- •GENERAL INFORMATION

- •FUEL REQUIREMENTS

- •VEHICLES WITHOUT TURBOCHARGED ENGINES

- •VEHICLES WITH 2.2L 16 VALVE ENGINES

- •THE FOLLOWING IS APPLICABLE TO ALL VEHICLES

- •FUEL DELIVERY SYSTEM

- •FUEL HOSES, CLAMPS, AND QUICK CONNECT FITTINGS

- •HOSES AND CLAMPS

- •QUICK CONNECT FITTINGS

- •FUEL PUMP ASSEMBLY

- •FUEL SYSTEM PRESSURE

- •MECHANICAL MALFUNCTIONS

- •FUEL PUMP REMOVAL

- •FUEL PUMP STRAINER SERVICE

- •FUEL PUMP INSTALLATION

- •REMOVAL

- •INSTALLATION

- •CHASSIS FUEL TUBES

- •FUEL TANKS

- •GENERAL INFORMATION

- •FUEL TANK FILLER TUBE

- •PRESSURE VACUUM FILLER CAPS

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •FUEL TANK

- •DRAINING FUEL TANK

- •FUEL TANK CAPACITIES

- •FUEL TANK REMOVAL

- •INSTALLATION

- •FUEL PUMP

- •FUEL RESERVOIR

- •FUEL LEVEL SENDING UNIT

- •DIAGNOSIS

- •REMOVAL

- •INSTALLATION

- •REMOVAL

- •INSTALLATION

- •ACCELERATOR PEDAL AND THROTTLE CABLE

- •ACCELERATOR PEDAL

- •REMOVAL

- •INSTALLATION

- •THROTTLE CABLE

- •REMOVAL

- •INSTALLATION

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •FUEL PRESSURE REGULATOR

- •THROTTLE BODY

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •SYSTEMS TEST

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IGNITION TIMING PROCEDURE

- •IDLE SPECIFICATIONS

- •FAULT CODE DESCRIPTION

- •FAULT CODE DESCRIPTION

- •FUEL LINES AND HOSES

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE BODY

- •REMOVAL

- •INSTALLATION

- •FUEL FITTING

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR

- •REMOVAL

- •INSTALLATION

- •THROTTLE POSITION SENSOR

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE SENSOR

- •REMOVAL

- •CANISTER PURGE SOLENOID

- •REMOVAL

- •INSTALLATION

- •ENGINE CONTROLLER SERVICE

- •OXYGEN SENSOR (O2 SENSOR)

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •IGNITION SWITCH ON (ZERO RPM) MODE

- •CRUISE OR IDLE MODE

- •ACCELERATION MODE

- •DECELERATION MODE

- •WIDE OPEN THROTTLE MODE

- •IGNITION SWITCH OFF MODE

- •THROTTLE BODY

- •FUEL SUPPLY CIRCUIT

- •FUEL INJECTORS AND FUEL RAIL ASSEMBLY

- •FUEL PRESSURE REGULATOR

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •FAULT CODE DESCRIPTION

- •SYSTEM TESTS

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IGNITION TIMING PROCEDURE

- •IDLE SPECIFICATIONS

- •THROTTLE BODY

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE POSITION SENSOR (TPS)

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •THROTTLE BODY REMOVAL

- •FUEL INJECTOR RAIL ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR SERVICE

- •WASTEGATE SOLENOID AND CANISTER PURGE SOLENOID

- •ENGINE CONTROLLER SERVICE

- •HEATED OXYGEN SENSOR (O2 SENSOR)

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •IGNITION SWITCH ON (ZERO RPM) MODE

- •CRUISE OR IDLE MODE

- •ACCELERATION MODE

- •DECELERATION MODE

- •WIDE OPEN THROTTLE MODE

- •IGNITION SWITCH OFF MODE

- •THROTTLE BODY

- •FUEL SUPPLY CIRCUIT

- •FUEL INJECTORS AND FUEL RAIL ASSEMBLY

- •FUEL PRESSURE REGULATOR

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •FAULT CODE DESCRIPTION

- •SYSTEM TESTS

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IGNITION TIMING PROCEDURE

- •IDLE SPECIFICATIONS

- •THROTTLE BODY

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE POSITION SENSOR (TPS)

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •THROTTLE BODY REMOVAL

- •INSTALLATION

- •FUEL INJECTOR RAIL ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTORS

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR SERVICE

- •WASTEGATE AND CANISTER PURGE SOLENOID SERVICE

- •ENGINE CONTROLLER SERVICE

- •HEATED OXYGEN SENSOR (O2 SENSOR)

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •THROTTLE BODY

- •FUEL SUPPLY CIRCUIT

- •FUEL PRESSURE REGULATOR

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •FAULT CODE DESCRIPTION

- •SYSTEM TESTS

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IDLE SPECIFICATIONS

- •IGNITION TIMING PROCEDURE

- •THROTTLE BODY SERVICE

- •THROTTLE BODY

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE POSITION SENSOR

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR RAIL ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR SERVICE

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTORS

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

- •CANISTER PURGE SOLENOID SERVICE

- •ENGINE CONTROLLER

- •HEATED OXYGEN SENSOR (O2 SENSOR)

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •THROTTLE BODY

- •FUEL SUPPLY CIRCUIT

- •FUEL INJECTORS AND FUEL RAIL ASSEMBLY

- •FUEL PRESSURE REGULATOR

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •SYSTEM TESTS

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IDLE SPECIFICATIONS

- •FAULT CODE DESCRIPTION

- •THROTTLE BODY REMOVAL

- •THROTTLE BODY

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE POSITION SENSOR

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR RAIL ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

- •CANISTER PURGE SOLENOID SERVICE

- •ENGINE CONTROLLER SERVICE

- •CRANKSHAFT TIMING SENSOR

- •REMOVAL

- •INSTALLATION

- •CAMSHAFT SENSOR SERVICE

- •REMOVAL

- •INSTALLATION

- •HEATED OXYGEN SENSOR (O2 SENSOR) SERVICE

- •SPECIFICATIONS

- •TEMPERATURE SENSOR SPECIFICATIONS

- •TORQUE

14 - 8 FUEL SYSTEMS |

|

Ä |

|

Fig. 9 Fuel Pump Service

Fig. 10 Fuel Strainer Service

INSTALLATION

(1)Lubricate the strainer O-ring with Mopar Silicone Spray Lube.

(2)Insert strainer O-ring into outlet of strainer so that it sits evenly on the step inside the outlet.

(3)Push strainer onto the inlet of the fuel pump reservoir body. Make sure the locking tabs on the reservoir body lock over the locking tangs on the strainer.

FUEL PUMP INSTALLATION

(1)Wipe seal area of tank clean and place a new O-ring seal in position on pump.

(2)Position fuel pump in tank with locking ring.

(3)Using a hammer and brass drift punch drive ring around clockwise to lock pump in place.

(4) Install tank. Refer to the Fuel Tank Section in this Group.

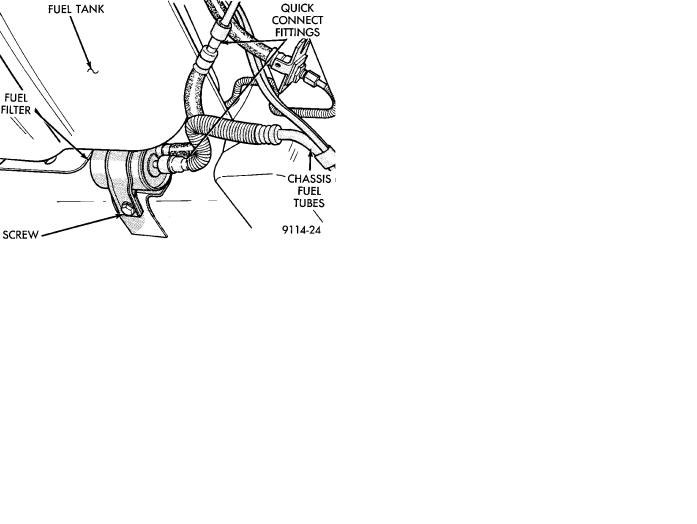

FUEL FILTERÐALL VEHICLES

REMOVAL

WARNING: FUEL SYSTEM PRESSURE MUST BE RELEASED BEFORE THE FUEL FILTER IS REMOVED.

(1)Perform the Fuel System Pressure Release procedure.

(2)) Remove the fuel filter retaining screw (Fig. 11). Remove fuel filter from mounting plate.

(3)Wrap a shop towel around hoses to absorb fuel. Remove quick-connect fittings at filter and fuel supply tube. Refer to Quick-Connect Fittings in this section.

Fig. 11 Fuel Filter

INSTALLATION

(1)Connect quick-connect fuel fittings to the filter and fuel supply line. Refer to Quick-Connect Fittings in this section.

(2)Position filter assembly on mounting plate and tighten mounting screw to 8 NIm (75 in. lbs.) torque.

CAUTION: When using the ASD Fuel System Test, the Auto Shutdown (ASD) Relay remains energized for either 7 minutes, until the test is stopped, or until the ignition switch is turned to the Off position.

(3) Place the ignition key in the ON position. Using the DRB II tester, access ASD Fuel System Test. The ASD Fuel System Test will activate the fuel pump and pressurize the system. Inspect for leaks.

CHASSIS FUEL TUBES

CAUTION: Over tightening the pump lock ring may result in a leak.

figure 12 shows fuel system component locations and chassis fuel tube routings.

Ä |

|

FUEL SYSTEMS 14 - 9 |

|

Fig. 12 Fuel Tank, Filter, and Chassis Line Routing