- •Навчальний посібник для студентів-технологів

- •Костянтинівка

- •Introduction то chemistry

- •Vocabulary

- •Exercises

- •1. Answer the questions.

- •2. Match the English word combinations with their Ukrainian equivalents;

- •3. Match the Ukrainian word combinations with their English equivalents

- •From the history of chemistry

- •Vocabulary

- •Exercises

- •Answer the questions

- •6. Translate the words in the brackets into English:

- •7. Translate the text using a dictionary. Some facts about chemistry

- •D. I. Mendeleyev

- •Exercises

- •1. Answer the questions

- •2. Translate the sentences paying attention to the passive constructions:

- •3. Open the brackets choosing the suitable word. Translate them.

- •Chemistry: key to progress and abundance

- •Vocabulary

- •Fields of chemistry

- •Vocabulary

- •Exercises

- •2.Answer the questions.

- •3.Fill in the gaps with suitable words given below.

- •4.Make up sentences out of these words.

- •5. Translate into English.

- •Symbols, formulas and equations

- •Vocabulary

- •Inorganic molecules and compounds

- •Vocabulary

- •Periodic law

- •Vocabulary

- •Exercises

- •Answer the questions.

- •True or false?

- •Найважливіші хімічні елементи

- •Rules of reading formulas and equations Правила читання хімічних формул

- •Приклади:

- •The periodic table of d.I. Mendeleyev

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Read and translate the text with vocabulary Joseph Priestley

- •Laboratory equipment

- •2.Learn the words and special term from the list.

- •Describe the functions of each piece of equipment. An experiment in the laboratory

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Give Ukrainian equivalents:

- •3. Translate the sentences:

- •4. Make the questions to the sentences:

- •The molecular theory of matter and the states of matter

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Give English equivalents:

- •3. Give Ukrainian equivalents:

- •4. Translate the sentences:

- •Atomic structure

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Give Ukrainian equivalents:

- •3. Give English equivalents:

- •8. Read and translate the text Molecules

- •Chemical and physical changes

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •Find the pairs of synonyms:

- •Find the pairs of antonyms:

- •4. Translate the following sentences, mind the Participles:

- •5. Open the brackets translating the Ukrainian words:

- •Nuclear fission

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Translate the sentences into Ukrainian:

- •Open the brackets choosing the suitable word and translate them into

- •4. Translate the text in writing

- •Vocabulary

- •Exercises

- •5. Read and translate the text The Temperature Scales

- •Exercises

- •1. Give Ukrainian equivalents:

- •2. Give English equivalents:

- •Liquids

- •Vocabulary

- •Exercises

- •Exercises

- •1. Find Ukrainian equivalents:

- •2. Find English equivalents:

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Give synonyms:

- •3. Translate the following sentences:

- •Acids and bases

- •1. Extremely useful – надзвичайно корисні

- •2. Are common to all – загальні для всіх

- •3. Acetic acid - оцтова кислота

- •Vocabulary

- •Exercises

- •1. Answer the following questions.

- •2. Complete the sentences (use the text).

- •3. Characterize acids and bases using the following plan.

- •Vocabulary

- •Exercises

- •Chlorine

- •Vocabulary

- •Exercises

- •1. Answer the questions.

- •Make up a description of any element you like. Hydrochloric acid

- •Vocabulary

- •Exercises

- •Match English word combinations with their Ukrainian equivalents.

- •Answer the questions.

- •Solutions

- •Vocabulary

- •Exercises

- •Answer the questions

- •2. Translate the following sentences:

- •Nitrogen

- •Vocabulary

- •Exercises

- •Match English word combinations with their Ukrainian equivalents.

- •Answer the questions.

- •Silicon

- •Vocabulary

- •Exercises

- •Match English word combinations with their Ukrainian equivalents.

- •Answer the questions

- •Cellulose

- •Vocabulary

- •Exercises

- •Answer the questions.

- •Analytical chemistry methods of analysis

- •Methods of separation

- •Ion exchange methods in analytical chemistry

- •Ionization

- •Vocabulary

- •Exercises

- •Chromatography and ion exchange technique

- •Chromatography techniques

- •Gas analysis

- •Some physical methods used in gas analysis

- •Extraction

- •Precipitation

- •Electrolysis

- •Polymers

- •Notes and commentary

- •Vocabulary

- •Exercises

- •1. Answer the questions.

- •2. Match English word combinations with their Ukrainian equivalents.

- •3. Match Russian word combinations with their English equivalents.

- •Retell text using questions from Ex. 1 as a plan.

- •5. Read, translate and do the tasks.

- •Some applications of polymers

- •Vocabulary

- •Exercises

- •1. Read and translate the sentences. Correct the false statements.

- •2. Read the text, translate it in written form using dictionary.

- •The nature of polymeric materials

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •Find the pairs of synonyms:

- •Find the pairs of antonyms:

- •Choose the Ukrainian equivalents from the right column:

- •5. Translate the sentences

- •6. Open the brackets choosing the suitable verb:

- •7. Open the brackets choosing the correct form of the verb:

- •7. Translate the text in writing

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2.Translate the following word-combinations:

- •Translate into English:

- •4. Open the brackets translating the Ukrainian words into English:

- •5. Translate the sentences into Ukrainian:

- •6. Translate the text using a dictionary

- •Microbiological production of industrial chemicals

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •Translate the following sentences into Ukrainian, mind the sentences of the predicate:

- •3. Translate the following sentences into English, mind the use of the tenses:

- •4. Translate the following sentences into Ukrainian

- •5. Translate from Ukrainian into English

- •The chemical elements essential to life

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Find the pairs of synonyms:

- •Find the pairs of antonyms:

- •4. Translate paying attention to the meanings of the word “provide”

- •5. Open the brackets translating the Ukrainian words into English

- •6. Translate the text with a dictionary Hydrogen in industry

- •Plastics

- •Vocabulary

- •Exercises

- •Answer the questions.

- •Glass and glass products

- •Vocabulary

- •Exercises

- •Translate into Ukrainian the following international words.

- •Match English word combinations with their Ukrainian equivalents.

- •Answer the questions.

- •The nature of ceramics

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Translate the sentences:

- •7. Read and translate the texts

- •Ceramics

- •Vocabulary

- •Exercises

- •Translate the following international words into Ukrainian.

- •Answer the questions.

- •What is ecology?

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Translate the following sentences:

- •3. Translate the sentences:

- •The water problem

- •Pollution

- •Air pollution

- •Water pollution

- •Earth pollution

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Translate the following word-combinations:

- •3. Translate the following sentences into Ukrainian:

- •4. Translate the sentences into Ukrainian:

- •5. Write the translation of the following text Lead

- •The environmental protection

- •Vocabulary

- •Exercises

- •1. Match the words:

- •2. Translate the sentences into English:

- •3. Put 4 types of the questions to the sentences:

- •4. Translate the text

- •Radioactivity

- •Notes on the text

- •Vocabulary

- •Exercises

- •4. Read and translate the text The discovery of X-Rays and Radioactivity

- •5. Open the brackets and translate the sentence into Ukrainian:

- •Chernobyl nuclear power station

- •Vocabulary

- •Exercises

- •Protection of the environment

- •Industry of ukraine

- •Chemical industry

- •Texts for reading glass

- •Glass history natural glasses

- •Early glasses

- •Blowing, (b) cutting and (c) flattening. Modern glasses soda-lime-silica glasses

- •Cutting and drilling of glass

- •Glass cutting principle (scribing, flexuring).

- •Applications of glass

- •Glazing

- •Containers

- •Optical glass

- •Glass fibres for insulation and reinforcement

- •Borate and related glasses

- •Window glass

- •Sheet wire glass

- •Stemalite

- •Hardened glass for ship’s port holes

- •Safety glass for ground transport

- •Slag glass-ceramic

- •Mechanics of Glass Processes

- •Batching

- •Melting

- •Float Process

- •Fusion Draw

- •Pressing

- •Fibre Process

- •Tensile Drawing

- •Centrifugal Drawing

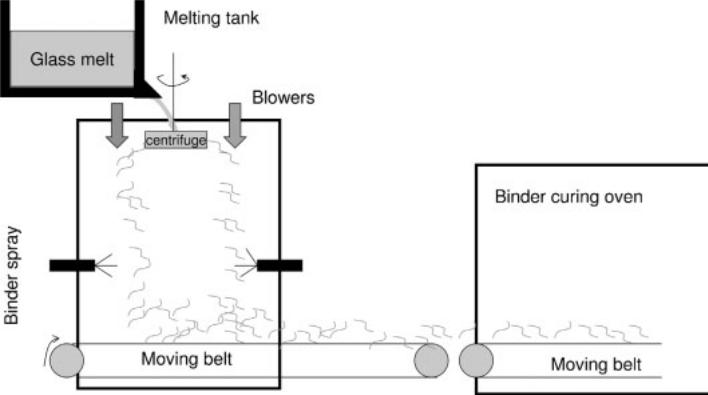

- •Wool fibre drawing process

- •Types of glass

- •Glass industry of ukraine

- •Glossary

- •Reference list

- •Contents

Pressing

Pressing

is used for widened containers (plates, cups and glasses) and also

for producing thicker cross-sections for automotive lenses. The gob

of molten glass is loaded in a mould, the plunger is lowered and

forces the glass to spread and fill the mould. Pressing can be

performed with free sides (without a ring) when dimension tolerance

is acceptable. The size of the plate or glass is then determined by

the parison temperature and the pressing force. Patterns on the

mould surface allow for imprinting the glass object and make it look

more attractive and more expensive than it is.

Pressing

is used for widened containers (plates, cups and glasses) and also

for producing thicker cross-sections for automotive lenses. The gob

of molten glass is loaded in a mould, the plunger is lowered and

forces the glass to spread and fill the mould. Pressing can be

performed with free sides (without a ring) when dimension tolerance

is acceptable. The size of the plate or glass is then determined by

the parison temperature and the pressing force. Patterns on the

mould surface allow for imprinting the glass object and make it look

more attractive and more expensive than it is.

For more dimensional control, the mould is closed by a ring allowing for production of automotive headlight lenses with high-precision shape. An automatic machine comprises 6 to 16 different moulds allowing for high production yield.

Fibre Process

Glass fibre production tools are very different when considering optical fibres, rovings or glass wool. Processes differ in the way drawing force is applied and three drawing modes are distinguished: tensile drawing, gas friction drawing, and centrifugal drawing.

Nowadays, processes employ either tensile or centrifugal drawing gas friction being combined with centrifugal drawing.

(Fibre drawing process)

Tensile Drawing

The process starts with molten glass delivered through a platinum heated orifice plate. The number of orifices varies from 200 to 8000 with diameters between 1 and 2.5mm. Glass flows through each orifice and is drawn downwards. The drawing speed determines the glass filament diameter. Common speeds are between 10 and 50ms. Rovings are produced by combining several hundred fibres (range 100–2000 filaments).

Anti-abrading treatment is then essential for keeping excellent mechanical resistance. Surface treatment also called sizing is required for adhesion to the matrix in the case of composites. In a typical fibre-forming machine, the coating applicator is located just below the fibre-forming bushing. Glass fibres leave the forming die at a temperature over 1000 ˚C and are rapidly quenched to deposition temperature (at 100 ˚C) by the aqueous sizing solution. Since the fibres are drawn under high speeds only short times.

Coatings play an essential role in the manufacturing of products made from glass fibre. Because of its abrasiveness, glass fibre would be useless if not coated during the sizing operation. In fact, without the protective coating the fibre loses its strength and destructs.

Centrifugal Drawing

Fibres used in glass wool and mats have to be chopped. Also, the surface treatment will control the performance in use. The process again starts with the glass delivery from a furnace. In 1955, Johns-Manville Company developed a process for low viscosity melt. Glass flow is dropped onto rotating cylinders spinning at an elevated velocity around their horizontal axis. Glass drops are projected from one cylinder to another before producing fibres of different lengths and reaching a moving belt downwards where remaining glass drops are aspired. Meanwhile the fibres are sprayed with organic binders with curing happening in the polymerization furnace downstream.