modified) since if one or more parameters within a top-level sequence is supplied, then all the applicable parameters within that sequence must also be supplied (otherwise DICOM requires their values to be cleared).

9.Initiate Machine Verification

The TDS performs another N-ACTION on the RT Conventional Machine Verification SOP Instance to request that the MPV re- perform treatment verification. See use case BBB.3.2.

Asanoptionalstep,theMPVmaynotifytheTDSthattheverificationisinprocessatanytime,bysendinganN-EVENT-REPORT signal to the TDS with an Event Type of Pending (9a).

10.Re-verify Machine Parameters

The MPV verifies the treatment parameters, and determines that the required adjustments have been made, i.e., all parameters are now within tolerance. It sends an N-EVENT-REPORT signal to the TDS with an Event Type of Done and an RT Conventional Machine Verification Status of VERIFIED.

Note

If another verification failure occurs, the override cycle can be repeated as many times as necessary.

11.Get RT Conventional Machine Verification (optional step)

See use case BBB.3.2.

The TDS then delivers the therapeutic radiation.

12.Store 'Beam x' RT Beams Treatment Record to Archive

See use case BBB.3.2.

13.Delete RT Conventional Machine Verification Instance

See use case BBB.3.2.

- Standard -

DICOM PS3.17 2020a - Explanatory Information |

Page 467 |

CCC Ophthalmic Axial Measurements and Intraocular Lens Calculations Use Cases (Informative)

CCC.1 Axial Measurements

An axial measurements device is used to take axial measurements of the eye, from the anterior surface of the cornea to either the surface of the retina (ultrasound) or the retinal photoreceptors (optical). The axial measurements are typically expressed in mm (Ophthalmic Axial Length (0022,1010). Currently these measurements are taken using ultrasound or laser light. The measurements are used in calculation of intraocular lens power for cataract surgery. Axial measurements devices and software on other systems perform intraocular lens power calculations using the axial measurements in addition to measurements from other sources (currently by manual data entry, although importation from other software systems is expected in the future).

When the natural lens of the eye turns opaque it is called a cataract. The cataract is surgically removed, and a synthetic intraocular lens is placed where the natural lens was before. The power of the lens that is placed determines what the patient's refractive error will be, meaning what power his glasses will need to be to maximize vision after surgery.

Axial measurements devices provide graphical displays that help clinicians to determine whether or not the probe used in taking the measurements is aligned properly. Annotations on the display provide information such as location of gates that assists the clinician in assessing measurement quality. High, fairly even waveform spikes suggest that the measurement producing a given graph is likely to be reliable. The quality of the graphical display is one of the factors that a clinician considers when choosing which axial length measurement to use in calculating the correct intraocular lens power for a given patient.

CCC.2 Intraocular Lens Calculations Introduction

Axial measurements devices and software on other systems perform intraocular lens power calculations for cataract surgery patients. The power selection of intraocular lens to place in a patient's eye determines the refractive correction (e.g., glasses, contact lenses, etc.) the patient will require after cataract surgery.

The data input for these calculations consists of ophthalmic axial length measurements (one dimensional ultrasound scans that are called "A-scans" in the eye care domain) and keratometry (corneal curvature) measurements in addition to constants and sometimes others kinds of measurements. The data may come from measurements performed by the device, on which the intraocular lens cal- culationsoftwareresides,orfrommanualdataentry,orfromanexternalsource.Thereareanumberofdifferentformulasandconstants available for doing these calculations. The selection of formula to use is based on clinician preference and on patient factors such as the axial length of the eye. The most commonly used constants, encoded by Concept Name Code Sequence (0040,A043) using CID 4237 “Lens Constant Type”, are a function of the model of intraocular lens to be used.

Themostcommonlyusedformulas,encodedbyIOLFormulaCodeSequence(0022,1029)usingCID4236“IOLCalculationFormula”, for intraocular lens calculation are inaccurate in a patient who has had refractive surgery, and numerous other formulas are available for these patients. Since most of them have not been validated to date, they were not included in this document.

Intraocularlenscalculationsoftwaretypicallyprovidestabulardisplaysofintraocularlenspowerinassociationwitheachlens'spredicted refractive error (e.g., glasses, contact lenses, etc).

- Standard -

Page 468 |

DICOM PS3.17 2020a - Explanatory Information |

Pupil

Cornea

Conjunctiva

Iris

Lens

Retina

Sclera

Optic nerve

Figure CCC.2-1. Sagittal Diagram of Eye Anatomy (when the lens turns opaque it is called a cataract)

Courtesy; National Eye Institute, National Institutes of Health; ftp://ftp.nei.nih.gov/eyean/eye_72.tif

Figure CCC.2-2. Eye with a cataract

Courtesy; National Eye Institute, National Institutes of Health; ftp://ftp.nei.nih.gov/eyedis/EDA13_72.tif

- Standard -

DICOM PS3.17 2020a - Explanatory Information |

Page 469 |

Figure CCC.2-3. Eye with Synthetic Intraocular Lens Placed After Removal of Cataract

This file is licensed under the Creative Commons Attribution Share Alike 2.5 License, Author is Rakesh Ahuja, MD (http:// en.wikipedia.org/wiki/Image:Posterior_capsular_opacification_on_retroillumination.jpg)

CCC.3 Output of An Ultrasound A-scan Device

FigureCCC.3-1demonstratesanA-scanwaveform-producedbyanultrasounddeviceusedforophthalmicaxiallengthmeasurement. This is referenced in the Ophthalmic Axial Measurements IOD in Referenced Ophthalmic Axial Length Measurement QC Image Se- quence (0022,1033).

Figure CCC.3-1. Scan Waveform Example

Time (translated into distance using an assumed velocity) is on the x-axis, and signal strength is on the y-axis. This waveform allows clinicians to judge the quality of an axial length measurement for use in calculating the power of intraocular lens to place in a patient's eye in cataract surgery. Figure CCC.3-1 above demonstrates a high quality scan, with tall, even spikes representing the ocular structuresofinterest.Thistellstheclinicianthattheprobewasproperlyalignedwiththeeye.Thefirst,doublespikeontheleftrepresents anterior cornea followed by posterior cornea. The second two, more widely spaced spikes represent anterior and posterior lens. The first tall spike on the right side of the display is the retinal spike, and the next tall spike to the right is the sclera. Smaller spikes to the

- Standard -

Page 470 |

DICOM PS3.17 2020a - Explanatory Information |

far right are produced by orbital tissues. Arrows at the bottom of the waveform indicate the location of gates, which may be manually adjusted to limit the range of accepted values. Note that in the lower right corner of the display two measurements are recorded. In the column labeled AXL is an axial length measurement, which on this device is the sum of the measurements for ACD (anterior chamberdepth),lens,andVCD(vitreouschamberdepth).Themeasuredtimevalueforeachofthesegmentsandapresumedvelocity ofsoundforthatsegmentareusedtocalculatetheaxiallengthforthatsegment.Anaveragevalueforeachcolumnisdisplayedbelow along with the standard deviation of measurements in that column. The average axial length is the axial length value selected by this machine, although often a clinician will make an alternative selection.

CCC.4 Output of An Optical A-scan Device

Figure CCC.4-1 demonstrates the waveform-output of a partial coherence interferometry (PCI) device used for optical ophthalmic axial length measurement. This is referenced in the Ophthalmic Axial Measurements IOD in Referenced Ophthalmic Axial Length Measurement QC Image Sequence (0022,1033).

Figure CCC.4-1. Waveform Output of a Partial Coherence Interferometry (PCI) Device Example

Physical distance is on the x axis, and signal strength is on the y axis. What is actually measured is phase shift, determined by looking atinterferencepatternsofcoherentlight.Physicaldistanceiscalculatedbydividing"opticalpathlength"bythe"refractivegroupindex" - using an assumed average refractive group index for the entire eye. The "optical path length" is derived from the phase shift that is actually observed. Similar to ultrasound, this waveform allows clinicians to judge the quality of an axial length measurement.

Figure CCC.4-1 above demonstrates a high quality scan, with tall, straight spikes representing the ocular axial length. The corneal spike is suppressed (outside the frame on the left hand side) and represents the reference 0 mm. The single spike on this display represents the signal from the retinal pigment epithelium (RPE) and provides the axial length measurement value (position of the circlemarker).SometimessmallerspikescanbeobservedontheleftorrightsideoftheRPEpeak.Thosespikesrepresentreflections from the internal limiting membrane (ILM,150-350 µm before RPE) or from the choroid (150-250 µm behind RPE) respectively.

Because all classical IOL power calculation formulas expect axial lengths measured to the internal limiting membrane (as provided by ultrasound devices), axial length measurements obtained with an optical device to the retinal pigment epithelium are converted to this convention by subtracting the retinal thickness.

Figure CCC.4-1 above displays five axial length measurements obtained for each eye (one column for each eye) and the selected axial length value is shown below the line.

CCC.5 IOL Calculation Results Example

Figure CCC.5-1 demonstrates a typical display of IOL (intraocular lens) calculation results.

- Standard -