- •Навчальний посібник для студентів-технологів

- •Костянтинівка

- •Introduction то chemistry

- •Vocabulary

- •Exercises

- •1. Answer the questions.

- •2. Match the English word combinations with their Ukrainian equivalents;

- •3. Match the Ukrainian word combinations with their English equivalents

- •From the history of chemistry

- •Vocabulary

- •Exercises

- •Answer the questions

- •6. Translate the words in the brackets into English:

- •7. Translate the text using a dictionary. Some facts about chemistry

- •D. I. Mendeleyev

- •Exercises

- •1. Answer the questions

- •2. Translate the sentences paying attention to the passive constructions:

- •3. Open the brackets choosing the suitable word. Translate them.

- •Chemistry: key to progress and abundance

- •Vocabulary

- •Fields of chemistry

- •Vocabulary

- •Exercises

- •2.Answer the questions.

- •3.Fill in the gaps with suitable words given below.

- •4.Make up sentences out of these words.

- •5. Translate into English.

- •Symbols, formulas and equations

- •Vocabulary

- •Inorganic molecules and compounds

- •Vocabulary

- •Periodic law

- •Vocabulary

- •Exercises

- •Answer the questions.

- •True or false?

- •Найважливіші хімічні елементи

- •Rules of reading formulas and equations Правила читання хімічних формул

- •Приклади:

- •The periodic table of d.I. Mendeleyev

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Read and translate the text with vocabulary Joseph Priestley

- •Laboratory equipment

- •2.Learn the words and special term from the list.

- •Describe the functions of each piece of equipment. An experiment in the laboratory

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Give Ukrainian equivalents:

- •3. Translate the sentences:

- •4. Make the questions to the sentences:

- •The molecular theory of matter and the states of matter

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Give English equivalents:

- •3. Give Ukrainian equivalents:

- •4. Translate the sentences:

- •Atomic structure

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Give Ukrainian equivalents:

- •3. Give English equivalents:

- •8. Read and translate the text Molecules

- •Chemical and physical changes

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •Find the pairs of synonyms:

- •Find the pairs of antonyms:

- •4. Translate the following sentences, mind the Participles:

- •5. Open the brackets translating the Ukrainian words:

- •Nuclear fission

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Translate the sentences into Ukrainian:

- •Open the brackets choosing the suitable word and translate them into

- •4. Translate the text in writing

- •Vocabulary

- •Exercises

- •5. Read and translate the text The Temperature Scales

- •Exercises

- •1. Give Ukrainian equivalents:

- •2. Give English equivalents:

- •Liquids

- •Vocabulary

- •Exercises

- •Exercises

- •1. Find Ukrainian equivalents:

- •2. Find English equivalents:

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Give synonyms:

- •3. Translate the following sentences:

- •Acids and bases

- •1. Extremely useful – надзвичайно корисні

- •2. Are common to all – загальні для всіх

- •3. Acetic acid - оцтова кислота

- •Vocabulary

- •Exercises

- •1. Answer the following questions.

- •2. Complete the sentences (use the text).

- •3. Characterize acids and bases using the following plan.

- •Vocabulary

- •Exercises

- •Chlorine

- •Vocabulary

- •Exercises

- •1. Answer the questions.

- •Make up a description of any element you like. Hydrochloric acid

- •Vocabulary

- •Exercises

- •Match English word combinations with their Ukrainian equivalents.

- •Answer the questions.

- •Solutions

- •Vocabulary

- •Exercises

- •Answer the questions

- •2. Translate the following sentences:

- •Nitrogen

- •Vocabulary

- •Exercises

- •Match English word combinations with their Ukrainian equivalents.

- •Answer the questions.

- •Silicon

- •Vocabulary

- •Exercises

- •Match English word combinations with their Ukrainian equivalents.

- •Answer the questions

- •Cellulose

- •Vocabulary

- •Exercises

- •Answer the questions.

- •Analytical chemistry methods of analysis

- •Methods of separation

- •Ion exchange methods in analytical chemistry

- •Ionization

- •Vocabulary

- •Exercises

- •Chromatography and ion exchange technique

- •Chromatography techniques

- •Gas analysis

- •Some physical methods used in gas analysis

- •Extraction

- •Precipitation

- •Electrolysis

- •Polymers

- •Notes and commentary

- •Vocabulary

- •Exercises

- •1. Answer the questions.

- •2. Match English word combinations with their Ukrainian equivalents.

- •3. Match Russian word combinations with their English equivalents.

- •Retell text using questions from Ex. 1 as a plan.

- •5. Read, translate and do the tasks.

- •Some applications of polymers

- •Vocabulary

- •Exercises

- •1. Read and translate the sentences. Correct the false statements.

- •2. Read the text, translate it in written form using dictionary.

- •The nature of polymeric materials

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •Find the pairs of synonyms:

- •Find the pairs of antonyms:

- •Choose the Ukrainian equivalents from the right column:

- •5. Translate the sentences

- •6. Open the brackets choosing the suitable verb:

- •7. Open the brackets choosing the correct form of the verb:

- •7. Translate the text in writing

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2.Translate the following word-combinations:

- •Translate into English:

- •4. Open the brackets translating the Ukrainian words into English:

- •5. Translate the sentences into Ukrainian:

- •6. Translate the text using a dictionary

- •Microbiological production of industrial chemicals

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •Translate the following sentences into Ukrainian, mind the sentences of the predicate:

- •3. Translate the following sentences into English, mind the use of the tenses:

- •4. Translate the following sentences into Ukrainian

- •5. Translate from Ukrainian into English

- •The chemical elements essential to life

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Find the pairs of synonyms:

- •Find the pairs of antonyms:

- •4. Translate paying attention to the meanings of the word “provide”

- •5. Open the brackets translating the Ukrainian words into English

- •6. Translate the text with a dictionary Hydrogen in industry

- •Plastics

- •Vocabulary

- •Exercises

- •Answer the questions.

- •Glass and glass products

- •Vocabulary

- •Exercises

- •Translate into Ukrainian the following international words.

- •Match English word combinations with their Ukrainian equivalents.

- •Answer the questions.

- •The nature of ceramics

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Translate the sentences:

- •7. Read and translate the texts

- •Ceramics

- •Vocabulary

- •Exercises

- •Translate the following international words into Ukrainian.

- •Answer the questions.

- •What is ecology?

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Translate the following sentences:

- •3. Translate the sentences:

- •The water problem

- •Pollution

- •Air pollution

- •Water pollution

- •Earth pollution

- •Vocabulary

- •Exercises

- •1. Answer the questions

- •2. Translate the following word-combinations:

- •3. Translate the following sentences into Ukrainian:

- •4. Translate the sentences into Ukrainian:

- •5. Write the translation of the following text Lead

- •The environmental protection

- •Vocabulary

- •Exercises

- •1. Match the words:

- •2. Translate the sentences into English:

- •3. Put 4 types of the questions to the sentences:

- •4. Translate the text

- •Radioactivity

- •Notes on the text

- •Vocabulary

- •Exercises

- •4. Read and translate the text The discovery of X-Rays and Radioactivity

- •5. Open the brackets and translate the sentence into Ukrainian:

- •Chernobyl nuclear power station

- •Vocabulary

- •Exercises

- •Protection of the environment

- •Industry of ukraine

- •Chemical industry

- •Texts for reading glass

- •Glass history natural glasses

- •Early glasses

- •Blowing, (b) cutting and (c) flattening. Modern glasses soda-lime-silica glasses

- •Cutting and drilling of glass

- •Glass cutting principle (scribing, flexuring).

- •Applications of glass

- •Glazing

- •Containers

- •Optical glass

- •Glass fibres for insulation and reinforcement

- •Borate and related glasses

- •Window glass

- •Sheet wire glass

- •Stemalite

- •Hardened glass for ship’s port holes

- •Safety glass for ground transport

- •Slag glass-ceramic

- •Mechanics of Glass Processes

- •Batching

- •Melting

- •Float Process

- •Fusion Draw

- •Pressing

- •Fibre Process

- •Tensile Drawing

- •Centrifugal Drawing

- •Wool fibre drawing process

- •Types of glass

- •Glass industry of ukraine

- •Glossary

- •Reference list

- •Contents

Cutting and drilling of glass

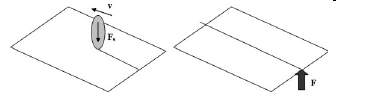

Another important aspect of contact behavior of glass is the cutting and drilling of glass sheets. Cutting is divided into three operations: scribing, flexuring and breaking.

Scribing of the glass under a sharp tip (in fact a glass-cutter wheel) allows the generation of median cracks similar to those described under a sharp indenter (one observes that for scribing a lateral movement is to be added. The applied vertical force Fs while scribing has to be controlled carefully to introduce median cracks while avoiding the generation of lateral ones that yield chips and degrade the glazing edge quality. Subsequently, the introduced median cracks are driven through the glass thickness applying tensile stresses on the indented side by bending the glazing. Scribing of good quality is achieved using sharp rollers to mark the glass and cutting oil to protect the mark from the atmosphere and so from ageing.

Cutting oil is applied on the glass surface with a pad in front of the cutting head. The plate is then bent setting the crack tip under tensile stresses to force its operations are carried out automatically on float lines.

The success of this procedure depends on the control of crack generation and flexure stress, and also on the amplitude of residual stresses that may appear during the cooling of the glass. Because of the development of thin glass and fibres, laser cutting has been developed. Thermal shock induced by the laser allows for crack formation and further development. For very thin glass (also fibres) laser-induced melting permits the direct separation (cutting) of the two pieces. One advantage of laser cutting is that in principle operations like grinding can be avoided.

Glass cutting principle (scribing, flexuring).

Applications of glass

Glass is used for a very large range of applications.The most well-known applications are glazing, container sand glass wool which correspond to the largest industrial volumes. There are many more applications, some of them appearing just recently: glass containers for long-term conservation of industrial wastes,hard disk drives, displays, glass ceramics for cooking tops, amorphous semiconductors for photocopiers and metallic glasses for golf clubs and cutting tools, metallic glasses allow for large elastic energy storages. The applications are driven by one or several properties that make the use of glass attractive. The different glasses used in their relevant fields. Obviously many applications concern optical properties. Glass fibres are employed to fabricate and strengthen composites, while borosilicate glass chemical inertness has proved to be very attractive for medical purposes.

Glazing

Soda-lime-silica

glazing is the most well-known application and is attributed to

economical reasons. Glazing can be produced as flat glass with

excellent surface quality, using the float process developed by

Pilkington in the1960s. This good surface quality encompasses

improved optical and mechanical performance. For safety reasons, in

particular in buildings and transportation, glazing are either

tempered (strengthened) or laminated, that is, formed by two

substrates bonded by a polyvinyl butyral  (PVB).Tempered

glazing offer more mechanical resistance and eventually break into

small harmless pieces. For very high strength levels required for

airplanes and trains, chemically tempered glazings are preferred.

Laminated glazing are preferred for roofs since, once breakage

happens, roofs remain in one single piece thanks to the PVB bond.

Optical transparency may be tailored by sanding, etching or rolling

the glass. This is very popular in interior architecture. Insulated

glasses allow for reducing heat transfer which occurs by radiation,

conduction and convection. Through the use of insulated glass units

with a low- conductivity gas fill between two or three panes of

glass, conductive and convective heat loss can be significantly

reduced. Radioactive heat loss requires tinted or coated glazing. In

fact, while visual transparency is in most cases required, tailored

properties have been developed in infrared (IR) and ultraviolet (UV)

domains to reduce heat transfer. For vehicles, glazings with complex

shapes are now being fabricated. In fact, glazing is an integral

part of the design of new cars. Moreover, glass roofs have become

more and more attractive. With increasing glazing surface area, anti

solar coatings are required. Such coatings are detected on the wind-

screen since they reflect blue (Renault vehicles) or pink (Pontiac

vehicles) colours. As mentioned for building applications, IR

insulation is now necessary to prevent extreme temperatures in

vehicles during summer and at the same time to reduce gas

consumption resulting from air-conditioning that equips most

vehicles having large glazing areas.

(PVB).Tempered

glazing offer more mechanical resistance and eventually break into

small harmless pieces. For very high strength levels required for

airplanes and trains, chemically tempered glazings are preferred.

Laminated glazing are preferred for roofs since, once breakage

happens, roofs remain in one single piece thanks to the PVB bond.

Optical transparency may be tailored by sanding, etching or rolling

the glass. This is very popular in interior architecture. Insulated

glasses allow for reducing heat transfer which occurs by radiation,

conduction and convection. Through the use of insulated glass units

with a low- conductivity gas fill between two or three panes of

glass, conductive and convective heat loss can be significantly

reduced. Radioactive heat loss requires tinted or coated glazing. In

fact, while visual transparency is in most cases required, tailored

properties have been developed in infrared (IR) and ultraviolet (UV)

domains to reduce heat transfer. For vehicles, glazings with complex

shapes are now being fabricated. In fact, glazing is an integral

part of the design of new cars. Moreover, glass roofs have become

more and more attractive. With increasing glazing surface area, anti

solar coatings are required. Such coatings are detected on the wind-

screen since they reflect blue (Renault vehicles) or pink (Pontiac

vehicles) colours. As mentioned for building applications, IR

insulation is now necessary to prevent extreme temperatures in

vehicles during summer and at the same time to reduce gas

consumption resulting from air-conditioning that equips most

vehicles having large glazing areas.