- •Putting CO2 to Use

- •Abstract

- •Highlights

- •Executive summary

- •CO2 is a valuable commodity

- •Early markets are emerging but the future scale of CO2 use is uncertain

- •Using CO2 can support climate goals, but with caveats

- •Cultivating early opportunities while planning for the long term

- •Findings and recommendations

- •Millions of tonnes of CO2 are being used today

- •New pathways for CO2 are generating global interest

- •CO2 use can contribute to climate goals, but with caveats

- •The future scale of CO2 use is highly uncertain

- •Where are the emerging market opportunities?

- •1. CO2-derived fuels

- •2. CO2-derived chemicals

- •3. Building materials from minerals and CO2

- •4. Building materials from waste and CO2

- •5. Crop yield boosting with CO2

- •CO2 use can complement CO2 storage, but is not an alternative

- •References

- •Policy recommendations

- •Technical analysis

- •Introduction

- •Setting the scene

- •What is CO2 use?

- •CO2-derived fuels

- •CO2-derived chemicals

- •CO2-derived building materials

- •Where is CO2 being used today?

- •What has spurred renewed interest in CO2 use?

- •Who is currently investing in CO2 use, and why?

- •How can CO2-derived products and services deliver climate benefits?

- •Understanding the future market for CO2-derived products and services

- •Which factors influence the future market?

- •Scalability

- •Competitiveness

- •The price and availability of hydrogen

- •The price and availability of CO2

- •Climate benefits

- •Origin of the CO2

- •Displaced product or service (reference system)

- •Energy input

- •Retention time of carbon in the product

- •Is it possible to assess the future market size?

- •Scaling up the market

- •CO2-derived fuels

- •What are CO2-derived fuels?

- •Are CO2-derived fuels scalable?

- •Under what conditions would CO2-derived fuels be competitive?

- •Can CO2-derived fuels deliver climate benefits?

- •What are the regulatory requirements?

- •CO2-derived chemicals

- •What are CO2-derived chemicals?

- •Are CO2-derived chemicals scalable?

- •Under what conditions would CO2-derived chemicals be competitive?

- •Can CO2-derived chemicals deliver climate benefits?

- •What are the regulatory requirements?

- •CO2-derived building materials from natural minerals

- •What are CO2-derived building materials?

- •Are CO2-derived building materials scalable?

- •Under what conditions would CO2-derived building materials be competitive?

- •Can CO2-derived building materials deliver climate benefits?

- •What are the regulatory requirements?

- •CO2-derived building materials from waste

- •What are building materials made from waste?

- •Are building materials from waste scalable?

- •Under what conditions are building materials from waste competitive?

- •Can building materials from waste deliver climate benefits?

- •What are the regulatory requirements?

- •CO2 use to enhance the yield of biological processes

- •What is yield boosting?

- •Is CO2 yield boosting scalable?

- •Under what conditions is CO2 yield boosting competitive?

- •Can CO2 yield boosting deliver climate benefits?

- •What are the regulatory requirements?

- •Where are suitable locations for an early market?

- •Implications for policy

- •Public procurement

- •Mandates

- •Economic incentives

- •Labelling, certification and testing

- •Research development and demonstration

- •Recommendations

- •References

- •General annex

- •Abbreviations and acronyms

- •Acknowledgements

- •Table of contents

- •List of figures

- •List of boxes

- •List of tables

Putting CO2 to Use: Creating Value from Emissions |

Technical analysis |

Setting the scene

What is CO2 use?

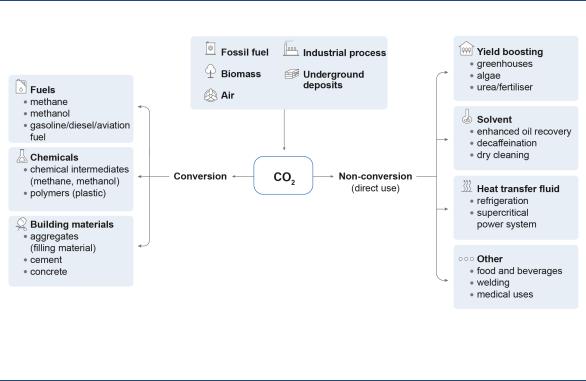

For this study, CO2 use has been defined as the process of using CO2 as a raw material for products or services with a potential market value. The range of potential applications is very large and includes direct use, where the CO2 is not chemically altered (non-conversion), and the transformation of CO2 to a useful product (conversion) (Figure 9).

Most existing commercial applications involve direct use of CO2 (non-conversion), including the production of food and beverages, metals fabrication, cooling, dry cleaning, healthcare, water treatment, fire suppression, and the injection of CO2 in oil reservoirs to enhance oil recovery (CO2-EOR). CO2 is also increasingly used to enhance yields from industrial processes, such as methanol production and crop cultivation in greenhouses. Most applications make use of several unique properties of CO2, including its large heat absorption capacity, stable and nonreactive nature, and its ability to act as a solvent. A future use of CO2 is in supercritical power cycles, where CO2 would replace water as a working fluid, increasing the efficiency of electricity generation.

The conversion route has sparked most interest in recent years, including opportunities to develop CO2-derived fuels, chemicals and building materials. There are a large number of chemical and biological pathways for CO2 conversion, many of which are still in an early stage of development but may become technically and commercially available in the future.

Figure 9. Simple classification of CO2 use pathways

IEA 2019. All rights reserved.

CO2 can be used in a broad range of applications involving direct use of CO2 or use through conversion into other products.

PAGE | 17

IEA. All rights reserved.

Putting CO2 to Use: Creating Value from Emissions |

Technical analysis |

CO2-derived fuels

CO2 can be used to produce many of the fuels available on the market today, such as methane, methanol, gasoline and aviation fuels.1 Most fuels have an application in the transportation sector, while some (e.g. methane) can also be used in industry, heating and power generation. CO2-derived fuels may notably be used in sectors for which few low-carbon alternatives exist, such as aviation.

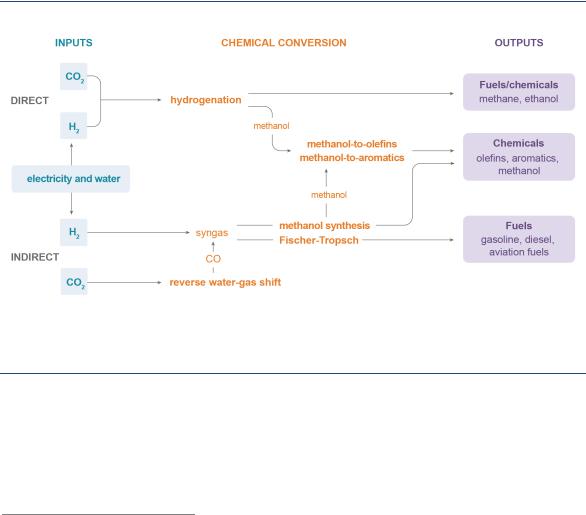

The most mature conversion pathways are direct conversion of CO2 (hydrogenation), and indirect conversion whereby the CO2 is first converted into CO (reverse water-gas shift), followed by a Fischer-Tropsch (FT) process or methanol synthesis process (Figure 10). The reverse water-gas shift conversion has been successfully demonstrated on a small scale, while the hydrogenation, FT and methanol synthesis processes are technologically mature. The direct conversion of CO2 into methane and methanol is carried out in several places around the world, and it has reached the early commercialisation stage in regions with low-cost renewable electricity. The largest CO2-based fuel plant in operation today is the George Olah Renewable Methanol facility located in Svartsengi, Iceland (CRI, 2019). Other chemical and biological conversion pathways, such as artificial photosynthesis, are still in the research stage.

Figure 10. Mature conversion route for CO2-derived fuels and chemical intermediates

IEA 2019. All rights reserved.

CO2 can be used to produce fuels and chemical intermediates through several conversion routes, but these require significant energy input.

Unlike the chemical compounds making up fossil fuels, CO2 is a very stable, non-reactive molecule with a low energy state, meaning that large amounts of external energy must be supplied to convert it into an energy-rich fuel. The conversion pathways that are most technologically mature use energy in the form of hydrogen, while some of the emerging pathways are able to use electricity or even sunlight. Nowadays, most hydrogen is produced

1 Fuels made from CO2 and energy can be referred to in several ways, including CO2-based fuels, carbon fuel carriers, synthetic (hydrocarbon) fuels and electrofuels. In this report, the term CO2-derived fuels is used for the sake of consistency with other CO2 use applications. However, the reader should be aware that CO2 is not the source of energy, but the donor of carbon to create a fuel that is easier to handle and use.

PAGE | 18

IEA. All rights reserved.

Putting CO2 to Use: Creating Value from Emissions |

Technical analysis |

from natural gas and other fossil fuels. This process can be decarbonised by applying CCS. Another production route is the electrolysis of water using low-carbon energy. This technology has attracted increasing interest in recent years, mainly due to spectacular cost reductions in solar PV and wind energy technologies, and the expectation that these technologies will be widely available in the future (IEA, 2019a).

CO2-derived chemicals

CO2-derived chemicals include a wide range of organic substances, including plastics, fibres and synthetic rubber. A well-established application is in the fertiliser industry, where CO2 is used to manufacture urea. In addition to urea, CO2 can be converted into chemical intermediates, such as methanol, ethylene and propylene, which in turn can be used as a source for a myriad of more complex chemicals. As is the case for fuels, the conversion of CO2 to methanol and methane is the most technologically mature pathway, but requires considerable electricity input.

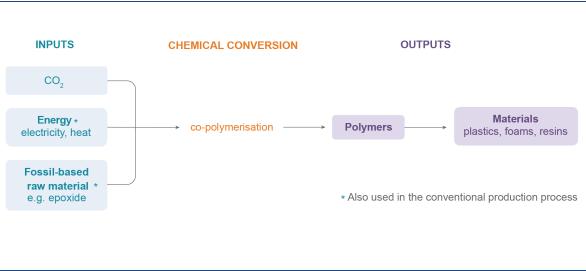

A special group of chemicals are polymers, which are used in the production of plastics and resins. CO2 can be used in the manufacturing process by replacing part of the fossil-based feedstock (Figure 11). Some polymers can contain up to 50% CO2 by weight. Unlike the conversion of CO2 to fuels and intermediate chemicals, the use of CO2 in polymer manufacturing does not require much energy input for the conversion process, because the energy is provided by the fossil feedstock in the polymer molecule that is not replaced by the CO2. A number of companies, such as Asahi Kasei Chemicals, Chi Mei Corp and Covestro, are producing polymers using CO2 (Fukuoka et al. 2007; Covestro, 2018).

Figure 11. Mature conversion pathway for CO2-derived polymers

IEA 2019. All rights reserved.

CO2 can be converted into polymers, which can be used in a wide variety of products.

CO2-derived building materials

CO2 can also be used in the production of concrete. Concrete is a mixture of cement, water and solid aggregates, such as sand and gravel. CO2 can be used to replace water during the mixing of the components, called CO2 curing; as a feedstock to produce aggregates; and in cement production. All applications involve the reaction of CO2 with calcium or magnesium minerals to form carbonates, which is the form of carbon that makes up concrete. Carbonates have an even lower energy state than CO2. Aggregates can be produced by reacting CO2 with

PAGE | 19

IEA. All rights reserved.