- •Important Comments

- •Legal Principles

- •Copyright

- •Personnel Qualification

- •Intended Use

- •Symbols

- •Font Conventions

- •Number Notation

- •Scope

- •Important Comments for Starting up

- •Abbreviation

- •The WAGO-I/O-SYSTEM 750

- •Technical Data

- •Manufacturing Number

- •Storage, Assembly and Transport

- •Mechanical Setup

- •Installation Position

- •Total Expansion

- •Assembly onto Carrier Rail

- •Carrier rail properties

- •WAGO DIN Rail

- •Spacing

- •Plugging and Removal of the Components

- •Assembly Sequence

- •Internal Bus / Data Contacts

- •Power Contacts

- •Wire connection

- •Power Supply

- •Isolation

- •System Supply

- •Connection

- •Alignment

- •Field Supply

- •Connection

- •Fusing

- •Supplementary power supply regulations

- •Supply example

- •Power Supply Unit

- •Grounding

- •Grounding the DIN Rail

- •Framework Assembly

- •Insulated Assembly

- •Grounding Function

- •Grounding Protection

- •Shielding (Screening)

- •General

- •Bus Conductors

- •Signal Conductors

- •WAGO Shield (Screen) Connecting System

- •Assembly Guidelines / Standards

- •Fieldbus Controller

- •Fieldbus Controller 750-841

- •Description

- •Hardware

- •View

- •Device Supply

- •Fieldbus Connection

- •Display Elements

- •Configuration and Programming Interface

- •Operating Mode Switch

- •Hardware Address (MAC-ID)

- •Operating System

- •Start-up

- •PLC Cycle

- •Process Image

- •Example of a Process Input Image

- •Example of a Process Output Image

- •Fieldbus specific Process Data Architecture for MODBUS/TCP

- •Digital Input Modules

- •Digital Output Modules

- •Analog Input Modules

- •Analog Output Modules

- •Specialty Modules

- •Data Exchange

- •Memory Areas

- •Addressing

- •Addressing the I/O Modules

- •Address Range

- •Absolute Addresses

- •Data Exchange between MODBUS TCP Master and I/O Modules

- •Data Exchange between Ethernet IP Master and I/O Modules

- •Data Exchange between PLC Functionality (CPU) and I/O Modules

- •Data Exchange between Master and PLC Functionality (CPU)

- •Example MODBUS TCP Master and PLC functionality (CPU)

- •Comparison of MODBUS TCP Addresses and IEC 61131-3 Addresses

- •Starting up an ETHERNET TCP/IP fieldbus node

- •Connecting PC and Fieldbus Node

- •Determining IP Addresses

- •Allocating the IP Address to the Fieldbus Node

- •Testing the Function of the Fieldbus Node

- •Deactivating the BootP Protocol

- •Programming the PFC with WAGO-I/O-PRO CAA

- •WAGO-I/O-PRO CAA library elements for ETHERNET

- •IEC 61131-3-Program transfer

- •Transmission via the Serial Interface

- •Transmission by the Fieldbus

- •Information on the web-based management system

- •LED Display

- •Blink code

- •Fieldbus status

- •Node status

- •Fault Message via Blink Code from the I/O-LED

- •Supply voltage status

- •Fault behavior

- •Fieldbus failure

- •Internal bus fault

- •Technical Data

- •I/O Modules

- •General

- •Digital Input Modules

- •Digital Output Modules

- •Analog Intput Modules

- •Analog Output Modules

- •Counter Modules

- •ETHERNET

- •General

- •Network Architecture – Principles and Regulations

- •Transmission Media

- •Network Topologies

- •Coupler Modules

- •Important Terms

- •Network Communication

- •Protocol layer model

- •Communication Protocols

- •ETHERNET

- •Channel access method

- •IP-Protocol

- •IP Multicast

- •TCP Protocol

- •Application Protocols

- •MODBUS

- •Ethernet/IP

- •BootP (Bootstrap Protocol)

- •HTTP (HyperText Transfer Protocol)

- •DHCP (Dynamic Host Configuration Protocol)

- •DNS (Domain Name Systems)

- •SNTP-Client (Simple Network Time Protocol)

- •FTP-Server (File Transfer Protocol)

- •SNMP V1 (Simple Network Management Protocol)

- •Configuration of SNMP

- •Description of MIB II

- •IpNetToMediaTable

- •Traps

- •SMTP (Simple Mail Transfer Protocol)

- •MODBUS Functions

- •General

- •Use of the MODBUS Functions

- •Description of the MODBUS Functions

- •Function Code FC1 (Read Coils)

- •Function Code FC2 (Read Input Discretes)

- •Function Code FC3 (Read multiple registers)

- •Function code FC4 (Read input registers)

- •Function Code FC5 (Write Coil)

- •Function Code FC6 (Write single register)

- •Function Code FC11 (Get comm event counter)

- •Function Code FC15 (Force Multiple Coils)

- •Function Code FC16 (Write multiple registers)

- •Function Code FC22 (Mask Write Register)

- •Function Code FC23 (Read/Write multiple registers)

- •MODBUS Register Mapping

- •Internal Variables

- •Description of the internal variables

- •Watchdog (Fieldbus failure)

- •Watchdog Register:

- •Diagnostic Functions

- •Configuration Functions

- •Firmware Information

- •Constant Registers

- •Ethernet/IP (Ethernet/Industrial Protocol)

- •General

- •Characteristics of the Ethernet/IP Protocol Software

- •Object model

- •General

- •Classes

- •CIP Common Classes

- •Static Assembly Instances

- •Application examples

- •Test of MODBUS protocol and fieldbus nodes

- •Visualization and control using SCADA software

- •Use in Hazardous Environments

- •Foreword

- •Protective measures

- •Classification meeting CENELEC and IEC

- •Divisions

- •Explosion protection group

- •Unit categories

- •Temperature classes

- •Types of ignition protection

- •Classifications meeting the NEC 500

- •Divisions

- •Explosion protection groups

- •Temperature classes

- •Identification

- •For Europe

- •For America

- •Installation regulations

Fieldbus Controller 750-841 • 85

Programming the PFC with WAGO-I/O-PRO CAA

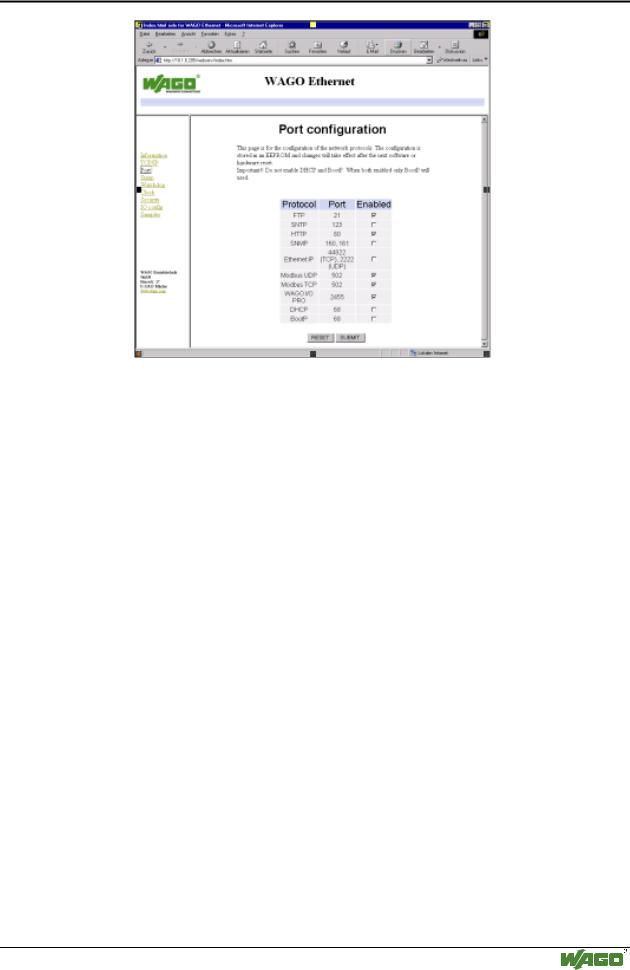

6.A list of all protocols supported by the controller is displayed. The BootP protocol is activated by default. To disable the protocol, click on the check box after BootP to remove the check mark.

7.You can disable other protocols you do not need in a similar way, or enable protocols you wish to use. It is possible to enable several protocols at the same time, since each protocol uses a different port.

8.To store the protocol selection, click the SUBMIT button and then perform a hardware reset. To do this, either switch off the power supply of the controller or press down the operating mode switch.

9.The protocol settings are now stored EEPROM and the controller is ready to operate.

3.1.7Programming the PFC with WAGO-I/O-PRO CAA

The WAGO 750-841 Programmable Fieldbus Controller (PFC) combines the functionality of an ETHERNET fieldbus coupler with the functionality of a Programmable Logic Controller (PLC). When the PFC is used as a PLC, all or some of its I/O modules can be control locally with the use of WAGO-I/O- PRO CAA. WAGO-I/O-PRO CAA is an IEC 61131-3 programming tool that is used to program and configure the 750-841 PFC. I/O modules which are not controlled locally (i.e., not controlled as a PLC), can be controlled remotely through the 10/100 Mbps ETHERNET Fieldbus port.

WAGO-I/O-SYSTEM 750 ETHERNET TCP/IP

86 • Fieldbus Controller 750-841

Programming the PFC with WAGO-I/O-PRO CAA

Note

To perform IEC 61131-3 programming in the 750-841 PFC, the WAGO-I/O- PRO port must be enabled. Enable and Disabling of this port is done with a checkbox in the “Port configuration” web page.

The purpose of this section is not to provide a comprehensive lesson on WAGO-I/O-PRO CAA programming. Instead, it highlights important programming and configuration notes of the IEC 61131-3 program when it is used with the 750-841 PFC.

More information

For a detailed description of how to use the software, please refer to the WAGO-I/O-PRO CAA manual. An electronic copy of this manual can be found on WAGO’s web site: www.wago.com

1.To start the WAGO-I/O-PRO CAA, click the Start menu item

Programs/CoDeSys for Automation Alliance/CoDeSys V2.3/ CoDeSys V2.3 .

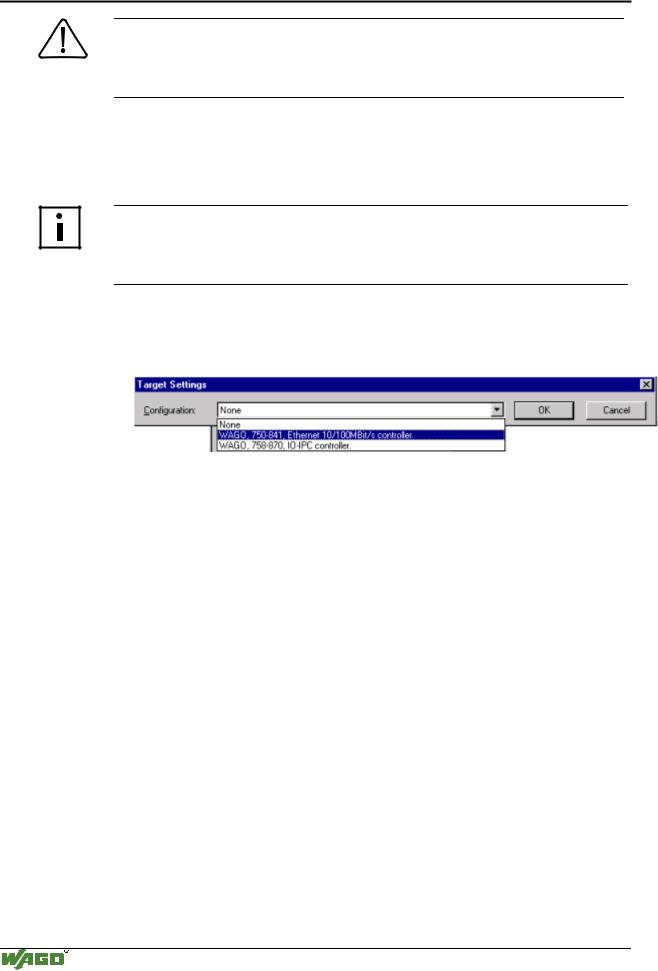

A dialog window will open. Select the target system for programming.

2.Choose WAGO, 750-841, Ethernet 10/100Mbps controller from the pull down list and click the OK button.

3.You can now create a new project in WAGO-I/O-PRO CAA via its menu item File/New. A dialog window will prompt you to select the programming language (i.e., IL, LD, FBD, SFC, etc.).

4.To access I/O modules of your node, the module configuration must first be mapped in the file "EA-config.xml". This file defines which system has write access to each particular I/O module (i.e., the IEC 61131-3 program, MODBUS TCP Fieldbus, or Ethernet IP Fieldbus).

This file can be generated in two different ways:

-in WAGO-I/O-PRO CAA

-in the “EA-config.xml” file stored in the controller.

Configuration with WAGO-I/O-PRO

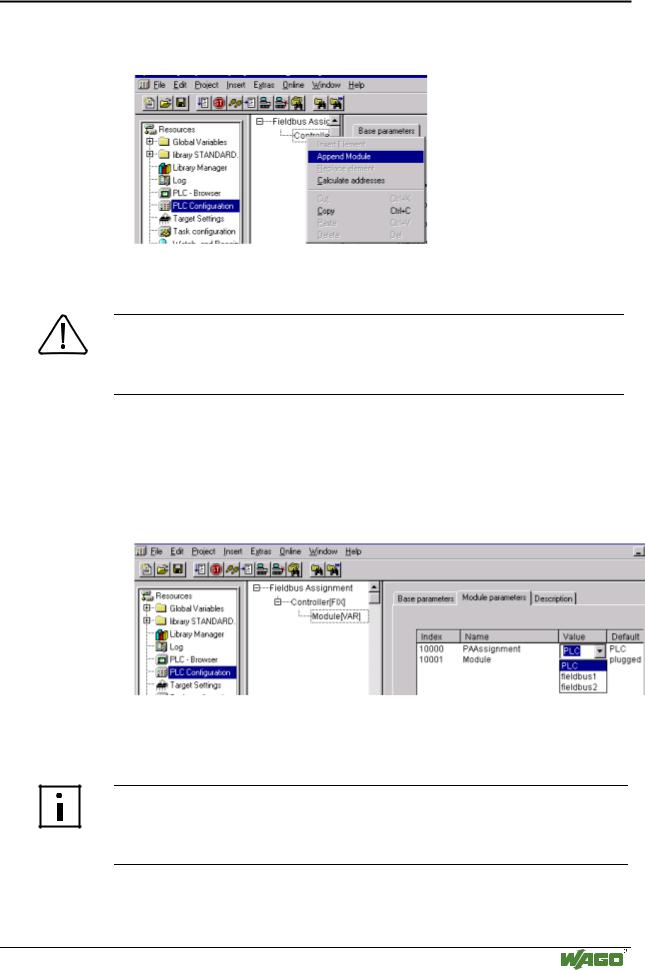

1.To configure the I/O of the fieldbus node in WAGO-I/O-PRO, select the Resources tab in the left window of the screen, then double click on PLC configuration in the tree structure.

2.The tree structure for the PLC configuration is displayed in the center window. Click on the plus sign (+) in front of Fieldbus Assignment to expand the tree structure, which then displays the text Controller[FIX] for the 750-841 controller.

WAGO-I/O-SYSTEM 750 ETHERNET TCP/IP

Fieldbus Controller 750-841 • 87

Programming the PFC with WAGO-I/O-PRO CAA

3.You can add to the tree structure in accordance with the hardware that you have by right-clicking the mouse button on the text Controller[FIX] and choosing Append Module in the context-sensitive menu that appears.

4.Add a module to the tree structure for each module in your node that supplies or expects data in bits or words.

Note

The number of modules that you add must agree with the physical hardware present (except for supply modules, potential multiplication modules, and end modules).

5.For each module added, click on the text Module[var] and then click on the Module parameters tab in the right-hand dialog window. From the dialog window, select the device (Index 10000) that will control the I/O module in the "Value" column. Your options include:

-PLC (The PFC controls its I/O locally)

-fieldbus 1 (A MODBUS TCP Fieldbus Master controls the I/O module)

-fieldbus 2 (An Ethernet IP Fieldbus Master controls the I/O module)

6.When you have completed the assignments, you can start programming with the IEC 61131-3 program tool. The configuration file “EA-config.xml” is generated as soon as you compile the project.

More information

For a detailed description on how to use the software, please refer to the WAGO-I/O-PRO CAA manual. An electronic copy of this manual can be found on WAGO’s web site: www.wago.com

WAGO-I/O-SYSTEM 750 ETHERNET TCP/IP

88 • Fieldbus Controller 750-841

Programming the PFC with WAGO-I/O-PRO CAA

Configuration with the “EA-config.xml” file

Note

If you wish to directly assign the module mapping using the EA-config.xml file stored in the controller, you must not have previously stored any configuration settings in WAGO-I/O PRO, since this file will be overwritten by the entries in WAGO-I/O-PRO on performing a download

1.Open the FTP client you wish to use (e.g., “LeechFTP”, which is freely downloadable on the Internet).

2.To access the file system of the controller, enter the IP address of the controller in the FTP client. Also, set the user name to admin and the password to wago. The “EA-config.xml” file can be found in the folder etc. on the PFC server.

3.Copy the file into a local directory on your PC and open it with a text editor (e.g., “NotePad”). The following syntax is already prepared in the file:

4.The fourth line contains the necessary information for the first module. The entry [MAP=“PLC“] assigns control rights to the IEC 61131-3 program for the first module. If you want to change the control setting, replace “PLC” with “FB1” for control rights from MODBUS TCP, or with “FB2” for control from Ethernet IP.

5.Now add under the fourth line the same syntax for each individual module with the appropriate control assignment:

<Module ITEM NO.=““ MAP=“(e.g.) PLC” LOC=“ALL”></Module>.

Note

The number of line entries must agree with the number of hardware modules present in your node.

6.Save the file and download it back to the file system of the controller using the FTP client.

7.You can now start programming with WAGO-I/O-PRO CAA.

More information

For a detailed description on how to use the software, please refer to the WAGO-I/O-PRO CAA manual. An electronic copy of this manual can be found on WAGO’s web site: www.wago.com

WAGO-I/O-SYSTEM 750 ETHERNET TCP/IP