- •I.P. Volchok, s.B. Belikov, V.V. Gazha

- •I.P. Volchok, s.B. Belikov, V.V. Gazha, 2008

- •Contents

- •Preface

- •1 Structural materials

- •1.1. Classification and General Properties of Structural Materials

- •Fig. 1.2. The major groups of engineering materials

- •1.2. Mechanical Properties

- •Fig. 1.8. Principle of Brinell hardness test:

- •1.3. Atomic-Crystal Structure of Metals

- •Fig. 1.20. Edge dislocation in a crystal lattice

- •1.4. Solidification and Metal Structure

- •Fig. 1.25. Cooling curves for a pure metal

- •1.5. Phase Diagrams and Structure of Alloys. System of Iron-Carbon Alloys

- •1.6. Heat-Treatment of Steel

- •1.7. Chemical Heat-Treatment (Casehardening) of Steel

- •1.8. Classification and Identification of Iron-Carbon Alloys

- •2 Metallurgy

- •2.1. Materials Used in Metallurgy

- •2.2. Blast-Furnace Process

- •2.3. Steel production

- •2.4. Production of Non-Ferrous Metals

- •2.5. Powder metallurgy

- •3 Foundry practice

- •3.1. Theoretical Fundamentals of Foundry

- •3.2. Manufacture of Castings in Sand Moulds

- •3.3 Shell-Moulding Process

- •3.4. Metal Mould Casting

- •3.5. Centrifugal Casting (Spinning)

- •3.6. Pressure-Die Casting

- •3.7. Investment Casting

- •3.8. Modern Processes of Metal Production for Castings

- •4 Metal forming

- •4.1. Physical and Mechanical Fundamentals of Metal Forming

- •4.2 Recovery and Recrystallization

- •4.3. Technological Plasticity

- •4.4. Heating of Metals

- •4.5. Rolling

- •4.6. Extrusion of Metals

- •4.7. Drawing

- •4.8. Hammering

- •4.9. Die Forging

- •4.10 Stamping

- •5 Welding

- •5.1. The Physical Fundamentals of Welding

- •5.2. Arc Welding

- •5.3. Gas Welding

- •5.4. Resistance Welding

- •5.5. Diffusion Welding

- •6 Metal cutting operations

- •6.1. Principles of Cutting and Shaping the Metals

- •6.2 Geometry of a Cutting Tool

- •6.3. Cutting Speed and Chip Formation

- •6.4. Cutting Materials

- •6.5. Machine Tools Classification

- •6.6. Lathe Works

- •6.7. Drilling

- •6.8. Planing, Shaping and Slotting

- •6.9. Milling

- •6.10. Gear - Cutting Methods

- •6.11. Grinding

- •6.12. Finishing and Microfinishing Processes in Machining of Metals

- •6.13 Electrophysical and Electrochemical Machining

- •Dictionary

- •Bibliography

6.11. Grinding

Grinding is a metal cutting process carried out with abrasive grains, which are bonded by special materials. Usually grinding tool has a shape of a disk; sometimes it has a shape of a cone, a bar and so on.

The abrasive cutting has peculiarities:

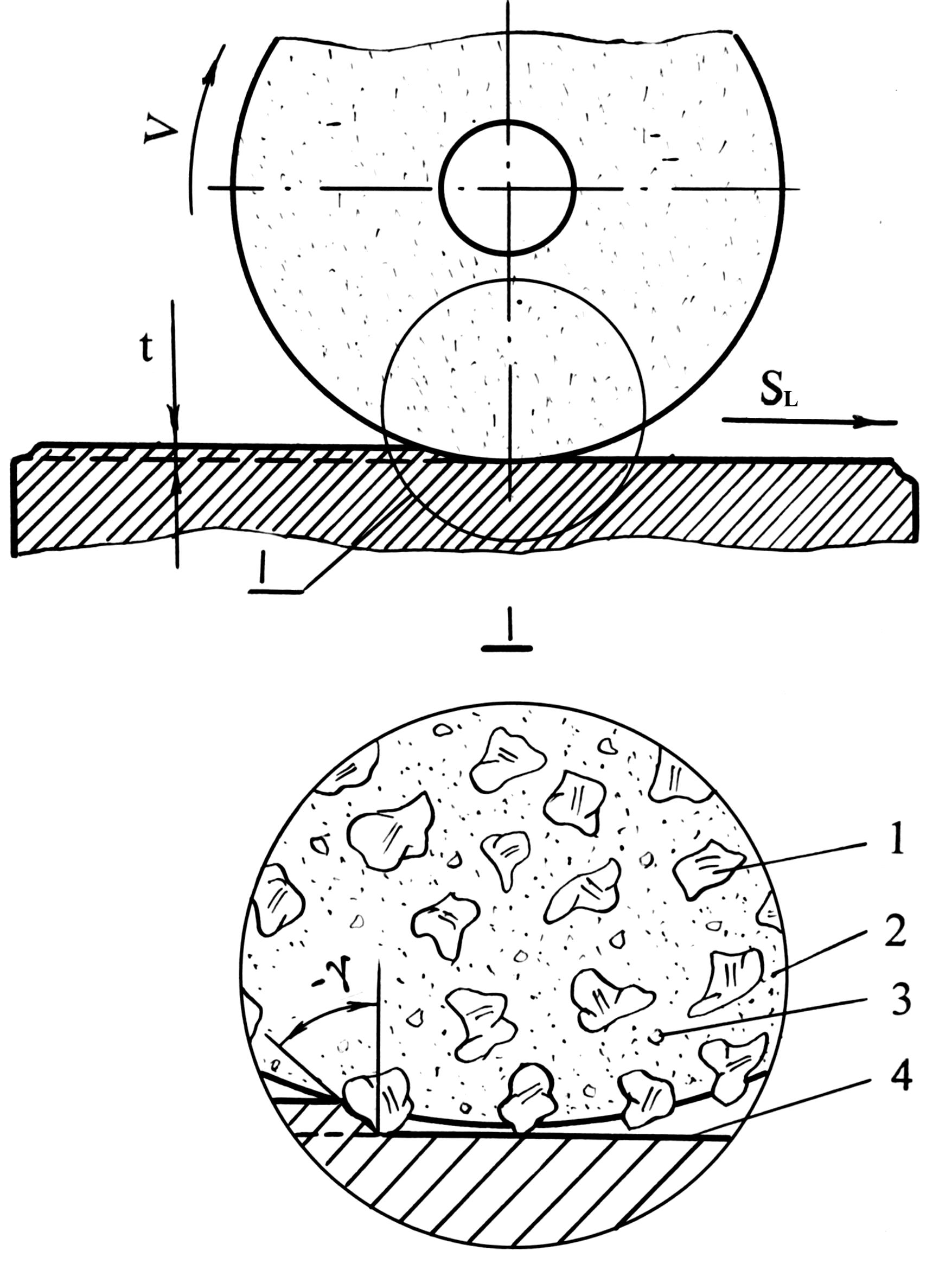

- grains have negative top rake angle (Fig. 6.23);

- the cutting speed is very high (v>30 m/sec ); the rotary speed of wheels is limited by strength of wheel bond;

- the grinding wheel is similar in action to multi-tooth milling cutter; it presents about 300 million cutting edges to a workpiece in 1 minute; grains break off periodically to present new cutting edges; bond wears away faster than grains, it allows to expose new grain for cutting; grinding wheel produces a chip just like any other cutting tool, but it is dust-fine chip, being visible only under a microscope;

- these chips are given in the form of sparks because of their high temperature.

Corundum A12O3, silica carbide SiC, boron carbide B4C and diamond C are used as abrasive materials. According to their sizes the distinction is made between:

- grains, which have sizes from 2.00 to 0.16 mm;

- powders, which have sizes from 0.12 to 0.03 mm;

- micropowders, which have sizes from 0.04 to 0.005 mm.

Fig. 6.23. Cutting by grinding tool: 1 – abrasive grain; 2 – bond (matrix); 3 – pore; 4 – blank

Fireclay, water glass, quartzite (non-organic substances) and bakelite, rubber, phenol-formaldehyde resins (organic substances) and other substances are used as a bond.

A distinguishing feature of grinding machines is a rotative abrasive tool. This group of machines is employed chiefly in finish machining operations accomplished by removing layers of metal from the work surface with an accuracy that may reach tenths of a micron and producing a very high class of surface finish.

Grinding machines handle workpieces that have been previously machined, in the most cases, in other types of machine tools, leaving a small grinding allowance of magnitude depending upon the required class of accuracy, size of the work and the proceeding machining operations to which it has been subjected.

Operations efficiently performed by grinding machine include:

- roughing and cutting off blanks;

- precise machining of flat surfaces, surfaces of revolution, profiles of gear teeth, thread and other helical surfaces, contoured surfaces, etc.;

- sharpening of all types of cutting tools.

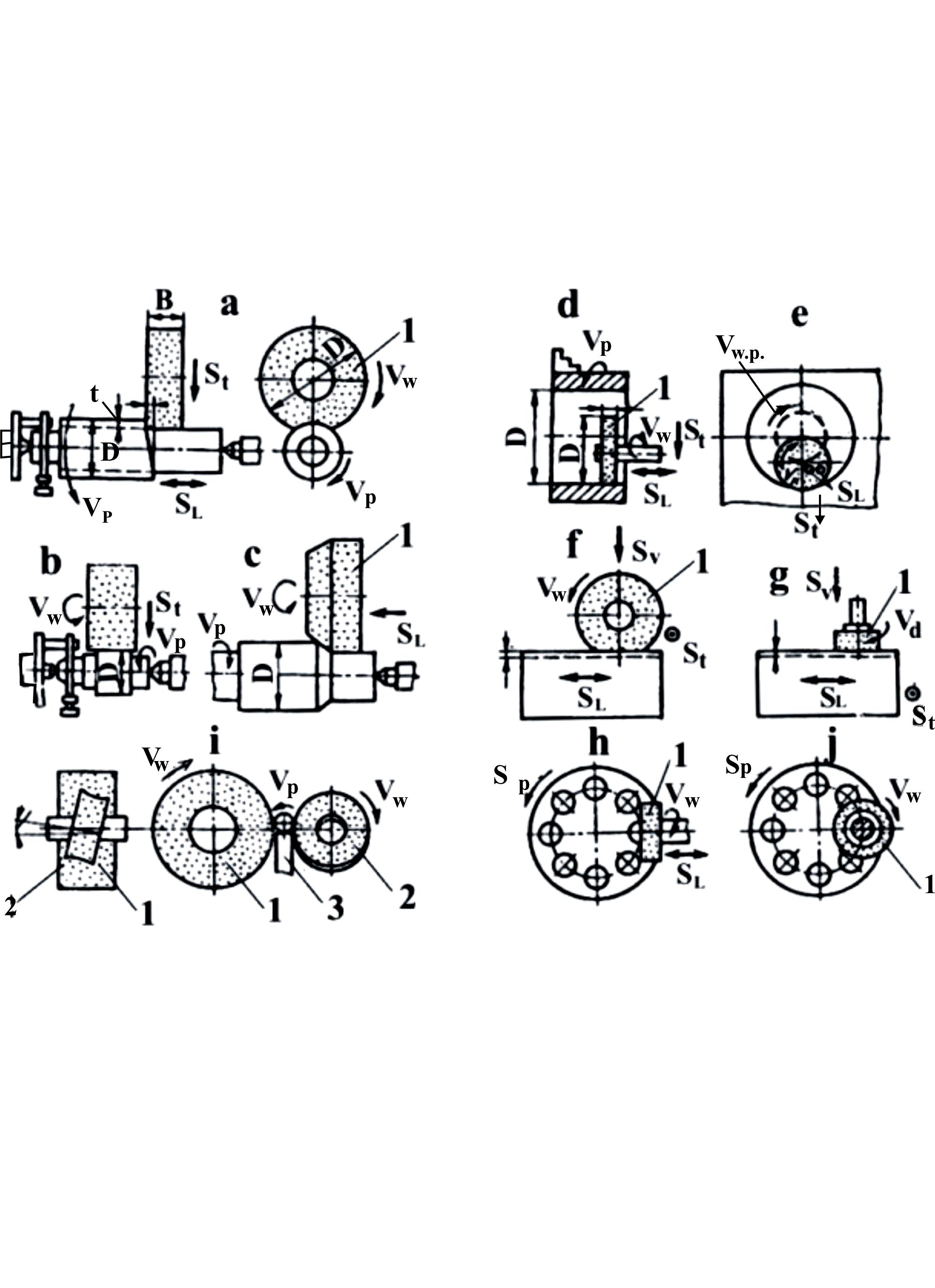

Cylindrical grinding machines (Fig. 6.24 a, b, c) are intended for grinding external cylindrical and tapered surfaces. The primary cutting motion is a grinding wheel rotation Vd. The auxiliary cutting motion is a workpiece rotation Vd. The longitudinal feed motion SL is a work motion and infeed traverse motion St is the periodic crosswise tool motion D is diameter of a workpiece, t is thickness of removed metal.

Internal grinding machines are intended for grinding cylindrical (Fig.6.24d) and tapered holes. The end faces of the workpiece are usually ground in these machines as well.

In addition to the primary cutting motion of the grinding wheel rotation Vw internal grinders of the chucking type have the following working motions:

- work revolution Vp;

- longitudinal motion (the reciprocating motion of the work or grinding wheel) SL;

- set-up - infeed motion ( the periodic crosswise motion of the wheel (wheel head) St.

In the planetary-type internal grinders (Fig. 6.24e), designed for finishing holes in workpieces of irregular shape, or large heavy workpieces, work rotation is replaced by rotation of the axis of grinding wheel in a circle about the axis of the hole being ground Vw.p.. The longitudinal motion SL is obtained by reciprocation of either the grinding wheel or work table, on which the work is clamped.

Fig. 6.24. Basic grinding operations: a, b, c, i – grinding of external cylindrical and tapered surfaces;

d, e – grinding of internal surfaces; f, g, h, j – grinding of flat surfaces; 1, 2 – abrasive disks;

3 – support (blade)

Today the most widely used types of surface grinders at the present time are the following: horizontal-spindle reciprocating-table grinders (Fig. 6.24f); vertical-spindle reciprocating-table grinders (Fig. 6.24g); horizontal-spindle rotary-table grinders (Fig. 6.24h); vertical-spindle rotary-table grinders (Fig. 6.24j).

In respect to the kind of surface they can grind, centreless grinders are classified as external (Fig. 6.24i) and internal centreless grinders. Workpiece is supported in the external centreless grinder on work-rest blade 3 and between grinding wheel 1 and regulating wheel 2. The grinding wheel rotates at a peripheral speed of 30 to 40 m per second and removes the grinding allowance from the work-piece. The regulating wheel rotates at a peripheral speed of 10 to 50 m per minute. It imparts both rotation and axial motion to the workpiece.

In the internal centreless grinder a work-piece is rotated between support roll, pressure roll and regulating roll, and is grounded by grinding wheel.