- •TABLE OF CONTENTS

- •CHAPTER 1 Structure of Materials

- •CHAPTER 2 Composition of Materials

- •CHAPTER 3 Phase Diagram Sources

- •Compressive Strength

- •Yield Strength

- •Shear Strength

- •Hardness

- •Abrasion Resistance

- •Fracture Toughness

- •Tensile Modulus

- •Young’s Modulus

- •Elastic Modulus

- •Compression Modulus

- •Bulk Modulus

- •Torsion Modulus

- •Modulus of Rupture

- •Elongation

- •Area Reduction

- •Viscosity

- •Dissipation Factor

- •Dielectric Strength

- •Tangent Loss

- •Density

- •Heat of Fusion

- •Thermal Conductivity

- •Thermal Expansion

- •Compressive Strength

- •Yield Strength

- •Flexural Strength

- •Friction

- •Abrasion Resistance

- •Poisson’s Ratio

- •Elongation

- •Area Reduction

- •Dissipation Factor

- •Tangent Loss

- •Permittivity

- •Arc Resistance

- •Flammability

CHAPTER 3 Phase Diagram Sources

List of Tables |

Phase Diagram Sources |

©2001 CRC Press LLC

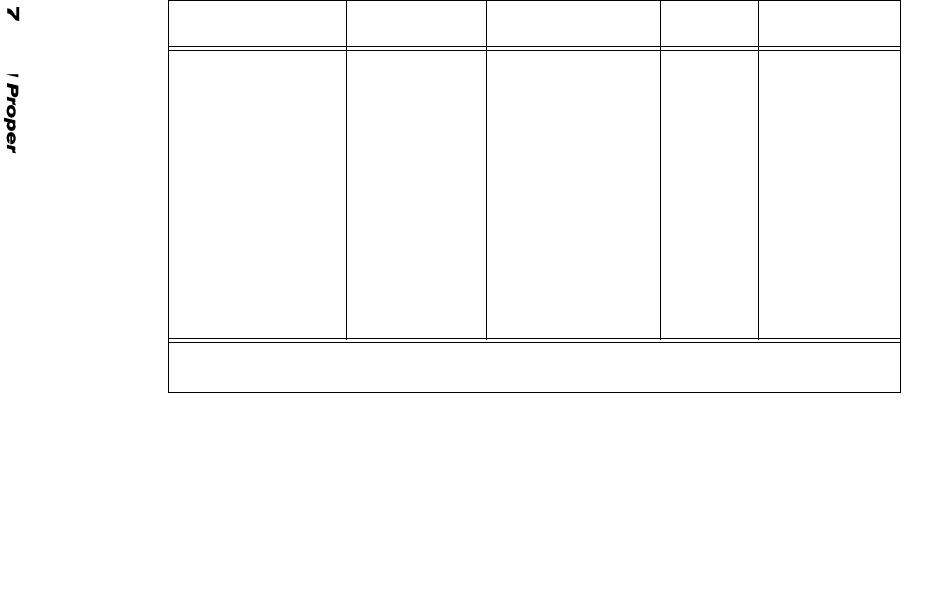

Phase Diagrams are especially useful tools for the field of materials science and engineering. In the last decade, a substantial effort has been made within the materials community to provide a comprehensive set of accurate phase equilibria information. Cooperative efforts involving academia, industry, and government have been coordinated through the professional societies, ASM International and the American Ceramic Society. As a result, the following references are available and new updates will become available on a regular basis.

|

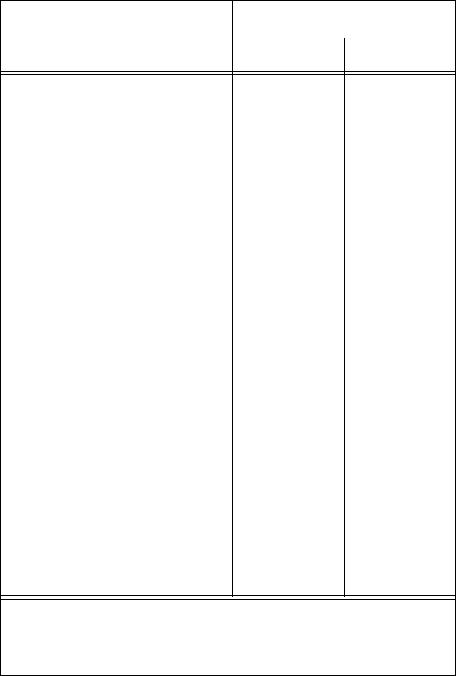

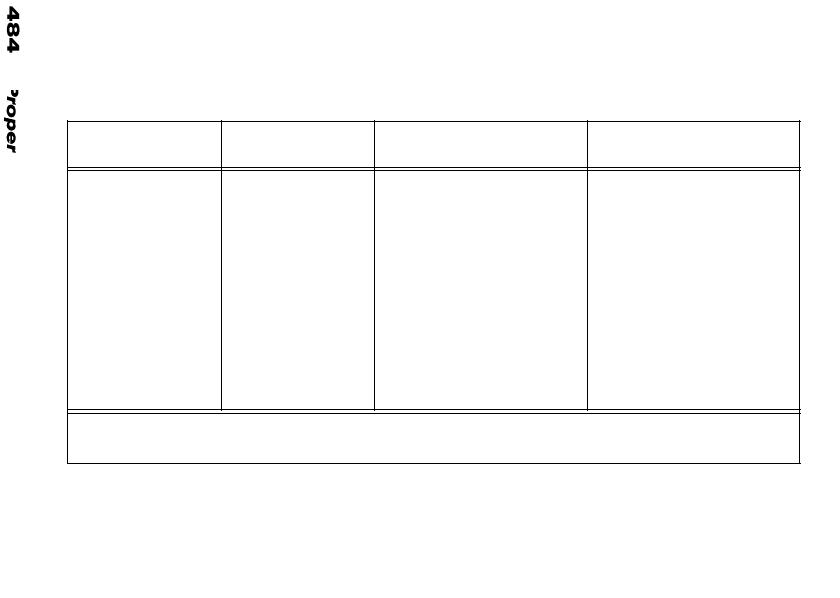

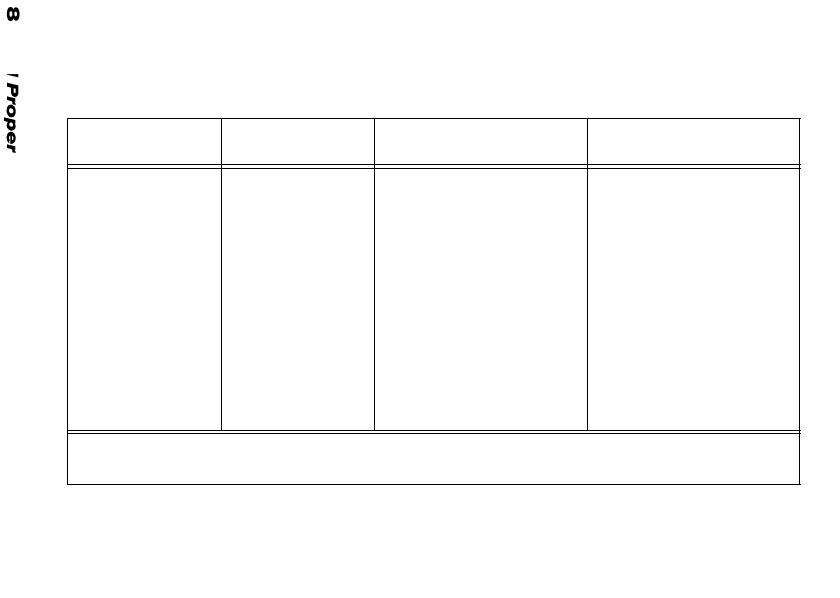

Table 63. PHASE DIAGRAM SOURCES |

|

|

|

|

Society |

|

Source |

|

|

|

|

|

|

American Ceramic |

|

Phase Diagrams for Ceramists, Vols. 1-12, American Ceramic |

|

Society, Westerville, Ohio, 1964, 1969, 1975, 1981, 1983, 1987, |

|

Society |

|

|

|

1989, 1989, 1992, 1994, 1995, and 1996. |

|

|

|

|

|

|

Binary Alloy Phase Diagrams, Second Edition, Vols. 1, 2 and 3, |

ASM International |

|

T.B. Massalski, et.al., ed., ASM International, Materials Park, |

|

|

Ohio, 1990. |

ASM International |

|

ASM Handbook, Vol. 3, ASM International, Materials Park, |

|

Ohio, 1992. |

|

|

|

|

|

|

|

©2001 CRC Press LLC

Shackelford, James F. & Alexander, W. “Thermodynamic and Kinetic Data”

Materials Science and Engineering Handbook

Ed. James F. Shackelford & W. Alexander Boca Raton: CRC Press LLC, 2001

CHAPTER 4

Thermodynamic and

Kinetic Data

List of Tables |

Bond Strengths |

|

Bond Strengths in Diatomic Molecules |

|

Bond Strengths of Polyatomic Molecules |

|

Solubility of Copper and Copper Alloys |

|

Heat of Formation of Inorganic Oxides |

Phase Change

Phase Change Thermodynamic Properties for The Elements

Phase Change Thermodynamic Properties of Oxides

Melting Point

Melting Points of the Elements

Melting Points of Elements and Inorganic Compounds

Melting Points Of Ceramics

Heat of Fusion & Sublimation

Heat of Fusion For Elements and Inorganic Compounds

Heats of Sublimation of Metals and Their Oxides

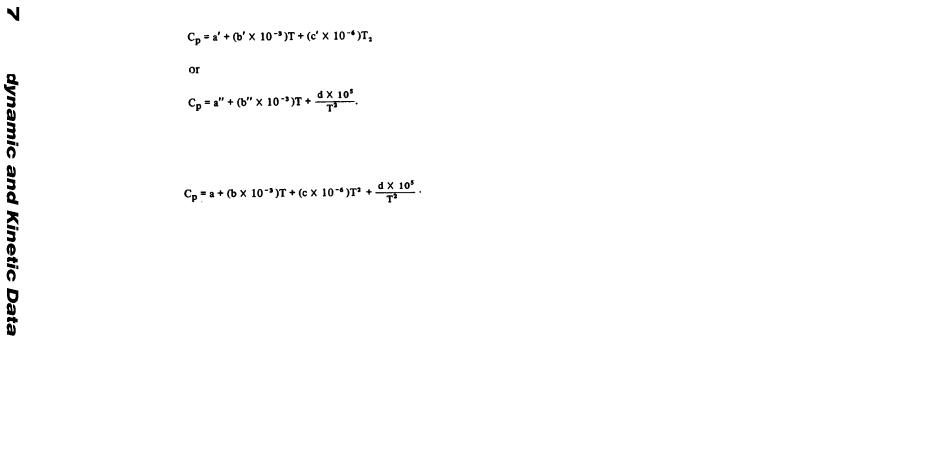

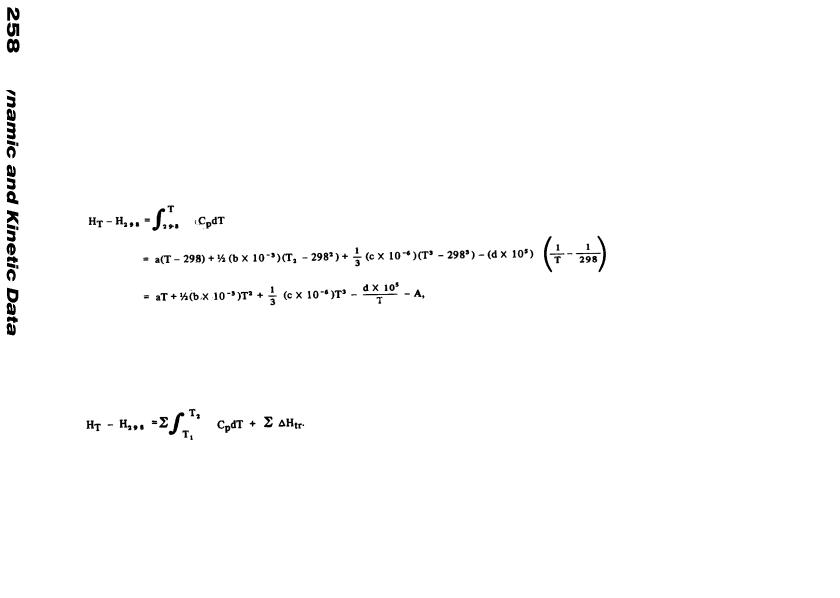

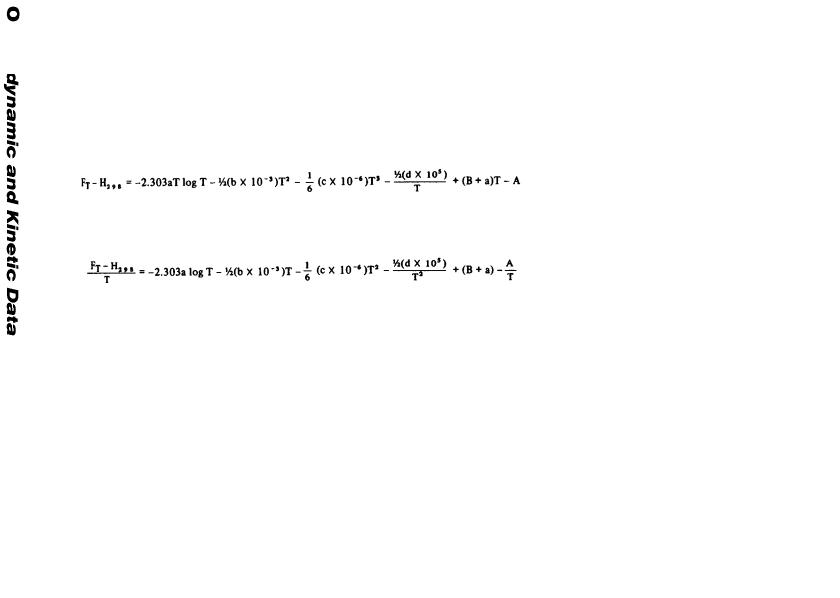

Thermodynamic Coefficients

Key to Tables of Thermodynamic Coefficients

Thermodynamic Coefficients for Selected Elements

Thermodynamic Coefficients for Oxides

Entropy

Entropy of the Elements

©2001 CRC Press LLC

List of Tables

(Continued)

Vapor Pressure

Vapor Pressure of the Elements at Very Low Pressures Vapor Pressure of the Elements at Moderate Pressures Vapor Pressure of the Elements at High Pressures Vapor Pressure of Elements and Inorganic Compounds

Diffusion

Values of The Error Function

Diffusion in Metallic Systems

Diffusion of Metals into Metals

Diffusion in Semiconductors

©2001 CRC Press LLC

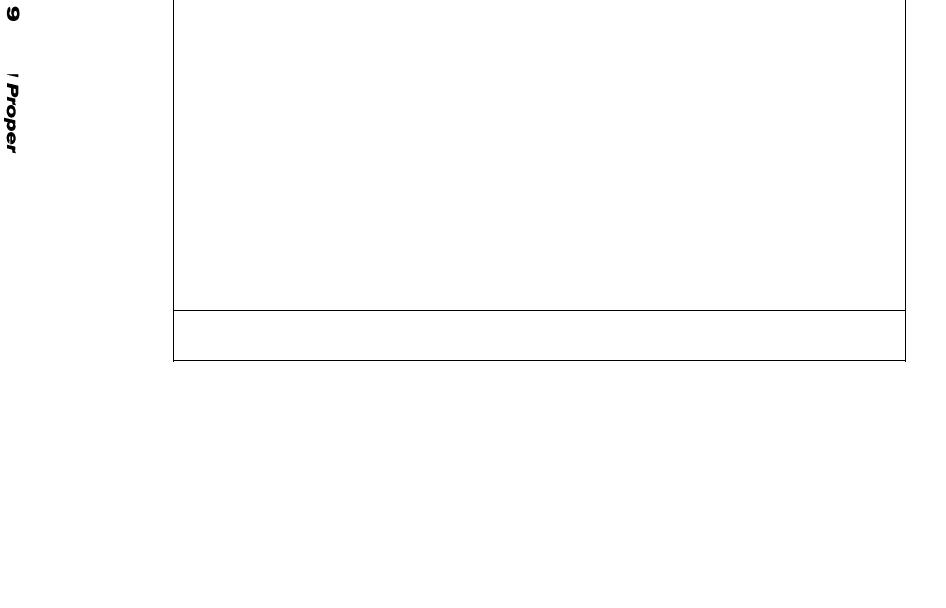

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 1 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

H–H |

104.207 |

|

± 0.001 |

H–D |

105.030 |

|

± 0.001 |

D–D |

106.010 |

|

± 0.001 |

H–Li |

56.91 |

|

± 0.01 |

H–Be |

54 |

|

|

H–B |

79 |

|

± 1 |

H–C |

80.9 |

|

|

H–N |

75 |

|

± 4 |

H–O |

102.34 |

|

± 0.30 |

H–F |

135.9 |

|

± 0.3 |

H–Na |

48 |

|

± 5 |

H–Mg |

47 |

|

± 12 |

H–Al |

68 |

|

± 2 |

H–Si |

71.4 |

|

± 1.2 |

H–P |

82 |

|

± 7 |

H–S |

82.3 |

|

± 2.9 |

H–Cl |

103.1 |

|

|

H–K |

43.8 |

|

± 3.5 |

H–Ca |

40.1 |

|

|

H–Cr |

67 |

|

± 12 |

H–Mn |

56 |

|

± 7 |

H–Ni |

61 |

|

± 7 |

H –Cu |

67 |

|

± 2 |

H–Zn |

20.5 |

|

± 0.5 |

H –Ga |

68 |

|

± 5 |

H–Ge |

76.8 |

|

± 0.2 |

H–As |

65 |

|

± 3 |

H–Se |

73 |

|

± 1 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 2 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

H–Br |

87.4 |

|

± 0.5 |

H–Rb |

40 |

|

± 5 |

H–Sr |

39 |

|

± 2 |

H–Ag |

59 |

|

± 1 |

H–Cd |

16.5 |

|

± 0.1 |

H–In |

59 |

|

± 2 |

H–Sn |

63 |

|

± 1 |

H–Te |

64 |

|

± 1 |

H–I |

71.4 |

|

± 0.2 |

H–Cs |

42.6 |

|

± 0.9 |

H–Ba |

42 |

|

± 4 |

H–Yb |

38 |

|

± 1 |

H–Pt |

84 |

|

± 9 |

H–Au |

75 |

|

± 3 |

H–Hg |

9.5 |

|

|

H–Ti |

45 |

|

± 2 |

H–Pb |

42 |

|

± 5 |

H–Bi |

59 |

|

± 7 |

Li–Li |

24.55 |

|

± 0.14 |

Li–O |

78 |

|

± 6 |

Li– F |

137.5 |

|

± 1 |

Li–Cl |

111.9 |

|

± 2 |

Li–Br |

100.2 |

|

± 2 |

Li–I |

84.6 |

|

± 2 |

Be–Be |

17 |

|

|

Be–0 |

98 |

|

± 7 |

Be–F |

136 |

|

± 2 |

Be–S |

89 |

|

± 14 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 3 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Be–Cl |

92.8 |

|

± 2.2 |

Be–Au |

~ 67 |

|

|

B–B |

~ 67 |

|

± 5 |

B–N |

93 |

|

± 12 |

B–0 |

192.7 |

|

± 1.2 |

B–F |

180 |

|

± 3 |

B–S |

138.8 |

|

± 2.2 |

B–Cl |

119 |

|

|

B–Se |

110 |

|

± 4 |

B–Br |

101 |

|

± 5 |

B–Ru |

107 |

|

± 5 |

B–Rh |

114 |

|

± 5 |

B–Pd |

79 |

|

± 5 |

B–Te |

85 |

|

± 5 |

B–Ce |

~ 100 |

|

|

B–Ir |

123 |

|

± 4 |

B–Pt |

114 |

|

± 4 |

B–Au |

82 |

|

± 4 |

B–Th |

71 |

|

|

C–C |

144 |

|

± 5 |

C–N |

184 |

|

± 1 |

C–0 |

257.26 |

|

± 0.77 |

C–F |

128 |

|

± 5 |

C–Si |

104 |

|

± 5 |

C–P |

139 |

|

± 23 |

C–S |

175 |

|

± 7 |

C–Cl |

93 |

|

|

C–Ti |

~128 |

|

|

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 4 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

C–V |

133 |

|

|

C–Ge |

110 |

|

± 5 |

C–Se |

139 |

|

± 23 |

C–Br |

67 |

|

± 5 |

C–Ru |

152 |

|

± 3 |

C–Rh |

139 |

|

± 2 |

C–I |

50 |

|

± 5 |

C–Ce |

109 |

|

± 7 |

C–Ir |

149 |

|

± 3 |

C–Pt |

146 |

|

± 2 |

C–U |

111 |

|

± 7 |

N–N |

226.8 |

|

± 1.5 |

N–O |

150.8 |

|

± 0.2 |

N–F |

62.6 |

|

± 0.8 |

N–Al |

71 |

|

± 23 |

N–Si |

105 |

|

± 9 |

N–P |

148 |

|

± 5 |

N–S |

~ 120 |

|

± 6 |

N–Cl |

93 |

|

± 12 |

N–Ti |

111 |

|

|

N–As |

116 |

|

± 23 |

N–Se |

105 |

|

± 23 |

N–Br |

67 |

|

± 5 |

N–Sb |

72 |

|

± 12 |

N–I |

~.38 |

|

|

N–Xe |

55 |

|

|

N–Th |

138 |

|

± 1 |

N–U |

127 |

|

± 1 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 5 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

O–O |

118.86 |

|

± 0.04 |

O–F |

56 |

|

± 9 |

O–Na |

61 |

|

± 4 |

O–Mg |

79 |

|

± 7 |

O–Al |

116 |

|

± 5 |

O–Si |

184 |

|

± 3 |

O–P |

119.6 |

|

± 3 |

O–S |

124.69 |

|

± 0.03 |

O–Cl |

64.29 |

|

± 0.03 |

O–K |

57 |

|

± 8 |

O–Ca |

84 |

|

± 7 |

O–Sc |

155 |

|

± 5 |

O–Ti |

158 |

|

± 8 |

O–V |

154 |

|

± 5 |

O–Cr |

110 |

|

± 10 |

O–Mn |

96 |

|

± 8 |

O–Fe |

96 |

|

± 5 |

O–Co |

88 |

|

± 5 |

O–Ni |

89 |

|

± 5 |

O–Cu |

82 |

|

± 15 |

O–Zn |

≤ 66 |

|

|

O–Ga |

68 |

|

± 15 |

O–Ge |

158.2 |

|

± 3 |

O–As |

115 |

|

± 3 |

O–Se |

101 |

|

|

O–Br |

56.2 |

|

± 0.6 |

O–Rb |

(61) |

|

± 20 |

O–Sr |

93 |

|

± 6 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 6 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

O–Y |

162 |

|

± 5 |

O–Zr |

181 |

|

± 10 |

O–Nb |

189 |

|

± 10 |

O–Mo |

115 |

|

± 12 |

O–Ru |

115 |

|

± 15 |

O–Rh |

90 |

|

± 15 |

O–Pd |

56 |

|

± 7 |

O–Ag |

51 |

|

± 20 |

O–Cd |

≤ 67 |

|

|

O–In |

≤ 77 |

|

|

O–Sn |

127 |

|

± 2 |

O–Sb |

89 |

|

± 20 |

O–Fe |

93.4 |

|

± 2 |

O–I |

47 |

|

± 7 |

O–Xe |

9 |

|

± 5 |

O–Cs |

67 |

|

± 8 |

O–Ba |

131 |

|

± 6 |

O–La |

188 |

|

± 5 |

O–Ce |

188 |

|

± 6 |

O–Pr |

183.7 |

|

|

O–Nd |

168 |

|

± 8 |

O–Sm |

134 |

|

± 8 |

O–Eu |

130 |

|

± 10 |

O–Gd |

162 |

|

± 6 |

O–Tb |

165 |

|

± 8 |

O–Dy |

146 |

|

± 10 |

O–Ho |

149 |

|

± 10 |

O–Er |

147 |

|

± 10 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 7 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

O–Tm |

122 |

|

± 15 |

O–Yb |

98 |

|

± 15 |

O–Lu |

159 |

|

± 8 |

O–Hf |

185 |

|

± 10 |

O–Ta |

183 |

|

± 15 |

O–W |

156 |

|

± 6 |

O–Os |

< 142 |

|

|

O–Ir |

≤ 94 |

|

|

O–Pt |

83 |

|

± 8 |

O–Pb |

90.3 |

|

± 1.0 |

O–Bi |

81.9 |

|

± 1.5 |

O–Th |

192 |

|

± 10 |

O–U |

182 |

|

± 8 |

O–Np |

172 |

|

± 7 |

O–Pu |

163 |

|

± 15 |

O–Cm |

≤ 134 |

|

|

F–F |

37.5 |

|

± 2.3 |

F–Na |

114 |

|

± 1 |

F–Mg |

110 |

|

± 1 |

F–Al |

159: |

|

± 3 |

F–Si |

116 |

|

± 12 |

F–P |

105 |

|

± 23 |

F–Cl |

59.9 |

|

± 0.1 |

F–K |

118.9 |

|

± 0.6 |

F–Ca |

125 |

|

± 5 |

F–Sc |

141 |

|

± 3 |

F–Ti |

136 |

|

± 8 |

F–Cr |

104.5 |

|

± 4.7 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 8 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

F–Mn |

101.2 |

|

± 3.5 |

F–Ni |

89 |

|

± 4 |

F–Cu |

88 |

|

± 9 |

F–Ga |

138 |

|

± 4 |

F–Ge |

116 |

|

± 5 |

F–Br |

55.9 |

|

|

F–Rb |

116.1 |

|

± 1 |

F–Sr |

129.5 |

|

± 1.6 |

F–Y |

144 |

|

± 5 |

Mg–I |

~.68 |

|

|

Mg–Au |

59 |

|

± 23 |

Al–Al |

44 |

|

|

Al–P |

52 |

|

± 3 |

Al–S |

79 |

|

|

Al–Cl |

119.0 |

|

± 1 |

Al–Br |

103.1 |

|

|

Al–I |

88 |

|

|

Al–Au |

65 |

|

|

Al–U |

78 |

|

± 7 |

Si–Si |

76 |

|

± 5 |

Si–S |

148 |

|

± 3 |

Si–Cl |

105 |

|

± 12 |

Si–Fe |

71 |

|

± 6 |

Si–Co |

66 |

|

± 4 |

Si–Ni |

76 |

|

± 4 |

Si–Ge |

72 |

|

± 5 |

Si–Se |

127 |

|

± 4 |

Si–Br |

82 |

|

± 12 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 9 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Si–Ru |

95 |

|

± 5 |

Si–Rh |

95 |

|

± 5 |

Si–Pd |

75 |

|

± 4 |

Si–Te |

121 |

|

± 9 |

Si–Ir |

110 |

|

± 5 |

Si–Pt |

120 |

|

± 5 |

Si–Au |

75 |

|

± 3 |

P–P |

117 |

|

± 3 |

F–Ag |

84.7 |

|

± 3.9 |

F–Cd |

73 |

|

± 5 |

F–In |

121 |

|

± 4 |

F–Sn |

111.5 |

|

± 3 |

F–Sb |

105 |

|

± 23 |

F–I |

67? |

|

|

F–Xe |

11 |

|

|

F–Cs |

119.6 |

|

± 1 |

F–Ba |

140.3 |

|

± 1.6 |

F–Nd |

130 |

|

± 3 |

F–Sm |

126.9 |

|

± 4.4 |

F–Eu |

126.1 |

|

± 4.4 |

F–Gd |

141. |

|

± 46.5 |

F–Hg |

31 |

|

± 9 |

F–Ti |

106.4 |

|

± 4.6 |

F–Pb |

85 |

|

± 2 |

F–Bi |

62 |

|

|

F–Pu |

129 |

|

± 7 |

Na–Na |

18.4 |

|

|

Na–Cl |

97.5 |

|

± 0.5 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 10 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Na–K |

15.2 |

|

± 0.7 |

Na–Br |

86.7 |

|

± 1 |

Na–Rb |

14 |

|

± 1 |

Na–I |

72.7 |

|

± 1 |

Mg–Mg |

8? |

|

|

Mg–S |

56? |

|

|

Mg–Cl |

76 |

|

± 3 |

Mg–Br |

75 |

|

± 23 |

P–S |

70 |

|

|

P–Ga |

56 |

|

|

P–W |

73 |

|

± 1 |

P–Th |

90 |

|

|

S–S |

101.9 |

|

± 2.5 |

S–Ca |

75 |

|

± 5 |

S–Sc |

114 |

|

± 3 |

S–Mn |

72 |

|

± 4 |

S–Fe |

78 |

|

|

S–Cu |

72 |

|

± 12 |

S–Zn |

49 |

|

± 3 |

S–Ge |

131.7 |

|

± 0.6 |

S–Se |

91 |

|

± 5 |

S–Sr |

75 |

|

± 5 |

S–Y |

127 |

|

± 3 |

S–Cd |

48 |

|

|

S–In |

69 |

|

± 4 |

S–Sn |

111 |

|

± 1 |

S–Te |

81 |

|

± 5 |

S–Ba |

96 |

|

± 5 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 11 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

S–La |

137 |

|

± 3 |

S–Ce |

137 |

|

± 3 |

S–Pr |

122.7 |

|

|

S– Nd |

113 |

|

± 4 |

S–Eu |

87 |

|

± 4 |

S–Gd |

126 |

|

± 4 |

S–Ho |

102 |

|

± 4 |

S–Lu |

121 |

|

± 4 |

S–Au |

100 |

|

± 6 |

S–Hg |

51 |

|

|

S–Pb |

82.7 |

|

± 0.4 |

S–Bi |

75.4 |

|

± 1.1 |

S–U |

135 |

|

± 2 |

Cl–Cl |

58.066 |

|

± 0.001 |

Cl–K |

101.3 |

|

± 0.5 |

Cl–Ca |

95 |

|

± 3 |

Cl–Sc |

79 |

|

|

Cl–Ti |

26 |

|

± 2 |

Cl–Cr |

87.5 |

|

± 5.8 |

Cl–Mn |

86.2 |

|

± 2.3 |

Cl–Fe |

84? |

|

|

Cl–Ni |

89 |

|

± 5 |

Cl–Cu |

84 |

|

± 6 |

Cl–Zn |

54.7 |

|

± 4.7 |

Cl–Ga |

114.5 |

|

|

Cl–Ge |

82? |

|

|

Cl–Br |

52.3 |

|

± 0.2 |

Cl–Rb |

100.7 |

|

± 1 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 12 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Cl–Sr |

97 |

|

± 3 |

Cl–Y |

82 |

|

± 23 |

Cl–Ag |

75 |

|

± 9 |

Cl–Cd |

49.9 |

|

|

Cl–In |

103.3 |

|

|

CI–Sn |

75? |

|

|

Cl–Sb |

86 |

|

± 12 |

Cl–I |

50.5 |

|

± 0.1 |

Cl–Cs |

106.2 |

|

± 1 |

Cl–Ba |

106 |

|

± 3 |

Cl–Au |

82 |

|

± 2 |

Cl–Hg |

24 |

|

± 2 |

Cl–Ti |

89.0 |

|

± 0.5 |

Cl–Pb |

72 |

|

± 7 |

Cl–Bi |

72 |

|

± 1 |

Cl–Ra |

82 |

|

± 18 |

Ar–Ar |

0.2 |

|

|

K–K |

12.8 |

|

|

K–Br |

90.9 |

|

± 0.5 |

K–I |

76.8 |

|

± 0.5 |

Ca–I |

70 |

|

± 23 |

Ca–Au |

18 |

|

|

Sc–Sc |

25.9 |

|

± 5 |

Ti–Ti |

34 |

|

± 5 |

V–V |

58 |

|

± 5 |

Cr–Cr |

<37 |

|

|

Cr –Cu |

37 |

|

± 5 |

Cr–Ge |

41 |

|

± 7 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 13 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Cr–Br |

78.4 |

|

± 5 |

Cr–I |

68.6 |

|

± 5.8 |

Cr–Au |

51.3 |

|

± 3.5 |

Mn–Mn |

4 |

|

± 3 |

Mn–Se |

48 |

|

± 3 |

Mn–Br |

75.1 |

|

± 23 |

Mn–I |

67.6 |

|

± 2.3 |

Mn–Au |

44 |

|

± 3 |

Fe–Fe |

24 |

|

± 5 |

Fe–Ge |

50 |

|

± 7 |

Fe–Br |

59 |

|

± 23 |

Fe–Au |

45 |

|

± 4 |

Co–Co |

40 |

|

± 6 |

Co–Cu |

39 |

|

± 5 |

Co–Ge |

57 |

|

± 6 |

Co–Au |

51 |

|

± 3 |

Ni–Ni |

55.5 |

|

± 5 |

Ni–Cu |

48 |

|

± 5 |

Ni–Ge |

67.3 |

|

± 4 |

Ni–Br |

86 |

|

± 3 |

Ni–I |

70 |

|

± 5 |

Ni–Au |

59 |

|

± 5 |

Cu–Cu |

46.6 |

|

± 2.2 |

Cu–Ge |

49 |

|

± 5 |

Cu–Se |

70 |

|

± 9 |

Cu–Br |

79 |

|

± 6 5 |

Cu–Ag |

41.6 |

|

± 2.2 |

Cu–Sn |

42.3 |

|

± 4 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 14 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Cu–Te |

42 |

|

± 9 |

Cu–I |

47? |

|

|

Cu–Au |

55.4 |

|

± 2.2 |

Zn–Zn |

7 |

|

|

Zn–Se |

33 |

|

± 3 |

Zn–Te |

49? |

|

|

Zn–I |

33 |

|

± 7 |

Ga–Ga |

3 |

|

± 3 |

Ga–As |

50.1 |

|

± 0.3 |

Ga–Br |

101 |

|

± 4 |

Ga–Ag |

4 |

|

± 3 |

Ga–Te |

60 |

|

± 6 |

Ga–I |

81 |

|

± 2 |

Ga–Au |

51 |

|

± 23 |

Ge–Ge |

65.8 |

|

± 3 |

Ge–Se |

114 |

|

± |

Ge–Br |

61 |

|

± 7 |

Ge–Te |

93 |

|

± 2 |

Ge–Au |

70 |

|

± 23 |

As–As |

91.7 |

|

|

As–Se |

23 |

|

|

Se–Se |

79.5 |

|

± 0.1 |

Se–Cd |

~75 |

|

|

Se–in |

59 |

|

± 4 |

Se–Sn |

95.9 |

|

± 1.4 |

Se–Te |

64 |

|

± 2 |

Se–La |

114 |

|

± 4 |

Se–Nd |

92 |

|

± 4 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 15 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Se–Eu |

72 |

|

± 4 |

Se–Gd |

103 |

|

± 4 |

Se–Ho |

80 |

|

± 4 |

Se–Lu |

100 |

|

± 4 |

Se–Pb |

72.4 |

|

± 1 |

Se–Bi |

67.0 |

|

± 1.5 |

Bi–Br |

46.336 |

|

± 0.001 |

Br–Rb |

90.4 |

|

± 1 |

Br–Ag |

70 |

|

± 7 |

Br–Cd |

~38 |

|

|

Br–In |

93 |

|

|

Bi–Sn |

47 |

|

± 23 |

Br–Sb |

75 |

|

± 14 |

Br–I |

42.8 |

|

± 0.1 |

Br–Cs |

96.5 |

|

± 1 |

Br–Hg |

17.3 |

|

|

Br–Ti |

79.8 |

|

± 0.4 |

Br–Pb |

59 |

|

± 9 |

Br–Bi |

63.9 |

|

± 1 |

Rb–Rb |

12.2 |

|

|

Rb–I |

76.7 |

|

± 1 |

Sr–Au |

63 |

|

± 23 |

Y–Y |

38.3 |

|

|

Y–La |

48.3 |

|

|

Pd–Pd |

33? |

|

|

Pd–Au |

34.2 |

|

± 5 |

Ag–Ag |

41 |

|

± 2 |

Ag–Sn |

32.5 |

|

± 5 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 16 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Ag–Te |

70 |

|

± 23 |

Ag–I |

56 |

|

± 7 |

Ag–Au |

48.5 |

|

± 2.2 |

Cd–Cd |

2.7 |

|

± 0.2 |

Cd–I |

33 |

|

± 5 |

In–In |

23.3 |

|

± 2.5 |

In–Sb |

36.3 |

|

± 2.5 |

In–Te |

52 |

|

± 4 |

In–I |

80 |

|

|

Sn–Sn |

46.7 |

|

± 4 |

Sn–Te |

76 |

|

± 1 |

Sn–Au |

58.4 |

|

± 4 |

Sb–Sb |

71.5 |

|

± 1.5 |

Sb–Te |

61 |

|

± 4 |

Sb–Bi |

60 |

|

± 1 |

Te–Te |

63.2 |

|

± 0.2 |

Te–La |

91 |

|

± 4 |

Te–Nd |

73 |

|

± 4 |

Te–Eu |

58 |

|

± 4 |

Te–Gd |

82 |

|

± 4 |

Te–Ho |

62 |

|

± 4 |

Te–Lu |

78 |

|

± 4 |

Te–Au |

59 |

|

± 16 |

Te–Pb |

60 |

|

± 3 |

Te–Bi |

56 |

|

± 3 |

I–I |

36.460 |

|

± 0.002 |

I–Cs |

82.4 |

|

± 1 |

I–Hg |

9 |

|

|

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 17 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

I–Ti |

65 |

|

± 2 |

I–Pb |

47 |

|

± 9 |

I–Bi |

52 |

|

± 1 |

Xe–Xe |

~ 0.7 |

|

|

Cs–Cs |

11.3 |

|

|

Ba–Au |

38 |

|

± 14 |

La–Ld |

58.6 |

|

|

La–Au |

80 |

|

± 5 |

Ce–Ce |

66 |

|

± 1 |

Ce–Au |

76 |

|

± 4 |

Pr–Au |

74 |

|

± 5 |

Nd–Au |

70 |

|

± 6 |

Au–Au |

52.4 |

|

± 2.2 |

Au–Pb |

31 |

|

± 23 |

Au–U |

76 |

|

± 7 |

Hg–Hg |

4.1 |

|

± 0.5 |

Hg–Tl |

1 |

|

|

Tl–Tl |

15? |

|

|

Pb–Pb |

24 |

|

± 5 |

Pb–Bi |

32 |

|

± 5 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

©2001 CRC Press LLC

Table 64. BOND STRENGTHS IN DIATOMIC MOLECULES*

(SHEET 18 OF 18)

Molecule |

|

kcal • mol-1 |

|

|

|

|

|

|

|

|

|

Bi–Bi |

45 |

|

± 2 |

Po–Po |

44.4 |

|

± 2.3 |

At–At |

19 |

|

|

Th–Th |

<69 |

|

|

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–204.

* |

Notes for Table of Bond Strengths in Diatomic Molecules |

|

The strength of a chemical bond, D (R–X), often known as the bond dissociation energy, is defined as the heat of the reaction: RX –> R + X. It is given by: D(R–X) = ΔΗf˚(R) +

Hf˚(X) – Hf˚(RX). Some authors list bond strengths for 0K, but here the values for 298K are given because more thermodynamic data are available for this temperature. Bond strengths, or bond dissociation energies, are not equal to, and may differ considerable from, mean bond energies derived solely from thermochemical data on molecules and atoms.

The values in this table have usually been measured spectroscopically or by mass spectrometric analysis of hot gases effusing from a Knudsen cell.

©2001 CRC Press LLC

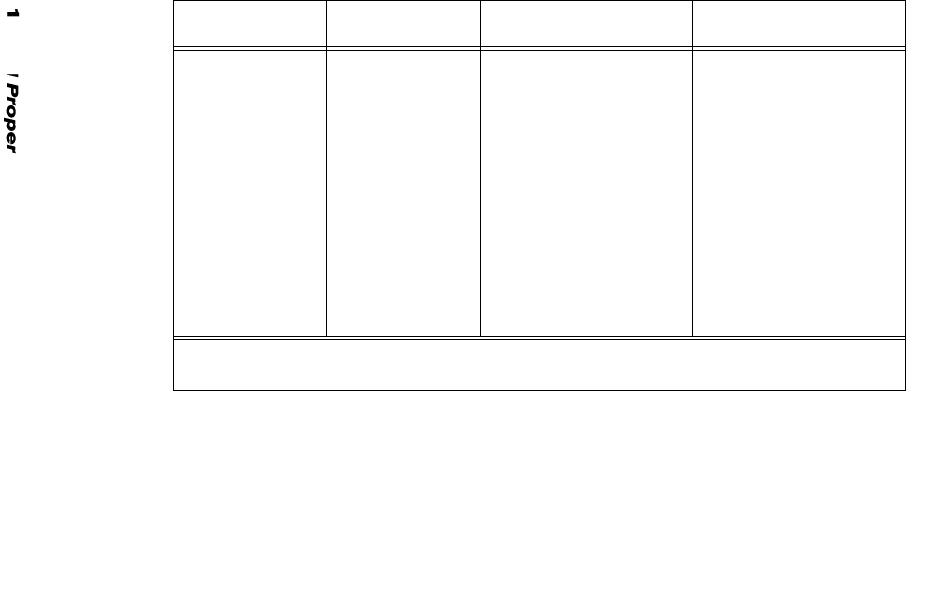

Table 65. BOND STRENGTHS OF POLYATOMIC MOLECULES*

(SHEET 1 OF 7)

|

|

Kcal • mol-1 |

|

|

|

|

|

Molecule |

Value |

|

Error |

|

|

|

|

|

|

|

|

H–CH |

102 |

|

± 2 |

H–CH2 |

110 |

|

± 2 |

H–CH3 |

104 |

|

± 1 |

H–ethynyl |

128 |

|

± 5 |

H–vinyl |

³ 108 |

|

± 2 |

H–C2H5 |

98 |

|

± 1 |

H–propargyl |

93.9 |

|

± 1.2 |

H–allyl |

89 |

|

± 1 |

H–cyclopropyl |

100.7 |

|

± 1 |

H–n–C3H7 |

98 |

|

± 1 |

H–i–C3H7 |

95 |

|

± 1 |

H–cyclobutyl |

96.5 |

|

± 1 |

H–cyclopropycarbinyl |

97.4 |

|

± 1.6 |

H–methdllyl |

83 |

|

± 1 |

H–s–C4H9 |

95 |

|

± 1 |

H–t–C4H9 |

92 |

|

± 1.2 |

H–cyclopentadien–1,3–yl–5 |

81.2 |

|

± 1.2 |

H–pentadien–1,4–yi–3 |

80 |

|

± 1 |

H–OH |

119 |

|

± 1 |

H–OCH3 |

103.6 |

|

± 1 |

H–OC2H5 |

103.9 |

|

± 1 |

H–OC(CH3)3 |

104.7 |

|

± 1 |

H–OC6H5 |

88 |

|

± 5 |

H–O2H |

90 |

|

± 2 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–213.

©2001 CRC Press LLC

Table 65. BOND STRENGTHS OF POLYATOMIC MOLECULES*

(SHEET 2 OF 7)

|

|

Kcal • mol-1 |

|

|

|

Molecule |

Value |

Error |

H–O2CCH3 |

112 |

± 4 |

H–O2CC2H3 |

110 |

± 4 |

H–O2Cn–C3H7 |

103 |

± 4 |

H–ONO |

78.3 |

± 0.5 |

H–ONO2 |

101.2 |

± 0.5 |

H–SH |

90 |

± 2 |

H–SCH |

³ 88 |

|

H–SiH3 |

94 |

± 3 |

H–Si(CH3)3 |

90 |

± 3 |

BH3–BH3 |

35 |

|

HC=CH |

230 |

± 2 |

H2C=CH2 |

172 |

± 2 |

H3C–CH3 |

88 |

± 2 |

CH3–C(CH3)2CH:CH2 |

69.4 |

|

C6H5CH2–C2H5 |

69 |

± 2 |

C6H5CH(CH3)– CH3 |

71 |

|

C6H5CH2–n–C3H7 |

67 |

± 2 |

CH3–CH2CN |

72.7 |

± 2 |

CH3–C(CH3)2CN |

70.2 |

± 2 |

C6H5C(CH3 )(CN)–CH3 |

59.9 |

|

NC–CN |

128 |

± 1 |

C6H5CH2CO– CH2C6H5 |

65.4 |

|

C6H5CO– CF3 |

73.8 |

|

CH3CO– COCH3 |

67.4 |

± 2.3 |

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–213.

©2001 CRC Press LLC

Table 65. BOND STRENGTHS OF POLYATOMIC MOLECULES*

(SHEET 3 OF 7)

|

|

Kcal • mol-1 |

|

|

|

|

|

Molecule |

Value |

|

Error |

|

|

|

|

|

|

|

|

C6H5CH2– COOH |

68.1 |

|

|

C6H5CH2– O2CCH3 |

67 |

|

|

C6H5CO– COC6H5 |

66.4 |

|

|

C6H5CH2– O2CC6H5 |

69 |

|

|

(C6H5CH2)2CH–COOH |

59.4 |

|

|

CH2F–CH2F |

88 |

|

± 2 |

CF2=CF2 |

76.3 |

|

± 3 |

CF3–CF3 |

96.9 |

|

± 2 |

C6H5CH2–NH2 |

71.9 |

|

± 1 |

C6H5NH–CH3 |

67.7 |

|

|

C6H5CH2–NHCH3 |

68.7 |

|

± 1 |

C6H5N(CH2)–CH3 |

65.2 |

|

|

C6H5CH2–N(CH3)2 |

60.9 |

|

± 1 |

CF3–NF2 |

65 |

|

± 2.5 |

CH2 = N2 |

≤ 41.7 |

|

± 1 |

CH3N:N–CH3 |

52.5 |

|

|

C2H5N:N–C2H5 |

50.0 |

|

|

i –C3H7N:N–i –C3H7 |

47.5 |

|

|

n –C4H9N:N–n –C4H9 |

50.0 |

|

|

i –C4H9N:N–i –C4H9 |

49.0 |

|

|

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–213.

©2001 CRC Press LLC

Table 65. BOND STRENGTHS OF POLYATOMIC MOLECULES*

(SHEET 4 OF 7)

|

|

Kcal • mol-1 |

|

|

|

|

|

Molecule |

Value |

|

Error |

|

|

|

|

|

|

|

|

s –C4H9N:N–s –C4H9 |

46.7 |

|

|

t –C4H9N:N–t –C4H9 |

43.5 |

|

|

C6H5CH2N:N–C6H5CH2 |

37.6 |

|

|

CF3N:N–CF3 |

55.2 |

|

|

C2H5–NO2 |

62 |

|

|

O=CO |

127.2 |

|

± 0.1 |

CH3–O2SCH3 |

66.8 |

|

|

Allyl–O2SCH3 |

49.6 |

|

|

C6H5CH2–O2SCH3 |

52.9 |

|

|

C6H5S–CH3 |

60 |

|

|

C6H5CH2–SCH3 |

53.8 |

|

|

F–CH3 |

103 |

|

± 3 |

Cl–CN |

97 |

|

± 1 |

Cl–COC6H5 |

74 |

|

± 3 |

Cl–CF3 |

86.1 |

|

± 0.8 |

Cl–CCl2F |

73 |

|

± 2 |

Cl–C2F5 |

82.7 |

|

± 1.7 |

Br–CH3 |

70.0 |

|

± 1.2 |

Br–CN |

83 |

|

± 1 |

Br–COC6H5 |

64.2 |

|

|

Br–CF3 |

70.6 |

|

± 1.0 |

Br–CBr3 |

56.2 |

|

± 1.8 |

Br–C2F5 |

68.7 |

|

± 1.5 |

Br –n –C3F |

66.5 |

|

± 2.5 |

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–213.

©2001 CRC Press LLC

Table 65. BOND STRENGTHS OF POLYATOMIC MOLECULES*

(SHEET 5 OF 7)

|

|

Kcal • mol-1 |

|

|

|

Molecule |

Value |

Error |

I–CH3 |

56.3 |

± 1 |

1–norbornyl |

62.5 |

± 2.5 |

I–CN |

73 |

± 1 |

I–CF3 |

53.5 |

± 2 |

CH3–Ga(CH3)2 |

59.5 |

|

CH3–CdCH3 |

54.4 |

|

CH3–HgCH3 |

57.5 |

|

C2H5–HgC2H5 |

43.7 |

± 1 |

n –C3H7–Hg n –C3H7 |

47.1 |

|

i –C3H7–Hg i –C3H7 |

40.7 |

|

C6H5–HgC6H5 |

68 |

|

CH3 –Tl(CH3)2 |

36.4 |

± 0.6 |

CH3–Pb(CH3)3 |

49.4 |

± 1 |

NH2–NH2 |

70.8 |

± 2 |

NH2–NHCH3 |

64.8 |

|

NH2 –N(CH3)2 |

62.7 |

|

NH2 –NHC6H5 |

51.1 |

|

NO–NO2 |

9.5 |

± 0.5 |

NO2–NO2 |

12.9 |

± 0.5 |

NF2–NF2 |

21 |

± 1 |

O–N2 |

40 |

|

O–NO |

73 |

|

HO–N:CHCH3 |

49.7 |

|

Cl–NF2 |

≈ 32 |

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–213.

©2001 CRC Press LLC

Table 65. BOND STRENGTHS OF POLYATOMIC MOLECULES*

(SHEET 6 OF 7)

|

|

Kcal • mol-1 |

|

|

|

|

|

Molecule |

Value |

|

Error |

|

|

|

|

|

|

|

|

HO–OH |

51 |

|

± 1 |

CH3O–OCH3 |

36.9 |

|

± 1 |

HO–OC(CH3)3 |

42.5 |

|

|

C2H5O–OC2H5 |

37.3 |

|

± 1.2 |

n –C3H7O–O n –C3H7 |

37.2 |

|

± 1 |

i –C3H7O–O i –C3H7 |

37.0 |

|

± 1 |

s –C4H9O–O s –C4H9 |

36.4 |

|

± 1 |

t –C4H9O–O t –C4H9 |

37.4 |

|

± 1 |

(CH3)3CCH2O–OCH2C(CH3)3 |

36.4 |

|

± 1 |

O–O2CIF |

58.4 |

|

|

CH3CO2–O2CCH3 |

30.4 |

|

± 2 |

C2H5CO2–O2CC2H5 |

30.4 |

|

± 2 |

n –C3H7CO2–O2Cn –C3H7 |

30.4 |

|

± 2 |

O–SO |

132 |

|

± 2 |

F–OCF3 |

43.5 |

|

± 0.5 |

Cl–OH |

60 |

|

± 3 |

O–ClO |

59 |

|

± 3 |

Br–OH |

56 |

|

± 3 |

I–OH |

56 |

|

± 3 |

ClO3–ClO4 |

58.4 |

|

|

|

|

|

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–213.

©2001 CRC Press LLC

Table 65. BOND STRENGTHS OF POLYATOMIC MOLECULES*

(SHEET 7 OF 7)

|

|

Kcal • mol-1 |

|

|

|

Molecule |

Value |

Error |

O = PF3 |

130 |

± 5 |

O = PCl3 |

122 |

± 5 |

O = PBr3 |

119 |

± 5 |

SiH3–SiH3 |

81 |

± 4 |

(CH3)3Si–Si(CH3)3 |

80.5 |

|

To convert kcal to KJ, multiply by 4.184.

Source: data from: Kerr, J. A., Parsonage, M. J., and Trotman–Dickenson, A. F., in Handbook of Chemistry and Physics, 55th ed., Weast, R. C., Ed., CRC Press, Cleveland, 1974, F–213.

*The values refer to a temperature of 298 K and have mostly been determined by kinetic methods. Some have been calculated from formation of the species involved according to equations:

D(R–X) = Hf˚ (R•) + Hf˚(X•) – Hf˚ (RX) or D(R–X) = 2 Hf˚ (R•) – Hf˚ (RR)

©2001 CRC Press LLC

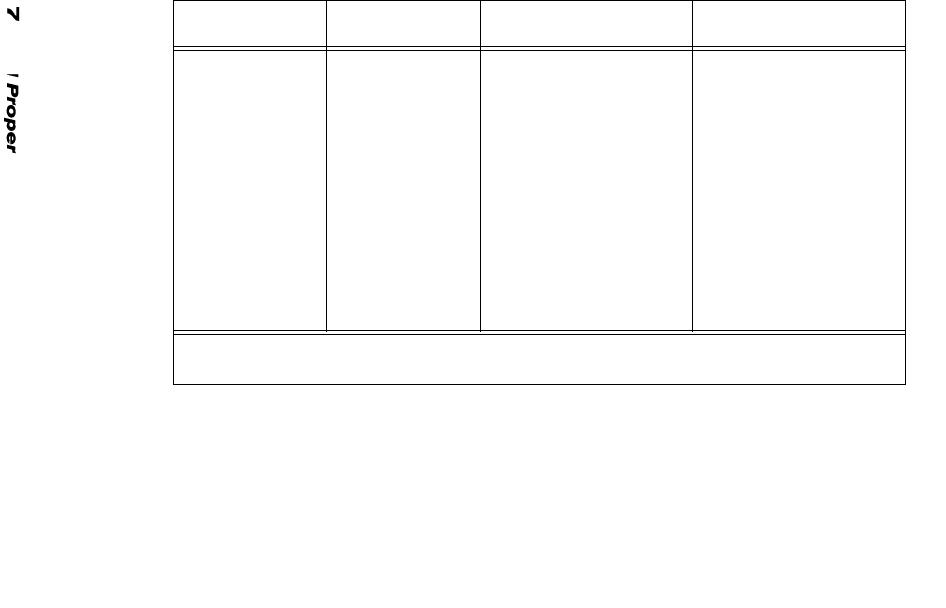

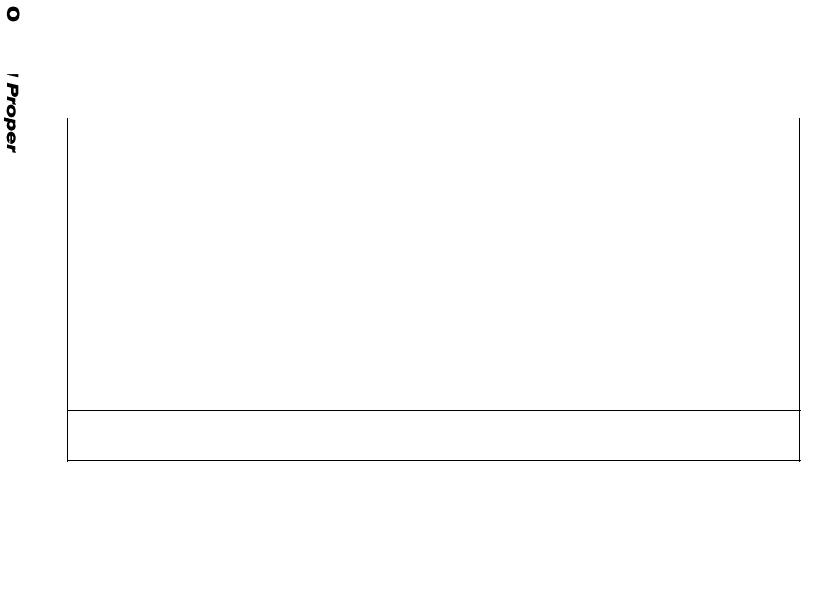

Table 66. SOLUBILITY OF COPPER AND COPPER ALLOYS

|

|

|

Solid Solubility at 20 °C |

Family |

Wrought Alloys UNS Numbers |

Principal Alloying Element |

(at. %) |

|

|

|

|

|

|

|

|

Brasses |

C20000, C30000, C40000, C66400 to C69800 |

Zn |

37 |

Phosphor bronzes |

C50000 |

Sn |

9 |

Aluminum bronzes |

C60600 to C64200 |

Al |

19 |

Silicon bronzes |

C64700 to C66100 |

Si |

8 |

Copper nickels, nickel silvers |

C70000 |

Ni |

100 |

|

|

|

|

Data from ASM Metals Reference Book, Third Edition, Michael Bauccio, Ed., ASM International, Materials Park, OH, p439, (1993).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 1 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 Ac(c) + 3/2 O2(g) = Ac2O3(c) |

298.16–1,000K |

–446,090 |

–16.12 |

– |

– |

+109.89 |

2 Al(c) + 1/2 O2(g) = Al2O(g) |

298.16–931.7K |

–31,660 |

+14.97 |

– |

– |

–72.74 |

2 Al(l) + 1/2 O2(g) = Al2O(g) |

931.7–2,000K |

–38,670 |

+10.36 |

– |

– |

–51.53 |

Al(c) + 1/2 O2(g) = AlO(g) |

298.16–931.7K |

+10,740 |

+5.76 |

– |

– |

–37.61 |

Al(l) + 1/2 O2(g) = AlO(g) |

931.7–2,000K |

+8,170 |

+5.76 |

– |

– |

–34.85 |

2 Al(c) + 3/2 O2(g) = Al2O3 (corundum) |

298.16–931.7K |

–404,080 |

–15.68 |

+2.18 |

+3.935 |

+123.64 |

2 Al(l) + 3/2 O2(g) = Al2O3 (corundum) |

931.7–2,000K |

–407,950 |

–6.19 |

–0.78 |

+3.935 |

+102.37 |

2 Sb(c) + 3/2 O2(g) = Sb2O3 (cubic) |

298.16–842K |

–169,450 |

+6.12 |

–6.01 |

–0.30 |

+52.21 |

2 Sb(c) + 3/2 O2(g) = Sb2O3 (orthorhombic) |

298.16–903K |

–168,060 |

+6.12 |

–6.01 |

–0.30 |

+50.56 |

2 As(c) + 3/2 O2(g) = As2O3 (orthorhombic) |

298.16–542K |

–154,870 |

+29.54 |

–21.33 |

–0.30 |

–8.83 |

2 As(c) + 3/2 O2(g) = As2O3 (monoclinic) |

298.16–586K |

–150,760 |

+29.54 |

–21.33 |

–0.30 |

–16.95 |

2 As(c) + 5/2 O2(g) = As2O5(c) |

298.16–883K |

–217,080 |

+12.32 |

–4.65 |

–0.50 |

+80.50 |

|

|

|

|

|

|

|

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 2 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ba(α) + 1/2 O2(g) = BaO(c) |

298.16–648K |

–134,590 |

–7.60 |

+0.87 |

+0.42 |

+45.76 |

Ba(β) + 1/2 O2(g) = BaO(c) |

648–977K |

–134,140 |

–3.34 |

–0.56 |

+0.42 |

+34.01 |

Be(c) + 1/2 O2(g) = BeO(c) |

298.16–1,556K |

–144,220 |

–1.91 |

–0.46 |

+1.24 |

+30.64 |

Bi(c) + 1/2 O2(g) = BiO(c) |

298.16–544K |

–50,450 |

–4.61 |

– |

– |

+35.51 |

Bi(l) + 1/2 O2(g) = BiO(c) |

544–1,600K |

–52,920 |

–4.61 |

– |

– |

+40.05 |

2 Bi(c) + 3/2 O2(g) = Bi2O3(c) |

298.16–544K |

–139,000 |

–11.56 |

+2.15 |

–0.30 |

+96.52 |

2 Bi(l) + 3/2 O2(g) = Bi2O3(c) |

544–1,090K |

–142,270 |

+2.30 |

–3.25 |

–0.30 |

+67.55 |

2 B(c) + 3/2 O2(g) = B2O(c) |

298.16–723K |

–304,690 |

+11.72 |

–7.55 |

+0.355 |

+34.25 |

2 B(c) + 3/2 O2(g) = B2O3(gl) |

298.16–723K |

–298,670 |

+26.57 |

–15.90 |

–0.30 |

–10.40 |

Cd(c) + 1/2 O2(g) = CdO(c) |

298.16–594K |

–62,330 |

–2.05 |

+0.71 |

–0.10 |

+29.17 |

Cd(l) + 1/2 O2(g) = CdO(c) |

594–1,038K |

–63,240 |

+2.07 |

–0.76 |

–0.10 |

+20.14 |

Ca(α) + 1/2 O2(g) = CaO(c) |

298.16–673K |

–151,850 |

–6.56 |

+1.46 |

+0.68 |

+43.93 |

Ca(β) + 1/2 O2(g) = CaO(c) |

673–1,124K |

–151,730 |

–4.14 |

+0.41 |

+0.68 |

+37.63 |

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 3 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C(graphite) + 1/2 O2(g) = CO(g) |

298.16–2,000K |

–25,400 |

+2.05 |

+0.27 |

–1.095 |

–28.79 |

C(graphite) + O2(g) = CO2(g) |

298.16–2,000K |

–93,690 |

+1.63 |

–0.7 |

–0.23 |

–5.64 |

2 Ce(c) + 3/2 O2(g) = Ce2O3(c) |

298.16–1,048K |

–435,600 |

–4.60 |

– |

– |

+92.84 |

2 Ce(l) + 3/2 O2(g) = Ce2O3(c) |

1,048–1,900K |

–440,400 |

–4.60 |

– |

– |

+97.42 |

Ce(c) + O2(g) = CeO2(c) |

298.16–1,048K |

–245,490 |

–6.42 |

+2.34 |

–0.20 |

+67.79 |

Ce(l) + O2(g) = CeO2(c) |

1,048–2,000K |

–247,930 |

+0.71 |

–0.66 |

–0.20 |

+51.73 |

2 Cs(c) + 1/2 O2(g) = Cs2O(c) |

298.16–301.5K |

–75,900 |

– |

– |

– |

+36.60 |

2 Cs(l) + 1/2 O2(g) = Cs2O(c) |

301.5–763K |

–76,900 |

– |

– |

– |

+39.92 |

2 Cs(l) + 1/2 O2(g) = Cs2O(l) |

763–963K |

–75,370 |

–9.21 |

– |

– |

+64.47 |

2 Cs(g) + 1/2 O2(g) = Cs2O(l) |

963–1,500K |

–113,790 |

–23.03 |

– |

– |

+145.60 |

2 Cs(c) + 3/2 O2(g) = Cs2O3(c) |

298.16–301.5K |

–112,690 |

–11.51 |

– |

– |

+110.10 |

2 Cs(l) + 3/2 O2(g) = Cs2O3(c) |

301.5–775K |

–113,840 |

–12.66 |

– |

– |

+116.77 |

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 4 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 Cs(l) + 3/2 O2(g) = Cs2O3(l) |

775–963K |

–110,740 |

–26.48 |

– |

– |

+152.70 |

2 Cs(g) + 3/2 O2(g) = Cs2O3(l) |

963–1,500K |

–148,680 |

–39.14 |

– |

– |

+229.87 |

Cl2(g) + 1/2 O2(g) = Cl2O(g) |

298.16–2,000K |

+17,770 |

–0.71 |

–0.12 |

+0.49 |

+16.81 |

1/2 Cl2(g) + 1/2 O2(g) = ClO(g) |

298.16–1,000K |

+33,000 |

– |

– |

– |

0.24 |

2 Cl2(g) + 3/2 O2(g) = ClO(g) |

298.16–500K |

+37,740 |

+5.76 |

– |

– |

+21.42 |

2 Cr(c) + 3/2 O2(g) = Cr2O3(β) |

298.16–1,823K |

–274,670 |

–14.07 |

+2.01 |

+0.69 |

+105.65 |

2 Cr(l) + 3/2 O2(g) = Cr2O3(β) |

1,823–2,000K |

–278,030 |

+2.33 |

–0.35 |

+1.57 |

+58.29 |

Cr(c) + O2(g) = CrO2 (c) |

298.16–1,000K |

–142,500 |

– |

– |

– |

+42.00 |

Cr(c) + 3/2 O2(g) = CrO3(c) |

298.16–471K |

–141,590 |

–13.82 |

– |

– |

+103.90 |

Cr(c) + 3/2 O2(g) = Cr2O3(l) |

471–600K |

–141,580 |

–32.24 |

– |

– |

+153.14 |

Co(α,β) + 1/2 O2(g) = CoO(c) |

298.16–1,400K |

–56,910 |

+0.69 |

– |

– |

+16.03 |

Co(γ) + 1/2 O2(g) = CoO(c) |

1,400–1,763K |

–58,160 |

–1.15 |

– |

– |

+22.71 |

2 Cu(c) + 1/2 O2(g) = Cu2O(c) |

298.16–1,357K |

+10,550 |

–1.15 |

–1.10 |

–0.10 |

+21.92 |

2 Cu(l) + 1/2 O2(g) = Cu2O(c) |

1,357–1,502K |

–43,880 |

+8.47 |

–2.60 |

–0.10 |

–3.72 |

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 5 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 Cu(l) + 1/2 O2(g) = Cu2O(l) |

1,502–2,000K |

–37,710 |

–12.48 |

+0.25 |

–0.10 |

+54.44 |

Cu(c) + 1/2 O2(g) = CuO(c) |

298.16–1,357K |

–37,740 |

–0.64 |

–1.40 |

–0.10 |

+24.87 |

Cu(l) + 1/2 O2(g) = CuO(c) |

1,357–1,720K |

–39,410 |

+4.17 |

–2.15 |

–0.10 |

+12.05 |

Cu(l) + 1/2 O2(g) = CuO(l) |

1,720–2,000K |

–41,060 |

–11.35 |

+0.25 |

–0.10 |

+59.09 |

2 Au(c) + 3/2 O2(g) = Au2O3(c) |

298.16–500K |

–2,160 |

–10.36 |

– |

– |

+95.14 |

Hf(c) + O2(g) = HfO2 (monoclinic) |

298.16–2,000K |

–268,380 |

–9.74 |

–0.28 |

+1.54 |

+78.16 |

H2(g) + 1/2 O2(g) = H2O(l) |

298.16–373.16K |

–70,600 |

–18.26 |

+0.64 |

–0.04 |

+91.67 |

H2(g) + 1/2 O2(g) = H2O(g) |

298.16–2,000K |

–56,930 |

+6.75 |

–0.64 |

–0.08 |

–8.74 |

D2(g) + 1/2 O2(g) = D2O(l) |

298.16–374.5K |

–72,760 |

–18.10 |

– |

– |

+93.59 |

D2(g) + 1 /2 O2(g) = D2O(g) |

298.16–2,000K |

–58,970 |

+5.50 |

–0.75 |

+0.085 |

–3.74 |

0.947 Fe(α) + 1/2 O2(g) = Fe0.9470(c) |

298.16–1,033K |

–65,320 |

–11.26 |

+2.61 |

+0.44 |

+48.60 |

0.947 Fe(α) + 1/2 O2(g) = Fe0.9470(c) |

1,033–1,179K |

–62,380 |

+4.08 |

–0.75 |

+0.235 |

+3.00 |

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 6 OF 16)

|

|

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

0.947 |

Fc(β) + 1/2 O2(g) = Fe0.9470(c) |

1,179–1,650K |

–66,750 |

–8.04 |

+0.67 |

–0.10 |

+42.28 |

|

0.947 |

Fe(γ) + 1/2 O2(g) = Fe0.9470(l) |

1,650–1,674K |

–64,200 |

–18.72 |

+1.67 |

–0.10 |

+73.45 |

|

0.947 |

Fe(γ) + 1/2 O2(g) = Fe0.9470(l) |

1,647–1,803K |

–59,650 |

–6.84 |

+0.25 |

–0.10 |

+34.81 |

|

0.947 |

Fe(δ) + 1/2 O2(g) = Fe0.9470(l) |

1,803–2,000K |

–63,660 |

–7.48 |

+0.25 |

–0.10 |

+39.12 |

|

3 |

Fe(α) + 2 O2(g) = Fe3O4(magnetite) |

298.16–900K |

–268,310 |

+5.87 |

–12.45 |

+0.245 |

+73.11 |

|

3 |

Fe(α) + 2 O2(g) = Fe3O4(β) |

900–1,033K |

–272,300 |

–54.27 |

+11.65 |

+0.245 |

+233.52 |

|

3 |

Fe(β) + 2 O2(g) = Fe3O4(β) |

1,033–1,179K |

–262,990 |

–5.71 |

+1.00 |

–0.40 |

+89.19 |

|

3 |

Fe(γ) + 2 O2(g) = Fe3O4(β) |

1,179–1,674K |

–276,990 |

~4.05 |

+5.50 |

–0.40 |

+213.52 |

|

2 |

Fe(α) + 3/2 O2(g) = Fe2O3(hematite) |

298.16–950K |

–200,000 |

–13.84 |

–1.45 |

+1.905 |

+108.26 |

|

2 |

Fe(α) + 3/2 O2(g) = Fe2O3(β) |

950–1,033K |

–202,960 |

–42.64 |

+7.85 |

+0.13 |

+188.48 |

|

2 |

Fe(β) + 3/2 O2(g) = Fe2O3(β) |

1,033–1,050K |

–196,740 |

–10.27 |

+0.75 |

–0.30 |

+92.26 |

|

2 |

Fe(β) + 3/2 O2(g) = Fe2O3(γ) |

1,050–1,179K |

–193,200 |

–0.39 |

–0.13 |

–0.30 |

+59.96 |

|

2 |

Fe(γ) + 3/2 O2(g) = Fe2O3(γ) |

1,179–1,674K |

–202,540 |

–25.95 |

+2.87 |

–0.30 |

+142.85 |

|

|

|

|

|

|

|

|

|

|

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 7 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

2 Fe(α) + 3/2 O2(g) = Fe2O3(γ) |

1,674–1,800K |

–192,920 |

–0.85 |

–0.13 |

–0.30 |

+61.21 |

Pb(c) + 1/2 O2(g) = PbO (red) |

298.16–600.5K |

–52,800 |

–2.76 |

–0.80 |

–0.10 |

+32.49 |

Pb(l) + 1/2 O2(g) = PbO (red) |

600.5–762K |

–53,780 |

–0.51 |

–1.75 |

–0.10 |

+28.44 |

Pb(c) + 1/2 O2(g) = PbO (yellow) |

298.16–600.5K |

–52,040 |

+0.81 |

–2.00 |

–0.10 |

+22.13 |

Pb(l) + 1/2 O2(g) = PbO (yellow) |

600.5–1,159K |

–53,020 |

+3.06 |

–2.95 |

–0.10 |

+18.08 |

I2(c) + 5/2 O2(g) = I2O5(c) |

298.16–386.8K |

–42,040 |

+2.30 |

– |

– |

+113.71 |

I2(l) + 5/2 O2(g) = I2O5(c) |

386.8–456K |

–43,490 |

+16.12 |

– |

– |

+81.70 |

I2(g) + 5/2 O2(g) = I2O5(c) |

456–500K |

–58,020 |

–6.91 |

– |

– |

+174.79 |

Ir(c) + O2(g) = IrO2(c) |

298.16–1,300K |

–39,480 |

+8.17 |

–6.39 |

–0.20 |

+20.33 |

3 Pb(c) + 2 O2(g) = Pb3O4(c) |

298.16–600.5K |

–174,920 |

+8.82 |

–8.20 |

–0.40 |

+72.78 |

Pb(c) + O2(g) = PbO2(c) |

298.16–600.5K |

–66,120 |

+0.64 |

–2.45 |

–0.20 |

+45.58 |

2 Li(c) + 1/2 O2(g) = Li2O(c) |

298.16–452K |

–142,220 |

–3.06 |

+5.77 |

–0.10 |

+34.19 |

|

|

|

|

|

|

|

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 8 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mg(c) + 1/2 O2(g) = MgO (periclase) |

298.16–923K |

–144,090 |

–1.06 |

+0.13 |

+0.25 |

+29.16 |

Mg(l) + 1/2 O2(g) = MgO (periclase) |

923–1,393K |

–145,810 |

+1.84 |

–0.62 |

+0.64 |

+23.07 |

Mg(g) + 1/2 O2(g) = MgO (periclase) |

1,393–2,000K |

–180,700 |

–3.75 |

–0.62 |

+0.64 |

+65.69 |

Mn(α) + 1/2 O2(g) = MnO(c) |

298.16–1,000K |

–92,600 |

–4.21 |

+0.97 |

+0.155 |

+29.66 |

Mn(β) + 1/2 O2(g) = MnO(c) |

1,000–1,374K |

–91,900 |

+1.84 |

–0.39 |

+0.34 |

+12.15 |

Mn(γ) + 1/2 O2(g) = Mno(c) |

1,374–1,410K |

–89,810 |

+7.30 |

–0.72 |

+0.34 |

–6.05 |

Mn(δ) + 1/2 O2(g) = MnO(c) |

1,410–1,517K |

–89,390 |

+8.68 |

–0.72 |

+0.34 |

–10.70 |

Mn(l) + 1/2 O2(g) = MnO(c) |

1,517–2,000K |

–93,350 |

+7.99 |

–0.72 |

+0.34 |

–5.90 |

3 Mn(α) + 2 O2(g) = Mn3O4(α) |

298.16–1,000K |

–332,400 |

–7.41 |

+0.66 |

+0.145 |

+106.62 |

2 Mn(α) + 3/2 O2(g) = Mn2O3(c) |

298.16–1,000K |

–230,610 |

–5.96 |

–0.06 |

+0.945 |

+80.74 |

Mn(α) + O2(g) = MnO2(c) |

298.16–1,000K |

–126,400 |

–8.61 |

+0.97 |

+1.555 |

+70.14 |

2 Hg(l) + 1/2 O2(g) = Hg2O(c) |

298.16–629.88K |

–22,400 |

–4.61 |

– |

– |

+43.29 |

Hg(l) + 1/2 O2(g) = HgO (red) |

298.16–629.88K |

–21,760 |

+0.85 |

–2.47 |

–0.10 |

+24.81 |

Mo(c) + O2(g) = MoO2(c) |

298.16–2,000K |

–132,910 |

–3.91 |

– |

– |

+47.42 |

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 9 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mo(c) + 3/2 O2(g) = MoO3(c) |

298.16–1,068K |

–182,650 |

–8.86 |

–1.55 |

+1.54 |

+90.07 |

Ni(α) + 1/2 O2(g) = NiO(c) |

298.16–633K |

–57,640 |

–4.61 |

+2.16 |

–0.10 |

+34.41 |

Ni(β) + 1/2 O2(g) = NiO(c) |

633–1,725K |

–57,460 |

–0.14 |

–0.46 |

–0.10 |

+23.27 |

2 Nb(c) + 2 O2(g) = Nb2O4(c) |

298.16–2,000K |

–382,050 |

–9.67 |

– |

– |

+116.23 |

2 Nb(c) + 5/2 O2(g) = Nb2O5(c) |

298.16–1,785K |

–458,640 |

–16.14 |

–0.56 |

+1.94 |

+157.66 |

2 Nb(c) + 5/2 O2(g) = Nb2O5(l) |

1,785–2,000K |

–463,630 |

–66.04 |

+2.21 |

–0.50 |

+317.84 |

N2(g) + 1/2 O2(g) = N2O(g) |

298.16–2,000K |

18,650 |

–1.57 |

–0.27 |

+0.92 |

+23.47 |

3/2 O2(g) = O3(g) |

298.16–2,000K |

+33,980 |

+2.03 |

–0.48 |

+0.36 |

+11.45 |

P (white) + 1/2 O2(g) = PO(g) |

298.16–317.4K |

–9,370 |

+2.53 |

– |

– |

–25.40 |

P(l) + 1/2 O2(g) = PO(g) |

317.4–553K |

–9,390 |

+3.45 |

– |

– |

–27.63 |

4 P (white) + 5 O2(g) = P4H10 (hexagonal) |

298.16–317.4K |

–711,520 |

+95.67 |

–51.50 |

–1.00 |

–28.24 |

2 K(c) + 1/2 O2(g) = K2O(c) |

298.16–336.4K |

–86,400 |

– |

– |

– |

+33.90 |

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 10 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 K(l) + 1/2 O2(g) = K2O(c) |

336.4–1,049K |

–87,380 |

+1.15 |

– |

– |

+33.90 |

2 K(g) + 1/2 O2(g) = K2O(c) |

1,049–1,500K |

–133,090 |

–16.12 |

– |

– |

+129.64 |

Ra(c) + 1/2 O2(g) = RaO(c) |

298.16–1,000K |

–130,000 |

– |

– |

– |

+23.50 |

Re(c) + 3/2 O2(g) = ReO3(c) |

298.16–433K |

–149,090 |

–16.12 |

– |

– |

+110.49 |

Re(c) + 3/2 O2(g) = ReO3(l) |

433–1,000K |

–146,750 |

–31.32 |

– |

– |

+145.16 |

2Re(c) + 7/2 02(g) = Re2O7(c) |

298.16–569K |

–301,470 |

–34.64 |

– |

– |

+250.57 |

2 Re(c) + 7/2 02(g) = Re2O7(l) |

569–635.5K |

–295,810 |

–73.68 |

– |

– |

+348.45 |

2 Re(c) + 4 O2(g) = Re2O8(l) |

420–600K |

–318,470 |

–87.50 |

– |

– |

+425.32 |

2 Rb(c) + 1/2 O2(g) = Rb2O(c) |

298.16–312.2K |

–78,900 |

– |

– |

– |

+32.20 |

2 Rb(l) + 1/2 O2(g) = Rb2O(c) |

312.2–750K |

–79,950 |

– |

– |

– |

+35.56 |

Se(c) + 1/2 O2(g) = SeO(g) |

298.16–490K |

+9,280 |

–3.04 |

+4.40 |

+0.30 |

–14.78 |

Se(l) + 1/2 O2(g) = SeO(g) |

490–1,027K |

+9,420 |

+8.70 |

– |

+0.30 |

–44.50 |

1/2 Se2(g) + 1/2 O2(g) = SeO(g) |

1,027–2,000K |

–7,400 |

–0.37 |

– |

+0.19 |

–0.80 |

Si(c) + 1/2 O2(g) = SiO(g) |

298.16–1,683K |

–21,090 |

+3.84 |

–0.16 |

–0.295 |

–33.14 |

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 11 OF 16)

Reaction |

Temperature range of validity |

H0 |

2.303a |

b |

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Si(l) + 1/2 O2(g) = SiO(g) |

1,683–2,000K |

–30,170 |

–7.78 |

–0.12 |

+0.25 |

–40.01 |

Si(c) + O2(g) = SiO2(α–quartz) |

298.16–848K |

–210,070 |

+3.98 |

–3.32 |

+0.605 |

+34.59 |

Si(c) + O2(g) = SiO2(β–quartz) |

848–1,683K |

–209,920 |

–3.36 |

–0.19 |

–0.745 |

+53.44 |

Si(l) + O2(g) = SiO2(l) |

1,883–2,000K |

–228,590 |

–15.66 |

– |

– |

+103.97 |

Si(c) + O2(g) = SiO2(α–cristobalite) |

298.16–523K |

–207,330 |

+19.96 |

–9.75 |

–0.745 |

–9.78 |

Si(c) + O2(g) = SiO2(β–cristobalite) |

523–1,683K |

–209,820 |

–3.34 |

–0.24 |

–0.745 |

+53.35 |

Si(c) + 02(g) = SiO2(α–tridymite) |

298.16–390K |

–207,030 |

+22.29 |

–11.62 |

–0.745 |

–15.64 |

Si(c) + O2(g) = SiO2(β–tridymite) |

390–1,683K |

–209,350 |

–1.59 |

–0.54 |

–0.745 |

+47.86 |

2 Ag(c) + 1/2 O2(g) = Ag2O2(c) |

298.16–1,000K |

–7,740 |

–4.14 |

– |

– |

+27.84 |

2 Ag(c) + O2(g) = Ag2O2(c) |

298.16–500K |

–6,620 |

–3.22 |

– |

– |

+52.17 |

2 Na(c) + 1/2 O2(g) = Na2O(c) |

298.16–371K |

–99,820 |

–7.51 |

+5.47 |

–0.10 |

+50.43 |

2 Na(l) + 1/2 O2(g) = Na2O(c) |

371–1,187K |

–100,150 |

+4.97 |

–2.45 |

–0.10 |

+22.19 |

The Ho values are given in gram calories per mole. The a, b, and I values listed here make it possible for one to calculate the F and S values by use

of the following equations: |

F |

= ΔΗ + 2.303aT log T + b x 10–3 T2 |

+ c x l05 T–1 + IT |

|

t |

o |

|

St = – a – 2.303a log T – 2b x 10–3T + c x l05 T–2 – I

Source: data from CRC Handbook of Materials Science, Vol I, Charles T. Lynch, Ed., CRC Press, Cleveland, (1974).

©2001 CRC Press LLC

Table 67. HEAT OF FORMATION OF INORGANIC OXIDES

(SHEET 12 OF 16)

Reaction |

|

|

|

Temperature range of validity |

|

H0 |

2.303a |

b |

|

c |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 Na(c) + O2(g) = Na2O2(c) |

|

|

|

298.16–371K |

|

–122,500 |

–2.30 |

– |

|

– |

+57.51 |

Sr(c) + 1/2 O2(g) = SrO(c) |

|

|

|

298.16–1,043K |

|

–142,410 |

–6.79 |

+0.305 |

|

+0.675 |

+44.33 |

S(rhombohedral) + 1/2 O2(g) = SO(g) |

298.16–368.6K |

|

+19,250 |

–1.24 |

+2.95 |

|

+0.225 |

–18.84 |

|||

S(monoclmic) + 1/2 O2(g) = SO(g) |

|

368.6–392K |

|

+19,200 |

–1.29 |

+3.31 |

|

+0.225 |

–18.72 |

||

S(lλ,μ) + 1/2 O2(g) = SO(g) |

|

|

|

392–718K |

|

+20,320 |

+10.22 |

–0.17 |

|

+0.225 |

–50.05 |

1/2 S2 (g) + 1/2 O2(g) = SO(g) |

|

|

|

298.16–2,000K |

|

+3,890 |

+0.07 |

– |

|

– |

–1.50 |

S(rhombohedral) + O2(g) = SO2(g) |

|

298.16–368.6K |

|

–70,980 |

+0.83 |

+2.35 |

|

+0.51 |

–5.85 |

||

S(monoclinic) + O2(g) = SO2(g) |

|

|

|

368.6–392K |

|

–71,020 |

+0.78 |

+2.71 |

|

+0.51 |

–5.74 |

S(lλ,μ) + O2(g) = SO2(g) |

|

|

|

392–718K |

|

–69,900 |

+12.30 |

–0.77 |

|

+0.51 |

–37.10 |

1/2 S2(g) + O2(g) = SO2(g) |

|

|

|

298.16–2,000K |

|

–86,330 |

+2.42 |

–0.70 |

|

+0.31 |

+10.71 |

S(rhombohedral) + 3/2 O2(g) = SO3(c–I) |

298.16–335.4K |

|

–111,370 |

–6.45 |

– |

|

– |

+88.32 |

|||

S(rhombohedral) + 3/2 O2(g) = SO3(c–II) |

298.16–305.7K |

|

–108,680 |

–11.97 |

– |

|

– |

+94.95 |

|||