- •1 What shall the crew do during bunkering operations?

- •2 Why shall care be taken?

- •3 What does the Pollution Emergency Team do?

- •1 What must Master do with cargo operations?

- •2 Whom shall Master notify?

- •3 What must regularly carried out and be as thorough and realistic as possible to exercise all crewmembers in their emergency duties ?

- •1 What should be followed if the hull's watertight integrity has been breached?

- •What should be done to fix the damages to own vessel?

- •What measures are taken if any risk of pollution exists?

- •1 What are the types of lifeboats?

- •2 What do wooden or metal lifeboats require?

- •3 What is the best course from the damaged ship?

- •1 What safety equipment are cargo and passenger vessels equipped with?

- •2 How are all liferafts installed?

- •3 What is the weight of liferaft?

- •1 What is every master obliged?

- •2 What is the responsibility of the Maritime Rescue Coordinating Centre ?

- •3 What does the abbreviation mrcc mean?

- •1 How should every drill be planned?

- •2 Where are tasks or instructions accepted attentively?

- •3 What does the unit leader do?

- •1 What should all crew members do before lowering a lifeboat?

- •2 Where is a chain pendant secured?

- •3 Where is other end shackled to?

- •1 What is the main material used in a ship?

- •2 Where are paints stowed?

- •3 What is the main protective coating?

- •The loaded voyage

1 What should all crew members do before lowering a lifeboat?

2 Where is a chain pendant secured?

3 Where is other end shackled to?

Deck maintenance

The main material used in a ship is steel. Unfortunately, steel rusts when in contact with air, water or salt solutions. To prevent the corrosion of steel, the metal is coated with cement wash, bitumen and paint. Cement wash is a mixture of cement powder and fresh water. It is used in freshwater tanks and double bottom tanks. Bitumen is used in bilges and peak tanks. It is also used on metal decks before they are covered with wood.

The main protective coating is paint There are many types, of paint in a wide variety of colors...Paints, are stowed in the paint locker, which is usually situated under the forecastle..

The most common kinds of paint on-board-ship are: metal . primers, undercoats, top coats, heat-resistant paints, non-slip paints and varnishes.

Metal primers are applied to a bare surface to give protection against rust and to act as a key to the next coat.

'Undercoats are used over the primer before the top coat.

Top coats give a hard-wearing surface and the required color.

Heat-resistant paints are used for radiators and pipes and for the ship's funnel.

Non-slip paints arc used on weather decks and other suitable surfaces such as companion-ways.

Varnishes give a clear protective coat to woodwork.

For painting, the surface of a ship's hull is divided into three areas: the topside, boot-topping and bottom. Topside paint is applied to the area of the ship's hull which is out of the water when the ship is loaded. Boot-topping is applied to that area of the hull which is out of. the water when the ship is in the light condition and under water when the ship is loaded. A ship's bottom is given a coating of anti- fouling paint. Anti-fouling paints contain toxicants which are poisonous to. marine life. The toxicants have to dissolve out of the paint into the water in order to be effective.

Before an area is painted, proper preparation is^ important. The area must be cleaned and washed with a cleaning solution to remove all" salt,, dirt and oil. The paintwork must be rinsed with clean fresh water and all the cleaning solution removed. Loose paint and scale is removed with a scraper and heavy rust with a chipping hammer. Finally, a wire brush must be used on all bare metal to remove the last" of the scale, before the first coat of paint is applied.

1 What is the main material used in a ship?

2 Where are paints stowed?

3 What is the main protective coating?

Contract of employment.

It is a sort of document between the Company or the Owner and the seaman. It shall bet signed by the master of the ship on behalf of the Shipping Company and the seaman. The Contract consists of several points and as a rule the number of which extend to 15.

Firstly the seaman is required to state his date and place of birth, nationality, and passport number. Seaman's book number, home address, next of kin are to be indicated as well. The position of his being engaged the name and type of the ship form a part of the document. The essential item is duration of employment. It may last from six up to nine "months plus / minds 1-2 at Owner's option. But the contract can be extended further subject to mutual consent of the parties to this agreement.

The second item is wages. Payment starts upon departure and ends upon s/off-disembarkation from the vessel. Breakdown of total monthly wages include basic wages, S.W.A., leave pay, fixed overtime for all in hours. It is further more explained that overtime apply only to ratings, officers' wages are inclusive everything.

The next one is hours of work. The normal work week consists of. forty hours as determined and prescribed by the Master, always in conformity with international maritime standards and practices. The seaman, however, will also work during such hours and at such times as may be ordered by the master, but always in accordance with the seaman's duties and position on board. It is also stated in the contract that the holidays are: New Year's Day (January 1-st), Easter (Good Friday, Easter Monday), Labour Day (May 1-st), Christmas Day (December 25-th), Second Day of Christmas (December 26-th). But the seaman will not be given extra compensation for any hours of duty necessitated by an emergency affecting the safety of the vessel, the passengers, the crew or the cargo; or in fire, boat, or emergency drill or work required to give assistance to other vessels or persons in immediate peril.

The item "Payment" explains that the seaman will be paid up 80 % of his total monthly earnings either by way of allotment to, his bank or family or by shipboard advances. The rest 20% will be paid to the seaman by the Master/Company upon completion of his contract.

Probationary period implies two months during which the company reserves the right to dismiss the seaman if the Master is not satisfied with his

services. In such a case this crew member is repatriated at his own expenses. If the seaman decides to terminate his engagement before the expiration of the contract period, he shall give the Master a thirty day notice in writing and pay his repatriation expenses.

Sometimes the Company can terminate the seaman's Contract, sign off and repatriate the seaman within-the first eight months of the contract paying him at the same time a severance; pay of two weeks' basic wages if a ship has been wrecked, sold laid-up or abandoned or the voyage undertaken can not be continued because of war, warlike activities, embargo or blockade. .

One of the Contract items is war and war-like operation. The seaman will be entitled to a bonus of 100% of his basic wages for the period during which the ship is within the so declared war or war-like zone.

The Contract also includes the item named accident - illness / insurance. The Company undertakes to keep the crew covered at all times with a reputable P +1 Club. If during the contract period the seaman suffers an accident or becomes ill, but not because of his own wilful act, default or misbehaviour, and must be repatriated according to doctor's orders, he is to receive for as long аг his treatment ashore lasts (but more than three months) a payment equal to 100 % of his monthly basis wages, effective from the date of his disembarkation. The medical care provided to the seaman shall be in compliance with the vessel's P+I Club insurance. Other possible cases of the seaman's disability and injuries are also described in detail. .

Two more items are given in the Contract. They are "Jurisdiction" and "Contribution to Union".

They explain where the seaman can address in the event of any dispute or disagreement between him and the Company and his agreement for monthly deduction from his wages as contribution to Seaman's Union.

The Contract of employment is dated and signed by the Seaman and Company/Master. The place is stated as well as witness to the contract (his signature).

1 What shall be signed by the master of the ship on behalf of the Shipping Company and the seaman?

2 When does the payment start?

3 What is the second item of employment contract?

Safety Methods While:

TAKING A PILOT ABOARD

1 Preparing of the pilot ladder is provided on the side required; 2.Prepairing of the life-buoy.

OPENING THE HATCHETS OF THE HOLDS

1. In dependence of the type of the hatch covers act accordingly. 2. Before closing the hold hatchets sweep off the comings.

MOORING

1 .Get ready the anchors;

-eliminate foam off the fairleads;

-remove fairlead sacks;

-remove(retake) clothing.

2.Remove brake lockers & dog stoppers, to keep the anchor chain only by band locker(breaker)

Switch on hydraulic pumps(motors) of the windlass.

Disengage anchor chain to be paid off the gear (or both).

5. On boatswain's (officer's) order to disengage band locker & pay out indicated number of shackles.

6. On boatswain's order to fix band locker

7. Having been assured that the vessel is brought up you may leave the forecastle.

8. To indicate the vessel been brought up,

day time at the forecastle - black ball is exhibited;

night time- anchor lights all round the forecastle & stern are exhibited.

TOWING ARRANGEMENT

1. Before every towing to all components of the towing arrangement particular attention should be paid to the towing hooks & winches state.

2. It is prohibited components of towing appliance not accordingly used.

3. When towing the vessels are prohibited to stay close to the towing hook, winch and at the tension line of towing hawser.

4. While paying out the towing hawser from forecastle and bollards it is prohibited to stay close to & ahead of the hook & bollards.

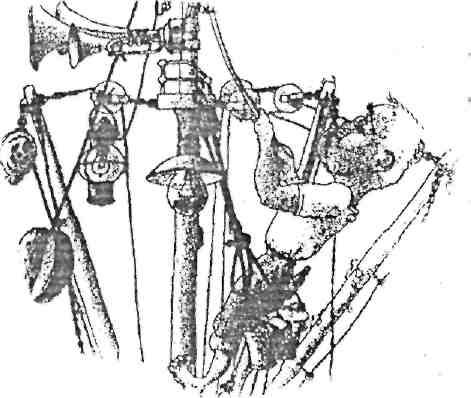

ANCHOR GEAR

■

1.Before letting go & heaving up the anchors it is necessary to assure in absence of persons in the chain locker & near by the fairleads;

& when being in port - also in persons absence in navigating craft under the fairleads.

2.When operating anchor gear, boatswain is prohibited

a) to leave the windlass control position when it is operating

b) to disengage chain drums against windlass gears not having assured in reliable fixing of anchor chain by band lockers.

3. It is prohibited to stay at the chain line ahead & back of the windlass while it is operating .

4. It is prohibited when staying in ports to leave the anchor chains fixed only by band lockers.

INTRODUCTION

Introduction.

According to UK Club research, a quarter of all major claims are for cargo liabilities.

Many claims occur because of the different interests of shippers, receivers, cargo handlers, charterers and shipowners.

This video focuses on bulk carriers, identifying frequent causes of cargo claims and ways to avoid them.

UK Club statistics show that:

nearly half of all major claims on UK Club bulk carriers stem from cargo damage

Dry bulk accounts for half of these, followed by steel and bagged bulk

Water causes most damage, often from leaking hatch covers

structural failure is much more prevalent in bulk carriers than in any other ships

Taking care of business saves lives and money.

BEFORE LOADING - PREPARING THE SHIP SEQUENCE

Being aware that contamination causes many claims.

Preparing holds appropriately.

The importance of asking for written instructions.

Difficulties in carrying out instructions because of sea conditions, port labour restrictions and regulations prohibiting discharge of cargo residues.

Safely clearing residues from the hold.

Persuading stevedores to leave a grab for residues.

Washing holds during the ballast voyage only when safe.

Being aware that many contamination claims are caused by cargo residues, loose scale and insects.

Realising that water does most damage to cargo.

Checking manhole covers are sealed and sounding pipes are clear.

Remembering that leaking hatch covers cause 50% of claims.

The importance of checking hatch covers by:

careful visual inspection

hose testing

chalk testing

ultrasonic testing

and logging the results.

Rinsing holds with fresh water.

Checking clean holds for signs of structural damage.

UK Club statistics showing two thirds of structural failure claims involve ships between 14 and 21 years old.

The importance of acting on early warnings of failure.

Drying holds and checking ventilators.

Disinfecting the bilges and burlapping gratings.

Limewashing to prevent corrosion.

Checking with cargo interests before painting.

Taking photographic and video records.

Passing pre-loading surveys first time - helped by

checking the charterer's particular requirements before arrival.

CHECKING CARGO CONDITION BEFORE LOADING

Being aware that damage to cargo before loading results in one in ten major claims.

Taking care to establish the cargo's "apparent order and condition" - protecting lives as well as dollars.

Responsibilities of the ship's officers for spotting

obvious defects like mouldy grain, contaminated ores and unsuitably packed cargoes such as chemicals.

Appreciating the condition of steel varies so much that P&l Clubs have issued standard clauses for use on Bills of Lading.

Protecting the ship's interests by good record keeping.

Considering the effect one cargo can have on others, such as problems of taint, infestation or dangerous cargo.

Understanding the chemical hazards of bulk cargoes with the help of IMO publications.

Being aware of major problems from loading wet cargoes:

wet steel rusting dry steel

ore with excess moisture upsetting the ship's stability

Responsibility of the shipper to provide details of a

cargo's characteristics including any chemical hazards and both its permitted and actual moisture limits.

Checking for excess moisture using particular methods explained in the IMO Code of Safe Practice.

Realising that one in ten major cargo claims could have been prevented by spotting the cargo's poor condition before loading.

Insisting on information from the shipper and contacting the Club for advice

CARGO HANDLING AND STOWAGECargo Handling and Stowage

Being aware that defective cargo handling equipment can cause injury or death as easily as damage.

Knowing that most countries have strict rules about the condition of this equipment enforced by inspections.

Maintaining gear properly before arrivals:

keeping safe working loads clearly visible

checking all controls and safety features

lubricating moving parts

freeing wires and seizing shackle pins

safe access to control positions

alerting onshore specialists if needed to await arrival

Loading cargo after establishing its apparent good order and condition.

Responsibility of the master for the actions of

stevedores - how their different interests help explain why improper loading or poor stowage cause one in five cargo claims.

Avoiding problems with stevedores by telling them:

when to segregate cargo

to keep bags clean

not to use untreated dunnage

correct use of slings

Master's legal obligation to stop or protest any practices that threaten seaworthiness.

Loading problems caused by:

overfilled grabs

dropping high density cargoes on unprotected tank tops

fewer high tonnage pours

jump loading

-loading to a ship's mark to eliminate sag - loading in the rain

- taking short cuts

Overcoming challenges posed by the most common bulk cargoes including:

Grain - applying the IMO Grain Rules on filling and trimming holds

- sampling cargo regularly to detect sprouting, mould, infestation and dampness

Ores - preventing excess moisture from liquifying cargo

Coal -the hazards of exceeding the Transportable Moisture Limit

- stopping loading in the rain

- seeking expert advice if heating is suspected Steel - never letting cold rolled steel get wet

taking special care to remove water if loading hot rolled steel in moderate rain

avoiding the overloading of slings, landing coils too heavily, and stowing with moisture releasing cargoes

following detailed guidance on securing cargoes