English((( / bearing

.docTomsk Polytechnic University

Machine Building Department

Project work

“Bearing”

By M.Trofimov

Tomsk 2007

Contents

1 Major types ____________________________________________3

2 Bearing friction _________________________________________3

3 Principles of operation ___________________________________4

4 Load bearing and performance capacities ____________________5

5 History and development _________________________________5

![]() [Show

more]

[Show

more]

Bearing

A bearing is a device to permit constrained relative motion between two parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation.

![]()

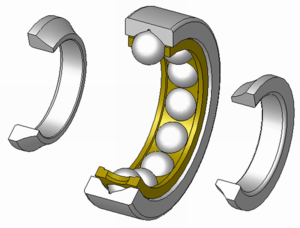

An example of a four-point contact ball bearing

Major types

Common motions include linear/axial and rotary/radial. A linear bearing allows motion along a straight line, for example a drawer being pulled out and pushed in. A rotary bearing or thrust bearing allows motion about a center, such as a wheel on a shaft or a shaft through a housing. Common kinds of rotary motion include both one-direction rotation and oscillation where the motion only goes through part of a revolution, such as with a hinge. Other kinds of bearings include spherical bearings such as ball joints which are used in car suspensions and some computer mice.

Bearing friction

Low friction bearings are often important for efficiency, to reduce wear and to facilitate high speeds. Essentially, a bearing can reduce friction by virtue of its shape, by its material, or by introducing and containing a fluid between surfaces.

By shape, gains advantage usually by using spheres or rollers.

By material, exploits the nature of the bearing material used. (An example would be using plastics that have low surface friction.)

By fluid, exploits the low viscosity of a layer of fluid, such as a lubricant or as a pressurised medium to keep the two solid parts from touching.

By fields, exploits electromagnetic fields, such as magnetic fields, to keep solid parts from touching.

Combinations of these, can even be employed with the same bearing. An example of this is where the cage is made of plastic, and it separates the rollers/balls, which reduce friction by their shape and finish.

Principles of operation

Animation of ball bearing

There are at least six common principles of operation:

sliding bearings, usually called "bushes", "bushings", "journal bearings", "sleeve bearings", "rifle bearings", or "plain bearings"

rolling-element bearings such as ball bearings and roller bearings

jewel bearings, in which the load is carried by rolling the axle slightly off-center

fluid bearings, in which the load is carried by a gas or liquid

magnetic bearings, in which the load is carried by a magnetic field

flexure bearings, in which the motion is supported by a load element which bends.

Load bearing and performance capacities

Bearings vary greatly over the forces and speeds that they can support.

Forces can be radial, axial (thrust bearings) or moments perpendicular to the main axis.

The maximum speeds that rotational bearings can support also vary, generally performance is defined in terms of the product 'DN' where D is the diameter (often in mm) of the bearing and N is the rotation rate in revolutions per minute.

History and development

An early type of linear bearing was an arrangement of tree trunks laid down under sleds. This technology may date as far back as the construction of the Pyramids of Giza, though there is no definitive evidence. Modern linear bearings use a similar principle, sometimes with balls in place of rollers.

The first plain and rolling-element bearings were wood, but ceramic, sapphire or glass can be used, and steel, bronze, other metals, and plastic (e.g., nylon, polyoxymethylene, teflon, and UHMWPE) are all common today. Indeed, stone was even used in various forms. Think of the "jeweled pocket watch", which incorporated stones to reduce frictional loads, and allow a smoother running watch. Of course, with older, mechanical timepieces, the smoother the operating properties, then the higher the accuracy and value. Wooden bearings can still be seen today in old water mills where the water has implications for cooling and lubrication.

Rotary bearings are required for many applications, from heavy-duty use in vehicle axles and machine shafts, to precision clock parts. The simplest rotary bearing is the sleeve bearing, which is just a cylinder inserted between the wheel and its axle. This was followed by the roller bearing, in which the sleeve was replaced by a number of cylindrical rollers. Each roller behaves as an individual wheel. The first practical caged-roller bearing was invented in the mid-1740s by horologist John Harrison for his H3 marine timekeeper. This used the bearing for a very limited oscillating motion but Harrison also used a similar bearing in a truly rotary application in a contemporaneous regulator clock.

Friedrich Fischer's idea from the year 1883 for milling and grinding balls of equal size and exact roundness by means of a suitable production machine formed the foundation for creation of an independent bearing industry.

Tapered steering head bearings for a motorcycle

http://science.howstuffworks.com/bearing.htm

http://www.mechanismen.be

http://www.reliableplant.com