01 POWER ISLAND / 01 CCPP / DOE__Understanding Natural Gas and Lng Options October 11 2017_1

.pdf

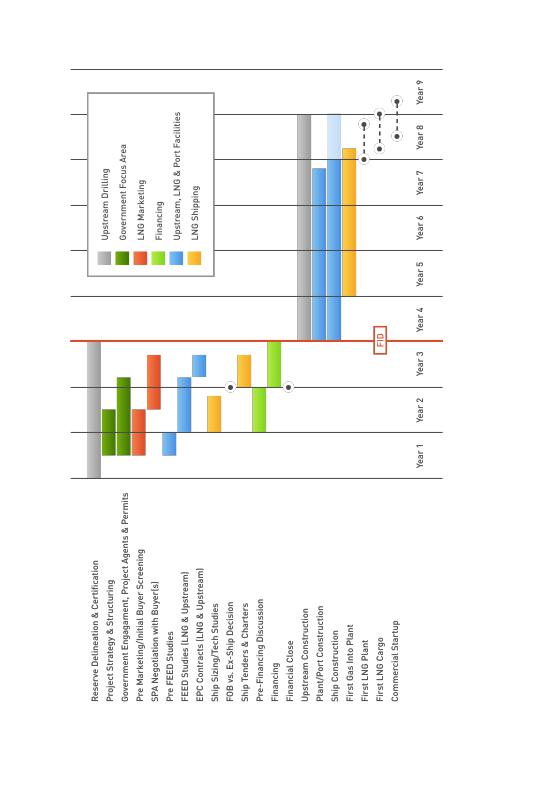

LNG DEVELOPMENT

Source: Galway Energy Advisors

106

LNG DEVELOPMENT

Key Success Factors

Some important factors contributing to the success of the LNG project include:

>Government support, timely issuance of permits and authorizations, timely access to the plant construction site.

>A complete set of geotechnical data from an adequate number of bore holes on the plant site to determine soil conditions and allow foundation planning or soil remediation if required. Seismic information to evaluate potential earthquake problems is also necessary.

>A well-qualified and experienced LNG EPC contractor. Key EPC personnel assigned to the project must be capable and experienced in the LNG area.

>EPC contract should be lump sum turnkey to increase project certainty:

•Ensures contractor has 'skin in the game' and is aligned with the company in being highly motivated to keep costs under control and project on schedule.

•Needs to be turnkey to provide the contractor the latitude needed to perform in order to take on the obligation of a lump sum contract.

>Company and EPC contractor relationship needs to be collaborative.

>EPC contractor needs to evaluate and formally endorse the company's FEED design (Design Endorsement Certificate). If it finds an issue with the FEED, it is to propose and agree with the company on a proposed

remedy to the FEED, and then provide the formal endorsement. This is important so as to avoid future costly change orders due to later design changes.

>Minimize change orders in the EPC no matter how attractive they may appear.

>Maintain focus on safety in all aspects of the LNG project. Maintain a strong, proactive, involved safety program in collaboration with the contractor.

107

LNG DEVELOPMENT

>In the EPC contract - secure strong guarantees on:

•LNG plant production capacity.

•Fuel consumption.

•LNG product quality meeting all specifications.

•Plant completion schedule.

•All other products or emissions meeting specifications.

•Completion.

>Ensure that LNG partners are fully aligned throughout the project development phase.

>Take measures, where available, to increase project execution certainty.

>Embrace new technology but on a measured basis. Avoid "Serial No. 1" unproven applications which almost always result in delays and increased costs.

>Implement an effective training program to facilitate utilization of local labor in the construction and operation of the LNG plant.

>Note that persistence and patience are critical - LNG plants are challenging and complex and take some time to implement.

>Keep the project as simple as possible.

>Recognize other associated investment opportunities that may be available with the LNG project, such as natural gas liquids extraction, helium recovery if it exists in the feed gas (the LNG process increases the concentration of helium 10-fold, and can make its recovery economic, as was the case in Qatar), potential for domestic gas deliveries for power generation, and so on.

108

Environment,

Social Impact

and Safety

Introduction

Environment

Safety and Security

Social and Economic Impact

ENVIRONMENT, SOCIAL IMPACT AND SAFETY

Introduction

Natural gas and LNG development projects can have a significant environmental and social impact in the communities where they are located, both positive and negative. These impacts can be managed through appropriate laws, regulations, and compliance balanced with corporate social responsibility, which becomes part of the social compact called the "social license to operate." In recent years, LNG project developers in partnership with central and local governments have included a wider constituency of stakeholders at an earlier stage of planning and as a result, this social compact has become a critical success factor of any major LNG project.

110

ENVIRONMENT, SOCIAL IMPACT AND SAFETY

Environmental Impacts of LNG

Facilities

The construction of LNG facilities, whether liquefaction or regasification/import terminals, gives rise to numerous potential environmental impacts. The potential impacts and associated necessary regulations vary depending on the project and the country. These general guidelines should be tailored to the hazards and risks established for each project on the basis of the results of an environmental impact assessment in which site-specific variables are taken into account. In general, the following types of impacts should be considered:

Threats to aquatic and shoreline environments: Construction and maintenance dredging, disposal of dredged soil, construction of piers, wharves, breakwaters and other structures, and erosion, may lead to short and long-term impacts on aquatic and shoreline habitats. Additionally, the discharge of ballast water and sediment from ships during LNG terminal loading operations may result in the introduction of invasive aquatic species.

Marine Environmental Impacts: The coastal/nearshore area, is composed of several marine coastal habitats, such as the sandy and rocky shores, mangroves, estuaries and deltas and seagrass meadows. An enormous diversity of associated fauna and flora congregates in these habitats, providing important goods and services for the local human population. The following are some of the potential environmental impacts on marine habitats of operations:

>Colonization of subsea structures – subsea structures can be recognized as drivers for aggregation of ocean life and they will provide surfaces for colonization by encrusting fauna and flora. Depending on the source of colonists, the impact could be positive (increasing of biodiversity consistent with the geographical area) or negative (invasive alien species threaten local species).

111

ENVIRONMENT, SOCIAL IMPACT AND SAFETY

>Impact on subsea and on benthic (ocean bottom dwelling) fauna during installation

>Impact on the marine habitat due to the discharge of cooling water

>Impact on the biodiversity from ballast water

>Impact on the water quality and marine fauna from liquid effluents

>Disturbance of marine environment, flora, and fauna from the offshore operations

Hazardous Materials Management: Storage, transfer, and transport of LNG may result in leaks or accidental release from tanks, pipes, hoses, and pumps at land installations and on LNG transport vessels. The storage and transfer of LNG also poses a risk of fire and, if under pressure, explosion due to the flammable characteristics of its boil-off gas.

Some recommended measures to manage these types of hazards include:

>LNG storage tanks and components (e.g. pipes, valves, and pumps) should meet international standards for structural design integrity and operational performance to avoid catastrophic failures and to prevent fires and explosions during normal operations and during exposure to natural hazards. Applicable international standards may include provisions for overfill/overpressure protection (relief valves, flares, etc.), secondary containment, metering and flow control, fire protection (including flame arresting devices), and grounding (to prevent electrostatic charge).

>Storage tanks and components (e.g. roofs and seals) should undergo periodic inspection for corrosion and structural integrity and be subject to regular maintenance and replacement of equipment (e.g. pipes, seals, connectors, and valves). A cathodic protection system should be installed to prevent or minimize corrosion, as necessary.

>Loading/unloading activities (e.g. transfer of cargo between LNG carriers and terminals) should be conducted by properly trained personnel according to pre-established formal procedures to prevent accidental releases and fire/explosion hazards. Procedures should include all aspects of the delivery or loading operation from arrival to departure, secure connection of grounding systems, verification of

112

ENVIRONMENT, SOCIAL IMPACT AND SAFETY

proper hose connection and disconnection, adherence to no smoking and no naked light policies for personnel and visitors.

Air emissions: Air emissions from LNG facilities include combustion sources for power and heat generation in addition to the use of compressors, pumps, and reciprocating engines. Emissions resulting from flaring and venting may result from activities at both LNG liquefaction and regasification terminals. Principal gases from these sources include nitrogen oxides (NOx), carbon monoxide (CO), carbon dioxide (CO2), and in the case of sour gases, sulfur dioxide (SO2).

Waste management: Waste materials should be segregated into nonhazardous and hazardous wastes and a waste management plan should be developed that contains a waste tracking mechanism from the originating location to the final waste reception location.

Noise: The main noise emission sources in LNG facilities include pumps, compressors, generators and drivers, compressor suction/discharge, recycle piping, air dryers, heaters, air coolers at liquefaction facilities, vaporizers used during regasification and general loading/unloading operations of LNG carriers/vessels.

LNG transport: Common environmental issues related to vessels and shipping are relevant for LNG import and export facilities. For example, emissions from tugs and LNG vessels, especially where the jetty is within close proximity to the coast may also represent an important source affecting air quality.

Environmental Impact Statements

Project developers must comply with all environmental laws and regulations of the host country. This will often require the preparation of a detailed environmental impact statement (EIS).

The principal purposes for preparing an EIS are to:

>Identify and assess potential impacts on the human environment that would result from implementation of the proposed action.

113

ENVIRONMENT, SOCIAL IMPACT AND SAFETY

>Identify and assess reasonable alternatives to the proposed action that would avoid or minimize adverse effects on the human environment.

>Facilitate public involvement in identifying significant environmental impacts.

>Identify and recommend specific mitigation measures to avoid or minimize environmental impacts.

The topics typically addressed in an EIS include: geology, soils, water use and quality, wetlands, vegetation, wildlife; fisheries and essential fish habitat (EFH), threatened, endangered, and special status species, land use, recreation, and visual resources; socioeconomics, transportation, cultural resources, air quality, noise, reliability and safety, cumulative impacts, and alternatives.

The EIS describes the affected environment as it currently exists and the potential environmental consequences of the project and compares the project’s potential impacts to those of alternatives. The EIS also presents the conclusions and recommended mitigation measures of the regulatory agency in charge of preparing the EIS and conducting the environmental and regulatory review of the project.

Other Environmental Considerations

Natural gas and LNG are viewed as part of a balanced approach to addressing environmental concerns that supports innovation, lowers greenhouse gas emissions, grows our economies, and strengthens energy security. Natural gas has contributed to lower emissions in many countries, in particular it has allowed the United States to be a leader in emissions reduction. Natural gas can be used for cooking, power generation, or heating and cooling. As economies develop, the need for energy will continue to grow not only for natural gas for export and power generation but also as an input to natural gas derived products, such as fertilizers and petrochemicals.

114

ENVIRONMENT, SOCIAL IMPACT AND SAFETY

Throughout the value chain, natural gas and LNG development should seek to minimize and reduce emissions. In an LNG facility, small gas flares are needed for operational safety but flaring should be minimized. Methane emissions must be measured and mitigated against throughout the value chain, including processing equipment, pipelines, storage tanks, valves, compressors, and other fugitive sources.

Rising sea levels require general consideration while designing ports and berths and a special consideration for weather modification both on-shore and offshore.

115