Yang Fluidization, Solids Handling, and Processing

.pdf

626 Fluidization, Solids Handling, and Processing

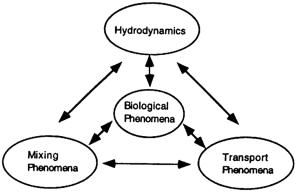

Figure 8. The relationship between biological, hydrodynamic, mixing, and transport phenomena in three-phase fluidized bed bioreactors.

The definition of phases in a three-phase fluidized bioreactor is not always as clear as in traditional three-phase fluidization applications. The solid phase is made up of bacterial, fungal, plant, or animal cells, immobilized on or in some type of support or self-immobilized in the form of flocs or pellets. If a support particle is not present, the reactor is considered to be a three-phase bioreactor if the bioflocs or cell aggregates are greater than 10 µm, at which scale they can be considered heterogeneous to the liquid phase in terms of fluid dynamics (Fan, 1989). The liquid phase constitutes the medium for cell growth. The gas phase may be supplied to the reactor through a distribution plate, as is typical for other three-phase fluidization applications, or the gas phase may be generated within the reactor as part of the biochemical reactions taking place, or both. Depending on whether the fermentation is aerobic or anaerobic, the gas phase may be air, oxygen, or an inert gas. If evolved during the fermentation, the gas phase may be, for example, carbon dioxide, methane, or hydrogen.

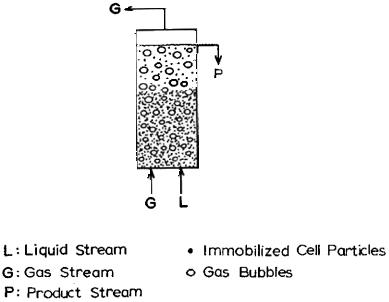

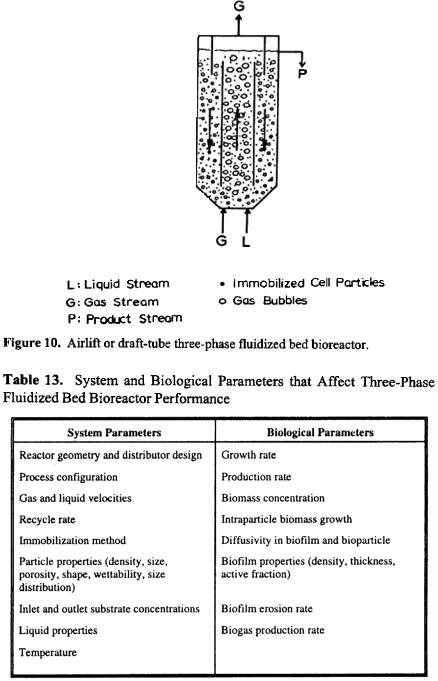

There are a wide variety of three-phase fluidized bioreactor designs possible. The conventional reactor, shown in Fig. 9, is fluidized by both gas and liquid entering at the bottom of the reactor and leaving at the top and is the most common type of three-phase fluidized bed bioreactor. This reactor may be configured to operate with little axial liquid mixing or in a well-mixed mode by adding a recycle stream. The airlift reactor or draft tube fluidized bed reactor, Fig. 10, is also frequently used. In this reactor, gas is injected at the bottom of a draft tube placed in the center of the

Three-Phase Fluidization Systems 631

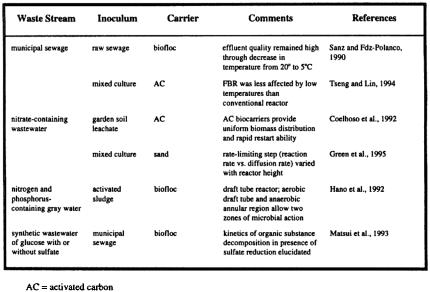

Table 14c. Recent Three-Phase Biofluidization Research on Treatment of Food Plant Wastewater

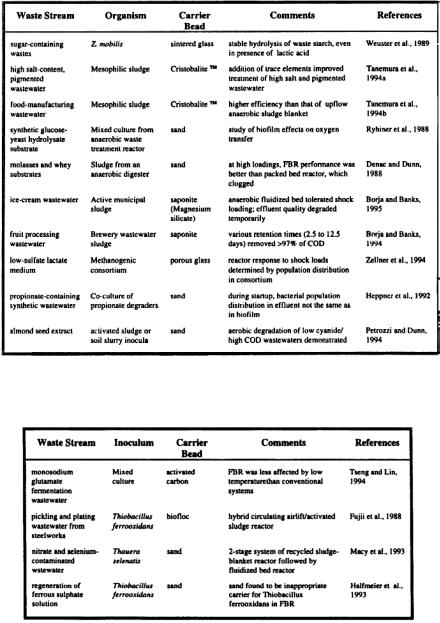

Table 14d. Recent Three-Phase Biofluidization Research on Treatment of Industrial Wastewater

632 Fluidization, Solids Handling, and Processing

The advantages of three-phase fluidization are especially suited to wastewater treatment. For instance, the high biomass retention inherent in immobilized cell reactors allows high pollutant loading, and the ability of the reactor to handle suspended solids without clogging is ideal for many sewage streams (Andrews, 1988; Weuster et al., 1989). Three-phase fluidized bed bioreactors allow for flexible operations; flow rate and pollutant loading can be varied over a wide range, a requirement in many sewage treatment systems (Tzeng, 1991). The high productivity of threephase fluidized bed bioreactors results in relatively compact units. This is of particular value when a given substrate can not be degraded by the wastewater treatment bioreactor that treats general plant effluents; a threephase fluidized bed bioreactor with an inoculum tailored to the recalcitrant substrate can easily be placed at the point of generation of that substrate, treating it before the waste streams are commingled.

Current work in this area is focusing on improved carrier materials, tailoring the reactor/inoculum system to a specific waste stream, improving reactor start-up, and determining optimum operating conditions. Low temperature treatment has been shown to be feasible (Sanz and FdezPolanco, 1990), and responses to shock loading of organics have been elucidated in several cases (Zellner et al., 1994; Borja and Banks, 1995). Adsorption and desorption of degradable substrates by the support particle can be effective in preventing toxic shock caused by sudden increases in the substrate concentration and can prevent excess amounts of the substrate in the reactor effluent. The ability of the support particle to desorb the substrate is critical in allowing regeneration of the particles (Mol et al., 1993; Petrozzi et al., 1993). Automatic control of pH has also been studied as a method of protecting the reactor from toxic surges in effluent pollutant concentrations, improving reactor stability and effluent quality, and reducing costs for alkali to treat reactor imbalances (Denac et al., 1990; Ehlinger et al., 1994).

Conditions during start-up can have a dramatic impact on time required to reach reasonable performance levels and on the ultimate reactor performance. Dilution rate, loading rate as measured by chemical oxygen demand (COD), carrier choice, inoculum amount, inoculum strategy, and inoculum species distribution are critical parameters (Sreekrishnan et al., 1991; Araki and Harada, 1994; Austermann-Haun et al., 1994; Yongming et al., 1993). Pore characteristics have a strong influence on time required for start-up and on the ultimate biomass density in the

Three-Phase Fluidization Systems 633

reactor; high porosity, adequate pore size, and large surface area all contribute to rapid reactor start-up and high cell density, though no single one of these parameters by itself is an adequate predictor of optimal cell retention for successful reactor start-up and operation (Yee et al., 1992). Control of reactor pH by controlling the feed rate has been shown to result in more rapid reactor start-up than without pH control (Hsu and Shieh, 1993).

During start-up, the microbial population distribution in the biofilm varies with time. Initial colonization of the particle may be by one or more species that alter the surface favorably for colonization by other species. For instance, in the operation of a butyrate-degrading fluidized bed bioreactor, methanogens attached to the sand particles early in the start-up process and produced a primary matrix of heteropolysaccharides that allowed attachment of other bacterial species (Sreekrishnan et al., 1991; Zellner et al., 1991; Yongming et al., 1993). This is contrary to findings in an acetate-propionate-butyrate degrading reactor, in which facultative anaerobes were found to be the initial colonizers (Lauwers et al., 1990).

The COD loading profiles used for start-up may be based on maximum efficiency or maximum loading. In the former, COD loading is gradually increased and residence time is gradually decreased as the biofilm develops; high COD removal percentages are achieved early in the reactor lifetime, but initial loading is low. The maximum loading profile starts with a short residence time and high COD loading, resulting in initially low COD removal efficiencies; the initially high substrate concentrations have been suggested to increase the rate of reactor start-up (Hsu and Shieh, 1993; Yongming et al., 1993).

One of the problems associated with waste treatment is the presence of recalcitrant or nonbiodegradable compounds in the waste stream (Keller, G., personal communication, Nov. 3, 1995). If the bioreactor cannot degrade toxic compounds that the law requires to be removed, either an alternative chemical or physical process must be completely substituted for the bioprocess or a supplemental process must be added to the treatment system. The combination of biodegradation with physical adsorption in a fluidized bed reactor has been successfully demonstrated for the treatment of cyanide-containing, phenolic wastewaters (Pfeffer and Suidan, 1989); the biofilm was immobilized on granulated activated carbon which acted as a sink for both the degradable substrate and toxic, nondegradable compounds. Fresh carbon was periodically added to the reactor, replacing exhausted carbon, so that the toxic nonbiodegradable compounds did not

634 Fluidization, Solids Handling, and Processing

build up in the bulk reactor fluid. Because much of the degradable substrate was consumed by the biofilm, carbon requirements were reduced from what they would be if no biodegradation took place (Pfeffer and Suidan, 1989).

Fermentations. Recent years have seen many investigations of fermentations to produce high-value products, such as pharmaceuticals and recombinant proteins, in fluidized bed bioreactors. Continuous production of these products in three-phase fluidized bed bioreactors is especially attractive, because the simplicity of construction of these bioreactors reduces the opportunities for contaminating organisms to gain entry to the reactor during long-term production. The advantages of threephase fluidized bed bioreactors have also been applied to more traditional bacterial fermentations, such as lactic acid or solvent production. For fermentations such as these that exhibit product inhibition, the potential to integrate product removal with the fermentation by adding adsorbent particles as part of the solid phase of the fluidized bed is a unique advantage currently being explored by several researchers (van der Wielen et al., 1990; Davison and Scott, 1992; Kaufman et al., 1995). Though several commercial scale three-phase fluidized bed bioprocess operations exist (Fan, 1989), much of the work in applying three-phase fluidization to fermentation is still at a laboratory scale. A partial survey of this burgeoning research is given in Table 15.

Fermentation applications in three-phase fluidization have lagged those of wastewater treatment, because the goal, biosynthesis of useful chemicals, is more constrained than that of simple biodegradation of waste. Sterilization, pure culture preparation, separation of intermediate or product inhibitors, bioreactor control, specialized techniques of microbial immobilization, and product recovery must be considered. Oxygen demands are generally higher for aerobic fermentations than they are for aerobic wastewater treatment applications, because the higher substrate concentrations in a fermentation feedstock result in higher metabolic requirements for oxygen (Andrews, 1988).

Several areas are receiving much of the research attention. Approaches that integrate product recovery with the fermentation in a threephase fluidized bed bioreactor reflect general research trends in biochemical engineering (Yabannavar and Wang, 1991; Davison and Thompson, 1992). The successful use of three-phase biofluidization has also been demonstrated for recombinant protein systems, where it may have some benefit in improving plasmid stability (Shu and Yang, 1996).