Chemical Tankers / Day 2 / Day 2 topic 4 Vapour Recovery Systems

.pdf

Chemical Training

Vapour System

Vapour recovery purpose and compliance

For majority of the noxious liquid substances (NLS) carried aboard chemical tanker, it is not possible to vent vapours from the cargo tanks, lines and connections to atmosphere. Such cargoes are normally classed as "Toxic Products" and are subject to closed loading conditions.

Vapour recovery purpose and compliance

This also applies when inerting the cargo lines, tanks and connections with nitrogen from ashore, such as for the carriage of Acetic Acid. If no vapour return line is fitted the nitrogen would have to be vented to the atmosphere, and the subsequent loss of the inerting nitrogen represents a huge cost to the terminal.

Vapour recovery purpose and compliance

Some toxic cargoes have a Threshold Limit Value (TLV) that is so low that any release to the atmosphere is hazardous to personnel in the surrounding area. For these cargoes the crew will wear protective suits on-deck and, while working cargo, access to and from the ship is suspended.

Vapour recovery purpose and compliance

Government and State Authorities such as the USCG have requirement

that terminals control their vapor emissions.

This includes those produced during loading ships.

Required under Marpol Annex VI since May 2005.

Vapour recovery purpose and compliance

Provide a vapour collection system (vapor control, vapor

emission control) aboard the ship that is flexible and has

minimum installation cost.

Vapour recovery purpose and compliance

As from 19th of May 2005, Marpol Annex VI requires all tankers to use a vapour collection system when handling Volatile Organic Compounds (VOC).

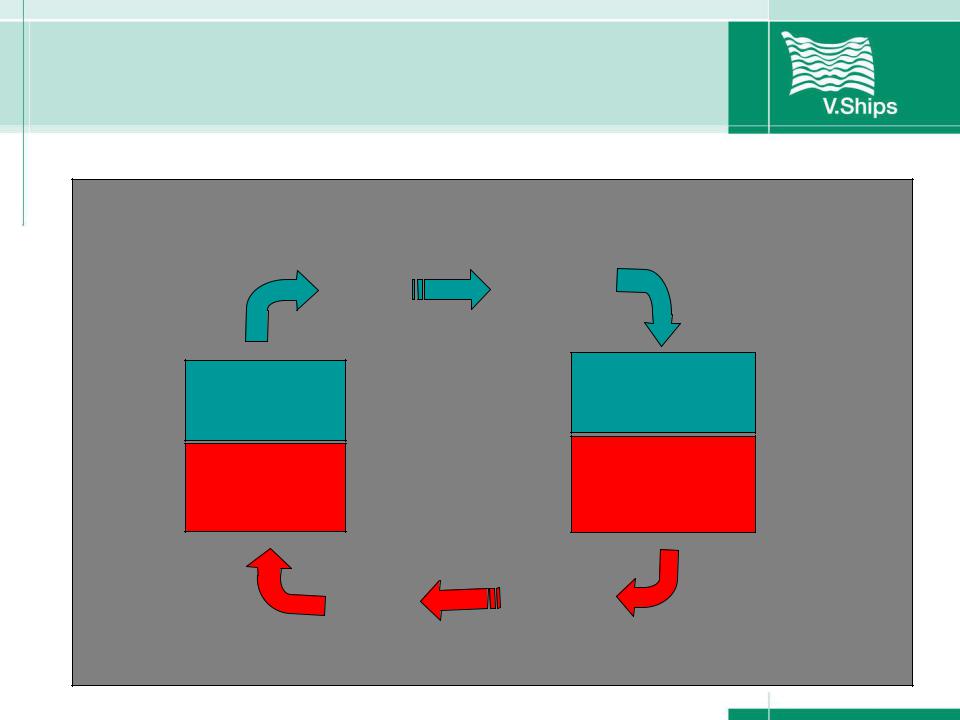

Vapour recovery system design

“ Vapor Recovery ” – Vapor returned to shore tank when loading

SHIP |

SHORE |

VAPOR

CARGO

Vapour recovery purpose and compliance

The vapour return line is a line running from the cargo tank back to the cargo manifold area. Each vapour return line will have its own separate manifold, which must be specially marked. This ensures that there is no mistake when connecting the loading line to the vapour return line.