- •Семестровая работа № 2 на тему: «Systems of automation and control of technological processes»

- •Содержание

- •Текст на английском языке

- •Перевод текста с английского языка на русский язык Системы автоматизации управления технологическими процессами

- •Иерархическая структура автоматизации

- •Задачи уровней автоматизации

- •Обмен информацией между уровнями

- •Преимущества и недостатки

- •Перевод терминов

- •Вопросы по тексту

- •Определение видовременных форм глаголов

- •Аннотация

- •Список использованной литературы

Некоммерческое акционерное общество

«АЛМАТИНСКИЙ УНИВЕРСИТЕТ ЭНЕРГЕТИКИ И СВЯЗИ»

Кафедра Иностранных языков

Семестровая работа № 2 на тему: «Systems of automation and control of technological processes»

По дисциплине: Английский язык

Специальность:6М070200-Электроэнергетика

Выполнила: ЗарыповаМ.А.Гр.:МЭППп-14 № зач.кн. 141М013

Руководитель: доцент Нурходжаева Х.А.

« ___»___________________________________________________20____г.

Алматы 2014

Содержание

Текст на английском языке…………………………………………………..3

Перевод текста с английского языка на русский язык……………………..8

Перевод терминов…………………………………………………………...14

Вопросы по тексту..........................................................................................15

Определение видовременных форм глаголов……………………………..15

Аннотация……………………………………………………………………16

Список использованной литературы……………………………………….17

Текст на английском языке

Systems of automation and control of technological processes

Hierarchical structure of automation

Increase of technical and economical indexes of control system by technical processes (TP) and production on the whole such, as management quality, reliability, cost reducing on planning, safety of exploitation, possibility of adaptation of control system (CS) to changing properties of objects (TP) the improvement of terms of work of operator in large part depends on the used technical equipments.

Presently the systems of automation of technological processes (SAC TP) are arranged in the aggregate complexes of technical equipments (CTE), that are the difficult systems of vehicle, programmatic and structural facilities decision-oriented both model and certain tasks on automation of technological processes executed in obedience to international standardization, formed IEC (International electrical Engineering Commission).

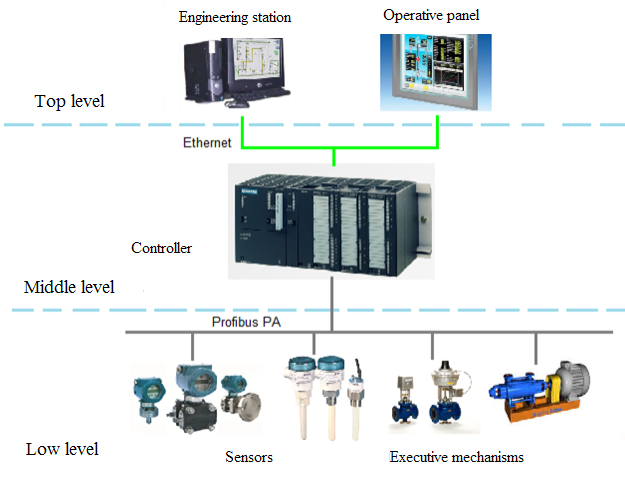

The tasks of automation can fundamentally decide the central or decentralized structure of automation. What structure befits better, depends on a process or productive cycle that must be automate. Many processes consist of partial processes and structured already from the point of view of technique - it is decentralized. In such cases every part of setting or the own system of automation is inferior a partial process. For a few from these decentralized systems of automation at subordinating level the additional general system coordinating these conformable systems is distinguished. Depending on complication or size of options subject to automation, above this level other levels can be situated. The hierarchical structures of decision-making result in the hierarchical structures of automation.

The structural model of the requirements produced to automation looks like the pyramid divided into levels. It allows to divide distinctly the tasks of automation and their decision the corresponding systems: by the systems optimally adjusted on a corresponding task.

Level of sensors and executive mechanisms (field level).

Control level.

Level of control of technological process.

Control level by a production (top level).

Planning level.

Picture 1 – Levels of automation

At the decision of tasks of automation for every level next principles operate:

A receipt and treatment of information on every level must come true independently, as far as it maybe;

Time of information exchange between levels must be as possible less and not critical at times;

Interfaces must be certain physically and on maintenance.

Tasks of levels of automation

The function of the lowest level the "field" is an account of parameters of the state and influence on parameters technical process. Sensors and executive elements (named also executive mechanisms) are here used.

Sensors are construction elements or devices, transforming physical sizes, as pressure and temperature, or concentration of chemicals in electric signals.

Executive mechanisms are drives, pumps, valves or captures.

At the level of control controllers carrying out the direct capture of data from sensors and control executive devices are situated. Size of data, that controller exchanges with eventual devices, usually makes a few bytes at speed of questioning of devices no more than 10 msec.

The lately examined structure of control system substantially becomes complicated, clear verges are here worn away between different levels. It is related to penetration of Internet/Intranet- technologies in an industrial sphere, by considerable successes of industrial Ethernet, by the use of some industrial networks of Fieldbus in explosive zones on enterprises chemical, oil and gas and other industries of industry with the dangerous terms of production. In addition, appearance of intellectual sensors and executive mechanisms and interfaces for connection with them actually means appearance of fourth, the lowest level of SAC TP - level of network of eventual devices.

At the level of control by a technological process current control and control come true either in the manual from operator stands or in the automatic mode on the stopped up algorithm. At this level the concordance of parameters of separate areas of production, working off emergency and pre emergency situations, parameterization of controllers of low level, loading of the technological programs, remote control by executive mechanisms are perform. An informative shot contains at this level, as a rule, a few ten of bytes, and possible delays can make from 100 to 1000 milliseconds depending on office hours.

At the level of control a production ordinary IBM- PC are situated - the compatible computers and file servers, incorporated by a local network. A task of the computer systems at this level is providing of visual control of basic parameters of production, construction of reports, archiving of data. The volumes of transferrable between knots data are measured by megabytes, and temporal indexes of exchange information are not critical.

Exchange by information between levels

All levels of pyramid must have vertical informatively-technical connection with each other; between them an exchange comes true by information. This exchange takes place information in both sides, from a top to low and from low to top. We will consider such "vertical communication" on the example of the field level - control level. Data from a process, e.g., measuring sizes are subject to the transmission on the local level of basilar automation. The question is about a few quantity of information being actual in certain moment of time, however, with a high requirement to speed of information transfer, e.g., report about the state of danger, that must result in the scram of aggregate. Separate sensors and executive elements on working today options frequently do not have yet own logic and added directly to the level of management. About communication it is yet impossible in own sense to talk, as information arises up constantly, e.g., as an analog signal. But also influence of microelectronics is already noticeable here. So, sensors, capable independently to process signals, produce the rough-down of measuring sizes, compare normal and maximum values or get and pass a few values, begin to use. These "intellectual" sensors are already reported with each other move, thus, part of tasks of automation to the field level. The same succeeds, in general, to increase the productivity of processing of data and simultaneously to shorten communication between the field level and standing above him level of basilar automation, as on a top level relevant data are passed only in a condense form. Logic of components is more expressed at the level of control. Already today they are reported not only with the systems of standing higher level of control by a production, but also with components into the level. Requirements to communication on hierarchical levels are different. At field level drives and sensors are reported mainly very intensively with each other or with a higher level; thus the volume of information is relatively small and period of service of data is small. But the high requirements of short time of reaction require communication in real time. With growth of levels in the hierarchy of task of automation centralized a force character in a greater degree. Although quantity of devices participating in the process of automation reduces, these devices become more producing. Frequency of separate transmissions between them grows short, but, opposite, a size and term of actuality of blocks of data increase, requirements fall down to the real time. In spite of these distinctions, a requirement in horizontal and vertical communication meets on all levels.

Thus every level works mainly with data that is inferior him. Data that must be passed on higher levels, it is necessary in the beginning to abbreviate and squeeze. Related to it an informative concentration prevents to that one level was overloaded by data from other level. Data that must be passed on a lower-level, it is necessary before it to extend additional information. If these principles at structuring of task of automation will be executed: if every level will be independent, as far as maybe, and exchange information between levels will be to minimum, then the volume of horizontal stream of information will increase on every level.

At direct connections (point-to point connections), communication between two components of one level is possible only through a higher level. Partly it introduces a long way for passing of information. Information can be late, if the higher system appears with a limit carrying capacity.

In particular on low levels, where a rapid transmission is especially important, for horizontal communication, for "transversal motion" into one level, it is needed to go another way. All devices and systems of level automations between that there are communicative relations must be related to each other. Otherwise speaking: every partner of communication must be connected with each other. In the large projects of automation such structure will become tangled soon.

Communication into the different levels of automation - from the field level to the level of planning - produces different requirements to the tire. A large value for power and cost of tire of communication of data is had method and amount of transferrable data. At field level between many partners data are passed a few and to the high degree of actuality. An environment of transmission must be inexpensive. What higher hierarchical position, the more descriptions have transferrable data. It means that between not many partners the large packages of given, being actual long time, are passed. Tire must get along at such information content. Regardless of topology of network for communication the different environments of transmission are used.

4. Advantages and disadvantages

The main advantages of automation are:

Increased throughput or productivity.

Improved quality or increased predictability of quality.

Improved robustness (consistency), of processes or product.

Increased consistency of output.

Reduced direct human labor costs and expenses.

The following methods are often employed to improve productivity, quality, or robustness.

Install automation in operations to reduce cycle time.

Install automation where a high degree of accuracy is required.

Replacing human operators in tasks that involve hard physical or monotonous work.

Replacing humans in tasks done in dangerous environments (i.e. fire, space, volcanoes, nuclear facilities, underwater, etc.)

Performing tasks that are beyond human capabilities of size, weight, speed, endurance, etc.

Economic improvement: Automation may improve in economy of enterprises, society or most of humanity. For example, when an enterprise invests in automation, technology recovers its investment; or when a state or country increases its income due to automation like Germany or Japan in the 20th Century.

Reduces operation time and work handling time significantly.

Frees up workers to take on other roles.

Provides higher level jobs in the development, deployment, maintenance and running of the automated processes.

The main disadvantages of automation are:

Causing unemployment and poverty by replacing human labor.

Security Threats/Vulnerability: An automated system may have a limited level of intelligence, and is therefore more susceptible to committing errors outside of its immediate scope of knowledge (e.g., it is typically unable to apply the rules of simple logic to general propositions).

Unpredictable/excessive development costs: The research and development cost of automating a process may exceed the cost saved by the automation itself.

High initial cost: The automation of a new product or plant typically requires a very large initial investment in comparison with the unit cost of the product, although the cost of automation may be spread among many products and over time.

In manufacturing, the purpose of automation has shifted to issues broader than productivity, cost, and time.