- •Inorganic chemistry

- •0514 Branch “Ecology”

- •Inorganic chemistry……..

- •Introduction

- •Lecture 1. Hydrogen

- •History of discovery

- •N 1 in periodic system

- •Occurrence

- •Physical properties

- •Industrial production of hydrogen

- •1. Iron-steam method

- •Chemical properties

- •Classification of hydrides

- •Lecture 2. Oxygen

- •Physical properties

- •Selected properties of the oxygen atom and molecule

- •History of discovery

- •A. Lavoisier

- •Oxygen occurrence

- •Oxygen preparation

- •Preparation in laboratory

- •5. Electrolysis of water

- •Oxygen as a ligand

Industrial production of hydrogen

The abundance of hydrogen compounds is colossal; therefore H2 production is determined only by demand and energy sources of a country.

1. Iron-steam method

4H2O + 3Fe = Fe3O4 + 4H2; Go = – 70.3 kJ

Although G <0, this reaction proceeds at a sufficient rate only at high temperature.

2. Reduction of hydrogen by carbon. At to> 1000 оС water steam interacts with incandescent coke forming water-gas (Н2 mixture with the carbon (II) oxide):

H2O + С = СO + H2

More frequently water-gas together with water steam is passed above catalyst (Fe or Co oxide) at 400оС , with СО conversion taking place:

СО + H2O(steam) = СO2 + H2

СO2 is easily removed from H2 by bubbling the resulting gaseous mixture through water under pressure.

3. Electrochemical preparation of H2. The electrolysis of water is conducted in alkaline solutions (16-18% NaOH or 25-29% KOH). The processes on electrodes (Fe or Ni) are shown below:

cathode: 2H2O + 2e- = H2 + 2OH- ;Eo = –0.83 V

anode : 4OH- = O2+ 2H2O + 4e- ;Eo = 0.401 V

Hydrogen obtained is very pure, but the process is energy consumptive. In accordance with theoretical evaluations about 2.8 kWh-hours is necessary to obtain 1 m3 of Н2 at STP. It is almost by 2 times less than in reality, due to overvoltage () of hydrogen evolved depending on the nature of electrode material, resistance of electrolyte, and the presence of diaphragms. Thus, about 20% of total output of hydrogen is produced by electrolysis. The electrolysis of water is conducted in alkaline solutions (16-18% NaOH or 25-29% KOH). The electrode processes (on Fe or Ni) are presented below:

cathode: 2H2O + 2e- = H2 + 2OH- ;Eo = –0.83 V

anode : 4OH- = O2+ 2H2O + 4e- ;Eo = 0.401 V

Especially pure hydrogen of more than 99.99% purity can be produced by electrolysis of hot barium hydroxide aqueous solutions on nickel electrodes. As shown above, this process is really energy expensive.

4. Liquefying of coke gas. Liquefying of coke gas is the main source of raw of hydrogen for NH3 synthesis. Coke gas is produced at high temperatures (at pyrolysis) of anthracite coal and contains: 55% Н2, 25% CH4, 2% ethane, 4-6% СО, 2% СО2 and 10-12% N2. The higher is the temperature of annealing of coal, the more is Н2 yield.

5. Interaction of methane with water steam. High temperature (~1100оС) interaction of CH4 with water steam and some oxygen at constant pressure is used to produce Н2 for the synthesis of NH3 and for hydrogenation coal:

CH4 + H2O(steam) = СО + 3Н2; Но = +204.6 kJ

CH4 + O2 = СО2 + H2O(steam) + 802.5 kJ

Therefore the components of the reaction are chosen and its concentrations are selected so that the process is slightly exothermic:

Conversion of CH4 takes place at 800оС, nickel catalyst is used. In petroleum refineries, hydrogen forms as a by-product from hydrocarbon processing.

GAS H2 PREPARATION IN A LABORATORY

1. Interaction of alkali and alkaline-earth metals with water:

2Na + 2H2O = 2NaOH + H2

Ca + 2H2O = Ca(OH)2 + H2

Since Na reacts with H2O too vigorously, Na amalgam is used that reacts more slowly. This method can be used for reduction “in the moment of liberation” («in statu nascendi») by atomic hydrogen.

2. Interaction of calcium hydride with water:

CaH2 +2H2O = Ca(OH)2 + 2H2

In this case, 0.94 kg of СаН2 is only required to produce 1 m3 of hydrogen. Even a less LiH mass (0.357 kg) is necessary to produce the same amount of hydrogen. For these reasons LiH is used in the safety “air-jackets” of marine aviation pilots.

3. Interaction of some metals with solutions of acids. For example:

Zn + 2H+ = Zn2+ + H2

Solutions of strong acids are used for this purpose (but not HNO3). The preparation of 1 cubic meter of H2 by such method requires 2.9 kg Zn or, for example, 2.5 kg Fe.

4. Interaction of aluminum or silicon with caustic alkalis:

2Al + 2 NaOH + 6H2O = 2Na[Al(OH)4] + 3H2

Si + 4NaOH = Na4SiO4 + 2H2

To obtain 1 cubic meter of hydrogen 0.81 kg Al or 0.63 kg Si are required, therefore the second method is more economically efficient.

USES

The chemical industry uses hydrogen gas in many industrial chemical processes. The largest use of industrial hydrogen is in ammonia (NH3) synthesis. The other applications can be mentioned in the catalytic hydrogenation of unsaturated liquid vegetable oils to solid, edible fats (margarine) in food industry; in the manufacture of bulk organic chemicals, particularly methanol, by the Oxo Process using a cobalt catalyst:

CO + 2H2 = CH3OH

Metallurgists use hydrogen to produce pure metals from their oxides.

Hydrogen gas that is lighter than air was once used by people to lift zeppelins and other airships into the sky, allowing trans-Atlantic voyages by air. However, the gas being so flammable, contributed to many explosive accidents.

Industries can use hydrogen's reaction with oxygen to create energy:

2H2 + O2 = 2H2O + energy

People may someday use hydrogen as fuel for automobiles, refrigerators, and airplanes, if it becomes easier to distribute, store, and use. Automobile manufacturers are developing vehicles that are powered by hydrogen fuel cells, devices that use hydrogen to produce electricity. The aerospace industry already uses liquid hydrogen as a fuel for rockets. Hydrogen fuel could also cut pollution, since it mostly produces water when it burns. Nuclear engineers and scientists use the hydrogen isotope deuterium and deuterium oxide (D2O), which is also called heavy water, to help control nuclear power plants and to perform experiments. Deuterium and tritium are also used in nuclear weapons, because they combine into helium and release energy more readily than protium does.

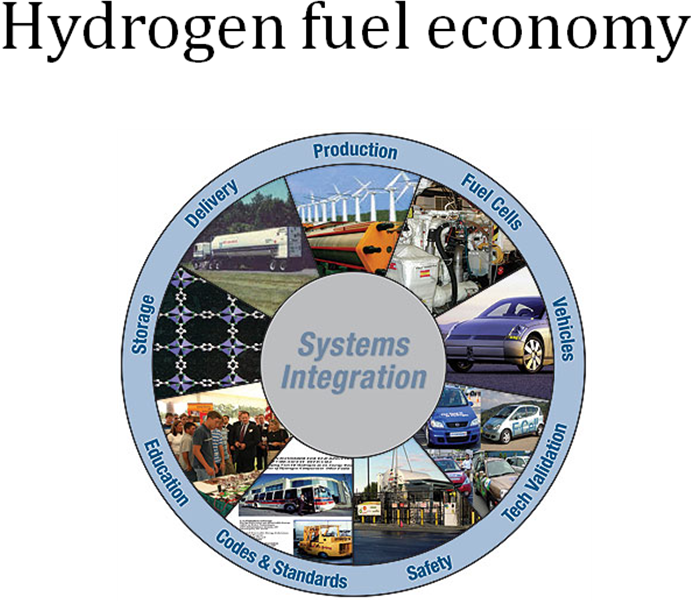

The diagram illustrating significance of hydrogen as an alternative fuel and the base of new economy is shown below (http:// ...):