Chemical Tankers / Day 2 / Day 2 topic 6 - Cargo Pumping Systems

.pdf

Centrifugal Pump

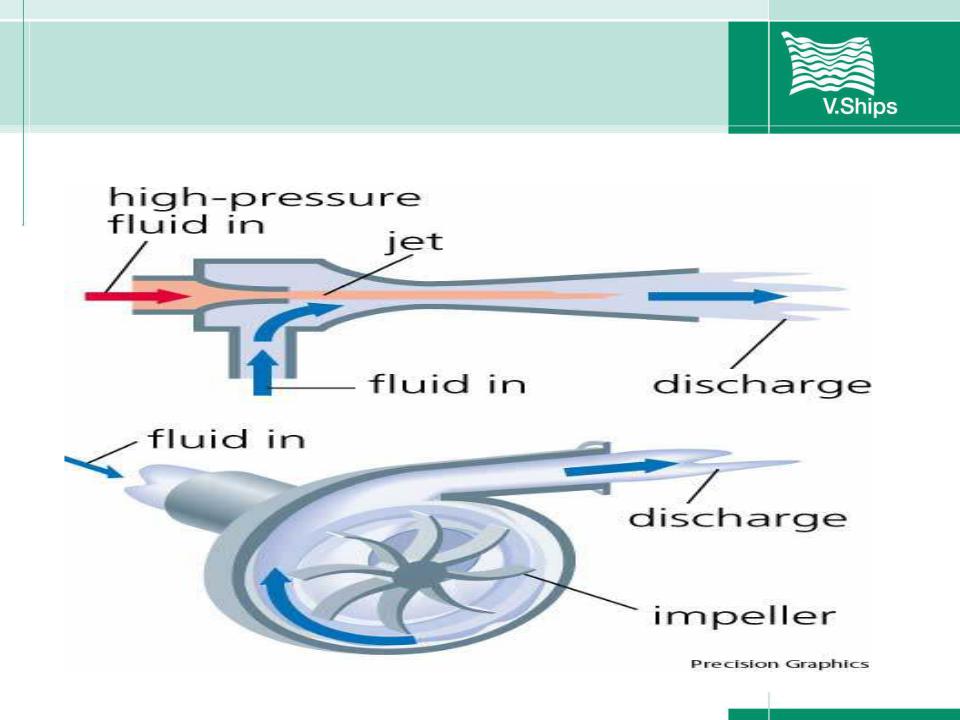

Eductor Systems

Cargo system associated fittings

Stripping system

Stripping Test and quantity

Stripping Pump

Stripping deep well pump

Use of air/inert gas

Heating system

Steam

Thermal oil

Steam traps

Steam reducing valve/steam pressure

Cargo Pumps

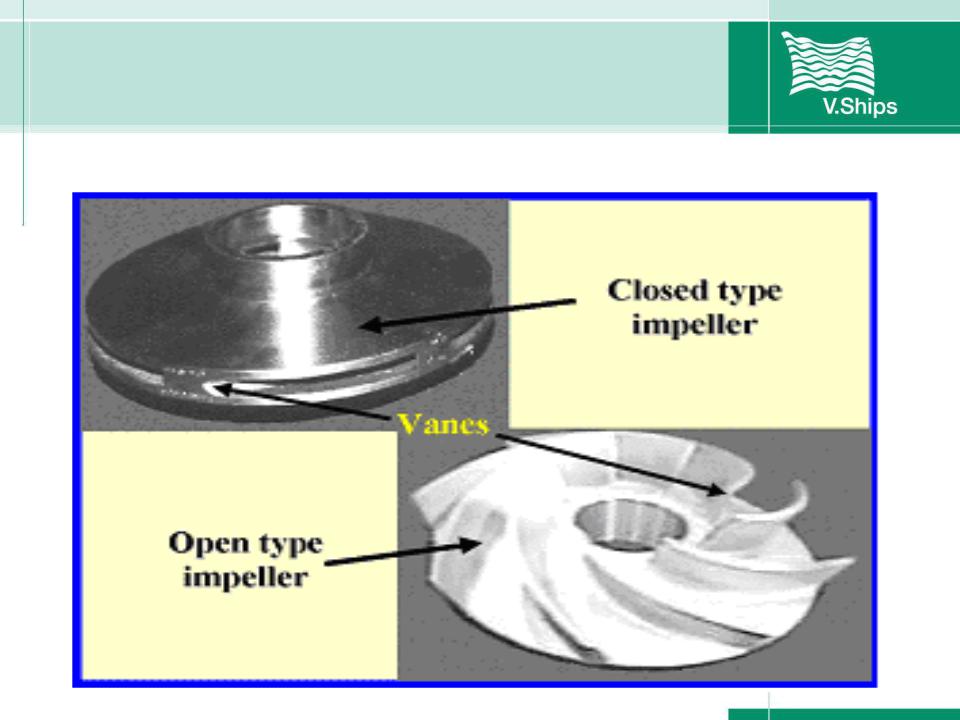

Centrifugal pumps

Stripping

Gassing

Viscous cargoes Problems

Screw pumps

Relief valve

Positive Displacement

Viscous cargo suitable

Reciprocating pumps

Positive Displacement

Viscous cargo suitable

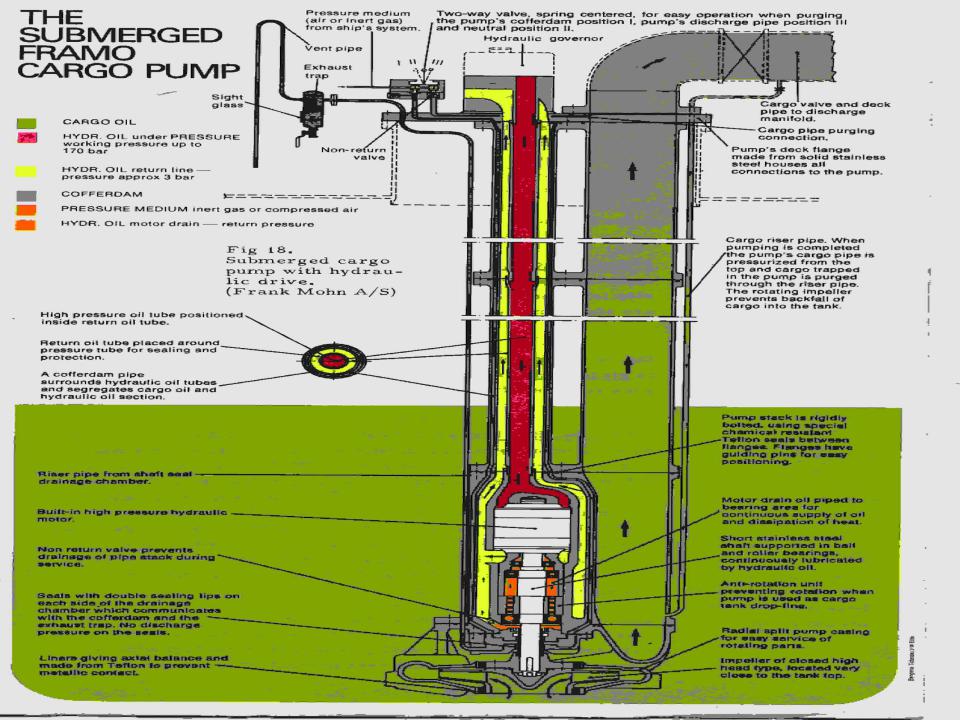

Deep well Pumps

Stripping/Individual pumps

Hydraulic Driven

Cold weatherHydraulic Piping LeakingNoise

Pump Inside tank

Electrical Driven

Long shaftCoolingStep-less Control

Cargo Pumps – Best Practice

Discharge pressure

Common discharge using individual pumps

Powerpack limitation/Electrical Load Limitation

Pressure gauges at manifold

Cargo pump maintenance

Cofferdam purging

Wear rings

Screw wear

Cargo Pumps

Cargo Piping Pressure test

Cargo valves

Markings

Butterfly valve

Gate valves

Ball valves

Precaution and problems ?

Cargo Pumps - various

Steaming of cargo piping

Double lip seal damage

Hydraulic oil leak in pump cofferdam

Portable pump(Emergency pump)

Precautions when connecting and disconnecting hydraulic hoses

Discharge hose coupling

Regular testing and familiarisation

Stripping of Cargo Tanks

Stripping of cargo tanks should be performed as per the guidance in the vessel's P&A Manual and with regard to any manufacturers' instructions. During tank stripping and line clearing the ship's list and trim must be maintained within the guidance in the P&A Manual.