Yang Fluidization, Solids Handling, and Processing

.pdf

Electrostatics and Dust Explosions 855

5.1Hazards Associated with Fluidization

Loading and Unloading. Loading granular solids into a fluidizing vessel is indistinguishable from loading any vessel of similar size. Many fires and explosions of electrostatic origin have occurred during vessel loading (or unloading) operations, and for this reason it is prudent to take all the same standard precautionary measures when loading fluidizing equipment. First of all, it is important to recognize that vessel size influences ignition risk and severity, simply because the larger mass of available fuel in a larger vessel will support a more powerful deflagration. A general rule of thumb is that dust explosions are possible only in vessels larger than approximately 1 m3 in volume, though the more conservative classification scheme of Table 7 is commonly adopted. In any safety assessment, initial effort must be made to measure or obtain a reliable estimate for the specific charge q/m of the incoming granular material. As revealed in Table 2, this quantity depends on the treatment to which the particles have been subjected prior to delivery to the vessel. The table shows that pneumatically transported materials charge the highest and, according to Table 3, should always be presumed to create ESD hazards for moderately or highly insulating particulate matter, that is, γ Ú 107 S-1m.

Table 7. Classification of Factors Involved in Dust Explosion Hazards for the Storage of Flammable Powders (Glor, 1988)

Vessel size |

Vessel type |

MIE ³ 10 mJ |

MIE £ 10 mJ |

< 0.2 m3 |

unlined & |

standard measures |

standard measures |

|

lined |

|

|

0.2 m3 to |

unlined |

standard measures |

avoid high-velocity |

2.0 m3 |

|

|

pneumatic transport |

|

lined |

guard against |

guard against |

|

|

propagating brush |

propagating brush |

|

|

discharges |

discharges |

> 2.0 m3 |

unlined |

standard measures |

special attention |

|

|

|

required |

|

lined |

special attention |

special attention |

|

|

required |

required |

856 Fluidization, Solids Handling, and Processing

Any rapid dumping of a large volume of dry solids from a loading or surge hopper into a fluidized bed reactor can be quite hazardous for insulating materials. Though other electrostatic discharge mechanisms can occur during such operations, the one most directly linked to vessel loading is the Maurer or cone discharge discussed in Sec. 4.2 and depicted in Fig. 10. This type of discharge is driven by the inflow of charged granular solids and it stops when the inflow stops.

With these observations in mind, the simplest practical measure to reduce electrostatic discharge risks associated with vessel loading is to reduce the rate at which the dry solids are added to the vessel. This approach works because the slower rate of flow provides an opportunity for accumulating charge to relax away by various mechanisms before hazardous conditions become established. Often, the same type of flow limitation is effective in reducing the likelihood of ESD during vessel unloading. In many cases, the maximum safe rate of inflow (or outflow) has to be determined by empirical means.

Hazards During Start-up and Shutdown. It is well-known from in situ measurements that transient field reversals can occur when loading operations are started or stopped (Cross, 1980). Furthermore, electrostatic ignitions are more likely to occur at these times. Fluidized bed start-up and shutdown procedures undoubtedly create transient periods of exposure to electrostatically induced dust ignition conditions. Especially during shutdown, the larger particles will fall quickly, leaving any fines and dust to settle much more slowly and providing some time period where dust concentration conditions in the freeboard are in the ignitable range. To the author’s knowledge, the time evolution of dust concentration conditions in a fluidized bed during start-up and shutdown has not been studied and would be a worthy subject for investigation from the standpoint of process safety. With no inflow of powder, Maurer (cone) discharges can be safely ignored; however, capacitive discharges from ungrounded conductors or propagating brush discharges from insulating surfaces are always a threat. The usual precautions of insuring secure grounding and bonding of all plant components (see in Sec. 5.2, “Plant Grounding and Bonding”) and avoiding any use of plastic piping or insulating liners where charged granular solids are present (see in Sec. 5.2, “Insulating Liners”) are imperative safety measures.

Electrostatics and Dust Explosions 857

5.2Hazards in Peripheral Equipment and Processes

Selected aspects of safe practice in solids handling are covered below. For additional information, refer to the rules for plant safety prepared by the Expert Commission for Safety in the Swiss Chemical Industry (ESCIS, 1988). While making no mention of fluidization, this source provides many practical suggestions for the avoidance of electrostatic ignition risks in powder handling operations.

Plant Grounding and Bonding. Most ignitions in manufacturing plants and commercial facilities where flammable dusts are present are due to capacitive sparks, and they can almost always be prevented by bonding together and grounding all conductive components. Therefore, the single most important measure that can be taken to reduce electrostatic risks is to insure that bonds and ground wires are installed in all equipment and that these remain in good repair at all times. Regular inspection and testing programs for bonds and ground connections are absolutely vital in any powder-processing facility. A particularly important inspection issue is to make sure that bonds and grounds are properly used. Far too many preventable accidents have occurred because perfectly adequate ground connections have not been reconnected after maintenance or installation work. The integrity of bonds and ground connections is ordinarily tested by a resistance meter. These measurements should be made at a voltage of 500 V; any lower value may give misleading results. For conductors supposed to be bonded together, the resistance reading should be less than ~10 ohms. Resistances several orders of magnitude higher than this figure, while in fact safe and acceptable, may indicate that corrosion or a damaged cable exists somewhere and that the bond should be checked.

A simple example of the ESD risk associated with failure to bond conductors together is shown in Fig. 12. Here, an ungrounded funnel is being used to dump powder into a mixing vessel. Triboelectrification occurs as the powder slides down the sides of the funnel; both the powder and the funnel become charged. If the funnel collects enough charge to exceed the breakdown condition, a capacitive spark jumps to the grounded vessel, creating the possibility of an ignition of any flammable dust. An ignition in this circumstance is likely to have serious consequences because of direct worker exposure to any explosion or fire that results. The problem is easily avoided by connecting the funnel to the vessel.

858 Fluidization, Solids Handling, and Processing

++ |

++ |

ungrounded |

funnel |

++

++

|

|

|

flammable |

|

|

|

atmosphere |

− |

− |

− |

|

|

− |

|

|

− |

|

− |

grounded |

− |

|

− |

mixing vessel |

product

Figure 12. An ungrounded funnel mounted on the top of a grounded mixing vessel. As it falls down, the powder charges the funnel, and if sufficient charge accumulates to exceed breakdown, a spark can jump to the grounded vessel, causing an ignition.

Reports of many actual incidents serve to show how the failure to ground or bond equipment in a plant can cause ignitions via some rather unexpected mechanisms. One such incident occurred in a large hopper used to store polymer granules (Britton and Kirby, 1989). A deflagration occurred as material was being loaded into the hopper from a pneumatic transport line. The granules were too large to ignite and the presence of flammable vapors was ruled out; however, fines were present in the vessel from a previous batch operation. When the loading commenced, the fines resuspended, forming an ignitable cloud. The ignition itself was traced to a braided cable originally installed as a capacitive level meter but no longer in use and disconnected. The cable became charged very rapidly—quite possibly by a Maurer discharge driven by the inflow of powder—and then it capacitively discharged to the tank wall, igniting the dust cloud. Another example involved a metallic flow restrictor held in place by a gasket. Initially, no external bond was provided, because the gasket was itself conductive and provided a good electrical bond. Eventually, the gasket required replacement, but unfortunately the importance of a conductivity

Electrostatics and Dust Explosions 859

specification for this disposable item was not recognized and an insulating gasket was installed. Thus, the flow restrictor became charged as powder flowed through it and a capacitive spark to ground ignited the powder. These examples serve to make us aware that there are some subtle aspects to bonding and grounding in powder handling equipment. The lesson here is an old one, that seemingly straightforward changes and maintenance procedures can have serious unintended consequences.

Tramp Metal. If a loose metal object, such as a misplaced tool, disconnected electrical cable, or broken blade from a blender falls into a vessel containing charged powder, this “tramp” metal will become electrostatically charged. If the object then comes close to a grounded wall or another metal object, a capacitive discharge may occur. Whether or not the energy of this spark is sufficient to cause an ignition depends on the size of the object and its charge. Table 6 shows that small metal implements generally have capacitance in the 10–20 pF range. Reference to the nomograph in Fig. 7 tells us that, to achieve sufficient energy to ignite polymer powders (MIE ³ 5 mJ), the object would have to become charged to 20,000 V. For a small object, a brush discharge probably will occur long before such a high potential can be reached. Therefore, electrical discharges from tramp metal objects less than ~5 cm (~2 in.) in size are not ordinarily energetic enough to ignite most dusts. The ESD risk posed by tramp metal when flammable vapors or gases are present in combination with granular solids is much higher (refer to Sec. 5.2, “Available Fuels in Granular Solids Operations”).

Insulating Liners. Plastic film is commonly used as a liner material for paper bags and sacks for packaging many dry products. Such liners, usually electrically insulating, have been reported to create some new electrostatic hazards where none existed before. Refer to Fig. 13 showing the manual operation of dumping the contents of a bag into a mixing hopper. As the contents of the bag slide out, the liner becomes charged and, especially if it partially protrudes into the grounded hopper, a discharge may occur. A number of incidents of this type have been reported, in some cases with injuries to plant operators. The sacks can not be grounded so other methods must be employed to provide worker protection. Serious explosion incidents with larger lined sacks and bags in the past has prompted development of a new class of synthetic cloth materials which have woven semiconducting fibers into the fabric and provided grounding for the fibers (Wurr, 1992). Sacks made from these new fabrics (flexible intermediate bulk containers or FIBCs) are useful in dissipating static electric charge while minimizing any capacitive spark hazard.

860 Fluidization, Solids Handling, and Processing

polyethylene  lined sack

lined sack

open hatchway

+

++

++

++ flammable

|

|

atmosphere |

|

− |

− − − |

− − |

grounded |

|

− |

mixing |

|

|

|

|

vessel |

product

Figure 13. Dumping of dry product from a plastic lined sack into a mixing hopper. The inside of the liner can become charged as the product slides out and a discharge can lead to ignition of a flammable atmosphere under some circumstances.

The use of plastic materials for piping and vessel internals is best avoided whenever possible. Likewise, glass or epoxy liners are not to be used except when absolutely required in a particular manufacturing or processing operation. Plastic, epoxy, and glass can become electrically charged by contact with granular solids. For insulating materials with any kind of conductive backing, such as lined vessels or pipes, very powerful propagating brush discharges, capable of igniting almost any flammable dust, become possible (refer to Sec. 4.2, “Propagating Brush Discharges”). Experience has shown that plastic pipe can become conductive on an exposed surface due to the accumulation of dirt or moisture from rain or snow (Lüttgens, 1985). Once this conductive layer has formed, the conditions are established for a propagating brush discharge.

In the case of lined vessels, one method for avoiding the occurrence of propagating brush discharges is to limit the maximum breakdown voltage of the liner to 4 kV or less (Lüttgens and Glor, 1989). According to this strategy, the liner must be thin enough so that electrical breakdown occurs

Electrostatics and Dust Explosions 861

through the liner before a propagating brush discharge can happen. Dielectric breakdowns through the liner are much less energetic than a propagating brush discharge and so are less likely to ignite powders. Unfortunately, the 4 kV breakdown restriction imposes an unrealistically low limit on the thickness for most typical liner materials. For example, the glass used in vessel liners, with a breakdown strength of 20 kV/mm, would be restricted to thicknesses less than 200 μm by this rule. Presentday glass-on-metal lining technology is not capable of making chemicalresistant linings with good uniformity less than ~1 mm. It is likewise difficult to prepare uniform epoxy liners at these thicknesses. Therefore, elaborate measures such as inerting are often employed when lined vessels are used with triboelectrically active, flammable materials.

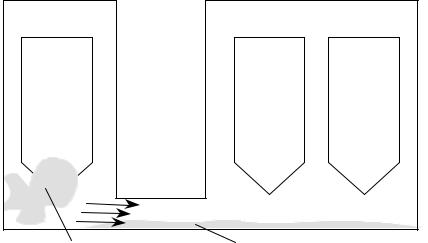

Secondary Explosions. The severity of a dust explosion can be greatly magnified if a secondary explosion takes place. Fig. 14 depicts a typical scenario for these destructive events. A localized, possibly quite minor deflagration occurs initially in one part of a plant. The associated air blast disturbs and entrains the dust layer accumulated on the floors and walls of the galleries and passageways connecting different parts of the plant. Then, either the initial thermal blast or the fire from the primary explosion ignites one or more secondary ignitions. These explosions can be very severe, propagating throughout the plant and engulfing an entire facility. Such incidents have been responsible for a number of truly devastating grain elevator explosions causing scores of fatalities. Their severity can be traced to dusty product that has been allowed to accumulate throughout the plant. Secondary explosions are easily prevented by good housekeeping. A useful rule of thumb, permitting quick assessment of the risk of a secondary explosion caused by deposited dust in a plant, is the “paper clip” test. If the deposited dust layer on the floor and other surfaces in a plant exceeds the thickness of a paper clip, about 1 mm (0.04 in), then the risk of a secondary explosion should be considered high. While true that conscientious cleanup practices greatly reduce hazards, a sudden piping or vessel containment failure also can create flammable dust suspensions in the galleries and passageways of any manufacturing facility.

Electrostatics enters into the problem of secondary explosions in several ways. First, an electrostatic spark may be the ignition source of the primary explosion. Second, an electrostatic spark can serve to ignite a dust cloud if particulate spews out at high velocity as a result of a sudden piping or vessel containment failure. Similar containment failures have occurred with insulating liquids and can not be ruled out for powders. For example,

862 Fluidization, Solids Handling, and Processing

the dust cloud issuing from a break in a pneumatic line is likely to be very highly charged. To guard against ESD ignition in such occurrences, good grounding and bonding practices are important so that the chance of a capacitive discharge is minimized.

gallery #1 |

gallery #2 |

|

|

silo |

silo |

silo |

|

|

passage |

|

|

|

air blast |

|

|

primary explosion |

dust layer disturbed and |

|

|

ignited by primary explosion |

|||

|

|||

Figure 14. A secondary explosion of the accumulated dust in passage ways and galleries by a minor initial explosion can propagate throughout a plant with devastating results.

Available Fuels in Granular Solids Operations. In powder and granular solids handling operations, dangerous underestimation of the likelihood of ignition results if due consideration is not given to the possibility that “unanticipated” fuel is present. An obvious example involves the form in which polymer solids are commonly packaged for delivery to commercial plastic component manufacturers. There is no possibility that these par- ticles—granules, prills, pellets, tablets, usually sized above ~1 mm—will ignite; however, attrition of these products during handling operations always produces fine particles. These fines settle out slowly and are usually quite flammable. There is also the fairly common situation during switch loading of a vessel that the fines from a previous operation provide the fuel for an ignition caused by the larger granules being loaded into the vessel. Refer back to the switch loading incident described in Sec. 5.2.

Electrostatics and Dust Explosions 863

Another far more dangerous unanticipated fuel problem exists when a flammable gas or solvent vapor is present with the granular solids. This combination is a serious ESD hazard because it brings together the high charging tendencies of large particles with the low MIE of flammable vapors (Jones and King, 1991). The nomograph of Fig. 7 shows that hydrocarbon vapors can be ignited with an energy of ~0.25 mJ, a factor of twenty lower than the conservative MIE value used for polymer powders. When this combination occurs in a vessel larger than approximately 2 m3 in volume, Table 7 specifies that special precautions are to be taken. This usually means seeking assistance from a qualified safety expert specializing in electrostatic hazards.

5.3Other Nuisances and Hazards

An ungrounded tote bin containing large granules of certain materials, especially polymers such as polyethylene, can retain triboelectric charge for days or weeks. Many an unsuspecting operator has discovered this lesson the hard way when using a bucket or scoop to collect a sample from a storage bin. If the person receives this shock while standing on a ladder or in any vulnerable position, there is the possibility of dropping a tool or sustaining a fall. Most human subjects can perceive an electrical discharge as low as 1 μC of transferred charge, and strong physiological shocks can cause involuntary muscle contractions. Such discharges are not ordinarily energetic enough to ignite powder (though flammable vapors would present a risk). To avoid unexpected, physiological shocks, tote bins should be grounded. Tote bins made of insulating plastic can be equipped with passive discharge foils, like the one shown Fig. 15, to reduce the risk.

passive discharge foil |

grounding strap |

|

|

insulative tote bin |

ground |

of electrically |

|

charged granules |

|

|

plant wall |

plant floor

Figure 15. Grounding foil for use in open bins of charged granular material. Foil must remain connected to ground.

864 Fluidization, Solids Handling, and Processing

The same particle charging that affects fluidization conditions has an adverse effect on powder flow due to increased cohesion. For example, it has been found that electrostatic effects increase pressure drops (Smeltzer, Weaver, and Klinzing, 1982) and also exacerbate choking phenomena (Joseph and Klinzing, 1983) in pneumatic transport lines. Humidification is often not a viable option in reducing these problems. Furthermore, bridging problems at discharge chutes are exacerbated. The conventional solution of using vibration to facilitate powder flow, while effective, is not always practical. There have been incidents where plant operators have encountered flow problems involving hoppers, have opened them up, attempted to unblock the discharge with metal rods or other implements, and have felt or observed strong electrostatic sparks. Besides the obvious ignition hazard involving the powder (or any other flammable material present), there is also the possibility of a worker receiving a shock and sustaining an injury.

6.0CONCLUSION

The objective of this chapter has been to place in context the electrostatic hazards associated with powder and granular solids handling in facilities where fluidized or spouted bed units are found. The first task undertaken has been to review triboelectrification, the principal charging mechanism associated with powders and granular materials, and charge relaxation, the mechanism by which charge is dissipated. Then, the relationships among charge, electric field, and electrostatic potential were elucidated. Next, certain electrostatic phenomena common in fluidized beds were covered. It is found that bipolar charging during fluidization limits hazards but that the specific charge held by individual particles is high enough to suggest potential risks in the right circumstances. Following this, some general aspects of ESD dust ignition criteria were summarized, including the fire triangle, the MIE (minimum ignition energy) of dusts, and the different types of electrostatic discharges and their relative likelihood of igniting flammable powders. Finally, some of the specific hazards, and steps required to abate them in dry solids handling facilities were discussed. The emphasis has been on known hazards associated with the conventional powder handling apparatus and systems needed in support of a fluidized or spouted bed unit.