A8_Microfluidics_fundamentals_II

.pdf

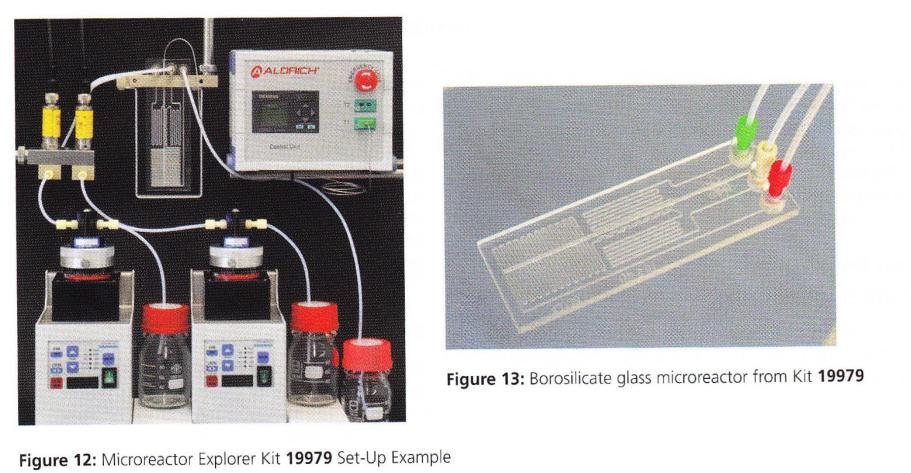

Commercial microreactor kit

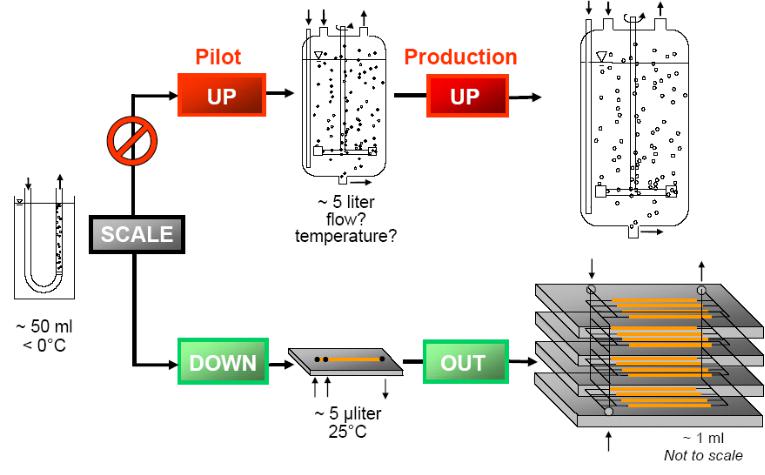

Microchemical systems

– scale down and out

Klavs Jensen, MIT

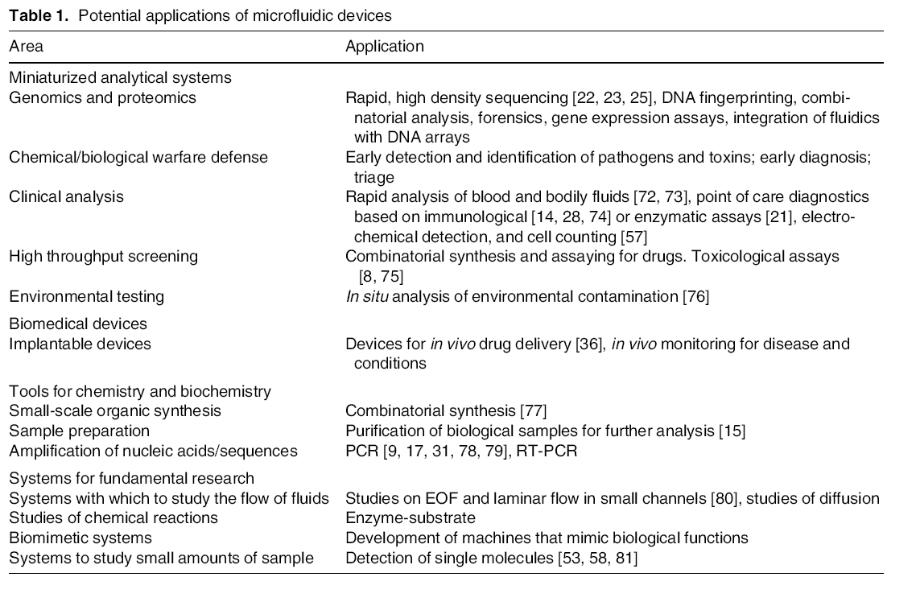

microfluidic chemical and biological analysis has been successfully applied to DNA sequencing, protein separation, single cell analysis, sample preparation/preconcentration, biomolecular sorting, and even single molecule detection

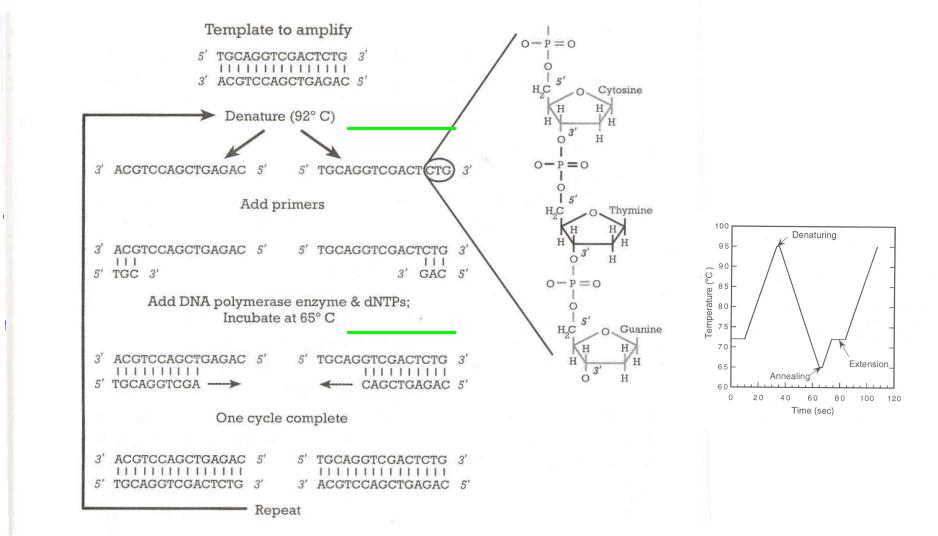

Miniature biochemical reaction chambers

PCR on a sylicon chip - I

(annealing)

(extension)

Temperature cycle for

a commercial macro-scale PCR machine

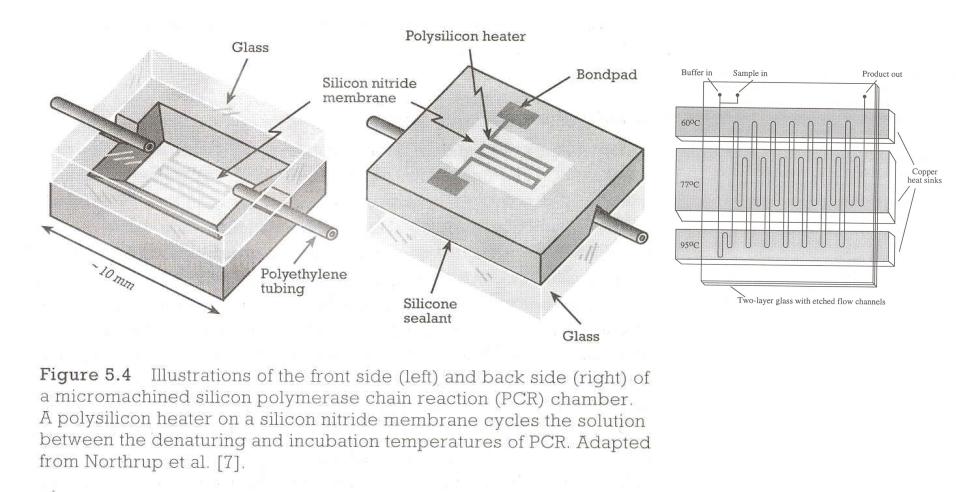

Miniature biochemical reaction chambers

PCR on a sylicon chip - II

•small thermal mass of chamber and fluid allows very fast temperature ramps

•small volume chamber

•many chambers can be arrayed

Continuous-flow PCR system

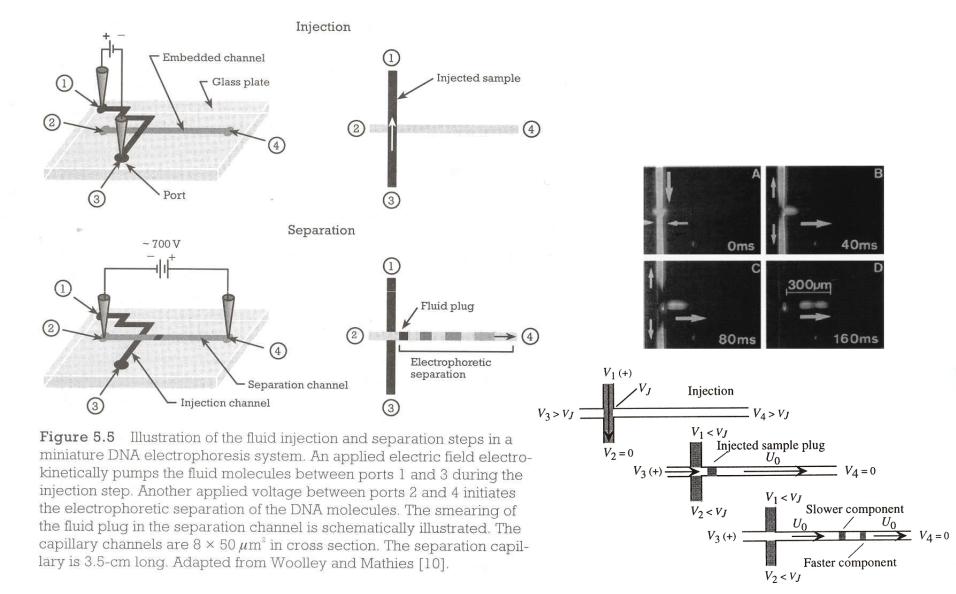

Electrophoresis on a chip

• small volumes

• high speed

• low voltage

• can be arrayed

• can be incorporated into a TAS system

Nanofluidic Coulter counter

passage of particle through pore disrupts electrical current betwen the two reservoirs – can detect single crossing events of submicron particles

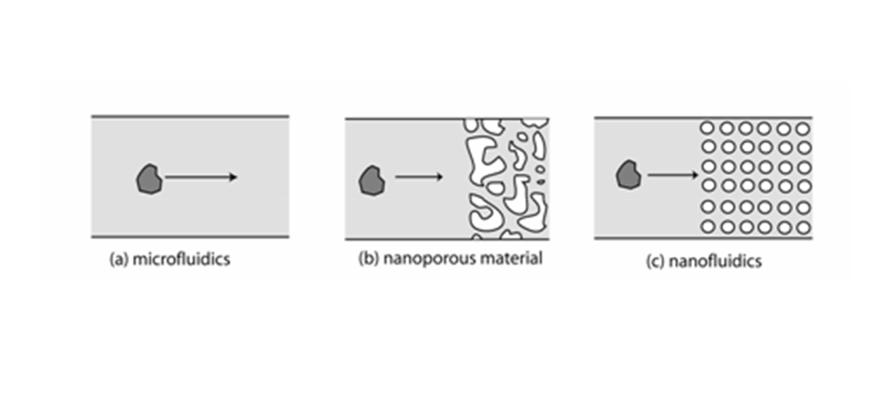

Microfluidics vs. nanofluidics

10-500 µm |

10-1000 nm |

Comparison between microfluidic and nanofluidic biomolecule separation:

(a)In microfluidic device, friction between liquid and the molecule determines the molecular mobility (often same mechanism as conventional analysis)

(b)In nanoporous material such as gel, molecules are filtered or sieved by random nanostructures

(c)In nanofluidic devices, the molecular sieve structure is well defined and regular

(b) and (c) interaction between the fluidic structure and molecules play dominant role, but in (c) it is easy to control and analyse

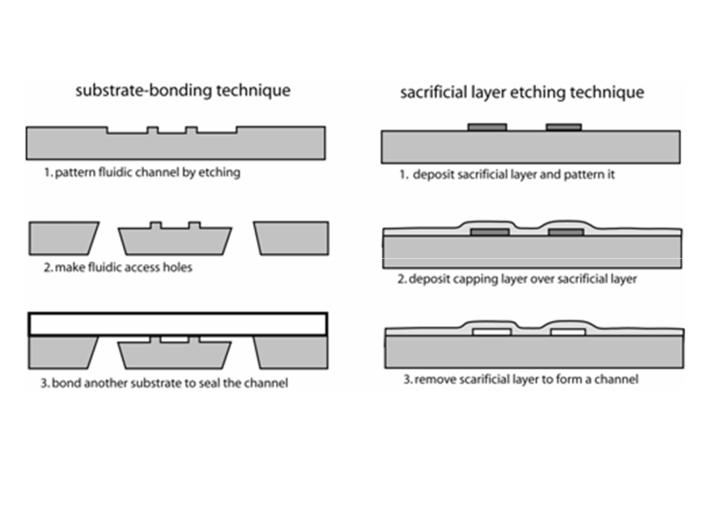

Nanofluidic fabrication

Two most common method for fabrication of nanofluidic devices.

(a) substrate-bonding method (b) sacrificial layer etching method.