- •Foreword

- •Preface the purpose of this book

- •Intended audience

- •Book organization

- •About b2t training

- •Chapter 1: Possess a Clear Understanding of Business Analysis overview

- •What is business analysis?

- •Business Analysis vs. Software Development

- •The Role of the Business Analyst

- •Business Analyst Traits

- •History of Business Analysis

- •Where Do Business Analysts Come From?

- •From it

- •Case in Point

- •From Business

- •Case in Point

- •Where Do Business Analysts Report?

- •Who makes a great business analyst?

- •Case in Point

- •Business Analyst Suitability (- відповідність) Questionnaire

- •Suitability Questionnaire

- •Answers

- •Business Analyst Career Progression

- •Key business analysis terms/concepts

- •What Is a Requirement?

- •Iiba Business Analysis Body of Knowledge® (babok®) definition of requirement:

- •Core Requirements Components

- •Why Document Requirements?

- •Why Do Requirements Need to Be Detailed?

- •High-Level Requirements Are Interpreted Differently

- •Many Analysts Only Use Text to Document Requirements

- •Complex Business Rules Must Be Found

- •Requirements Must Be Translated

- •Case in Point

- •What Is a Project?

- •What Is a Product?

- •What Is a Solution?

- •Case in Point

- •What Is a Deliverable?

- •System vs. Software

- •It Depends

- •Business analysis certification

- •Iiba babok®

- •Summary of key points

- •Bibliography

- •Chapter 2: Know Your Audience overview

- •Establish trust with your stakeholders

- •With whom does the business analyst work?

- •Executive or Project Sponsor

- •Case in Point: Giving the Sponsor Bad News

- •Project Manager

- •Why Does a Project Need a Project Manager and a Business Analyst?

- •Project Manager and Business Analyst Skills Comparison

- •Tips for Those Performing Both Roles

- •Other Business Analysis Professionals

- •Subject Matter Experts and Users

- •Getting to Know Your Subject Matter Experts

- •A Manager Who Does Not Understand His or Her Employees’ Work

- •When the Expert Is Not Really an Expert

- •When the Expert Is Truly an Expert

- •The Expert Who Is Reluctant to Talk

- •The Expert Who Is Angry about Previous Project Failures

- •The Expert Who Hates His or Her Job

- •Quality Assurance Analyst

- •When “qa” Is a Bad Word in Your Organization

- •Usability Professional

- •It Architect

- •Case in Point

- •It Developer

- •Case in Point

- •The Developer Who Is Very Creative

- •The Developer Who Codes Exactly to Specs

- •The Developer’s Industry Knowledge

- •Data Administrator/Architect/Analyst

- •Database Designer/Administrator

- •Stakeholder Analysis

- •Balancing stakeholder needs

- •Case in Point

- •Understanding the Political Environment

- •Working with dispersed teams

- •Physical Distance

- •Time Zone Differences

- •Nationality/Cultural Differences

- •Language Differences

- •Using Team Collaboration Tools

- •Using a Shared Presentation

- •Sharing a Document

- •Summary of key points

- •Bibliography

- •Chapter 3: Know Your Project

- •Why has the organization decided to fund this project?

- •Business Case Development

- •Case in Point

- •Project Initiated Because of a Problem

- •Case in Point

- •Project Initiated to Eliminate Costs (Jobs)

- •Project Initiated by Outside Regulation

- •Project Initiated by an Opportunity

- •Projects for Marketing or Advertising

- •Case in Point

- •Projects to Align Business Processes

- •Strategic planning

- •Portfolio and Program Management

- •How Does Your Project Relate to Others?

- •Enterprise Architecture

- •Business Architecture

- •The Organizational Chart

- •Locations

- •Swot (Strengths, Weaknesses, Opportunities, Threats)

- •Products

- •Information Architecture

- •Application Architecture

- •Technology Architecture

- •Case in Point

- •Security Architecture

- •Communicating Strategic Plans

- •Project Identification

- •Project initiation

- •Naming the Project

- •Initiation

- •Approach or Methodology

- •Statement of Purpose

- •Objectives

- •Problems/Opportunities

- •Stakeholders

- •Business Risks

- •Items Out of Scope

- •Assumptions

- •Scope of the Business Area

- •Scoping the Analysis Area Using a Context-Level Data Flow Diagram

- •Area of Study

- •High-Level Business Processes

- •Scoping the Analysis Area Using a Use Case Diagram

- •Project Initiation Summary Revisit Scope Frequently

- •Scope Creep

- •Summary of key points

- •Bibliography

- •Chapter 4: Know Your Business Environment overview

- •Case in Point

- •How does a business analyst learn about the enterprise?

- •Read the Company’s Marketing Materials

- •Read the Company’s Financial Reports

- •Review the Corporate Strategic Plan

- •Seeing things from the business perspective

- •Case in Point

- •Prioritizing Requests

- •Case in Point

- •How a business analyst learns the business: elicitation techniques

- •Review Existing Documentation

- •Case in Point

- •Observation

- •Case in Point

- •Case in Point

- •Interviews

- •Surveys and Questionnaires

- •Facilitated Sessions

- •Why Use a Facilitated Session?

- •Challenges for the Business Analyst as the Facilitator

- •Focus Groups

- •Competitive Analysis

- •Interface Analysis

- •Learn the current (as is) system

- •Case in Point

- •What is a business process?

- •Essential Analysis

- •Perfect Technology

- •No Storage Limitations or Constraints

- •Case in Point

- •Completely Error-Free Processing

- •Case in Point

- •No Performance Limitations

- •Technology Is Available at No Cost

- •Case in Point

- •Summary of Perfect Technology

- •Essential Business Processes

- •Case in Point

- •What Is the Difference between a Process and a Use Case?

- •Describing a Process

- •Seeing Things from the Top and from the Bottom

- •Implementation Planning

- •Training

- •Rollout Plan

- •Schedule

- •Metrics

- •Procedures/Organizational Changes

- •Summary of tips for learning your business

- •Summary of key points

- •Bibliography

- •Chapter 5: Know Your Technical Environment overview

- •Case in Point

- •Why does a business analyst need to understand the technical environment?

- •Understand Technology, But Don’t Talk Like a Technologist

- •Case in Point

- •What does a business analyst need to know about technology?

- •Software Development/Programming Terminology

- •Does a Business Analyst Need to Know How to Develop Software?

- •Software Development Methodologies

- •Methodology/Software Development Life Cycle

- •Waterfall

- •Planning Phase

- •Analysis Phase

- •Design Phase

- •Construction Phase

- •Testing Phase

- •Information Engineering

- •Joint Application Development/Design

- •Rapid Application Development

- •Iterative/Incremental Development Approaches

- •Object-Oriented Analysis and Design

- •Rational Unified Process

- •Agile Development Approaches

- •An Organization’s Formal Methodology

- •Why Don’t Most Methodologies Detail the Business Analysis Approach?

- •An Organization’s Informal Standards

- •Technical Architecture

- •Operating Systems

- •Case in Point

- •Computer Networking

- •Data Management

- •Relational Database

- •Structured Query Language

- •Software Usability/Human Interface Design

- •Software Testing

- •Case in Point

- •Software Testing Phases

- •Unit Testing

- •Integration Testing

- •System Testing

- •Regression Testing

- •Case in Point

- •User Acceptance Testing

- •Post-Implementation User Assessment

- •Working with it Communicating with Developers

- •When to Get it Involved in a Project

- •It Corporate Culture

- •Summary of key points

- •Bibliography

- •Chapter 6: Know Your Analysis Techniques overview

- •Case in Point

- •Categorizing and presenting requirements Collecting and Managing Requirements

- •What Is a Requirement?

- •Categorizing Requirements

- •Case in Point

- •Why Categorize Requirements?

- •Developing a System for Organizing Requirements

- •Iiba babok Categories

- •A Recommended Categorization System

- •Business Requirements

- •Functional Requirements

- •Technical Requirements

- •Core requirements components

- •Overview of Core Requirements Components Data (Entities and Attributes)

- •Processes (Use Cases)

- •External Agents (Actors)

- •Business Rules

- •Case in Point

- •Core Requirements Component: Entities (Data)

- •Core Requirements Component: Attributes (Data)

- •Attribute Uniqueness

- •Mandatory or Optional

- •Attribute Repetitions

- •Core Requirements Component: Processes (Use Cases)

- •Core Requirements Component: External Agents (Actors)

- •Internal vs. External

- •Core Requirements Component: Business Rules

- •Finding Business Rules

- •Analysis techniques and presentation formats

- •Glossary

- •Workflow Diagrams

- •Why Use Workflow Diagrams?

- •Entity Relationship Diagramming

- •Why Build a Logical Data Model?

- •Business Process Modeling with the Decomposition Diagram

- •Why Build a Decomposition Diagram?

- •Use Case Diagram

- •Use Case Descriptions

- •Why Use Use Cases?

- •Case in Point

- •Prototypes/Simulations

- •Why Use Prototypes/Simulations?

- •Other Techniques Event Modeling

- •Entity State Transition/uml State Machine Diagrams

- •Object Modeling/Class Modeling

- •User Stories

- •Traceability Matrices

- •Gap Analysis

- •Data Flow Diagramming

- •Choosing the Appropriate Techniques

- •Using Text to Present Requirements

- •Using Graphics to Present Requirements

- •Using a Combination of Text and Graphics

- •Choosing an Approach

- •Case in Point

- •Business Analyst Preferences

- •Case in Point

- •Subject Matter Expert Preferences

- •Case in Point

- •Developer Preferences

- •Project Manager Preferences

- •Standards

- •Case in Point

- •As is vs. To be analysis

- •Packaging requirements How Formally Should Requirements Be Documented?

- •What Is a Requirements Package?

- •Case in Point

- •Request for Proposal Requirements Package

- •Characteristics of Excellent Requirements

- •Getting Sign-Off

- •Requirements Tools, Repositories, and Management

- •Summary of key points

- •Bibliography

- •Chapter 7: Increase Your Value overview

- •Build your foundation Skill: Get Started

- •Skill: Think Analytically

- •Skill: Note Taking

- •Technique: Brainstorming

- •Skill: Work with Complex Details

- •Case in Point

- •How Much Detail? Just Enough!

- •Case in Point

- •Time management Skill: Understand the Nature of Project Work

- •Skill: Work on the Most Important Work First (Prioritize)

- •Case in Point

- •Technique: Understand the 80-20 Rule

- •Technique: Timeboxing

- •Build your relationships and communication skills Skill: Build Strong Relationships

- •Skill: Ask the Right Questions

- •Case in Point

- •Skill: Listen Actively

- •Barriers to Listening

- •Listening for Requirements

- •Skill: Write Effectively

- •Case in Point

- •Skill: Make Excellent Presentations

- •Skill: Facilitate and Build Consensus

- •Skill: Conduct Effective Meetings

- •Prepare for the Meeting/Select Appropriate Attendees

- •Meeting Agenda

- •Conducting the Meeting

- •Tips for Conducting Successful Meetings

- •Follow-Up/Meeting Minutes

- •Skill: Conduct Requirements Reviews

- •How to Conduct a Review

- •Step 1. Decide on the Purpose of the Review

- •Step 2. Schedule Time with Participants

- •Steps 3 and 4. Distribute Review Materials and Have Participants Review Materials Prior to the Session

- •Case in Point

- •Step 5. Conduct the Review Session

- •Steps 6 and 7. Record Review Notes and Update Material

- •Step 8. Conduct a Second Review If Necessary

- •Typical Requirements Feedback Corrections

- •Missing Requirements

- •Unclear Sentences

- •Scope Creep

- •Keep learning new analysis techniques Technique: Avoid Analysis Paralysis!

- •Technique: Root Cause Analysis

- •The Five Whys

- •Case in Point

- •Skill: Intelligent Disobedience

- •Continually improve your skills

- •Skill: Make Recommendations for Solutions

- •Understand the Problem

- •Imagine Possible Solutions

- •Case in Point

- •Evaluate Solutions to Select the Best

- •Skill: Be Able to Accept Constructive Criticism

- •Case in Point

- •Skill: Recognize and Act on Your Weaknesses

- •Technique: Lessons Learned

- •Business analysis planning

- •Technique: Map the Project

- •Examples of Mapped Projects

- •Skill: Plan Your Work

- •Technique: Assess Business Impact

- •Case in Point

- •Factors That Determine Business Impact

- •Case in Point

- •Technique: Conduct Stakeholder Analysis

- •Technique: Plan Your Communications

- •Skill: Choose Appropriate Requirements Deliverables

- •Skill: Develop a Business Analysis Task List

- •Skill: Estimate Your Time

- •Summary of key points

- •Bibliography

Glossary

An important component of strong communication is the consistent use of terms and phrases. It is easy to forget how dependent human beings are on language. Every conversation involves a common understanding of terms. When someone uses a term that you have never heard before, or uses a known term in a different way, the message is incomplete. Your brain may even get distracted thinking about the unknown term and miss the rest of the communication. Understanding the importance of terms is critical to successful analysis. Analysts must be precise when discussing and presenting requirements. The accurate use of terms, especially terms that are unique to a business domain, will ensure successful communication of requirements.

This points out another important lesson for the business analysis professional. You must be able to use the terms from the business even when they are foreign or unfamiliar to you. This is where a glossary can help. The analyst should begin jotting down important terms from the very first meetings with stakeholders. Terms that seem common and well known should be confirmed. Each term should be defined and the definition should be agreed upon by all project stakeholders. Undefined terms create ambiguous requirements.

An SME may describe a process as:

A customer purchases products by logging into the Web site and placing items in the shopping cart. When the buyer is ready to check out, the screen should display the total shipping charges and the total order amount.

Is the customer the same person as the buyer? Is an item always a product? What is the difference between the shopping cart and the order? Using inconsistent terminology in requirements often leads to mistakes in solution development.

Analysts must listen very carefully to the use of terms by stakeholders. As inconsistencies are found, they must be exposed. Be aware, though, that simply exposing an inconsistency will not correct it. If one department has been using the term customer and another department has been using the term client, you will not be able to quickly change either of their habits. You must first determine if they are using the terms in exactly the same way. If not, there may be two different words that are important and relevant here. Your job, as the analyst, is to point out the inconsistency, get agreement on the term definitions, and work to bring the group to consensus on shared language to be used in procedures and systems.

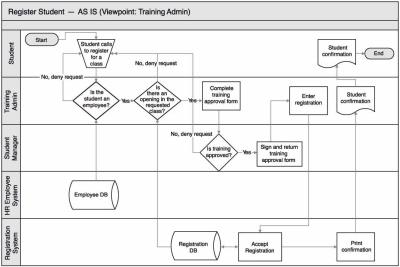

Workflow Diagrams

A workflow diagram visually details one or more business processes to clarify understanding or to make process improvement recommendations. Workflow diagrams (also known as flowcharting, UML activity diagrams, and process maps) are one of the oldest and most well-established analysis techniques. See Figure 6.2 for an example of a workflow diagram.

Workflow diagrams show how work is accomplished, including the sequence in which things are done. They can also show information flows through the processes and how business people and other external agents are involved with the process. They may be used to visually represent a current process (as is) or to represent a recommended future process (to be).

There are many variations of workflow diagrams. Almost every software development approach recommends their use for requirements. The American National Standards Institute (ANSI) (www.ansi.org) standardized symbols and shapes for use in these diagrams in the 1970s. A small subset of the standard is commonly used, and a few shapes (like the diamond for a decision) have become almost universally understood. A workflow diagram can be divided into sections to show departments or divisions within an organization. These sections are referred to as swim lanes. The UML shapes vary a bit from ANSI for use in the UML activity diagram.

The workflow diagram is one of the first techniques that a new analyst should learn. It is the most flexible technique, with few rules for its creation. The flexibility of the technique allows its use on many different types of projects. Its flexibility also makes it challenging for analysts. One of the decisions that an analyst will make when using this technique is whether or not a final diagram will be used as a formal deliverable. Although this decision is made for every technique, workflow diagrams are unique because they may be created at various levels of detail, for current or future systems, and for various audiences. When a workflow diagram is used as a formal deliverable, care must be taken to clearly communicate its purpose and its viewpoint.

Figure

6.2: Sample

Workflow Diagram

Figure

6.2: Sample

Workflow Diagram

Workflow diagrams are a great tool for analysts to use for note taking during requirements elicitation. Business stakeholders frequently describe their work as a series of tasks, interjecting notes about worker involvement and current software support. The analyst draws a picture of the business process to help understand it and confirm that understanding with the SMEs. Using a workflow diagram as a conversation tool does not imply that it must become a formal deliverable.

A relatively new approach to creating workflow diagrams is called Business Process Modeling Notation© (www.bpmn.org). This notation was defined by the Business Process Management Initiative, a non-profit professional organization striving to standardize business process modeling techniques. This organization merged with the Object Management Group (www.omg.org), which maintains the UML standards. Together the groups hope to produce a seamless transition from business modeling to software design.

Another type of workflow diagram is found in the Six Sigma approach to process improvement. The Six Sigma workflow diagram is called the SIPOC diagram (Supplier, Inputs, Process, Outputs, and Customer) and is used to show a high-level view of an entire business transaction. A process on a SIPOC diagram may be decomposed into a more detailed SIPOC diagram. This Six Sigma technique is used to identify and measure current business activities (as is) and perform root cause analysis to find process inefficiencies (Pande et al., 2000).

Lean approaches use a technique called value stream mapping to analyze the flow of materials and information to bring a product or service to the customer. It includes standard symbols for supply chain entities. The focus is on improving processes and reducing waste (www.lean.org).

Workflow diagrams are also used for implementation or transition requirements.

Employee procedure manuals, standard operating procedures, and rollout plans are all better communicated by including visual instructions rather than just text.