- •I.P. Volchok, s.B. Belikov, V.V. Gazha

- •I.P. Volchok, s.B. Belikov, V.V. Gazha, 2008

- •Contents

- •Preface

- •1 Structural materials

- •1.1. Classification and General Properties of Structural Materials

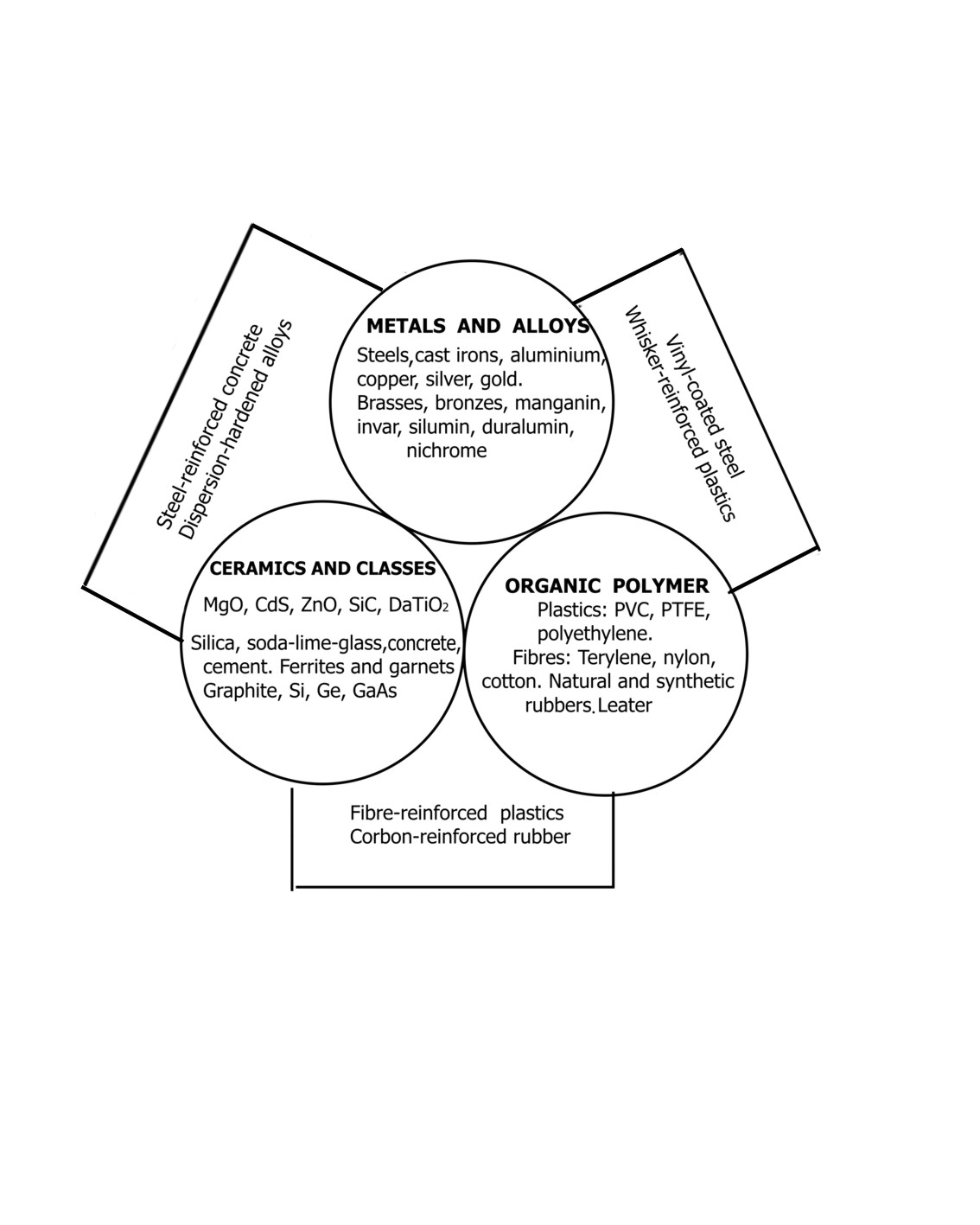

- •Fig. 1.2. The major groups of engineering materials

- •1.2. Mechanical Properties

- •Fig. 1.8. Principle of Brinell hardness test:

- •1.3. Atomic-Crystal Structure of Metals

- •Fig. 1.20. Edge dislocation in a crystal lattice

- •1.4. Solidification and Metal Structure

- •Fig. 1.25. Cooling curves for a pure metal

- •1.5. Phase Diagrams and Structure of Alloys. System of Iron-Carbon Alloys

- •1.6. Heat-Treatment of Steel

- •1.7. Chemical Heat-Treatment (Casehardening) of Steel

- •1.8. Classification and Identification of Iron-Carbon Alloys

- •2 Metallurgy

- •2.1. Materials Used in Metallurgy

- •2.2. Blast-Furnace Process

- •2.3. Steel production

- •2.4. Production of Non-Ferrous Metals

- •2.5. Powder metallurgy

- •3 Foundry practice

- •3.1. Theoretical Fundamentals of Foundry

- •3.2. Manufacture of Castings in Sand Moulds

- •3.3 Shell-Moulding Process

- •3.4. Metal Mould Casting

- •3.5. Centrifugal Casting (Spinning)

- •3.6. Pressure-Die Casting

- •3.7. Investment Casting

- •3.8. Modern Processes of Metal Production for Castings

- •4 Metal forming

- •4.1. Physical and Mechanical Fundamentals of Metal Forming

- •4.2 Recovery and Recrystallization

- •4.3. Technological Plasticity

- •4.4. Heating of Metals

- •4.5. Rolling

- •4.6. Extrusion of Metals

- •4.7. Drawing

- •4.8. Hammering

- •4.9. Die Forging

- •4.10 Stamping

- •5 Welding

- •5.1. The Physical Fundamentals of Welding

- •5.2. Arc Welding

- •5.3. Gas Welding

- •5.4. Resistance Welding

- •5.5. Diffusion Welding

- •6 Metal cutting operations

- •6.1. Principles of Cutting and Shaping the Metals

- •6.2 Geometry of a Cutting Tool

- •6.3. Cutting Speed and Chip Formation

- •6.4. Cutting Materials

- •6.5. Machine Tools Classification

- •6.6. Lathe Works

- •6.7. Drilling

- •6.8. Planing, Shaping and Slotting

- •6.9. Milling

- •6.10. Gear - Cutting Methods

- •6.11. Grinding

- •6.12. Finishing and Microfinishing Processes in Machining of Metals

- •6.13 Electrophysical and Electrochemical Machining

- •Dictionary

- •Bibliography

1 Structural materials

1.1. Classification and General Properties of Structural Materials

Structural or engineering materials are materials used to manufacture parts of structures, machines and devices. Structures are the objects without moving parts erected by engineers, such as a concrete dam, a steel melting furnace, a suspension bridge and an oil refinery tower. Machines include lathes, steam and gas turbines, engines, electric motors and generators. Devices are the most recent addition to engineering materials and refer to such innovations as a transistor, a photoelectric cell, piezoelectric pressure gauges, ceramic magnets, lasers, transformers, voltmeters, etc.

All structural materials fall into two large classes: metals and non-metals. In their turn metallic materials are divided into two groups: ferrous and non-ferrous metals or alloys. The examples of ferrous metals are iron, manganese and chrome. Ferrous alloys are the combination of more than one metal, or metals and non-metals. Ferrous metals and alloys are divided into steels and cast irons (Fig. 1.1). The rest of metals (copper, aluminium, titanium, nickel, silver, gold, etc.) are referred to as non-ferrous ones and used both in pure state and as alloys. Non-metallic materials fall in two groups: organic (wood, leather, plastic, rubber, etc.) and non-organic (ceramics, glass, concrete, graphite, etc.) ones. Organic materials are polymers whose molecules consist of many repeating links.

Another way of classifying the engineering materials is based on their nature:

metals and alloys;

ceramics and glasses;

organic polymers.

Metals and alloys possess characteristic appearance. In addition to their capability of changing permanently their shape, metals and alloys have good thermal and electrical conductivity. Ceramics and glasses are nonmetallic inorganic substances, which are brittle and have good thermal and electrical insulating properties. Organic polymers are relatively inert and light and generally have a high degree of plasticity. Fig. 1.2 lists typical examples from each of these three groups of materials. In addition, a number of examples of materials, which are composites, made up of two groups also shown.

To manufacture any machine, device, or part of a machine an engineer must know properties of structural materials. There are several kinds of properties of structural materials such as physical, chemical, mechanical, technological and service ones.

The physical properties include mass density, melting point, heat and electric conductivity, thermal expansion, magnetic saturation and permeability, etc.

Fig. 1.1. Classification of structural materials

The chemical properties of materials determine their ability to resist moist air, acids and other aggressive media. Hence, corrosion and oxidation resistance are one the main chemical properties.

Structural materials must possess sufficiently high technological properties such as machinability, malleability, weldability, foundry properties (fluidity, shrinkage, etc.) Thus, the technological properties indicate how much labor, machine time, tools and materials are needed to produce a machine part.