- •GENERAL INFORMATION

- •FUEL REQUIREMENTS

- •VEHICLES WITHOUT TURBOCHARGED ENGINES

- •VEHICLES WITH 2.2L 16 VALVE ENGINES

- •THE FOLLOWING IS APPLICABLE TO ALL VEHICLES

- •FUEL DELIVERY SYSTEM

- •FUEL HOSES, CLAMPS, AND QUICK CONNECT FITTINGS

- •HOSES AND CLAMPS

- •QUICK CONNECT FITTINGS

- •FUEL PUMP ASSEMBLY

- •FUEL SYSTEM PRESSURE

- •MECHANICAL MALFUNCTIONS

- •FUEL PUMP REMOVAL

- •FUEL PUMP STRAINER SERVICE

- •FUEL PUMP INSTALLATION

- •REMOVAL

- •INSTALLATION

- •CHASSIS FUEL TUBES

- •FUEL TANKS

- •GENERAL INFORMATION

- •FUEL TANK FILLER TUBE

- •PRESSURE VACUUM FILLER CAPS

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •FUEL TANK

- •DRAINING FUEL TANK

- •FUEL TANK CAPACITIES

- •FUEL TANK REMOVAL

- •INSTALLATION

- •FUEL PUMP

- •FUEL RESERVOIR

- •FUEL LEVEL SENDING UNIT

- •DIAGNOSIS

- •REMOVAL

- •INSTALLATION

- •REMOVAL

- •INSTALLATION

- •ACCELERATOR PEDAL AND THROTTLE CABLE

- •ACCELERATOR PEDAL

- •REMOVAL

- •INSTALLATION

- •THROTTLE CABLE

- •REMOVAL

- •INSTALLATION

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •FUEL PRESSURE REGULATOR

- •THROTTLE BODY

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •SYSTEMS TEST

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IGNITION TIMING PROCEDURE

- •IDLE SPECIFICATIONS

- •FAULT CODE DESCRIPTION

- •FAULT CODE DESCRIPTION

- •FUEL LINES AND HOSES

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE BODY

- •REMOVAL

- •INSTALLATION

- •FUEL FITTING

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR

- •REMOVAL

- •INSTALLATION

- •THROTTLE POSITION SENSOR

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE SENSOR

- •REMOVAL

- •CANISTER PURGE SOLENOID

- •REMOVAL

- •INSTALLATION

- •ENGINE CONTROLLER SERVICE

- •OXYGEN SENSOR (O2 SENSOR)

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •IGNITION SWITCH ON (ZERO RPM) MODE

- •CRUISE OR IDLE MODE

- •ACCELERATION MODE

- •DECELERATION MODE

- •WIDE OPEN THROTTLE MODE

- •IGNITION SWITCH OFF MODE

- •THROTTLE BODY

- •FUEL SUPPLY CIRCUIT

- •FUEL INJECTORS AND FUEL RAIL ASSEMBLY

- •FUEL PRESSURE REGULATOR

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •FAULT CODE DESCRIPTION

- •SYSTEM TESTS

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IGNITION TIMING PROCEDURE

- •IDLE SPECIFICATIONS

- •THROTTLE BODY

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE POSITION SENSOR (TPS)

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •THROTTLE BODY REMOVAL

- •FUEL INJECTOR RAIL ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR SERVICE

- •WASTEGATE SOLENOID AND CANISTER PURGE SOLENOID

- •ENGINE CONTROLLER SERVICE

- •HEATED OXYGEN SENSOR (O2 SENSOR)

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •IGNITION SWITCH ON (ZERO RPM) MODE

- •CRUISE OR IDLE MODE

- •ACCELERATION MODE

- •DECELERATION MODE

- •WIDE OPEN THROTTLE MODE

- •IGNITION SWITCH OFF MODE

- •THROTTLE BODY

- •FUEL SUPPLY CIRCUIT

- •FUEL INJECTORS AND FUEL RAIL ASSEMBLY

- •FUEL PRESSURE REGULATOR

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •FAULT CODE DESCRIPTION

- •SYSTEM TESTS

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IGNITION TIMING PROCEDURE

- •IDLE SPECIFICATIONS

- •THROTTLE BODY

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE POSITION SENSOR (TPS)

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •THROTTLE BODY REMOVAL

- •INSTALLATION

- •FUEL INJECTOR RAIL ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTORS

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR SERVICE

- •WASTEGATE AND CANISTER PURGE SOLENOID SERVICE

- •ENGINE CONTROLLER SERVICE

- •HEATED OXYGEN SENSOR (O2 SENSOR)

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •THROTTLE BODY

- •FUEL SUPPLY CIRCUIT

- •FUEL PRESSURE REGULATOR

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •FAULT CODE DESCRIPTION

- •SYSTEM TESTS

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IDLE SPECIFICATIONS

- •IGNITION TIMING PROCEDURE

- •THROTTLE BODY SERVICE

- •THROTTLE BODY

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE POSITION SENSOR

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR RAIL ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR SERVICE

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTORS

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

- •CANISTER PURGE SOLENOID SERVICE

- •ENGINE CONTROLLER

- •HEATED OXYGEN SENSOR (O2 SENSOR)

- •GENERAL INFORMATION

- •SYSTEM DIAGNOSIS

- •ENGINE CONTROLLER

- •MODES OF OPERATION

- •THROTTLE BODY

- •FUEL SUPPLY CIRCUIT

- •FUEL INJECTORS AND FUEL RAIL ASSEMBLY

- •FUEL PRESSURE REGULATOR

- •FUEL SYSTEM DIAGRAM

- •VISUAL INSPECTION

- •ON BOARD DIAGNOSTICS

- •MONITORED CIRCUITS

- •HIGH AND LOW LIMITS

- •FAULT CODE DESCRIPTION

- •SYSTEM TESTS

- •OBTAINING FAULT CODES

- •STATE DISPLAY TEST MODE

- •STATE DISPLAY INPUTS AND OUTPUTS

- •STATE DISPLAY SENSORS

- •CIRCUIT ACTUATION TEST MODE

- •OBTAINING CIRCUIT ACTUATION TEST

- •THROTTLE BODY MINIMUM AIR FLOW CHECK PROCEDURE

- •IDLE SPECIFICATIONS

- •FAULT CODE DESCRIPTION

- •THROTTLE BODY REMOVAL

- •THROTTLE BODY

- •FUEL SYSTEM PRESSURE RELEASE PROCEDURE

- •THROTTLE POSITION SENSOR

- •REMOVAL

- •INSTALLATION

- •AUTOMATIC IDLE SPEED (AIS) MOTOR

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR RAIL ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •FUEL PRESSURE REGULATOR

- •REMOVAL

- •INSTALLATION

- •FUEL INJECTOR

- •REMOVAL

- •INSTALLATION

- •MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

- •CANISTER PURGE SOLENOID SERVICE

- •ENGINE CONTROLLER SERVICE

- •CRANKSHAFT TIMING SENSOR

- •REMOVAL

- •INSTALLATION

- •CAMSHAFT SENSOR SERVICE

- •REMOVAL

- •INSTALLATION

- •HEATED OXYGEN SENSOR (O2 SENSOR) SERVICE

- •SPECIFICATIONS

- •TEMPERATURE SENSOR SPECIFICATIONS

- •TORQUE

Ä |

|

FUEL SYSTEMS 14 - 117 |

|

3.0L MULTI-POINT FUEL INJECTIONÐGENERAL DIAGNOSIS

INDEX

|

page |

60-Way Engine Controller Wiring Connector |

. . . . 127 |

Circuit Actuation Test Mode . . . . . . . . . . . . |

. . . . 125 |

Fault Code Description . . . . . . . . . . . . . . . . . |

. . . 122 |

Fuel System Diagram . . . . . . . . . . . . . . . . . . |

. . . 117 |

On Board Diagnostics . . . . . . . . . . . . . . . . . |

. . . 121 |

FUEL SYSTEM DIAGRAM

The 3.0L MPI system is managed by the engine controller. The controller receives inputs from various switches and sensors (Fig. 1). Based on these inputs, the engine controller adjusts ignition timing and idle speed through various output devices. Refer to the Multi-Point Fuel InjectionÐ3.0L Engine section of this group for system and component descriptions.

VISUAL INSPECTION

Perform a visual inspection for loose, disconnected, or misrouted wires and hoses before diagnosing or servicing the fuel injection system. A visual check saves unnecessary test and diagnostic time. A thorough visual inspection includes the following checks:

|

page |

State Display Test Mode . . . . . . . . . . . . . . . . . . |

. 125 |

System Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . |

124 |

Throttle Body Minimum Air Flow Check Procedure |

. 125 |

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . |

117 |

(1)Check for correct spark plug cable routing. Ensure the cables are completely connected to the spark plugs and distributor.

(2)Check ignition coil electrical connections (Fig. 2).

(3)Verify the electrical connector is attached to the Purge Solenoid (Fig. 3).

(4)Verify vacuum connection at Purge Solenoid is secure and not leaking (Fig. 3).

(5)Verify the electrical connector is attached to the MAP sensor (Fig. 4).

(6)Check MAP sensor hose at MAP Sensor Assembly (Fig. 4), and at Vacuum Connection at Intake Plenum Fitting.

(7)Check alternator wiring connections. Ensure the accessory drive belt has proper tension.

Fig. 1 Multi-Point Fuel Injection Components

14 - 118 FUEL SYSTEMS

Fig. 2 Ignition Coil Electrical Connection

Fig. 3 Electrical Connector Canister Purge Solenoid

Fig. 4 Map Sensor Electrical and Vacuum Connec-

tions

(8)Verify hoses are securely attached to the vapor canister (Fig. 5).

(9)Verify the engine ground strap is attached at the engine and dash panel (Fig. 6).

Ä

Fig. 5 Vapor Canister

Fig. 6 Oxygen Sensor Connector

(10)Ensure the heated oxygen sensor connector is connected to the harness connector (Fig. 6).

(11)Verify the distributor connector is connected to the harness connector (Fig. 7).

Fig. 7 Distributor Connector

Ä |

|

FUEL SYSTEMS 14 - 119 |

|

(12)Verify the coolant temperature sensor connector is connected to the harness connector (Fig. 8).

(13)Check vacuum hose connection at fuel pressure regulator and intake plenum connector (Fig. 8).

Fig. 10 Throttle Body Electrical and Vacuum Hose

Connections

Fig. 8 Coolant Temperature Sensor and Vacuum

Connections

(14)Ensure the harness connector is securely attached to each fuel injector.

(15)Check the oil pressure sending unit electrical connection (Fig. 9).

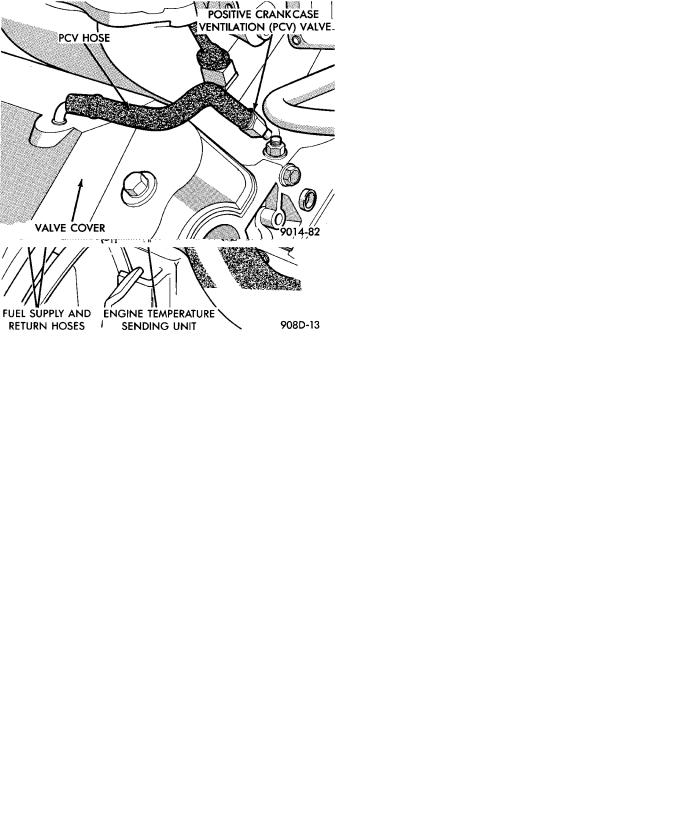

Fig. 11 Positive Crankcase Ventilation (PCV) System

Fig. 9 Oil Pressure Sending Unit Electrical Connec-

tion

(16)Check hose connections at throttle body (Fig.

10).

(17)Check throttle body electrical connections (Fig.

10).

(18)Check PCV hose connections (Fig. 11).

Fig. 12 EGR System Vacuum Hose Connections

(19)If equipped, check EGR system vacuum hose connections (Fig. 12).

(20)If equipped, check EGR tube to intake plenum connections (Fig. 12).

14 - 120 FUEL SYSTEMS |

|

Ä |

|

(21)Inspect the electronic EGR transducer solenoid electrical connector.

(22)Ensure the vacuum connections at the electronic EGR transducer is secure and not leaking.

(23)Check Power Brake Booster and Speed Connections (Figs. 13 and 14).

Fig. 15 Automatic Transmission Electrical Connec-

tions

Fig. 13 Power Brake Booster and Speed Control

Vacuum Hose Connections (Without Anti-lock

Brakes)

Fig. 14 Speed Control Vacuum Hose Connection

(With Anti-lock Brakes)

(24)Inspect engine harness to main harness connections.

(25)Check all automatic transmission electrical connections (Fig. 15).

(26)Check the distance sensor electrical connection (Fig. 16).

(27)Inspect the engine controller 60-way electrical connector for damage or spread terminals. Verify the 60-way connector is fully inserted into the socket of the engine controller. Ensure wires are not stretched or pulled out of the connector (Figs. 17, 18, and 19).

Fig. 16 Distance Sensor Electrical Connector

Fig. 17 Engine ControllerÐAA Body

(28)Check the air conditioning, starter, ASD, fuel pump and radiator fan relay connections (Figs. 20, 21, and 22).

(29)Check battery cable connections.

(30)Check hose and electrical connections at fuel pump. Ensure connector is making contact with terminals on pump.