- •I.P. Volchok, s.B. Belikov, V.V. Gazha

- •I.P. Volchok, s.B. Belikov, V.V. Gazha, 2008

- •Contents

- •Preface

- •1 Structural materials

- •1.1. Classification and General Properties of Structural Materials

- •Fig. 1.2. The major groups of engineering materials

- •1.2. Mechanical Properties

- •Fig. 1.8. Principle of Brinell hardness test:

- •1.3. Atomic-Crystal Structure of Metals

- •Fig. 1.20. Edge dislocation in a crystal lattice

- •1.4. Solidification and Metal Structure

- •Fig. 1.25. Cooling curves for a pure metal

- •1.5. Phase Diagrams and Structure of Alloys. System of Iron-Carbon Alloys

- •1.6. Heat-Treatment of Steel

- •1.7. Chemical Heat-Treatment (Casehardening) of Steel

- •1.8. Classification and Identification of Iron-Carbon Alloys

- •2 Metallurgy

- •2.1. Materials Used in Metallurgy

- •2.2. Blast-Furnace Process

- •2.3. Steel production

- •2.4. Production of Non-Ferrous Metals

- •2.5. Powder metallurgy

- •3 Foundry practice

- •3.1. Theoretical Fundamentals of Foundry

- •3.2. Manufacture of Castings in Sand Moulds

- •3.3 Shell-Moulding Process

- •3.4. Metal Mould Casting

- •3.5. Centrifugal Casting (Spinning)

- •3.6. Pressure-Die Casting

- •3.7. Investment Casting

- •3.8. Modern Processes of Metal Production for Castings

- •4 Metal forming

- •4.1. Physical and Mechanical Fundamentals of Metal Forming

- •4.2 Recovery and Recrystallization

- •4.3. Technological Plasticity

- •4.4. Heating of Metals

- •4.5. Rolling

- •4.6. Extrusion of Metals

- •4.7. Drawing

- •4.8. Hammering

- •4.9. Die Forging

- •4.10 Stamping

- •5 Welding

- •5.1. The Physical Fundamentals of Welding

- •5.2. Arc Welding

- •5.3. Gas Welding

- •5.4. Resistance Welding

- •5.5. Diffusion Welding

- •6 Metal cutting operations

- •6.1. Principles of Cutting and Shaping the Metals

- •6.2 Geometry of a Cutting Tool

- •6.3. Cutting Speed and Chip Formation

- •6.4. Cutting Materials

- •6.5. Machine Tools Classification

- •6.6. Lathe Works

- •6.7. Drilling

- •6.8. Planing, Shaping and Slotting

- •6.9. Milling

- •6.10. Gear - Cutting Methods

- •6.11. Grinding

- •6.12. Finishing and Microfinishing Processes in Machining of Metals

- •6.13 Electrophysical and Electrochemical Machining

- •Dictionary

- •Bibliography

3.3 Shell-Moulding Process

The shell-moulding process (shell-mould casting) was developed in Germany during the second word war (introduced in the USSR in 1950 on Leningrad carburetor plant).

The principal characteristics of the process are:

- production of castings with high standard of surface finish and dimensional accuracy;

- high productivity from a small floor space;

- reduction in mould and core sands consumption up to 10 times.

In conventional sand moulding the sand grains are bonded by clay, whereas, in shell moulding the clay is replaced by a synthetic resin. The shell-moulding mixture consists of 6...7 % of synthetic resin (phenolformaldehyde resin) and fine grain sand as a rest. Low thickness of shell mould (6 to 20 mm) does not prevent gas evacuation and allows to use a fine grain sand (silica, magnesite or zirconium sands).

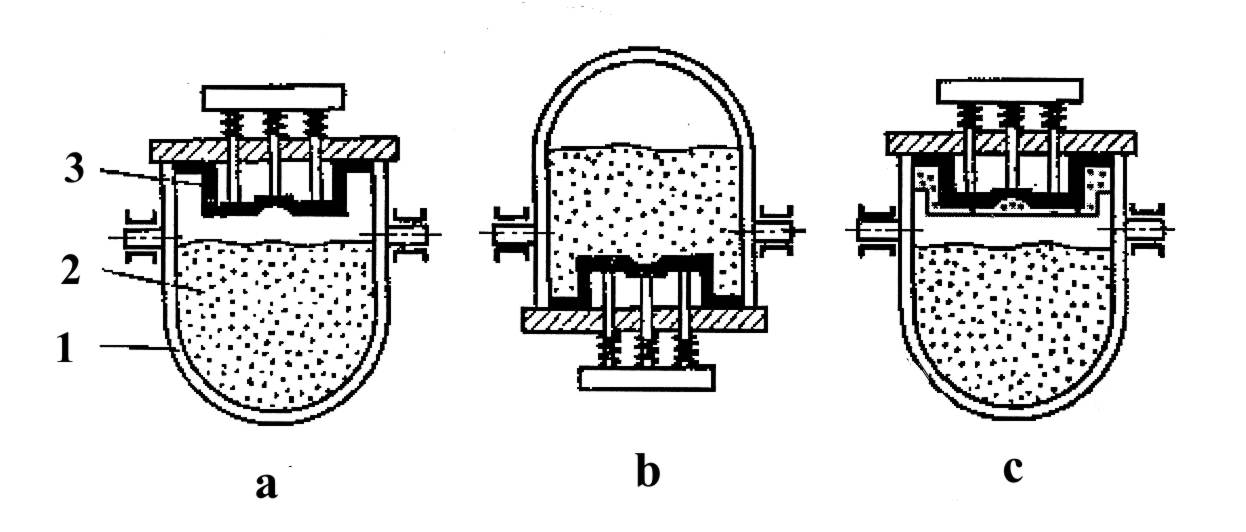

Figure 3.10 shows the successive steps of shell-making.

Fig. 3.10. Shell making process: a – initial position; b – shell formation;

c – a shell on the pattern and pattern plate; 1 – box; 2 – sand-resin mixture; 3 – pattern

The metal pattern plate and pattern 3 are preheated to 200...220°C by electric heaters and placed with the pattern facing downward on top of a turning dump box 1 filled with sand-resin mixture 2. The box is turned over and resin-sand mixture covers the pattern by a layer of about 350...400 mm. The hot plate and pattern causes the resin to soften and flow with sand grains producing precise imprint of the pattern. Chemical reactions take place in the heated resin that enables to bond grains of sand. After about 20 seconds changes are only partially completed, but the shell is formed. Next, the dump box is inverted, the shell of sand, bonded by the partly cured resin, adheres to the pattern plate, the remainder of the mixture falls back into container and is available for subsequent use. The pattern is placed in an oven for final solidification (curing). This is carried out at about 400°C and may take up to 2 min. When curing is completed the shell is hard and rigid and can be stripped from the pattern by means of spring-loaded ejector pins.

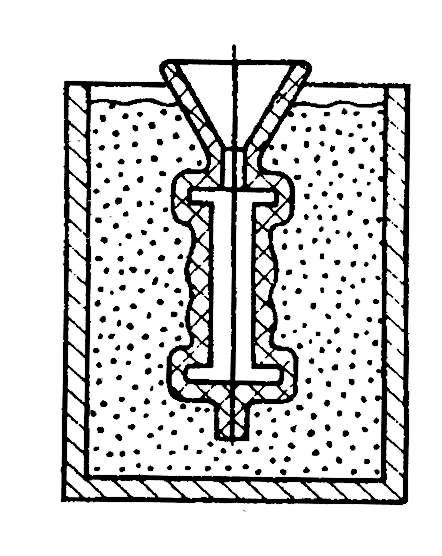

Two such shells form a complete mould and are mutually fixed by gluing or by clamps before being poured. As a rule shell moulds are surrounded in a box by sand or by cast iron shot before pouring (Fig. 3.11). After hot metal pouring resin burns, shell mould is destroyed and shake out operation is not required.

Fig. 3.11. Shell mould

Main disadvantage of the method is high price of phenolformaldehyde resin and pulverbakelite. For this reason mass of castings does not exceed 100kg. Usually, the shell-moulding process is mechanized and automatized.

3.4. Metal Mould Casting

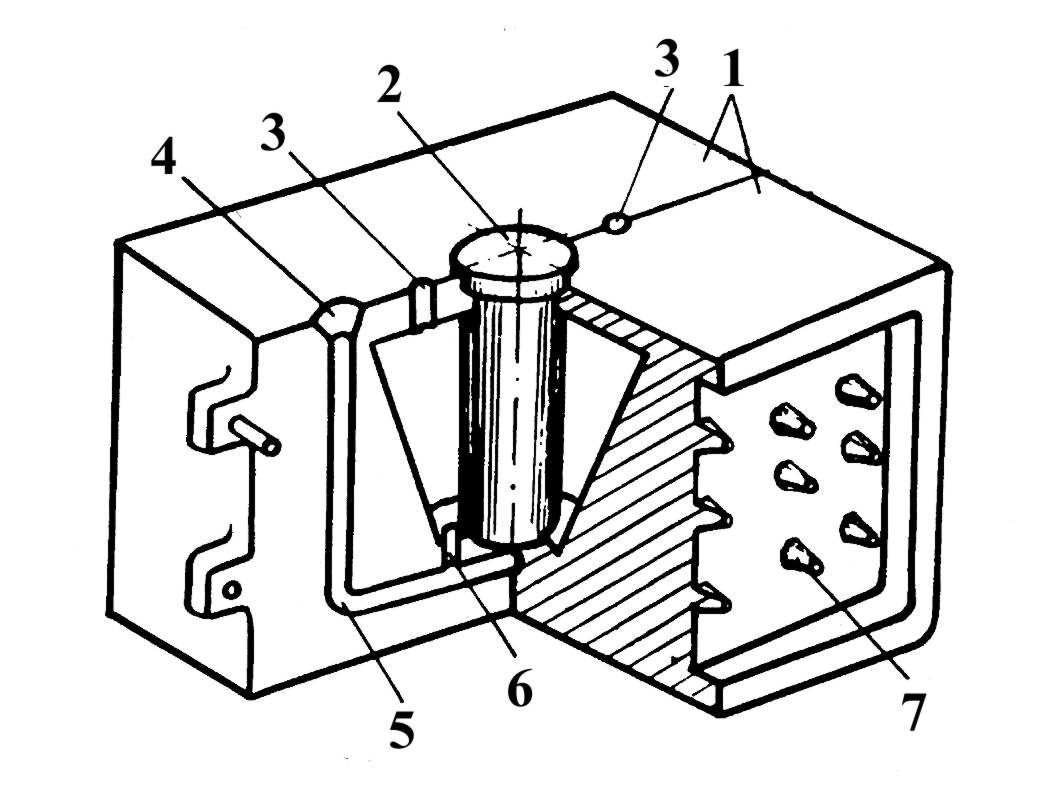

Unlike the ordinary sand mould process, the molten alloy is poured in metal mould, named permanent mould, or gravity die (Fig. 3.12). About 15% of castings are produced using this method. The pattern is not needed. Both metal and sand cores are used to make cavities in cast pieces.

The metal mould life is equal to: dozens and hundreds of thousand castings produced when Al and Mg alloys are poured; thousands castings produced of Cu-alloys and cast iron; hundreds castings produced of steel.

Fig. 3.12. Metal (chill) mould: 1-half-moulds; 2-core; 3-gas relief sprue; 4-pouring basin;

5-downgate; 6-ingate (runner); 7-dowels for high-rate heat removal

The advantages of the method are the following:

- the metal mould is used repeatedly to obtain large number of castings;

- stable sizes of the metal mould provide stable sizes of casting and small machining allowance;

- high heat conductivity of the metal mould provides high rate of crystallization, high density, fine structure and high mechanical and service properties;

- structure segregation is developed rarely;

- sand mixes are not used or used in small quantities;

- high production rate from a small floor space;

- patternless method.

The disadvantages of the method are characterized by the following facts:

- the metal mould does not possess gas permeability that sometimes provokes gas porosity in castings;

- the metal mould is rigid, i.e. is not compliant to shrinkage and may cause casting's cracking;

- cast iron chilling appears sometimes as a sequence of high cooling rate.

To prevent cast iron chilling and increase service life the moulds are heated to 150...450°C and painted with refractory paint before pouring. About 45 % of aluminium and magnesium, 30 % of copper, 12 % of cast iron and 6 % of steel castings are produced in metal moulds.

Usually metal mould machines are used. They may be mechanized, semi-automatic and automatic machines.

Metal moulds are normally made of cast iron. Sometimes steel is used. But cast iron has better service properties and lower price.