Учебное пособие 2161

.pdf

Russian Journal of Building Construction and Architecture

9.Kanygina S. Yu. Prognozirovanie ostatochnykh deformatsii dorozhnykh odezhd nezhestkogo tipa na zemlyanom polotne iz glinistykh gruntov. Avtoref. diss. kand. tekhn. nauk [Prediction of residual deformations of road pavement of non-rigid type on the roadbed of clay soils. Cand. eng. sci. diss.]. Moscow, 1999. 20 p.

10.Leonovich I. I., Vyrko N. P. Vodno-teplovoi rezhim zemlyanogo polotna [Water-heat regime of the roadbed]. Minsk, BNTU Publ., 2013. 332 p.

11.Mavledinov Z. A. [Determination of the depth of the core of the soil of the roadbed]. Trudy MADI-TU "Problemy stroitel'stva i ekspluatatsii, avtomobil'nykh dorog" [Proc. of MADI-TU "Problems of construction and operation of roads"]. Moscow, 1998, pp. 45––47.

12.Matua V. P., Chirva D. V., Mironchuk S. A. Ispytanie materialov [Material test]. Avtomobil'nye dorogi, 2012, vol. 7 (968), pp. 86––89.

13.Matua V. P. Issledovanie napryazhenno-deformirovannogo sostoyaniya dorozhnykh konstruktsii s uchetom ikh neuprugikh svoistv i prostranstvennogo nagruzheniya. Diss. d-ra tekh. nauk [Study of the stress-strain state of road structures taking into account theirinelastic properties and spatialloading.Dr.eng.sci.diss.]. MADI,2002.484p.

14.Matua V. P., Chirva D. V., Isaev E. N. Metodika issledovaniya svyaznykh gruntov na nakoplenie ostatochnykh deformatsii [Method of investigation of cohesive soils on the accumulation of residual deformations]. Vestnik Tomskogo gosudarstvennogo arkhitekturno-stroitel'nogo universiteta, 2016, no. 3 (56), pp. 186––194.

15.Matua V. P., Mironchuk S. A. Novoe laboratornoe oborudovanie i metodika provedeniya ispytanii dorozhnostroitel'nykh materialov pod vozdeistviem dinamicheskikh nagruzok [New laboratory equipment and methods of testing road-building materials under the influence of dynamic loads]. Nauka i tekhnika v dorozhnoi otrasli, 2012, no. 4, pp. 16––18.

16.Matua V. P., Mironchuk S. A., Isaev E. N. Primenenie datchika WaterScout dlya monitoringa vlazhnosti grunta zemlyanogo polotna [Application of the WaterScout sensor for monitoring the soil moisture of the roadbed]. Vestnik Tomskogo gosudarstvennogo arkhitekturno-stroitel'nogo universiteta, 2017, no. 5, pp. 1921––99.

17.Matua V. P., Mironchuk S. A., Nikulin Yu. Ya., Isaev E. N. Energoeffektivnoe oborudovanie dlya obespecheniya kachestva asfal'tobetonov [Energy-efficient equipment for asphalt concrete quality assurance]. Nauchnoe obozrenie, 2014, no. 7, vol. 3, pp. 884––887.

18.Matua V. P. e. a. Pribor dinamicheskikh ispytanii [Dynamic test device]. Patent RF, no. 2014137088, 2015.

19.Chmshkyan A. V. Sovershenstvovanie metodov rascheta prosadochnykh deformatsii [Improvement of methods of calculation of subsidence deformations]. Inzhenernyi vestnik Dona, 2012, no. 4, vol. 2. Available at: ivdon.ru/ru/magazine/archive/n4p2y2012/1256.

20.Masrouri F., Bicalho K. V., Kawai K. Laboratory hydraulic testing in unsaturated soils. Geotechnical and Geological Engineering, 2008, vol. 26, no. 6, pp. 691––704.

21.Tuller M., Or D. Water Retention and Characteristic Curve. Encyclopedia of Soils in the Environment. Elsevier Ltd., 2015, pp. 278—289.

22.Parikh A. K., Mehta M. N., Pradhan V. H. Тranscendental Solution of Fokker-Planck Equation of Vertical Ground Water Recharge in Unsaturated Homogeneous Porous Media. International Journal of Engineering Research and Applications, 2011, vol. 1, no. 4, pp. 1904—1911.

23.Zhang J., Jiang Q., Zhang Y., Dai L., Wu H. Nondestructive Measurement of Water Content and Moisture Migration of Unsaturated Red Clays in South China. Advances in Materials Science and Engineering, 2015, no. 1, pp. 1––7. doi: 10.1155/2015/542538.

80

Issue № 3 (43), 2019 |

ISSN 2542-0526 |

DOI 10.25987/VSTU.2019.3.43.007

UDC 625.7/.8

A. N. Tiraturyan1

NEW APPROACH TO TECHNICAL MONITORING OF THE CONDITION OF FLEXIBLE ROADWAY PAVEMENTS

Don State Technical University1

Russia, Rostov-on-Don

1PhD in Engineering, Assoc. Prof. of the Dept. of Highways, tel.: +7-951-820-03-03, e-mail: tiraturjan@list.ru

Statement of the problem. Ensuring an increased life cycle of flexible road pavements requires significant improvement of the organizational and technical mechanisms for managing their condition. One of such elements is the monitoring the condition of flexible road pavements, which receives insufficient attention in the road practice of the Russian Federation. The development of a conceptual framework for monitoring the state of flexible pavements is the main objective of the study reported in this article.

Results. The main parameter characterizing the state of flexible road pavement is to use the density of the energy dissipated during the passage of the settlement car determined based on the area of its dynamic hysteresis loop. The article looks at the methods of constructing dynamic hysteresis loops at the design stage and operation stage. The results of full-scale and cameral studies on the establishment of statistical laws for the distribution of structural parameters of flexible pavements at the operational stage are presented.

Conclusions. A new approach to monitoring the state of flexible road pavements was developed based on the analysis of the energy dissipation density in the pavement structure and taking into account the stochastic nature of the distribution of its main structural parameters allowing for operational planning and management of the technical condition of flexible road pavements.

Keywords: pavement, technical monitoring, residual life, density, dissipation energy, dynamic hysteresis loop, damping coefficient.

Introduction. Due to a transition to a 24-year gap in the maintenance of flexible pavements, it is increasingly important to improve their management mechanisms. Recent years have seen a significant development in the infrastructure of diagnostic equipment for their instrumental evaluation. A number of effective solutions have been set forth for its integration into a current technical base available in the Russian Federation.

© Tiraturyan A. N., 2019

81

Russian Journal of Building Construction and Architecture

One of the ways of addressing this is by designing effective decision-making mechanisms. There are comprehensive unified systems of road maintenance which rely on the major assumptions of the Guidelines on the Road Evaluation and Maintenance (ОДН 218.0.006-2002) [1, 3, 4, 12]. Individual approaches to the maintenance of flexible road pavements are employed based on the evaluation of their residual life [2, 5, 10, 13] and condition prior to the commencement of the project [16––18]. It should be noted, however, that one of the essential elements in any management system is monitoring. In this country’s road industry the term is seen as a superficial one meaning nothing except a set of comprehensive measures to evaluate road pavements in order to assess their deterioration rates [8, 14]. The analysis of foreign literature on the topic suggests that new technologies of collecting, storing and processing road evaluation data have been a focus of attention [11, 17, 19]. At the same time in accordance with the GOST (ГОСТ) Р 54257-2010 “Reliability of Building Structures and Foundations”, identification of a particular technological monitoring method is a broader effort that involves systemic assessment of the structure in order to control its quality, compliance with the project specifications and guidelines, predicting actual load-bearing capacity and residual life cycles resulting in informed decision-making with regard to ensuring longer emergency-free operation of the object.

1. Modelling the effect of a dynamic hysteresis on the road pavement surface under the impact of a calculated vehicle. Existing system of road pavement evaluation criteria involves the design of a comprehensive set of operational (longitudinal evenness, adhesion coefficient, rutting) and structural characteristics of flexible road pavements (the overall elasticity modulus, average visual evaluation score). At the same time there is no energy parameter that would describe a road structure and account for a combination of all of the above factors. This could be the density of dissipated energy as the calculated vehicle passes through which is defined as

|

|

ij d ij dS Eпов EP,S E*, |

(1) |

0 |

|

where the left-hand part of the expression identifies energy losses in the environment under the impact of a surface source with a contact spot ; ij , ij are the strains and deformations on the surface of a road structure; Eпов is the energy infinitely transferred by surface waves;

EP,S is the energy of volumetric waves; E* is the energy dissipated in the road structure due to the viscosity properties and internal anomalies.

82

Issue № 3 (43), 2019 |

ISSN 2542-0526 |

This can be calculated using the area of a dynamic hysteresis loop [9, 25] obtained while modeling a vehicle’s wheel path along a pavement surface. The solution will be implemented by applying the mechanic and mathematical modeling of the stress-strain of flexible road pavement. The mathematical model is based on the solution of a system of boundary integral equations and is described in [11, 25].

Considering that in real conditions under the wheel impact on the road pavement surface, there is a spatial dynamic stress-strain. The energy density should thus be given by the formula

|

|

|

|

W xx d xx yy d yy zz d zz , |

(2) |

||

0 |

0 |

0 |

|

where W is the density of the dissipated energy, J/m3.

For more on the results of the numerical modeling of the density of the dissipated energy of road structures with different rigidity ratios of their layers see [25].

2. Restoring the parameters of dynamic stress-strain of flexible road pavement at the operation stage. Implementation of a system of technical monitoring of flexible road pavements involves obtaining similar parameters at the operation stage, which requires restoring the parameters of its dynamic stress-strain.

The use of modern equipment and software packages allows the elasticity modulus s of construction layers of flexible road pavements to be identified at the operation stage using the elastic deflection measurements [6, 7, 22, 23]. The area of a dynamic hysteresis loop is determined apart from the elasticity modulus s by its attenuation characteristics. This could be a damping coefficient of the layer determined based on the amplitude-time characteristics of displacements measured on the road pavement surface under shock loading using FWD for measuring vertical deformations at the load application point as well as away from it using 9 sensor geophones (Fig. 1).

Sensor 1 (0 mm)

Sensor 1 (0 mm)

Sensor 2 (200 mm)

Sensor 2 (200 mm)

Sensor 3 (300 mm)

Sensor 3 (300 mm)

Sensor 4 (450 mm)

Sensor 4 (450 mm)

Sensor 5 (600 mm)

Sensor 5 (600 mm)

Sensor 6 (900 mm)

Sensor 6 (900 mm)

Sensor 7 (1200 mm)

Sensor 7 (1200 mm)

Sensor 8 (1500 mm)

Sensor 8 (1500 mm)

Sensor 9 (1800 mm)

Sensor 9 (1800 mm)

Sensor 10 (2100 mm)

Sensor 10 (2100 mm)

Fig. 1. Amplitude-time characteristics of displacements measured under shock loading

83

Russian Journal of Building Construction and Architecture

The results of imitation modeling presented in [24] allowed us to conclude that changes in the damping coefficient of the asphalt concrete layers are associated with a time difference between the extremums of amplitude-time characteristics of the displacements in the area 0––0.30 m away from the shock loading point, the foundation layers in the area 0.3––1.2 m, the subgrade soil –– 1.2––2.5 m.

The damping coefficient can be identified in accordance with the formula [20]:

|

|

|

|

|

, |

(3) |

|

|

|

|

|||

2 2 |

2 |

|||||

|

ln |

A1 |

t 1 |

, |

||

|

|

|||||

|

|

A |

|

|

||

|

|

2 |

|

|

|

|

where is a logarithmic attenuation decrement; A1 , |

A2 |

are the extrema of the amplitudes of |

||||

vertical displacements where the damping coefficient is calculated.

Based on the natural experiments, the method of restoring the parameters of the stress-strain of flexible road pavements at the operation stage was designed (Fig. 2).

Instrumental evaluation of flexible road pavements

Measurement of amplitude-time characterristics of displacements and deflection bowls of flexible road pavements using a shock loading setup

Determining the thickness of the layers of flexivle road pavements using a georadar intubation

Statistical distribution of the elasticity modulus |

|

Statistical distribution |

s and damping coefficients in the investigated areas |

|

of the thickness of the road |

of the highway |

|

pavement layers |

Analytical model of the dynamic stress-strain of the road structure

Distribution of the main components of the stress-strain of the road structure

σxx (εxx );σyy (εyy );σzz (εzz )

Statistical processing of the results:

––identifying the character of the distribution;

––evaluation of the mean value with 95 %, 5 % of the available sources

Fig. 2. Algorithm for restoring the parameters of a dynamic stress-strain of flexible road pavements at the operation stage

84

Issue № 3 (43), 2019 |

ISSN 2542-0526 |

3. Natural experiments of statistical laws of the distribution of the elasticity modulus s and damping coefficients of flexible road pavements. Possible restoration of the parameters of the dynamic strain-stress of road pavements using the results of instrumental evaluation and mechanic and mathematical modeling allows their actual condition to be evaluated in accordance to the design project. It should be noted, however, that in order to do this, it is necessary that the statistical laws of the distribution of the major structural parameters of flexible road pavements and laws of their degradation throughout the life cycle.

In order to solve this problem, from 2014 to 2018 studies were conducted in the operating areas of the highways so that the statistical laws of the distribution of the major structural parameters (elasticity modulus s and damping coefficients) of flexible road pavements and their change during operation were identified. For this purpose, all the investigated areas of the highways were divided into three groups with the life cycle of 0––5 years, 5––10 years, over 10 years. The total length of the investigated areas was 260 km where over 3000 deflection bowls and amplitude-time characteristics of displacements were recorded. According to the analysis of the results, it was found that the distribution of the elasticity modulus and damping coefficients of flexible road pavements obeys the logarithmically normal law:

f t |

|

1 |

|

e |

lnt m 2 |

|

|

|

2 2 , |

(4) |

|||

t |

|

2 |

||||

|

|

|

|

|

where m and σ are the parameters of the logarithmically normal distribution (scale parameters and distribution forms).

Based on the measurements, the averaged parameters of the logarithmically normal distribution for road pavements with the life cycle of 0––5 years, 5––10 years, 10––15 years (Table 1––2).

Таble 1

Average values of the parameters of the logarithmically normal distribution of the elasticity modulus s of construction layers of road pavements for different types of areas

|

|

|

Groups of the investigated area |

|

||

Statistical parameter |

|

|

|

|

|

|

Group I (with the life |

|

Group II (with the life |

|

Group III (with the life |

||

|

|

cycleof less than 5 years) |

|

cycle of 5––10 years) |

|

cycle of over 10 years) |

|

|

|

|

|

|

|

Asphalt |

m |

7.96 |

|

7.41 |

|

7.34 |

concrete |

|

|

|

|

|

|

σ |

0.20 |

|

0.24 |

|

0.36 |

|

|

|

|

|

|

|

|

Foundation |

m |

5.65 |

|

5.24 |

|

5.10 |

|

|

|

|

|

|

|

σ |

0.20 |

|

0.25 |

|

0.37 |

|

|

|

|

||||

|

|

|

|

|

|

|

Subgrade soil |

m |

4.30 |

|

4.10 |

|

4.02 |

|

|

|

|

|

|

|

σ |

0.15 |

|

0.20 |

|

0.23 |

|

|

|

|

||||

|

|

|

|

|

|

|

85

Russian Journal of Building Construction and Architecture

Таble 2

Average parameters of the logarithmically normal distribution of the damping coefficients of road pavement layers for different types of areas

Statistical |

|

Groups of the investigated area |

|

||

|

|

|

|

|

|

parameter |

|

Group I (with the life cycle |

Group II (with the life |

|

Group III (with the life |

|

of less than 5 years) |

cycle of 5––10 years) |

|

cycle of over 10 years) |

|

|

|

|

|||

|

|

|

|

|

|

Asphalt |

m |

–2.79 |

–2.18 |

|

–1.63 |

concrete |

|

|

|

|

|

σ |

0.29 |

0.33 |

|

0.40 |

|

|

|

|

|

|

|

Foundation |

m |

–3.54 |

–3.07 |

|

–2.72 |

|

|

|

|

|

|

σ |

0.31 |

0.31 |

|

0.36 |

|

|

|

||||

|

|

|

|

|

|

Subgrade soil |

m |

–3.36 |

–3.83 |

|

–3.89 |

|

|

|

|

|

|

σ |

0.25 |

0.22 |

|

0.22 |

|

|

|

||||

|

|

|

|

|

|

The obtained averaged parameters of the logarithmically normal distribution are the foundation for modeling changes in the dynamic contour of hysteresis loops on the road pavement surface at different stages of its operation and are accounted for in determining the calculated and residual resources of road pavements.

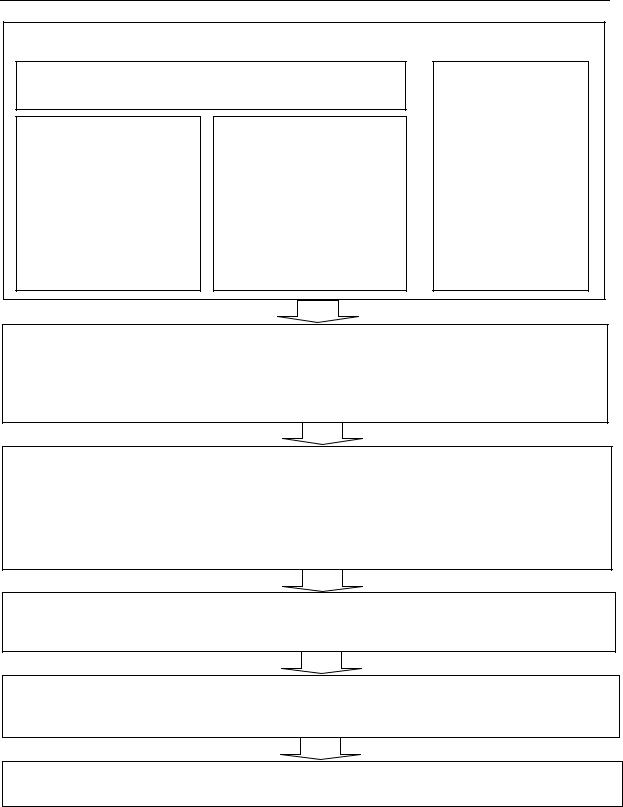

4. Тheoretical foundations of the implementation of the system of technical monitoring of road pavements. A set of theoretical and natural experiments allowed the main approaches to be formulated that are set forth as part of the system of technical monitoring of flexible road pavements including three major sections (Fig. 3––5).

––determining the calculated contour (development) of road pavements throughout its life cycle;

––identifying the residual resource and gamma-percentage resource of road pavements, evaluation of design solutions;

––specifying the thickness of the reinforcement of road pavements for its design life cycle. The suggested approaches rely on calculating the total dissipated energy in the road pavement structure throughout its life cycle based on calculating dynamic hysteresis loops over a loading cycle under the calculated vehicle’s wheel considering the statistical laws of the distribution of the major structural and operational parameters of flexible road pavements (Fig. 3). The use of the modern equipment enabling the major structural and operational parameters of flexible road pavements to be determined allows one to calculate the actual dynamic stress-strain of road pavements at their operation stage followed by calculations of actual dynamic hysteresis loops of the road structure and identifying its actual development before the experiments got underway.

86

Issue № 3 (43), 2019 |

ISSN 2542-0526 |

Input data:

Road structure:

Elasticity modulus s of the layers E1…En

Thickness of the layers h1…hn

Damping coefficients λ1…λn

Longitudinal evenness IRI

Transport load:

Total number of calculated load applications –– 115 kN

Statistical modeling of the input data based on the laws of the degradation of the highways identified in the natural experiments

E1…En

|

|

|

|

|

|

Hist ogram of |

Var3 |

|

|

|

|

|

|

||

|

|

|

Var3 = 100*2. 0000*Normal(x, 15. 2698,4. 9841) |

|

|

|

|

||||||||

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of Observations |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

|

|

|

|

|

Var3 |

|

|

|

|

|

|

|

|

h1...hn

|

|

|

|

|

|

Histogram of |

Var3 |

|

|

|

|

|

|

||

|

|

|

Var3 = 100*2. 0000*Normal( x, 15. 2698, 4. 9841) |

|

|

|

|

||||||||

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of Observations |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

|

|

|

|

|

Var3 |

|

|

|

|

|

|

|

|

λ1…λn

|

|

|

|

|

|

Histogram of |

Var3 |

|

|

|

|

|

|

||

|

|

|

Var3 = 100*2. 0000*Normal(x, 15.2698, 4. 9841) |

|

|

|

|

||||||||

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

vatonsi |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of Obser |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

|

|

|

|

|

Var3 |

|

|

|

|

|

|

|

|

ΣNр

|

|

|

|

|

|

Histogram of |

Var3 |

|

|

|

|

|

|

||

|

|

|

Var3 = 100*2.0000*Normal(x,15.2698, 4.9841) |

|

|

|

|

||||||||

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

vatonsi |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Obser |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

|

|

|

|

|

Var3 |

|

|

|

|

|

|

|

|

IRI

|

|

|

|

|

|

Histogram of |

Var3 |

|

|

|

|

|

|

||

|

|

|

Var3 = 100*2.0000*Normal(x,15.2698, 4.9841) |

|

|

|

|

||||||||

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

vatonsi |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Obser |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

|

|

|

|

|

Var3 |

|

|

|

|

|

|

|

|

Analysis of the dynamic stress-strain of the road structure using the analytical model for the investigated combinations of the input parameters

Calculating the density of the dissipated energy under the calculated vehicle’s wheel for each year of the life cycle of the road structure based on the dynamic hysteresis loops designed

for the investigated combinations of the input parameters in the spatial setting:

Wxx (σxx εxx ), |

Wyy (σyy εyy ), |

Wzz.пр (σzz εzz ) |

Summing the density of the dissipated energy on the road structure surface throughout the life cycle for the investigated combinations of the input parameters

|

|

|

|

|

|

|

Histogram |

of Var3 |

|

|

|

|

|

|

||

|

|

|

|

Var3 = 100*2. 0000*Normal(x, 15. 2698, 4. 9841) |

|

|

|

|

||||||||

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

onsi |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of Observat |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

|

|

|

|

|

|

|

|

Var3 |

|

|

|

|

|

|

|

|

W i |

W i |

|

|

|

W i |

|

|

W i |

||||||||

пр |

|

|

xx.пр |

|

|

|

|

yy.пр |

|

|

zz.пр |

|||||

Determining the calculated development as the total density of the dissipated energy in the road pavement throughout the life cycle of the specified level

95 % (Category I), 90 % (Category II), 80 % (Category III)

Fig. 3. Determining the calculated total development of the road pavement at the design stage

The difference between the calculated development of the road pavement determined in accordance with the algorithm in Fig. 3 and actual development identified at the construction stage allows the residual resource of the road structure to be calculated (Fig. 4).

87

Russian Journal of Building Construction and Architecture

Operation stage

Evaluation of the structural parameters of the road structure at the operation stage:

––elasticity modulus of the asphalt concrete layer;

––elasticity modulus

of the foundation layer;

–– elasticity modulus of the subgrade soil

–– damping coefficient

of the asphalt concrete layer;

––damping coefficient of the foundation layer;

––damping coefficient of the subgrade soil;

––damping coefficients of the layers

Evaluation of actual longitudinal evenness of the road pavement surfacing

Analysis of the dynamic stress-strain of the road structure using the analytical model for actual parameters of the road structure specified at the operation stage:

эксплxx ( xx ), |

эксплyy ( yy ), |

эксплzz ( zz ) |

Calculating the density of the dissipated energy under the calculated vehicle’s wheel for each year of the life cycle of the road structure based on the dynamic hysteresis loops in the spatial setting designed for the actual parameters specified at the operation stage:

Wxx.экспл( xx xx ), |

Wyy.экспл ( yy yy ), |

Wzz.экспл( zz zz ) |

Determining the total density of the dissipated energy in the road structure throughout the operation

period: W'экспл (Wxx.экспл Wyy.экспл Wzz.экспл ) N р

Calculation of the residual density of the dissipated energy transferred during vehicle movement:

W'ост Wполн Wэкспл

Calculation of the residual resource, residual life cycle, gamma-percentage residual resource, gamma-percentage residual life cycle

Fig.4. Determiningtheindices of theresidualresourceandresiduallife cycleof roadpavements attheoperationstage

Using the suggested approach the thickness of the reinforcement layer of road pavements can be determined that would allow the density of the energy dissipated on the surface of flexible road pavements to be reduced to the calculated (design) level (Fig. 5).

88

Issue № 3 (43), 2019 |

ISSN 2542-0526 |

Designing stage

Analysis of the dynamic stress-strain of the road structure under the calculated vehicle’s wheel for the design parameters of theroadstructure based on its life cycle:

Wxx.пр ( xx xx ), |

Wyy.пр ( yy yy ), |

Wzz.пр ( zz zz ) |

Determining the density of the dissipated energy under the calculated vehicle’s wheel based on the life cycle of the road structure:

Wпрi Wxxi .пр Wyyi .пр Wzzi .пр

Operation stage

Monitoring the operational condition of the road structure while measuring the structural parameters of the road structure

Identifying the characteristic sections of the road pavements based on the monitoring results

Analysis of the dynamic stress-strain of the road structure under the calculated vehicle’s wheel for the operational parameters of the road structure based on its life cycle:

Wxx.факт( xx xx), |

Wyy.факт( yy yy), |

Wzz.факт( zz zz ) |

Determining the density of the dissipated energy under the calculated vehicle’s wheel based on the life cycle of the road structure:

Wфактi Wxxi .факт Wyyi .факт Wzzi .факт

Comparison of Wпрi and Wфактi

Wпрi Wфактi –– the structure is operational

Wпрi Wфактi –– the structure is not operational

Choosing the thickness of the layer

Fig. 5. Method of the design of the reinforcement measures of road pavements

The approach was tested in one of the operated areas of the highway М-4 Don. The structure of the road pavement in this area is shown in Fig. 6. The total number of the calculated loads for the structure was 12 233 000 calculation loads А11.5 (115 kN) throughout the life cycle.

89