- •PROJECT BACKGROUND

- •PROJECT SCOPE

- •PROJECT DESIGN BASIS

- •Site Characteristics

- •Location

- •Topography

- •Transportation Access

- •Available Utilities

- •Site Ambient Conditions

- •Site Specific Design Considerations

- •Rainfall/Snowfall

- •Frost Penetration

- •Wind

- •Seismic Data

- •Flood Plain

- •Soil Conditions

- •Noise

- •Maintenance and Accessibility

- •Modularization Requirements

- •Fuel Feedstock and Flue Gas Characteristics

- •Power Plant Fuel Data

- •Flue Gas Conditions

- •PERMITTING PATHWAY

- •Air Permitting

- •Prevention of Significant Deterioration (PSD) Modeling Overview

- •Potentially Applicable Air Permitting Scenarios

- •Scenario 1: Carbon Capture Plant as a Single Source with PSGC

- •Scenario 2A: Carbon Capture Plant as a Separate Source with Only Emissions Created by the Carbon Capture Plant Subject to Permitting

- •Scenario 2B: Carbon Capture Plant as a Separate Source with ALL Emissions from Carbon Capture Plant Subject to Permitting

- •Air Permitting Strategy Recommendation

- •Water and Wastewater Permitting

- •Background

- •Makeup Water Permitting

- •Wastewater Permitting

- •Mechanical Draft Cooling Tower

- •Wastewater Treatment

- •BASIC CONTRACTING AND PURCHASING STRATEGY

- •Procurement Strategy

- •Engineering Interface

- •Vendor Quality Management

- •Long-Lead Procurement

- •ENGINEERING DESIGN PACKAGES

- •Process Engineering

- •Process Flow Diagrams

- •Heat Balance

- •HAZOP/PHA

- •PHA Process

- •Methodology

- •PHA Recommendations

- •Equipment List and Specifications

- •Cause and Effect Diagrams (six diagrams, pages 75-85)

- •Overpressure Relief Study

- •Introduction

- •Relief Philosophy

- •Evaluation Method

- •Civil Engineering

- •Geologic and Soil Load Assessment

- •Geotechnical Investigation

- •Subsurface Conditions

- •Frost Protection

- •Storm Water Runoff and Spill Containment Assessment

- •Structural Engineering

- •Mechanical Engineering

- •3D model and/or equipment elevation sections & plan drawings

- •Electrical Engineering

- •Electrical load lists

- •One-line diagram(s)

- •Instrumentation & Controls Engineering (System Integration)

- •Communications Infrastructure

- •Control Cabinet

- •Call Station

- •Bi-Directional Loudspeaker

- •Line Balance Assembly

- •Amplifiers

- •Horn and Driver Assemblies

- •Junction Boxes

- •Fire Protection Engineering

- •Authority Having Jurisdiction

- •Building and Fire Codes

- •Methodology

- •Occupancies

- •Fire Alarm System

- •Water Supply

- •Facilities Engineering

- •HVAC

- •General HVAC Design Criteria

- •Admin / Warehouse Building HVAC Design

- •Water Treatment Building HVAC Design

- •HVAC Design Standards / Reference

- •Site Security

- •Plant Layout and Construction Access

- •Constructability

- •Site Work

- •Site Preparation

- •Trenching and Excavation

- •Backfilling

- •Grading

- •Roads and Parking

- •Temporary Construction Trailers

- •Temporary Power

- •Temporary Water

- •Waste Disposal

- •Construction Stormwater Management

- •Lay-down Areas

- •Sequencing of construction work

- •Piping

- •Equipment

- •Pipe Rack Modularization (ISBL)

- •Project Cost Estimate (~ +/- 15%)

- •Project Cost of Capture

- •Calculating Cost of Capture

- •Cost of Capture Summary

- •Estimated Project Schedule

belonging to the carbon capture plant owner, and directly associated with the carbon capture process, would need to be considered when applying for the air permit. The pollutants contained in the flue gas coming over from Unit 2 at PSGC, and being treated by the absorbers, would not be included in the air permit for the carbon capture plant. For a facility to have emissions that are exiting stacks at its plant, but that are authorized in a permit at separate source, is a relatively rare and unique situation, but not without precedent. If Illinois EPA were to decide that the carbon capture plant should be responsible for all the pollutants coming out of its four stacks (including the pollutants coming over from PSGC and not created at the carbon capture plant) as under Scenario 2B, a much more intensive permitting effort would be required. This approach also has the potential to make the carbon capture plant subject to a wide range of regulatory requirements that currently apply to Unit 2 at PSGC.

For these reasons, it is recommended that the team present SCENARIO 2A as the project’s desired permitting path to the Illinois EPA and ask for their concurrence to this plan for obtaining the air permit for this proposed plant.

Water and Wastewater Permitting

Background

The CO2 capture process produces several fluid streams, such as condensate collected from the flue gas in the polishing flue gas desulfurization system, floor drains, and dewatering system filtrate. These streams will be blended with water drawn from the Kaskaskia River and recycled for use as cooling tower and steam generator makeup after treatment. Therefore, the wastewater from the CO2 capture system will consist entirely of cooling tower blowdown. The wastewater will be discharged into the Kaskaskia River from a new outfall, after treatment, to comply with applicable water quality standards.

Makeup Water Permitting

The raw water to supply the CO2 capture facility will utilize the existing pipeline from the existing PSGC intake structure to a new pond, which serves the same function as the existing Northeast Pond. The existing river intake pumps will be replaced with higher capacity pumps to accommodate the increased flow demand of the CO2 capture facility. Sufficient Kaskaskia River water will be stored in the new pond

Page 29 of 145

to supply the CO2 capture system while river level is low during a 25-year draught. New pumps deliver water from the new pond to the makeup water treatment system.

The new raw water supply pumps will transfer raw water to a new storage pond. From the storage pond, raw water will be pumped to a new water treatment system supporting the CO2 capture facility. The new water treatment system will treat the raw water for use as cooling tower makeup as well as for auxiliary boiler makeup and other high-quality water demand within the CO2 capture facility.

The CO2 capture facility will need to file a request to use public water from the Kaskaskia River through the Illinois Department of Natural Resources (IDNR). If new construction activities such as installing pumps, building a pump house, or setting pipelines will not occur in the waterway, only a request to use public water is needed to be filed to IDNR. Otherwise, if new construction activities occur in the waterway, a joint permit application to IDNR, Illinois Environmental Protection Agency (IEPA), and the US Army Corps of Engineers (USACE) will be required.

One of the key conditions in the permit to use public water is the determination of the minimum flow, which defines when the river water is not available for withdrawal during drought conditions. IDNR bases this decision of the magnitude of the minimum flow on the existing aquatic biodiversity integrity in the vicinity of the intake in the river.

However, if Baldwin Energy Station or any other Lake Shelbyville and/or Carlyle Lake water allocation holder ceases operations then additional water allocation will be made available for use by the CO2 capture facility. If this occurs, the carbon capture facility will need to obtain water allocation rights that will allow the entities to release water from the lakes. To obtain water allocation right from Lake Shelbyville and Carlyle Lake, a request needs to be filed with IDNR. IDNR will then evaluate the request and assess the availability of the water storage in both lakes. IDNR will then determine the water allocation amount, water supply release conditions, billing, etc. IDNR then will enter into an agreement with the CO2 capture facility to allocate the water stored in the two lakes for use by the facility during times of drought.

Page 30 of 145

Wastewater Permitting

To discharge the cooling tower blowdown into the Kaskaskia River will require a National Pollutant Discharge Elimination System (NPDES) permit. It is anticipated that this permit will be issued to the future third party owner/operator of the CO2 capture system.

Some limitations exist within the current facility and Illinois regulatory environment that will impact the operation and feasibility of the potential wastewater treatment system. This report is based on the following assumptions:

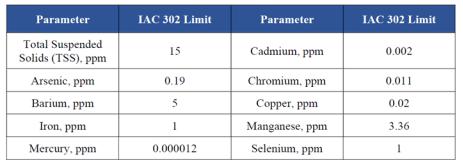

•Removal of trace metals in the cooling tower blowdown to the concentrations indicated in 35 Illinois Administrative Code (IAC) 302 is required to meet Illinois water quality regulations. The study assumes no mixing zone at the new cooling tower blowdown discharge to the Kaskaskia River will be allowed.

•NPDES discharge limitations for total suspended solids (TSS) will be like those for the existing PSGC cooling tower blowdown.

A summary of the NPDES discharge limitations derived from IAC 302 is listed in Table 8 below. These limitations are indicative of the most stringent limits that may be applied.

Table 8. NPDES Discharge Limitations

Mechanical Draft Cooling Tower

The CO2 capture process has a significant cooling demand that will be provided by circulating cooling water. The cooling water is heated as it passes through the process heat exchangers and this heat must be

Page 31 of 145

rejected to the environment prior to circulating back to the process equipment. This system includes a mechanical draft cooling tower (MDCT).

The evaporation necessary to reject the heat from the CO2 capture system must be made up with treated river water. The evaporation also concentrates constituents in the circulating water system. The cooling tower blowdown is set to a preliminary flow rate of one-third of the makeup flow to limit concentration to three “Cycles-of-concentration” (COC). Three COC is selected so that the cooling tower blowdown will meet NPDES permit limits for TSS without further wastewater treatment. However, further wastewater treatment has been incorporated to meet the discharge limitations summarized in Wastewater Permitting above. This being the case, some optimizations of the COC due to wastewater treatment should be considered during detailed design. To allow optimization it is recommended that COC not be strictly limited to three.

Wastewater Treatment

The solubility of metal-sulfide complexes is orders of magnitude lower than metal-hydroxide complexes typically achieved in water softening systems. Trace metal removal systems take advantage of metal-sulfide solubility to remove dissolved metals to very low levels.

The wastewater treatment system will have organosulfide dosing into a 20-min hydraulic residence time (HRT) tank, followed by coagulant dosing into a separate 10-min HRT. This corresponds to 75,000gallon reaction tank and 20,000-gallon coagulation tank, respectively. The pretreatment chemistry and HRT will be confirmed with jar testing.

In order to remove precipitated salts a filtration system with a very small nominal pore size, such as ultrafiltration (UF). The PSGC wastewater treatment system includes UF designed for a feed flow of 3615 gpm at 95% recovery and would generate 3434 gpm permeate. In order to reduce capital costs, the proposed wastewater treatment system includes 3 trains, at N-1 redundancy. This allows two trains to treat the full flow when one train is offline for Clean-In-Place (CIP) or backwash. This results in an instantaneous flux of 25.4 gfd with all three trains online, and 40.9 gfd with two trains online (while the 3rd train is cleaning).

Page 32 of 145