- •Tomsk 2007

- •1.History

- •2.Description

- •2.1Parts of a lathe

- •2.2. Accessories

- •2.3. Modes of use

- •3. Major categories of lathes

- •3.1. Woodworking lathes

- •3.2. Metalworking lathes

- •3.3. Cue lathes

- •3.4. Glassworking lathes

- •3.5. Metal spinning lathes

- •3.6. Ornamental turning lathes

- •3.7. Reducing Lathe

- •3.8 Rotary lathes

- •3.9 Watchmaker's lathes

- •4.Gallery

- •4.1 Examples of lathes

- •4.2 Examples of work produced from a lathe

Tomsk Polytechnic University

Machine Building Department

Project work

“Lathe”

By M.Ondar

Tomsk 2007

Contents

1 History ……………………………………………………………………………….3

2 Description …………………………………………………………………………..4

2.1 Parts of a lathe ………………………………………………….………….4

2.2 Accessories ………………………………………………………………..5

2.3 Modes of use ………………………………………………………………5

3 Major categories of lathes ……………………………………………………….…..6

3.1 Woodworking lathes………………………………………………..….…..6

3.2 Metalworking lathes ……………………………………………...….…….6

3.3 Cue lathes ………………………………………………………….………6

3.4 Glassworking lathes …………………………………………….……..…..7

3.5 Metal spinning lathes ………………………………………………….…..7

3.6 Ornamental turning lathes …………………………………………………7

3.7 Reducing Lathe …………………………………………………………....7

3.8 Rotary lathes …………………………………………………………..…..8

3.9 Watchmaker's lathes ………………………………………………….……8

4 Gallery ………………………………………………………………………….……8

4.1 Examples of lathes ……………………………………………………..…..8

4.2 Examples of work produced from a lathe ………………………………….9

Contents………………………………………………………………………..10

![]()

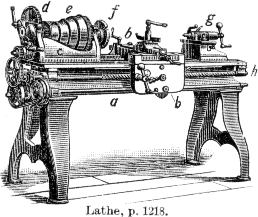

A lathe from 1911 showing component parts. a = bed, b = toolrest, c = headstock, d = geartrain to drive automatic screw shaft, e = pullies for belt drive from an external power source, f = spindle, g = tailstock. h = automatic screw shaft.

1.History

The lathe is an ancient tool, dating at least to the Egyptians and, known and used in Assyria, Greece, the Roman and Byzantine Empires.

A turned wood bowl with natural edges

The origin of turning dates to around 1300BC when the Egyptians first developed a two-person lathe. One person would turn the wood work piece with a rope while the other used a sharp tool to cut shapes in the wood. The Romans improved the Egyptian design with the addition of a turning bow. Early bow lathes were also developed and used in Germany, France and Britain. In the Middle Ages a pedal replaced hand-operated turning, freeing both the craftsman's hands to hold the woodturning tools. The pedal was usually connected to a pole, often a straight-grained sapling. The system today is called the "spring pole" lathe. Spring pole lathes were in common use into the early 20th Century. A two-person lathe, called a "great lathe", allowed a piece to turn continuously (like today's power lathes). A master would cut the wood while an apprentice turned the crank.

2.Description

2.1Parts of a lathe

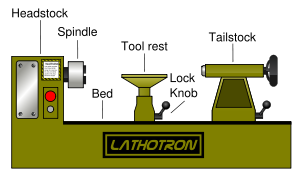

Parts of a wood lathe

A lathe may or may not have a stand (or legs), which sits on the floor and elevates the lathe bed to a working height. Some lathes are small and sit directly on a workbench or table, and do not have a stand.

All lathes have a "bed", which is (almost always) a horizontal beam (although some CNC lathes have a vertical beam for bed to ensure that swarf, or chips, falls free of the bed.

At one end of the bed (almost always the left, as the operator faces the lathe) is a "headstock". The headstock contains high-precision spinning bearings.

Rotating within the bearings is a horizontal axle, with an axis parallel to the bed, called the "spindle". Spindles are often hollow, and have exterior threads and/or an interior Morse taper on the "inboard" (i.e., facing to the right / towards the bed) by which accessories which hold the workpiece may be mounted to the spindle. Spindles may also have exterior threads and/or an interior taper at their "outboard" (i.e., facing away from the bed) end, and/or may have a handwheel or other accessory mechanism on their outboard end. Spindles are powered, and impart motion to the workpiece.

The spindle is driven, either by foot power from a treadle and flywheel or by a belt drive to a power source. In some modern lathes this power source is an integral electric motor, often either in the headstock, to the left of the headstock, or beneath the headstock, concealed in the stand.