01 POWER ISLAND / # installation Guide Steam Turbine Package (crop)

.pdf

SUMMARY |

|

|

INTRODUCTION ............................................................................................................................................... |

5 |

|

DOCUMENT LIST ............................................................................................................................................. |

6 |

|

1. FOUNDATIONS ...................................................................................................................................... |

15 |

|

1.1. |

Check and Prepare Foundation (Refer to IC-000524) ............................................................. |

15 |

1.2. |

Set fixators ...................................................................................................................................... |

15 |

1.3. |

Grouting........................................................................................................................................... |

17 |

2. TURBINE MECHANICAL AND CENTERLINE INSTALLATION ..................................................... |

18 |

|

2.1. |

Standards and Foundation Plate Setting and Alignment ......................................................... |

18 |

2.2. |

Set Lower Half Exhaust Hood ...................................................................................................... |

21 |

2.3. |

Set lower LP inner casing in Lower Half Exhaust Hood........................................................... |

23 |

2.4. |

Install and Pre-Align Lower Half LP Diaphragms ...................................................................... |

25 |

2.5. |

Set Upper Half inner casing.......................................................................................................... |

27 |

2.6. |

Set Upper Half Exhaust Hood ...................................................................................................... |

28 |

2.7. |

Exhaust Hood Centerline Anchor/key block soleplate.............................................................. |

29 |

2.8. |

TOPS ON before welding Condenser......................................................................................... |

30 |

2.9. |

Weld Exhaust Hood to condenser ............................................................................................... |

31 |

2.10. |

TOPS ON after welding Condenser ............................................................................................ |

32 |

2.11. |

Remove Upper LP Exhaust Hood ............................................................................................... |

32 |

2.12. |

Remove Upper Inner casing......................................................................................................... |

32 |

2.13. |

TOPS OFF ...................................................................................................................................... |

32 |

2.14. |

Set LP Rotor ................................................................................................................................... |

33 |

2.15. |

LP Turbine alignment .................................................................................................................... |

34 |

2.16. |

Complete LP Turbine Assembly .................................................................................................. |

36 |

2.17. |

HP & IP Turbine setting................................................................................................................. |

40 |

2.18. |

Standards Closing.......................................................................................................................... |

48 |

2.19. |

Install Heat Retention Insulation .................................................................................................. |

49 |

2.20. |

Turbine Acoustic Enclosure......................................................................................................... |

50 |

3. STEAM PIPING AND VALVE INSTALLATION.................................................................................. |

51 |

|

3.1. |

General Piping Information........................................................................................................... |

51 |

3.2. |

Hot Reheat Steam Lines............................................................................................................... |

52 |

3.3. |

Main Steam Lines .......................................................................................................................... |

53 |

3.4. |

Extraction Steam Lines ................................................................................................................. |

53 |

3.5. |

Turbine Mid-Span Packing Blow down Valve (if required)....................................................... |

53 |

3.6. |

Install Reheat cooling steam pipe................................................................................................ |

54 |

3.7. |

Steam Seal System ....................................................................................................................... |

54 |

3.8. |

Turbine Steam Drains ................................................................................................................... |

55 |

3.9. |

Boiler and Steam Line Blow down............................................................................................... |

55 |

4. LUBE OIL AND HYDRAULIC SYSTEM INSTALLATION................................................................. |

56 |

|

4.1. |

General ............................................................................................................................................ |

56 |

|

4.2. |

Lube oil tank filling ......................................................................................................................... |

56 |

|

4.3. Lube Oil System Flushing............................................................................................................. |

57 |

|

|

4.4. |

Hydraulic Power System Flush .................................................................................................... |

58 |

5. |

TURBINE PIPING SYSTEMS - OTHER ............................................................................................. |

58 |

|

6. |

TURBINE ELECTRICAL AND INSTRUMENTATION INSTALLATION.......................................... |

59 |

|

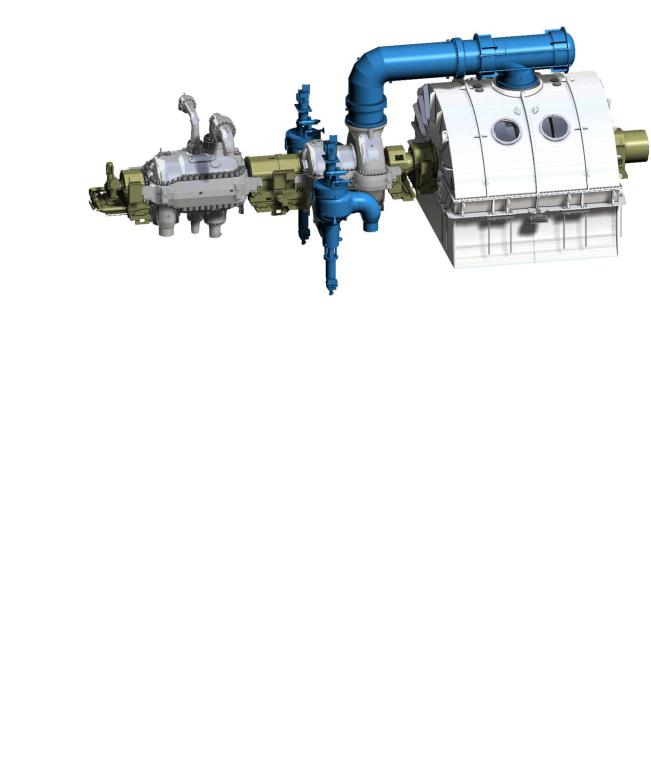

GENERAL VIEW OF D850 STEAM TURBINE

INTRODUCTION

This Installation Guide provides an overview of the activities involved with installing a General Electric D850 Type Steam Turbine.

Exact details regarding the specific design of hardware purchased will be provided in the requisition – specific document package supplied with the unit.

Note: Variations exist within this specific code type that may affect the overall installation work scope.

This Installation guide covers the Steam Turbine portion of the centerline equipment. The Generator guide is covered by a separate document. Nevertheless, Steam turbine

guide has been designed to facilitate Steam turbine construction integration within the centerline installation.

-This document is a general guideline dedicated to D850 Steam Turbine erection but is not intended to compensate for the employment of skilled assembly personnel. Minor deviations are allowed according to unforeseen situations but shall be documented for disposition from GE.

-The reader must note that this document cannot be used for commercial purposes or for exact scope description to award an erection contract.

DOCUMENT LIST

The following table lists all required system drawings and related documents for the installation of the equipment and material covered in this installation guide. The latest revisions of these drawings and documents shall be reviewed thoroughly prior to commencing with any of the activities described in this installation guide.

Some of these Documents are classified as “GE inter nal” “Critical”. Consult your GE Technical Advisor to obtain needed information from these documents

It is necessary for the GE representative to check the applicability of the listed documents and to record revisions of each documents before beginning of the work.

This document is a general guideline dedicated to D650 Steam Turbine erection but is not intended to compensate for the employment of skilled assembly personnel. Minor deviations are allowed according to unforeseen situations but shall be documented for disposition from GE.

The reader must note that this document cannot be used for commercial purposes or for exact scope description to award an erection contract.

Pictures in this installation guide are only for example and should not be considered as part of D850 Steam Turbine.

MLI |

STEAM TURBINE SYSTEM DESCRIPTION |

GE Ref |

Part list |

|

A07H |

CROSS SECTION ASSEMBLY |

122T1372 |

|

|

A09H |

LIFTING DEVICES |

108T3182 |

108T3182G0001 |

|

A10H |

SPECIAL WRENCH & TOOLS |

|

108T3183G0001 |

|

A14H |

KIT WRENCH & TOOLS |

|

108T3185G0001 |

|

A18F |

TURNING GEAR FIELD ASSEMBLY |

|

Not Yet Defined |

|

A350 |

MID SPAN BALANCE ACCESS ASSY |

117T9749 |

117T9749G0001 |

|

A800 |

PERFORMANCE TEST, PIPING STANDARD ASSY |

108T3365 |

108T3365G0001 |

|

A80H |

PERF TEST PPG STD ASM |

111E2205 |

|

|

A80H |

DETAILS, PERFORMANCE TEST PIPING |

111E2206 |

|

|

A80H |

PERFORMANCE TEST PIPING FUNCTIONAL |

U8164 |

|

|

SPECIFICATION FACTORY ASSY) |

|

|||

|

|

|

||

A80H |

PERFORMANCE TEST PIPING FUNCTIONAL |

U8165 |

U8165P009A1B0C0 |

|

SPECIFICATION SITE ASSY) |

D0E8 |

|||

|

|

|||

A92R |

RHT SHIPPING BRACKET GEN END CRITICAL |

117T9782 |

117T9782G0001 |

|

A93R |

RHT SHIPPING BRACKET TURB END CRITICAL |

117T9783 |

117T9783G0001 |

|

B350 |

TCPL HOLDER ASSEMBLY 1ST STAGE REHEAT |

117T9839 |

117T9839G0001 |

MLI |

STEAM TURBINE SYSTEM DESCRIPTION |

GE Ref |

Part list |

|

B350 |

THERMOCOUPLE HOLDER ASSEMBLY CRITICAL |

186C7772 |

186C7772G0002 |

|

B410 |

HP CASING BOLTING ARRGT |

122T6217 |

|

|

B420 |

REHEAT CASING BOLTING ARRGT |

122T3809 |

|

|

B56A |

MID STANDARD ASSEMBLY CRITICAL |

108T3647 |

108T3647G0001 |

|

B58A |

FT000SNN STANDARD ASSEMBLY (LPA STD) |

121T6001 |

121T6001G0001 |

|

B58G |

LPA STANDARD TUNNEL APPEN CRITICAL |

111T1175 |

111T1175G0001 |

|

B60A |

FT-0-N-LP-M1B LP HOOD STANDARD VENDOR |

111T0008 |

111T0008G0001 |

|

ASSEMBLY (LP1) CRITICAL |

||||

|

|

|

||

B60G |

LP END STANDARD TUNNEL AP CRITICAL |

111T0973 |

111T0973G0001 |

|

B62A |

FG-0-N-LP-M1C LP HOOD STANDARD VENDOR |

111T0013 |

111T0013G0001 |

|

ASSEMBLY (LP2) CRITICAL |

||||

|

|

|

||

B62C |

COUPLING GUARD ASSEMBLY |

117T9747 |

117T9747G0001 |

|

B62C |

COUPLING GUARD OIL COOLING HOSE KIT |

117T1803 |

117T1803G0001 |

|

B62G |

GEN CPLG GD OIL HOUSING CRITICAL |

114T3000 |

114T3000G0001 |

|

B650 |

MISC TCPL HOLDER ASSY HP |

117T9750 |

117T9750G0001 |

|

B650 |

THERMOCOUPLE HOLDER ASSEMBLY WINDAGE |

110T2505 |

110T2505G0010 |

|

B650 |

THERMOCOUPLE HOLDER ASSEMBLY CRITICAL |

186C7772 |

186C7772G0002 |

|

|

|

|

|

|

B650 |

THERMOCOUPLE HOLDER ASSEMBLY |

186C7678 |

186C7678G0002 |

|

B650 |

THERMOCOUPLE HOLDER ASSEMBLY |

194D7273 |

|

|

B680 |

MID STD GUIDES AND BASE PLATE ASSEMBLY |

117T9795 |

117T9795G0001 |

|

B81H |

EXTERIOR MSI FLANGE HARDWARE |

119T5827 |

119T5827G0001 |

|

B880 |

EXPANSION JOINT ROTOR COOLING ASSY |

119T6102 |

119T6102G0001 |

|

B89H |

EXTERNAL OVERLOAD VALVE SHELL HARDWARE |

119T5828 |

119T5828G0001 |

|

UH & LH CRITICAL |

||||

|

|

|

||

BAA0 |

ASSEMBLY - BELLOWS TO HOOD |

108T5225 |

108T5225G0001 |

|

C12A |

MAIN ASSEMBLY PARTS LP |

110T3661 |

110T3661G0001 |

|

C140 |

FRONT STANDARD SE000SEN BOLTING |

114T0007 |

114T0007G0001 |

|

|

FT000SNN2 LPA STANDARD BOLTING/ |

112T5859/ |

|

|

C17L |

INST, LPA STD FIXED SHELL ARMS SHIMABLE |

112T5859G0001 |

||

117T2634 |

||||

|

KEYS |

|

||

|

|

|

||

C17M |

SM450SNN MID STANDARD BOLTING / INST, MID |

117T9796/ |

117T9796G0001 |

|

STD FIXED SHELL ARMS SHIMABLE KEYS |

117T2950 |

|||

|

|

|||

C17M |

INSTL, MID STD DIRECT SUPPORT SHIMABLE |

121T3686 |

|

|

KEYS |

|

|||

|

|

|

||

C280 |

HP SHIPPING SUPPORT ASSY, TUR END |

117T9781 |

117T9781G0001 |

|

C300 |

HP SHIPPING SUPPORT ASSY, GEN END |

108T3335 |

108T3335G0001 |

|

C60L/62L |

BOLTING, PACKING BOX TO LP HOOD |

117T9774 |

117T9774G0001 |

|

CDA0 |

LP HOOD INNER CASING GIB AND KEY |

119T2957 |

119T2957G0001 |

|

CLEARANCES CRITICAL |

||||

|

|

|

||

CDD0 |

ATMOSPHERIC RELIEF DIAPH. ASSY |

196C7235 |

196C7235G0008 |

|

CDDS |

ALUMINUM DIAPH. |

313A7231 |

313A7231P0008 |

|

CDJ0 |

ARRANGEMENT, EXH HOOD FOUNDATION |

119T3272 |

119T3272G0001 |

|

PLATES |

||||

|

|

|

||

CDK0 |

FRONT STANDARD FIXATORS |

119T0139 |

119T0139G0001 |

|

CDK0 |

MID STANDARD FIXATORS |

119T3466 |

119T3466G0001 |

|

CDK0 |

LP HOOD FIXATORS |

119T0693 |

119T0693G0001 |

|

CDK0 |

LPA STANDARD FIXATORS |

119T5189 |

119T5189G0001 |

|

CDK0 |

LP STANDARD FIXATORS |

119T6240 |

119T6240G0001 |

|

CDK0 |

DIRECT SUPPORT AND REFERENCE FIXATORS |

119T0308 |

|

MLI |

STEAM TURBINE SYSTEM DESCRIPTION |

GE Ref |

Part list |

|

CDK0 |

FIXATOR ADJUSTABLE SUPPORT DEVICES |

325B4987 |

|

|

CDS0 |

EXHAUST HOOD BOLTING ARRANGEMENT |

123T7437 |

|

|

CFA0 |

CONDENSER JOINT SHIELD |

111E2884 |

111E2884G0013 |

|

CFR0 |

ASSEMBLY, STEAM GUIDE |

108T3392 |

108T3392G0001 |

|

CGF0 |

COUPLING GUARD ASSY |

121T3159 |

121T3159G0001 |

|

CHA0 |

ANCHOR ASSY, EXHAUST HOOD |

119T3278 |

119T3278G0001 |

|

CHD0 |

HOOD FIELD ASSY |

122T0769 |

|

|

CXG0 |

L-1 THERMOCOUPLE PROVISION |

108T3394 |

108T3394G0001 |

|

DEA0 |

ARRANGEMENT JOINT STUD LP INNER CASING |

122T6923 |

|

|

DILA |

DIAPHRAGM SUPPORT BAR ASSY |

211D3850 |

|

|

DKA0 |

ERECTION INSPECTION FORMS 270T865 |

|

Not Yet Defined |

|

DKA0 |

ERECTION INSPECTION FORMS 270T866 |

|

Not Yet Defined |

|

E01H |

BEARING ALIGNMENT DIAGRAM |

122T1526 |

|

|

E02H |

THRUST RING AND BEARING ASSEMBLY |

117T9741 |

117T9741G0001 |

|

E11H |

ST COMPONENT ALIGNMENT HP |

122T1063 |

|

|

E11L |

ST COMPONENT ALIGNMENT LP |

122T4021 |

|

|

E11R |

ST COMPONENT ALIGNMENT IP (REHEAT) |

121T4823 |

|

|

EAB5 |

BEARING ASSY, 20X17 DTP, 4 PAD 60 PERCENT |

117T9719 |

117T9719G0001 |

|

PIVOT CRITICAL |

||||

|

|

|

||

EAB6 |

BEARING AND BEARING RING ACCUMLATION |

117T9720 |

117T9720G0001 |

|

EAB6 |

BEARING ORIFICE |

383A4866 |

383A4866P0001 |

|

EHB1 |

BEARING ASSY 13X7 6 PAD .5 PIVOT |

117T9715 |

117T9715G0001 |

|

EHB2 |

BEARING ASSY 15X7 6 PAD .5 PIVOT WITH LIFT |

100T1333 |

100T1333G0003 |

|

OIL PROV |

||||

|

|

|

||

EHBT |

THRUST BEARING COMBO ASSY |

|

117T9727G0001 |

|

ERB3 |

15X8 DTP ASSY 6 PAD .5 PIVOT WITH LIFT OIL |

139E5217 |

139E5217G0003 |

|

PROVISION CRITICAL |

||||

|

|

|

||

ERB4 |

BEARING ASSEMBLY 19X10 4 PAD .6 PIVOT |

117T9718 |

117T9718G0001 |

|

F1HR |

PACKING RING ARRANGEMENT N1 / |

108T3346 / |

108T3346G0001 |

|

ASSEMBLY OF PACKING RING |

U833 |

|||

|

|

|||

F2HR |

PACKING RING ARRANGEMENT N2 / |

108T3347 / |

108T3347G0001 |

|

ASSEMBLY OF PACKING RING |

U833 |

|||

|

|

|||

F3IR |

PACKING RING ARRANGEMENT N3 |

117T9771 |

117T9771G0001 |

|

F4IR |

PACKING RING ARRANGEMENT N4 |

117T9772 |

117T9772G0001 |

|

F5AR |

BRUSH SEALS ARRANGEMENT N5 CRITICAL |

108T3505 |

108T3505G0001 |

|

F6AR |

BRUSH SEALS ARRANGEMENT N6 CRITICAL |

108T3506 |

108T3506G0001 |

|

FA5P |

LP PACKING BOX CRITICAL |

108T3403 |

108T3403G0001 |

|

FA6P |

LP PACKING BOX CRITICAL |

108T3403 |

108T3403G0001 |

|

|

BRUSH SEALS ARRGT DIAPH LP / |

117T9828 / |

|

|

FABD |

STANDALONE BRUSH SEAL ASSY DRAWING. |

117T9828G0001 |

||

100T3153 |

||||

|

CRITICAL |

|

||

|

|

|

||

FH1B |

PACKING CASING HOLDER N-1 CRITICAL |

108T3255 |

108T3255G0001 |

|

FH2B |

PACKING CASING HOLDER N-2 CRITICAL |

108T3262 |

108T3262G0001 |

|

FR3B |

PACKING CASING, BOLTED N-3 CRITICAL |

108T3576 |

108T3576G0001 |

|

FR4B |

PACKING CASING, BOLTED N-4 CRITICAL |

108T3577 |

108T3577G0001 |

|

G700 |

OUTLINE STEAM TURBINE LAGGING ENCLOSURE |

122T3154 |

|

|

H050 |

FRONT STANDARD ELECTRICAL CONNECTIONS |

117T9845 |

117T9845G0001 |

|

H050 |

JUNCTION BOX ASSY - EMERGENCY TRIP |

114T1517 |

114T1517G0001 |

|

H05A |

JUNCTION BOX ASSY - EMERGENCY TRIP |

109T2735 |

109T2735G0001 |

|

HLB0 |

CONTROL START THERMOCOUPLE ELEC CONN |

117T9848 |

117T9848G0001 |

MLI |

STEAM TURBINE SYSTEM DESCRIPTION |

GE Ref |

Part list |

|

HLB0 |

JUNCTION BOX ASSEMBLY 2 DIN RAILS |

112T8204 |

112T8204G0001 |

|

HLEH |

SPEED PICKUP ASSEMBLY - ATEX |

103T2801 |

103T2801G0001 |

|

HLF0 |

EXHAUST ELEC CONNS |

118T6940 |

118T6940G0001 |

|

HLKA |

JOURNAL BEARING METAL THERMOCOUPLES LP |

117T9734 |

117T9734G0001 |

|

HLKH |

JOURNAL BEARING METAL THERMOCOUPLES HP |

117T9736 |

117T9736G0001 |

|

HLKR |

JOURNAL BEARING METAL THERMOCOUPLES |

117T9735 |

117T9735G0001 |

|

REHEAT (IP) |

||||

|

|

|

||

HLP1 |

ELECTRICAL CONNECTIONS HLP1 STANDARD |

117T9798 |

117T9798G0001 |

|

HLP1 |

JUNCTION BOX ASSEMBLY DIN RAIL |

112T6556 |

112T6556G0001 |

|

COMPONENTS |

||||

|

|

|

||

HLP2 |

GEN STD ELECTRICAL CONNECTION |

|

117T9799G0001 |

|

HLP2 |

JUNCTION BOX ASSEMBLY DIN RAIL |

112T6556 |

112T6556G0001 |

|

COMPONENTS |

||||

|

|

|

||

HLPA |

CONDUIT ARRGT LPA STD |

|

117T9954G0001 |

|

HLSH |

THRUST BRG THERMOCOUPLES |

117T9737 |

117T9737G0001 |

|

HLTH |

MID STD ELECTRICAL CONNECTION |

117T9850 |

117T9850G0001 |

|

HMC0 / |

INSTRUMENTS INSTALLATION |

117T9852 |

117T9852G0001 |

|

VE70 |

||||

|

|

|

||

HMC0 |

THERMOCOUPLE ASSEMBLY |

237C3726 |

|

|

J06H |

MAIN STM FLANGE HDWR |

117T9816 |

117T9816G0001 |

|

J110 |

STOP VALVE INLET SUPPORT |

121T3697 |

121T3697G0001 |

|

J190 |

CROSSOVER ASSEMBLY |

108T3343 |

108T3343G0001 |

|

J190 |

SEQUENCE OF ASSY CROSSVER |

113T0554 |

|

|

J44U |

BLOWDOWN COVER ASSY OLV |

117T9859 |

|

|

K010 |

FC000STN FRONT STANDARD ASSEMBLY |

121T4094 |

121T4094G0001 |

|

K02A |

NAMEPLATE ARRGT |

105T7553 |

|

|

K02X |

STEAM TURBINE NAMEPLATE 270T865 |

121T7944 |

121T7944G0001 |

|

K02X |

STEAM TURBINE NAMEPLATE 270T865 (FOREIGN |

121T7944 |

121T7944G0002 |

|

LANGAUGE) |

||||

|

|

|

||

K02X |

STEAM TURBINE NAMEPLATE 270T866 |

121T7829 |

121T7829G0001 |

|

K02X |

STEAM TURBINE NAMEPLATE 270T866 (FOREIGN |

121T7829 |

121T7829G0002 |

|

LANGAUGE) |

||||

|

|

|

||

K340 |

SE000SEN BASEPLATE AND GUIDES ASSEMBLY |

114T2890 |

114T2890G0001 |

|

K990 |

BLANK NAMEPLATES |

121T9236 |

121T9236P0001 to 6 |

|

K99A |

ARRANGEMENT BLANK NAMEPLATES |

121T8635 |

|

|

KKS0 |

KKS TAGS FOR 270T865 |

117T9948 |

117T9948G0001 |

|

KKS0 |

KKS TAGS FOR 270T866 |

117T9948 |

117T9948G0002 |

|

L310 |

SHELL EXPANSION DETECTOR ASSEMBLY |

122T1080 |

122T1080G0001 |

|

L320 |

SHELL EXPANSION DETECTOR ASSY (SLIDING |

117T6076 |

117T6076G0001 |

|

BASE PLATE) |

||||

|

|

|

||

M21F |

SVCV FIELD ASSEMBLY |

117T9884 |

117T9884G0001 |

|

M21F |

MAIN STOP AND CONTROL VALVE CHEST |

219D5516 |

|

|

ELECTRICAL SCHEMATIC |

|

|||

|

|

|

||

M21S |

SVCV CASING HYDROTEST SEAT TIGHTNESS |

117T9886 |

|

|

M21S |

METHOD OF STUD EXTENSION MEASURMENT |

111B6911 |

|

|

CONTROL VALVES |

|

|||

|

|

|

||

M49L |

ASSEMBLY INSTRUCTIONS FOR VLV STEM & |

364A7002 |

|

|

CONNECTOR |

|

|||

|

|

|

||

MR10 |

CRV 1 ASSY 16CRHA08B |

117T9877 |

117T9877G1200 |

|

MR20 |

CRV 2 ASSY 16CRHA08B |

117T9877 |

117T9877G3200 |

MLI |

STEAM TURBINE SYSTEM DESCRIPTION |

GE Ref |

Part list |

|

MR10/20 |

CRV WIRING DIAGRAM |

196D5131 |

|

|

H40L |

|

|||

|

|

|

||

MR1K |

CRV-1 HYDRO ASSY |

117T9880 |

117T9880G1200 |

|

MR2K |

CRV-2 HYDRO ASSY |

117T9880 |

117T9880G3200 |

|

MT10 |

OVERLOAD VALVE ASSEMBLY |

118T4027 |

118T4027G2200 |

|

MT1K |

OVERLOAD VALVE HYDRO ASSY |

118T4026 |

118T4026G1200 |

|

MT1F |

VALVE WIRING DIAGRAM - REXROTH - OLV |

109T7375 |

|

|

N010 |

CV SUPPORT ASM |

893E500 |

0893E500G0035 |

|

N230 |

VALVE SUPPORT ASSY – POGO CRITICAL |

108T8489 |

108T8489G0001 |

|

P03F |

PIPING, VENT AND SEAL |

117T9831 |

117T9831G0001 |

|

P230 |

CONNECTION ASSY 1st STAGE HP |

176C5919 |

176C5919G0015 |

|

P99H |

MATING FLANGE HARDWARE CRITICAL |

119T6099 |

119T6099G0001 |

|

P99L |

HP LARGE FLANGE ASSEMBLY CRITICAL |

117T9819 |

117T9819G0001 |

|

PC01 |

LUBE OIL PIPING |

117T9943 |

117T9943G0001 |

|

PC20 |

BYPASS KIT, HYDRAULIC |

109T1354 |

109T1354G0001 |

|

|

|

|

109T8714G0001 |

|

PC20 |

BYPASS KIT, HYDRAULIC |

109T8714 |

/ |

|

|

|

|

109T8714G0002 |

|

PD34 / |

FLUSHING KIT 16.00 DRAIN 5.00 FEED SINGLE |

117T6078 |

117T6078G0001 |

|

B56X |

VALVE |

|||

|

|

|||

PD34 / |

FLUSHING KIT 16.00 DRAIN 3.50 FEED SINGLE |

118T6093 |

118T6093G0001 |

|

B58X |

VALVE |

|||

|

|

|||

PD34 / |

16.00 FLUSHING DRAIN ASSY |

120T3459 |

120T3459G0001 |

|

B58X |

||||

|

|

|

||

PD34 / |

FLUSHING KIT 16.00 DRAIN 5.00 FEED SINGLE |

117T6078 |

117T6078G0001 |

|

B60&2X |

VALVE |

|||

|

|

|||

PD34 / |

FRONT STANDARD FLUSHING ASSY |

114T2623 |

114T2623G0001 |

|

K01X |

||||

|

|

|

||

PD34 / |

INSTALLATION, FLUSHING PIPE ASSEMBLIES |

117T4693 |

|

|

K01X |

CRITICAL |

|

||

|

|

|||

PJ01 |

MAIN STEAM PIPES |

121T5795 |

121T5795G0001 |

|

To G0009 |

||||

|

|

|

||

PP02 |

VSL FONCTINNAL SPEC (SITE ASSY) |

113T9892 |

113T9892G0003 |

|

PR01EL |

ELECTRICAL ELEMENTARY LUBE OIL MODULE |

120T8406 |

|

|

PR01L |

P&ID – LUBE OIL TANK |

120T7620 |

120T7620G0001 |

|

PR90EL |

ELECTRICAL ELEMENTARY HYDRAULIC POWER |

120T9031 |

|

|

UNIT |

|

|||

|

|

|

||

PR90H |

P&ID, HYDRAULICS |

120T7621 |

120T7621G0001 |

|

PS01 |

PS01 CLOSE STEAM PIPING |

117T9300 |

117T9300G0001 |

|

PS13 |

OUTLINE - EM DESUP, SPRAY NOZZLE |

0874A911 |

0874A911P0007 |

|

PS13 |

OUTLINE - DESUPERHEATER, EMER |

245C8572 |

|

|

PS13 |

OUTLINE - PIPE LINE STRAINER |

303A2026 |

303A2026P0005 |

|

PV01 |

OUTLINE – MOTOR OPERATED VALVE - MOV-SSD- |

103T9286 |

103T9286P0001 |

|

2 and 3 |

||||

|

|

|

||

PV01 |

OUTLINE - MOTOR OPERATED VALVE - MOV-SSV- |

103T9286 |

103T9286P0004 |

|

3 A, B and 4 A ,B |

||||

|

|

|

||

PV01 |

OUTLINE - MOTOR OPERATED VALVE - MOV-SSD- |

103T9286 |

103T9286P0006 |

|

1 |

||||

|

|

|

||

PV01 |

OUTLINE - MOTOR OPERATED VALVE - MOV-SV-1 |

103T9286 |

103T9286P0012 |

|

to 6 and MOV-SPDV-2 |

||||

|

|

|

||

|

|

|

|

MLI |

STEAM TURBINE SYSTEM DESCRIPTION |

GE Ref |

Part list |

|

PV01 |

OUTLINE - MOTOR OPERATED VALVE - MOV- |

122T4297 |

|

|

SPDV-1 2” |

|

|||

|

|

|

||

PV01 |

OUTLINE - MOTOR OPERATED VALVE - MOV- |

122T7196 |

|

|

SSFV-B 3” |

|

|||

|

|

|

||

PV01 |

OUTLINE - MOTOR OPERATED VALVE - MOV- |

122T7197 |

|

|

SSDV-B 6” |

|

|||

|

|

|

||

PV01 |

OUTLINE - MOTOR OPERATED VALVE - MOV-VBV- |

219D5732 |

219D5732P0005 |

|

1 |

||||

|

|

|

||

PV01 |

DIAGRAM, SCHEM-MOTOR OPERATED VLV |

138E8107 |

|

|

PV02 |

OUTLINE - AIR OPERATED VALVE - AOV-WSV |

100T7227 |

100T7227P0013 |

|

PV02 |

OUTLINE - AIR OPERATED VALVE - AOV-EDV |

114T6941 |

114T6941P0017 |

|

PV02 |

OUTLINE - AIR OPERATED (TCV-260) COOLING |

114T8014 |

114T8014P0006 |

|

WATER CONTROL VALVE |

||||

|

|

|

||

PV02 |

OUTLINE - AIR OPERATED VALVE - AOV-SSCDV |

121T9536 |

121T9536P0026 |

|

PV02 |

OUTLINE - AIR OPERATED VALVE - AOV-SSEDV |

121T9536 |

121T9536P0012 |

|

PV02 |

OUTLINE - AIR OPERATED VALVE - AOV-CSBV |

121T9770 |

121T9770P0047 |

|

PV02 |

OUTLINE - AIR OPERATED VALVE - AOV-HSBV-1 |

121T9770 |

121T9770P0006 |

|

PV02 |

OUTLINE - AIR OPERATED VALVE - AOV-HSBV-2 |

121T9770 |

121T9770P0024 |

|

PV02 |

OUTLINE - AIR OPERATED VALVE - AOV-SSFV |

365B9700 |

365B9700P0058 |

|

PV02 |

OUTLINE - AIR OPERATED VALVE (AOV-SSDV) |

365B9701 |

365B9701P0015 |

|

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – WSCV |

237A6323 |

237A6323P2003 |

|

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – WSV- |

237A6323 |

237A6323P3003 |

|

B , U and D |

||||

|

|

|

||

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – SSD-1 |

237A6323 |

237A6323P6101 |

|

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – SSD-2 |

237A6323 |

237A6323P4001 |

|

and 3 |

||||

|

|

|

||

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – SV-1 to |

237A6323 |

237A6323P6102 |

|

6 and SPDV-2 |

||||

|

|

|

||

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – SPDV- |

237A6323 |

237A6323P6103 |

|

1 |

||||

|

|

|

||

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – R1A |

352B8206 |

352B8206P0017 |

|

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – SSFV- |

365A4843 |

365A4843P2203 |

|

U and D |

||||

|

|

|

||

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – SSDV- |

365A4844 |

365A4844P1406 |

|

D and U |

||||

|

|

|

||

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – SPDV- |

237A6323 |

237A6323P2003 |

|

1 |

||||

|

|

|

||

PV03 |

OUTLINE - MANUALLY OPERATED VALVE – EDV-B, |

237A6323 |

237A6323P3003 |

|

U and D |

||||

|

|

|

||

U190 |

SPARE BALANCE WEIGHT & PLUG |

108T3463 |

108T3463G0001 |

|

U230 |

ROTOR COUPLING ASSEMBLY & DISASSEMBLY |

234A2134 |

|

|

INSTR. |

|

|||

|

|

|

||

U240 |

COUPLING PARTS HP GE |

|

117T9743G0001 |

|

U580 |

SPACER PLATE HP-IP CRITICAL |

117T9830 |

117T9830G0001 |

|

UE4D |

CLEARANCE DATA LPA |

121T9389 |

|

|

UE60 |

COUPLING PARTS LPA TE |

|

117T9744G0001 |

|

UE80 |

COUPLING SPACER PLATE IP-LP CRITICAL |

108T3490 |

108T3490G0001 |

|

UF10 |

BAR CHECK LPA |

122T1700 |

|

|

UG60 |

ORDERING DRAWING -LPA TO GEN COUPLING |

|

108T3491G0001 |

|

PARTS |

|

|||

|

|

|

||

|

|

|

|