- •Electronic Configurations & Oxidation States

- •Physical properties

- •Physical Properties. Summary Some Alkaline-Earth Metals Subgroup Trends

- •History Of Discovery

- •Preparation

- •In industry:

- •Alkaline-earth metals chemical properties (1)

- •Alkaline-earth metals chemical properties (2)

- •Alkaline-earth metals chemical properties (3) Compounds hydrides

- •Tests for alkali and alkaline-earth metals subgroups elements

- •Hardness of water and its removal

Preparation

Beryllium is obtained by two most important methods:

1. Reduction of BeF2 with metallic magnesium

BeF2 + Mg = MgF2 + Be (powder)

2. Electrolysis of molten mixture BeCl2 + NaCl (at 350С) at cathode: Be2+ + 2e = Be

Magnesium is obtained by:

1. Electrolysis of fused MgCl2 or carnalitte. Obtaining 1 ton of Mg requires about 20 MWt-hours of electric energy.

2. Electrothermal method is based on the reversible reaction:

MgO

+ C

![]() Mg

+ CO H

= 640 kJ/mol,

Mg

+ CO H

= 640 kJ/mol,

equilibrium of which is displaced to the right at higher than 2000C temperature. MgO mixture with grinded coal is made red hot in electric furnace, the vapor of Mg which is formed, is mixed up with strongly cooled gaseous Н2 at the exit of the furnace. The temperature there quickly drops to 150-200C so that there is no time for equilibrium to be desplaced to the left. Dust-like magnesium obtained is then remelted.

In industry:

Ca and Sr: 1. Electrolysis of molten mixtures CaCl2 and CaF2; SrCl2 and KCl,

2. Alumothermy in vacuum:

4CaO + 2Al = 3Ca + CaO·Al2O3

2SrO + 2Al = 3Sr + Al2O3

Ba: alumino- or silicothermy in vacuum at 1200С:

3BaO + 2Al = 3Ba + Al2O3

3BaO + Si = 2Ba + BaSiO3

The annual production of metallic Са makes up several thousand tons, the output of Sr and Ba is much less because of much less application. The Ra accumulated world wide makes up about 2.5 kg.

Uses

Magnesium is the third most commonly used constructional metal, following steel and aluminium. In large volumes Mg is used in a free state: reducing agent in metallothermy, corrosion protection (marine ships, gas pipelines), for making of strong and light alloys (mostly in automotive and truck components – alloy of Mg with Al (magnaly) and under the name “electron” a series of Mg alloys with Al (up to 10.5%), Zn (up to 4.5%) and Mn (up to 1.7%) is known. An interesting feature of these alloys is that they (unlike Al), are indifferent towards solutions of alkalis and HF. Economy of mass which is achieved as a result of using the electron, makes up nearly 80% as compared to Fe, 20-40% - with duralumin, more than 40% - with wood.

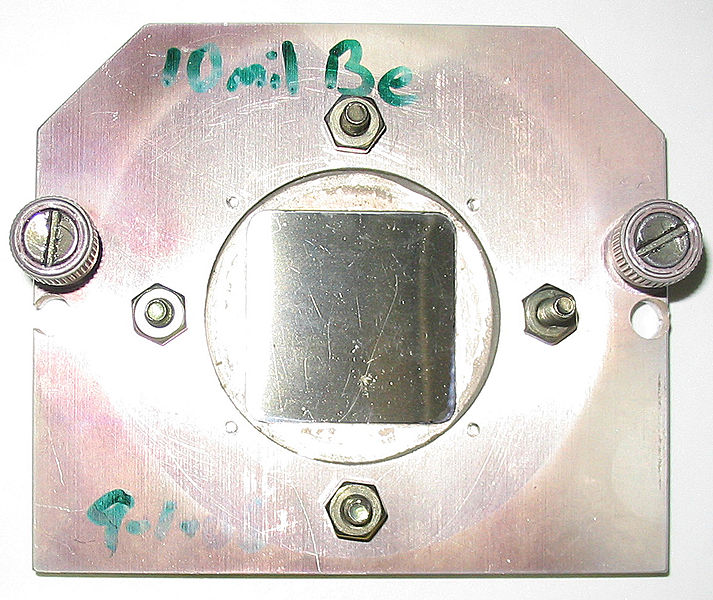

Metallic Be is used for making “windows” in X-ray devices (radiation windows for X-ray tubes). Beryllium, due to its low atomic number, is highly transparent to X-rays. Its alloys with copper (up to 2% Be only) are named beryllium brasses. They have steel hardness and extraordinarily high mechanical strength. Remember that Be is poisonous.

Alkaline-earth metals chemical properties (1)

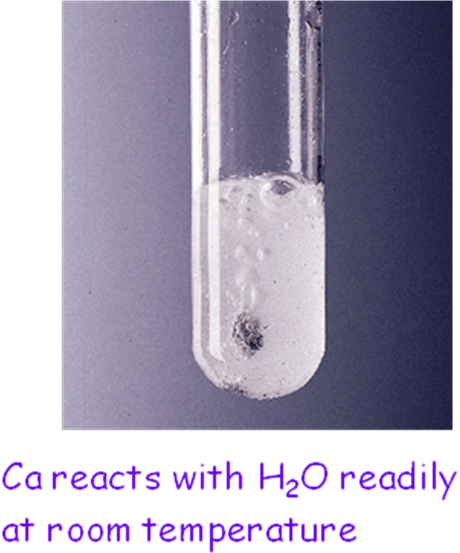

Ca, Sr, Ba. These metals are very reactive. Activity grows towards Ва.

Already in the dry air Ca, Sr, Ba surfaces are quickly covered with gray films, which are not protective and consist of oxide, peroxides and nitrides.

2Ca + O2 = 2CaO

Ba + O2 = BaO2

3Sr

+ N2

![]() Sr3N2

Sr3N2

At STP they react with non-metals very vigorously. At slight heating they also react with usually chemically extremely inert N2. Akaline-earth metals interact with C, Si, B at high temperatures:

Me + 2C MeC2

Me + 2Si MeSi2

Me + 6B MeB6

Except for halogenides and chemically stable refractory borides, those binary compounds are decomposed even in water with the formation of hydroxides and hydrogen compounds:

Me3N2 + 6H2O = 3Me(OH)2 + 2NH3

MeC2 + H2O = Me(OH)2 + C2H2

At elevated temperatures Ca, Sr, Ba react with Н2 with the formation of stable hydrides МeН2.

Their reaction with water and acids results in the formation of H2, and with HNO3 they form NH4NO3.

At heating alkali-earth reduce metals and non-metals oxides to the elemental substances, which is used (especially, Ca) for obtaining of free metals (U, Th, Cr, V):

V2O5 + 5Ca 5CaO + 2V