- •FOREWORD

- •CONTENTS

- •1. INTRODUCTION

- •1.1. BACKGROUND

- •1.2. IMPLICATIONS OF THE FUKUSHIMA ACCIDENT

- •1.3. OBJECTIVE

- •1.4. SCOPE

- •1.5. USERS

- •1.6. STRUCTURE

- •2. CONSTRUCTION MANAGEMENT — PREPARATORY PHASE

- •2.1. PLANNING

- •2.2. ESTABLISHMENT OF THE PROJECT MANAGEMENT ORGANIZATION

- •2.3. ENGINEERING MANAGEMENT

- •2.4. MAIN CONTRACT MANAGEMENT

- •2.5. LICENSING MANAGEMENT

- •2.6. PROJECT RISK MANAGEMENT

- •2.7. CONSTRUCTION INFRASTRUCTURE DEVELOPMENT

- •2.8. SECURITY

- •3.1. OVERVIEW OF ORGANIZATIONS (SITE AND HQ) AND MAIN ACTIVITIES DURING CONSTRUCTION

- •3.2. MANUFACTURING AND CONSTRUCTION MANAGEMENT

- •3.3. COORDINATION OF CONSTRUCTION ACTIVITIES

- •3.4. CATEGORIZATION OF CONSTRUCTION WORK PACKAGES

- •3.5. PROJECT SCHEDULING AND CONTROL DURING THE CONSTRUCTION PHASE

- •3.6. QUALITY PLANNING AND MANAGEMENT

- •3.7. CONSTRUCTION INSPECTION

- •3.8. SAFETY AND ENVIRONMENTAL MANAGEMENT SYSTEM

- •3.9. DEVELOPING A HUMAN RESOURCES PLAN

- •4.1. CONSTRUCTION COMPLETION PROCESS

- •4.2. TURNOVER PROCESSES

- •4.3. PRESERVING REFERENCE DATA, MATERIAL CONDITIONS, KEEP TEST MATERIAL

- •5.1. CONSTRUCTION MANAGEMENT ISSUES

- •5.2. COUNTRY SPECIFIC LESSONS LEARNED

- •5.3. COUNTRY REPORT SUMMARY

- •6. CONCLUSIONS AND RECOMMENDATIONS

- •REFERENCES

- •ABBREVIATIONS

- •Glossary

- •I–1. BRIEF DESCRIPTION

- •I–2. LESSONS LEARNED

- •II–1. BRIEF DESCRIPTION OF BELENE NPP

- •II–2. LESSONS LEARNED

- •IV–1. BRIEF DESCRIPTION OF NPP

- •IV–2. LESSONS LEARNED

- •IV–3. PROJECT MANAGEMENT – CONSTRUCTION PHASE

- •V–1. CONSTRUCTION APPROACH

- •V–2. COMMISSIONING SCHEME

- •V–3. GRADING OF HEPCO’ INVOLVEMENT

- •V–4. PROCESS OF TURNOVERS

- •V–5. COMMISSIONING FOR SYSTEMS AND PLANT TURNOVER

- •VI–1. STATUS OF NPP IN THE REPUBLIC OF KOREA

- •VI–2. CONSTRUCTION MANAGEMENT ISSUE

- •VI–3. LESSONS LEARNED

- •VII–1. BRIEF DESCRIPTION OF NPP

- •VII–2. LESSONS LEARNED

- •VIII–1. HISTORY OF THE DEVELOPMENT AND INTEGRATION OF DESIGN SOLUTIONS IN THE REPUBLIC OF RUSSIA

- •IX–1. BRIEF DESCRIPTION

- •IX–2. LESSONS LEARNED

- •BIBLIOGRAPHY

- •CONTRIBUTORS TO DRAFTING AND REVIEW

|

|

|

|

|

|

|

|

|

|

|

|

|

BALANCE OF PLANT |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Outsourc. for |

|

|

|

|

|

Main Contractor / Architect Engineer |

BOP Constr.– Simulator - Site |

||||||||

|

|

|

|

|

|

|

|

|

|

|

Services – Insurance and others |

|||||

|

Engineering |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Constr./Commiss. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

support |

|

|

|

|

|

Slovenske |

|

|

|

|

Contractor 1 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Design Author |

|

|

|

|

|

Elektrarne a.s. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

||||||||||||

|

Supervision |

|

|

|

|

|

|

|

|

|

|

|

|

Contractor 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Safety Board |

|

|

|

|

|

|

|

|

Contractor N |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Primary |

ECCS |

Ventil. |

Main |

Civil |

|

C N1 * |

|

C Nn * |

|||||||

syst. |

Radw. |

Decont |

I&C |

works |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NUCLEAR ISLAND |

NUCLEAR ISLAND |

MAIN CONTRACTS |

OTHER CONTRACTS |

EPCM

CONTRACTOR

C1 |

C2 |

C3 |

|

CONTRACTORS |

|

CONVENTIONAL ISLAND

~ 70 CONTRACTS

* Includes mainly: special I&C, supply and erection of field instrumentation and electrical systems

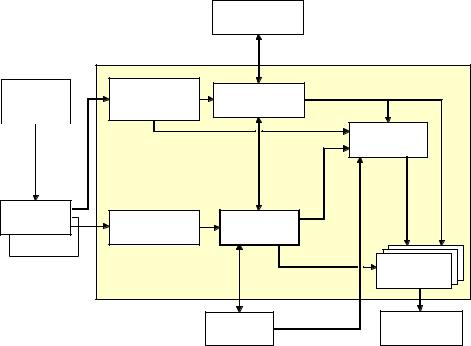

FIG. IX–2. Mochovce NPP contractor type.

IX–2. LESSONS LEARNED

IX–2.1. Project management — Preparatory phase

The feasibility study for MO 3, 4 began in January 2006 and set the basis for the re-starting activity. The purpose of the feasibility study was to define in detail all technical, financial, legal and authorization aspects of the completion of MO34 in order to provide the Utility management with all the necessary information for a final decision.

The feasibility study structure is composed of three main objects:

—Elaboration of a basic design

—Approval of design changes by NRA

—Preparatory works for tenders

In 2007 Enel-SE completed the Feasibility Study and prepared the Investment Memo, necessary for the project evaluation. In July 2007 Enel-SE provided communication about the Mochovce Project to the European Union as per Article 41 of the EURATOM Treaty. Enel-SE obtained approval of the European Commission in July 2008.

The interface with the state and regulatory bodies is managed through official channels between the MO 3, 4 project and the state and regulatory bodies — Permits and Licensing Managers (appointed by two members of the Board of Directors).

Internal directives are issued to regulate the interface with supervisory and state authorities. They contain the main principles to abide by:

—Good underlying knowledge of the legal framework of the MO34 project;

—Good underlying knowledge of the professional areas;

—Openness and willingness to communicate;

—Open mind and attitude understanding to avoid misunderstanding (troubles).

117

|

|

RESOURCES ANALYSIS |

|

NPP TECHNICAL |

PROJECT MASTER |

PROGRESS ANALYSIS |

|

SCHEDULE |

|

||

& FUNCTIONAL |

|

||

AND PROJECT |

|

||

TARGET MILESTONES |

|

||

DESCRIPTION |

|

||

SHEDULE UPDATING |

|

||

+ / - CHANGES |

|

||

NPP WBS |

|

||

|

|

||

|

|

|

|

|

|

|

EARNED VALUE |

|

|

|

ANALYSIS |

NPP COST |

TOTAL JOB |

|

|

ESTIMATE |

COST CONTROL |

|

|

AUTHORIZED BUDGET |

|

||

|

TOTAL JOB |

|

|

|

+ / - CHANGES |

|

|

AUTHORIZED |

|

|

|

|

|

|

|

BUDGET |

|

|

|

|

|

|

PROJECT |

|

|

|

BUDGETING |

|

|

|

PROCESS |

|

|

|

COMPANY |

|

|

BOOK KEEPING |

BUDGETING |

|

|

|

PROCESS |

FIG. IX–3. The macro flowchart of the project planning and control.

Planning and scheduling, physical progress control, total job or period cost control, performance assessment through the “earned value analysis” method are correlated activities and are considered essential parts of the same activity ‘“project planning and control’, although each one applies different methodologies.

The integrated project planning and control activity is not limited to verifying the degree of achievement of the project objectives, but it includes also the promotion and the implementation of suitable measures to pursue the respect of the objectives, and where possible, their improvement.

The macro flowchart of the project planning and control process is represented in the following picture. The process owner defines the distribution of responsibilities in the directives if the process involves units that are subordinated to the process owner. From the point of view of the process management, the procedure set forth in the Process Model application is binding and decisive for all employees involved in the particular processes.

The Work Breakdown Structure — WBS is the typical hierarchical tree representation of the overall Project scope and constitutes a basic reference point for the Project Planning and of the estimating phases, assuring consistency between the activities and physical items.

The WBS for each contractor scope of work originates from a unique element representing the Contractors Schedule and it is developed into lower levels, each providing a subsequent breakdown of Project scope and a more detailed description of its elements – WBE.

The project planning and control process includes:

—Project WBS definition;

—Project realization time scheduling;

—Planning and control of the project physical progress;

—Project total job costs control;

—Control and management of project changes;

—Project accounting period planning and control;

—Performance assessment through the ‘earned value analysis’;

—Reporting on project status.

118

IX–2.2. Project Management — Construction phase

Completion activities included in Mochovce NPP units 3&4 completion or related early works is performed and managed in line with the project management principles so that the implementation meets the project goals without exceeding the budget and in compliance with the construction license.

The Construction organization plan (COP) was revised in order to define the areas of the related site facilities; this revision incorporates comments from all contractors. To ensure the proper handover of the defined areas to the contractor in line with the COP revision, the handover is documented in a protocol.

Construction Management — main responsibilities

—Oversee observance of quality in accordance with the design documentation, relevant acts and regulations;

—Implement Technical Superintendent of the owner activity system;

—Handover the site/workplaces and all related areas to contractors, define requirements regarding the site management;

—offset up interfaces and coordinate completion activities;

—Manage the COP processes;

—Call completion kick-off meetings with individual contractors;

—Appoint the owner’s technical superintendent for the site;

—Provide for preparation of equipment/construction and technical support for inspection and supervisory activities by the authorities;

—Provide for data collection regarding work processes, prepare monthly progress report and submit it to the project controlling manager;

—Oversee the identification process and management of non-conformities in line with valid internal procedures;

—Provide for evaluation of takeover protocols and final protocols (or MoM);

—Provide for implementation and maintenance of the monitoring system, analyzing and improvement of the completion management system (including coordination of contractors);

—Organize takeover of units 3&4 equipment to technical operation and maintenance, call and manage takeover commissions and provide for preparation of Work takeover protocols.

The main quality document which describes the quality system related to project MO34 is the quality assurance programme that complies with NRA requirements, IAEA recommendations and STN EN ISO 9001: 2009, STN EN ISO 14001: 2005 and OHSAS 18001:2008 standards. It contains:

—The description of the quality system of the license holder or the part related to a particular nuclear facility (facilities);

—Details of processes, which fall under the responsibility of the SE-MO34 Plant Director (non-centralized processes), or when details of the centralized process provided in the IMSM were not sufficient for the specific conditions of the plant;

—A complete description of the SE-MO34 management system;

—Quality assurance requirements for the completion/performance of Detailed Design of the 3rd and 4th units of Mochovce NPP;

—Quality requirements for all Safety related and to all activities influencing the quality of these items and thereby also NPP safety.

The Reference Quality Assurance (RQAP) programme states the basic requirements, principles and objectives to be applied so that the quality of the nuclear facility is upheld. Acceptance and application of these basic requirements are applied to all individuals and companies that perform actions influencing the nuclear safety during construction, commissioning, operation and decommissioning. The RQAP is valid for the responsible organization and its suppliers. The suppliers should transfer the requirements of this RQAP to their sub-suppliers.

The Sub-supplier quality assurance program (SQAP) relates to all items /equipment, systems/ important in terms of the NPP nuclear safety and to all activities influencing the quality of these items and thereby also NPP safety.

119

The SQAP is not directly provided to employees of contractors´ organizations. Its requirements, concerning directly the performance of safety related activities and the safety of the NPP, are transferred through the RQAP and constitute annexes to the contracts. Contractors are thereby contractually bound to respect and meet these requirements.

120