- •Idle Speed Adjustment

- •Отметить

- •Предостережение

- •Предостережение

- •Отметить

- •Отметить

- •If any spoke brakes, it should be replaced immediately. A missing spoke places an additional load on the other spokes, which will eventually cause other spokes to break.

- •Caution

- •Caution

- •If dirt or dust is allowed to pass through into the throttle assy, the throttle may become stuck, possibly causing an accident. Caution

- •If dirt gets through into the engine, excessive engine wear and possibly engine damage will occur.

- •Caution

- •Caution

- •3.0 L (When filter is removed)

- •3.4 L (When engine is completely dry)

- •A warning

- •Install the clamp screws horizontally as shown. Otherwise the screws could come in contact with the vacuum adjusting screws, resulting in an unsafe riding condition.

- •Caution

- •Caution

- •Caution

- •Caution

- •If dirt or dust is allowed to pass through into the carburetor, the throttle may become stuck, possibly causing accident. Caution

- •If dirt gets through into the engine, excessive engine wear and possibly engine damage will occur.

- •Caution

- •Coolant Flow Chart

- •Caution

- •Caution

- •Valve Closing Temperature (for reference)

- •Caution

- •Caution

- •Caution

- •Caution

- •Caution

- •Caution

- •Caution

- •Inlet sprocket must use "l" marked bolt holes. Exhaust sprocket must use "e" marked bolt holes.

- •Valve Seating Surface Outside Diameter

- •Valve Seating Surface Width

- •Valve/Valve Guide Clearance (Wobble Method)

- •Valve Seat Cutter Holder - 05.5 Valve Seat Cutter Holders Bar

- •Caution

- •5700-1097 [C] Piston Base, 02.3: 5700-1336 [d]

- •Install the clamp screws horizontally. Otherwise the screws could come in contact with the vacuum adjusting screws, resulting in an unsafe riding condition.

- •Caution

- •Caution

- •Caution

- •If new dry steel plates and friction plates are installed, apply engine oil to the surfaces of each plate to avoid clutch plate seizure.

- •Caution

- •Caution

- •If the oil passage plug is removed while the engine is warm, hot engine oil will drain through the oil passage; take care against burns.

- •Оглавление

- •Caution

- •Коленчатый вал/Коробка Передач

- •92028-1692 Crankcase

- •Caution

- •Caution

- •Caution

- •Caution

- •Caution

- •Inside Circlip Pliers: 57001-143

- •Caution

- •A warning

- •Caution

- •Caution

- •Caution

- •Final drive 11-1 11

- •Inside Circlip Pliers: 57001-143

- •Brakes 12-1 12

- •Inside Circlip Pliers: 57001-143

- •Immediately wash away any brake fluid that spills.

- •Caution

- •Immediately wash away any brake fluid that spills.

- •Immediately wipe up any brake fluid that spills.

- •Immediately wipe up any brake fluid that spills.

- •Caution

- •Immediately wipe up any brake fluid that spills.

- •Suspension 13-1 13

- •Caution

- •If the inner tune is badly bent or creased, replace it. Excessive bending, followed by subsequent straightening, can weaken the inner tube.

- •Caution

- •Caution

- •Steering 14-1 14

- •Table of Contents

- •A warning

- •Frame 15-1 15

- •Inspection.................................. 16-46

- •Installation ................................. 16-51

- •Inspection.................................. 16-61

- •Inspection.................................. 16-62

- •Igniter Checker Assembly: 57001-1378

- •Caution

- •Initial Charge

- •Caution

- •Caution

- •If by chance an excessive amount of gas is generated due to overcharging, the safety valve operates to keep the battery safe.

- •Caution

- •If possible, do not quick charge. If the quick charge is done due to unavoidable circumstances, do standard charge later on.

- •Caution

- •Caution

- •Caution

- •Caution

- •Ignition System

- •Ignition System Circuit

- •Ignition System

- •Caution

- •Ignition System

- •Ignition System

- •Ignition Timing

- •Ignition System

- •Caution

- •Ic Igniter Operation Voltage Check

- •Ignition System

- •Ic Igniter Operation Voltage: Battery Voltage

- •Ignition Coil Primary Peak Voltage Inspection

- •Ignition System

- •Ignition Coil Primary Peak Voltage Standard: dc100 V or more

- •Ignition System

- •Ignition System

- •Ignition System note

- •Caution

- •Valve noise:

Caution

If the inner tune is badly bent or creased, replace it. Excessive bending, followed by subsequent straightening, can weaken the inner tube.

Temporarily assemble the inner and outer tubes, and pump them back and forth manually to check for smooth operation.

If you feel binding or catching, the inner and outer tubes must be replaced.

A straightened inner or outer fork tube [B] may fail in use, possibly, causing an accident. Replace a badly bent or damaged inner or outer tube, and inspect the other tube carefully before reusing it.

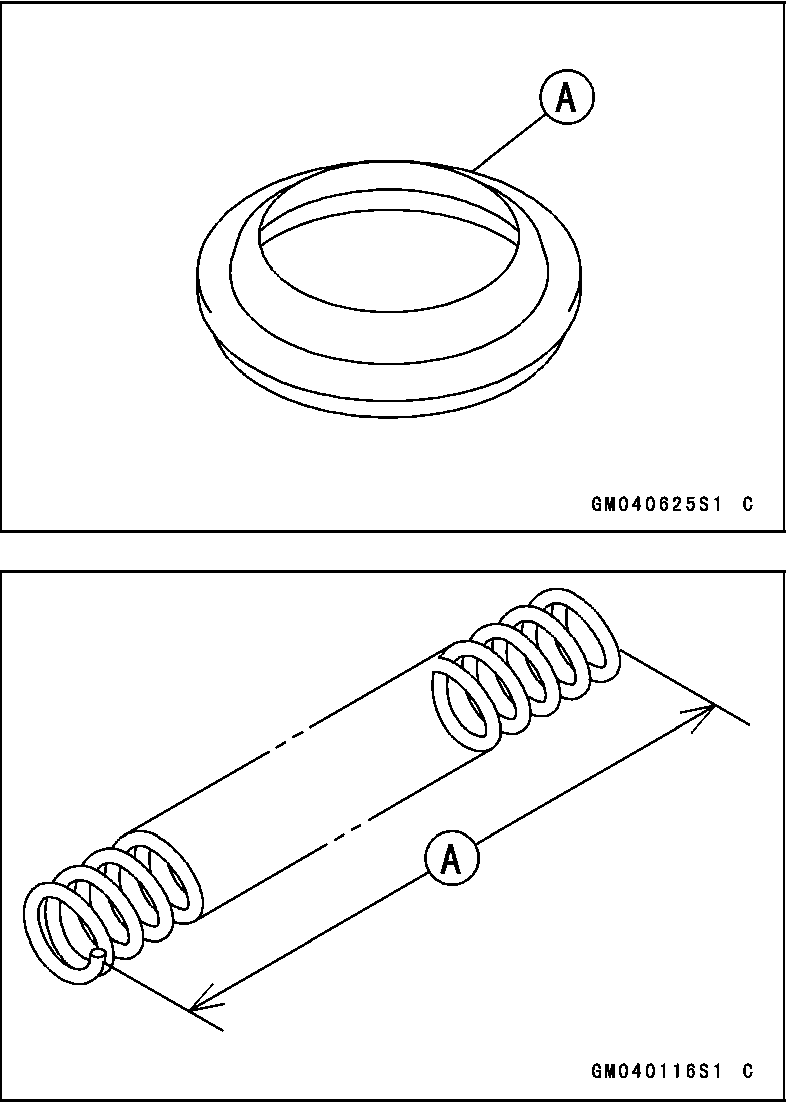

Inspect the dust seal [A] for any signs of deterioration or damage.

Replace them if necessary.

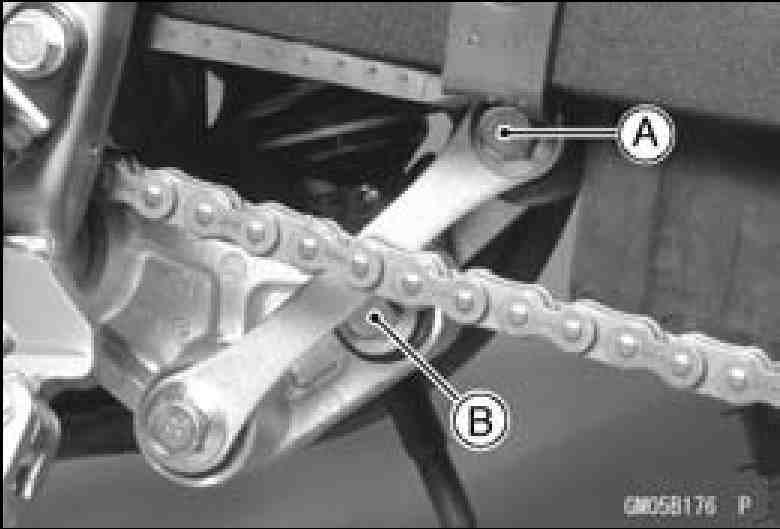

Spring Tension

Since the spring becomes shorter as it weakens, check its free length [A] to determine its condition.

If the spring of either fork leg is shorter than the service limit, it must be replaced.

If the length of a replacement spring and that of the remaining spring vary greatly, the remaining spring should also be replaced in order to keep the fork legs balanced for motorcycle stability.

Spring Free Length Standard: 522.5 mm (20.57 in.)

Service Limit: 512 mm (20.16 in.)

SUSPENSION 13-13 Rear Shock Absorber

The spring preload adjuster on the rear shock absorber has 5 positions so that the spring tension can be adjusted for different road and loading conditions.

• Using the hook wrench [A], turn the adjuster to adjust the spring tension.

Spacial Tool - Hook Wrench: 57001-1101

OThe standard adjuster position for an average-build rider of 68 kg (150 lb) with no passenger and no accessories is 2nd step from the weakest position.

• If the spring action feels too soft or too stiff, adjust it in accordance with the following table.

Spring Preload Adjustment

Position |

Spring Force |

Setting |

Load |

Road |

Speed |

1 |

Strong t ¦ 4 Weak |

Soft t ¦ 4 Hard |

Light t ¦ 1 Heavy |

Good t ¦ 1 Bad |

Low t ¦ 1 High |

2 |

|||||

3 |

|||||

4 |

|||||

5 |

Rear Shock Absorber Removal

Squeeze the brake lever slowly and hold it with a band [A].

Set the jack under the engine and raise the rear wheel.

Special Tool - Jack: 57001-1238

Remove the seat (see Seat Removal in the Frame chapter).

Remove the Side Covers (see Side Cover Removal in the Frame chapter).

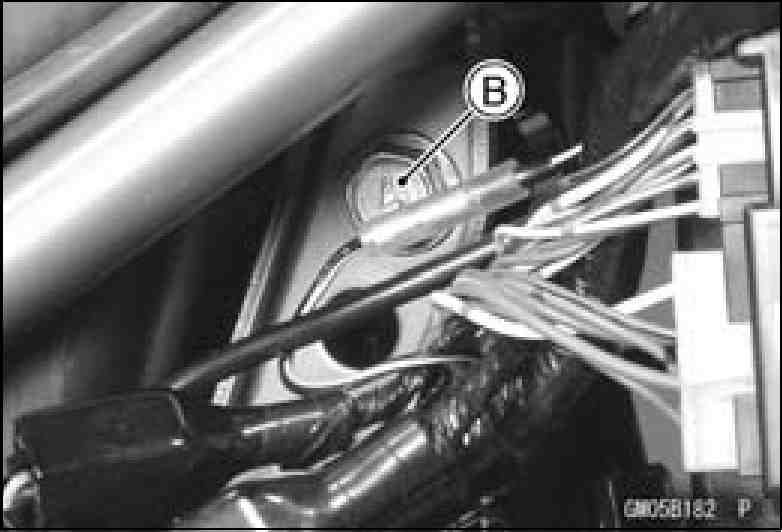

Remove the upper tie-rod bolt [A] and nut.

Remove the mounting bolts [B] and pull off the rear shock absorber [C].

|

13-14 SUSPENSION

Rear Shock Absorber

Remove the upper tie-rod bolt [A] and nut.

Remove the mounting bolts [B] and pull off the rear shock absorber [C].

• Tighten the mounting bolts.

Torque-Rear Shock Absorber Upper Mounting Nut: 59 N-m (6.0 kgf-m, 43 ft-lb) Rear Shock Absorber Lower Mounting Nut: 98 N-m (10 kgf-m, 72 ft-lb)

• Adjust the rear shock absorber position (see Rear Shock Absorber Adjustment).

Rear Shock Absorber Wear

Remove the rear shock absorbers (see Rear Shock Absorber Removal).

Compress each rear shock absorber.

Visually inspect the following items.

Compression Stroke Oil Leakage Other Damage

• If there is any damage to the rear shock absorber, replace the shock absorbers.

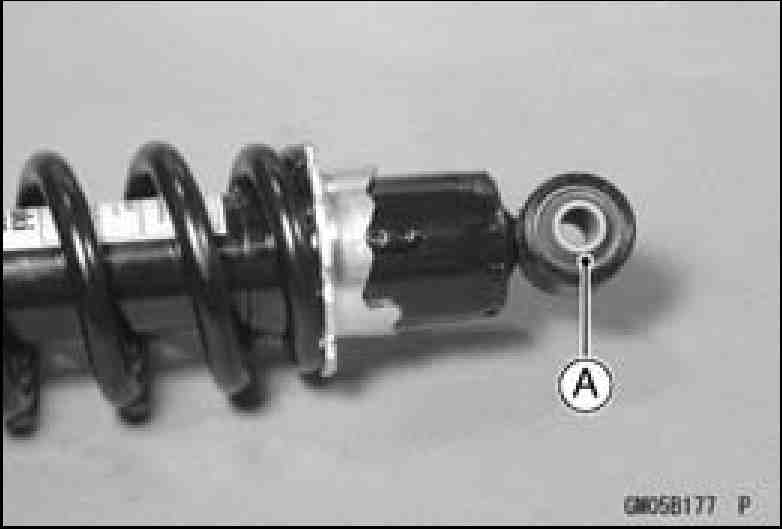

Bushing Wear

Visually inspect the rubber bushing [A].

If it shows any signs of damage, replace it.

Rear Shock Absorber Oil Leak Inspection • Refer to the Rear Shock Absorber Oil Leak Inspection in the Periodic Maintenance chapter.

SUSPENSION 13-15

Swingarm

CAUTION

Do not tap the swingarm pivot shaft when removing or installing. Push or pull the pivot shaft while turning the shaft. Tapping on the shaft could damage the needle bearings in the swingarm.

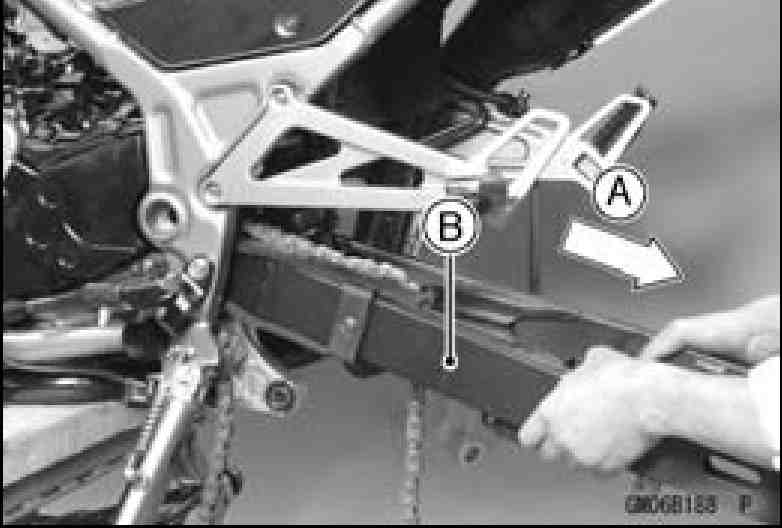

• Remove:

Rear Wheel (see Rear Wheel Removal in the

Wheels/Tires chapter)

Upper Tie Rod Bolt and Nut

Rear Brake Hose Clamps [A]

Rear Shock Absorber Lower Mounting Bolts and Nut

Chain Cover [B] and Chain Guide

Pivot Shaft Caps

• Remove the pivot shaft nut [A], and pull out the pivot shaft from right side.

NOTE

○Make sure the swingarm dose not catch the Rear Brake Switch.

Swingarm Sleeve and Needle Bearing Wear