- •Foreword

- •Предисловие

- •Chapter 1. Introduction

- •From the history of aeroengines development. Classification of air gas turbine engines

- •Table 1.1

- •Table 1.2

- •1.2. Design features of manifold types of gas turbine engines

- •Main specifications for some serial turboprop and turboshaft

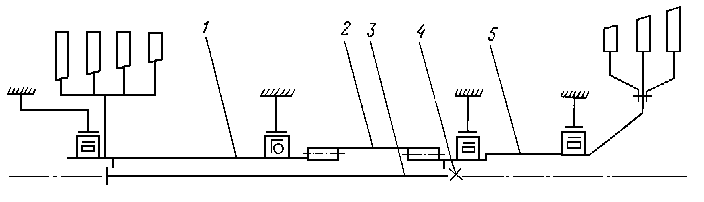

- •Fig. 1.3. Principal scheme of a two-shaft afterburning

- •Fig. 1.4. Principal scheme of a two-shaft tfe

- •Fig. 1.5. Principal scheme of a three-shaft tfe

- •Fig. 1.8. Principal scheme of a tpfe with a coaxial propfan

- •Main stages of gas turbine engines creation

- •1.4. Absolute and specific parameters of gas turbine engines

- •1.4.1. Absolute and specific parameters of turbojet engines

- •1.4.2. Absolute and specific parameters of turboprop engines

- •I.5. Air gas turbine engine’s lives

- •1.5.1. Nomenclature of lives

- •1.5.2. Sequence of assigning, setting and increase of lives

- •1.5.3. General requirements to life testing of engines and their main elements

- •1.5.4. Forming of test cycles

- •1.5.5. Forming of programs of life tests

- •Questions for self-check

- •2.1. Types of loads acting upon gas turbine engine structural elements

- •2.1.1. Classification of loads

- •2.1.2. Gas loads

- •2.1.3. Mass (inertial) forces and momenta

- •2.1.4. Temperature stresses

- •Fig. 2.4. For determination of the centrifugal forces

- •Fig. 2.5. For determination of the disc temperature stresses

- •2.1.5. Concept of dynamic loads

- •Fig. 2.9. Gas flow velocity behind nozzle vanes

- •2.2. Axial gas forces coming into action in gas turbine engines. Formation of thrust in gas turbine engines of manifold types

- •2.2.1. Axial gas forces acting on the basic gas turbine engine units

- •Fig. 2.10. Scheme of axial forces acting on basic gte units

- •2.3. Determination of axial gas force acting on impeller of gas turbine engine centrifugal compressor

- •2.4. Torques coming into action in gas turbine engines. Balance of torques

- •In gas turbine engines

- •2.4.1. Torques in turbine and compressor

- •Fig. 2.14. For determination of turbine rotor wheel torque

- •2.4.2. Torque balance in gas turbine engines of manifold types

- •Questions for self-check

- •Engine blades

- •Loads acting on blades. The blade stressed state characteristic

- •Fig. 3.1. Loads acting on the blade (a) and the scheme of blade loading

- •Determination of rotor blade tensile stress caused by centrifugal forces

- •The design scheme

- •3.2.2. Equation of a rotor blade stressed state

- •Integrating equation (3.3) in view of the ratio (3.1), we will get

- •3.2.3. Calculation of tensile stress at manifold laws of change of blade section area along its length

- •If the blade section area decreases from the root to periphery under the linear law:

- •In this case an integration by formula (3.7) yields

- •Determination of rotor blade bending stress caused by gas forces

- •3.3.1. Design scheme of a blade

- •3.3.2. Determination of gas load intensities

- •Determination of the bending momenta in axial and circumferential planes

- •3.3.4. Determination of the blade section geometrical characteristics

- •Determination of bending stress caused by gas force

- •Determination of rotor blade bending stress caused by centrifugal forces

- •The design scheme

- •3.4.2. Equation of the bending momenta

- •3.5. Guide and nozzle diaphragm vanes strength calculation features

- •3.5.1. Console type vanes

- •3.5.2. Double-support vanes

- •3.5.3. Frame type vanes

- •3.6. Evaluation of gte rotor blades strength

- •3.6.1. Grounding of blade stressed state criterion

- •3.6.2. Estimation of the blade temperature

- •3.6.3. Determination of blade strength safety factor coefficients

- •Questions for self-check

- •4.1. Loads affecting discs

- •The design scheme and assumptions made at disc strength calculations

- •Fig.4.1. Design scheme of the disc

- •4.3. Design ratings

- •4.4. Disc thermal condition

- •4.5. The disc stressed state equation. Boundary conditions

- •4.5.1. An equilibrium equation

- •4.5.2. Equation of deformations generality

- •4.5.3. Determination of stresses in rotating, unevenly heated elastic disc with an arbitrary profile

- •Fig. 4.2. Elementary disc forms

- •Fig. 4.3. Discs of arbitrary profiles

- •4.5.4. The procedure of the arbitrary profile disc stresses calculation

- •4.6. Disc durability criteria and safety factor coefficients

- •4.6.1. Selection of the stressed state criteria

- •4.6.2. Disc safety factor coefficients

- •Integrating an equilibrium equation, we find

- •4.7. Features of strength calculation of centrifugal compressor and radial-inflow turbine discs

- •The weight of the carrier disc for a chosen ring makes

- •Fig. 4.5. Design scheme and character of the radial and circumferential stresses change along radius of two-sided impeller of centrifugal compressor

- •4.8. Peculiarities of stresses calculation in drum-and-disc designs

- •Fig. 4.6. Design scheme of a drum-and-disc rotor

- •From here

- •Questions for self-check

- •Chapter 5. Static strength of gas turbine engine shafts

- •Loads acting on shafts

- •Design schemes and stressed state of shafts. Safety factor coefficient estimation

- •In an axial direction the shaft tensile (compressive) stresses are equal to

- •The shaft static strength is estimated by a safety factor coefficient value

- •Questions for self-check

- •Chapter 6. Dynamic strength of gas turbine engine blades

- •6.1. Vibrations of blades and forces causing vibrations

- •6.2. Kinds and forms of blade normal modes

- •Fig. 6.3. Flexural vibration modes of rotor blades

- •Fig. 6.4. For rotor blade normal mode frequency definition

- •6.3. Normal modes of blades with a stationary cross-section area

- •6.4. Normal modes of blades with a variable cross-section area

- •6.5. Influence of blade attachment effort to the disc

- •6.6. Influence of centrifugal forces on blade vibration frequency

- •F ig. 6.7. Determination of blade dynamic normal mode frequency

- •Influence of variable temperature

- •6.8. Forces damping blade vibrations

- •6.9. Resonant modes of the blade vibrations. The frequency diagram

- •F ig. 6.8. Example of turbine rotor wheel frequency diagram

- •6.10. Torsional and composite blade vibrations

- •6.11. Elimination of blade vibrational breakages

- •6.12. Concept of blades self-oscillations

- •Versus vibration amplitude

- •Questions for self-check

- •Chapter 7. Dynamic strength of gas turbine engine discs

- •General information

- •Forms of disc normal modes

- •Wave linear speed equals

- •Disc normal mode frequency

- •The compressor and turbine rotor wheel vibration calculation

- •Factors influencing the disc normal mode frequency

- •Disc forced undulations

- •The ways to eliminate dangerous resonance oscillations of rotor wheels

- •Questions for self-check

- •Chapter 8. Critical rotational speeds of gas turbine engine rotor

- •8.8. Measures taken to reduce intensity of rotor oscillation connected with critical rotational speeds.

- •Concept of critical rotational speeds of gas turbine engine rotor

- •Critical rotational speed of the two-support weightless shaft with disc

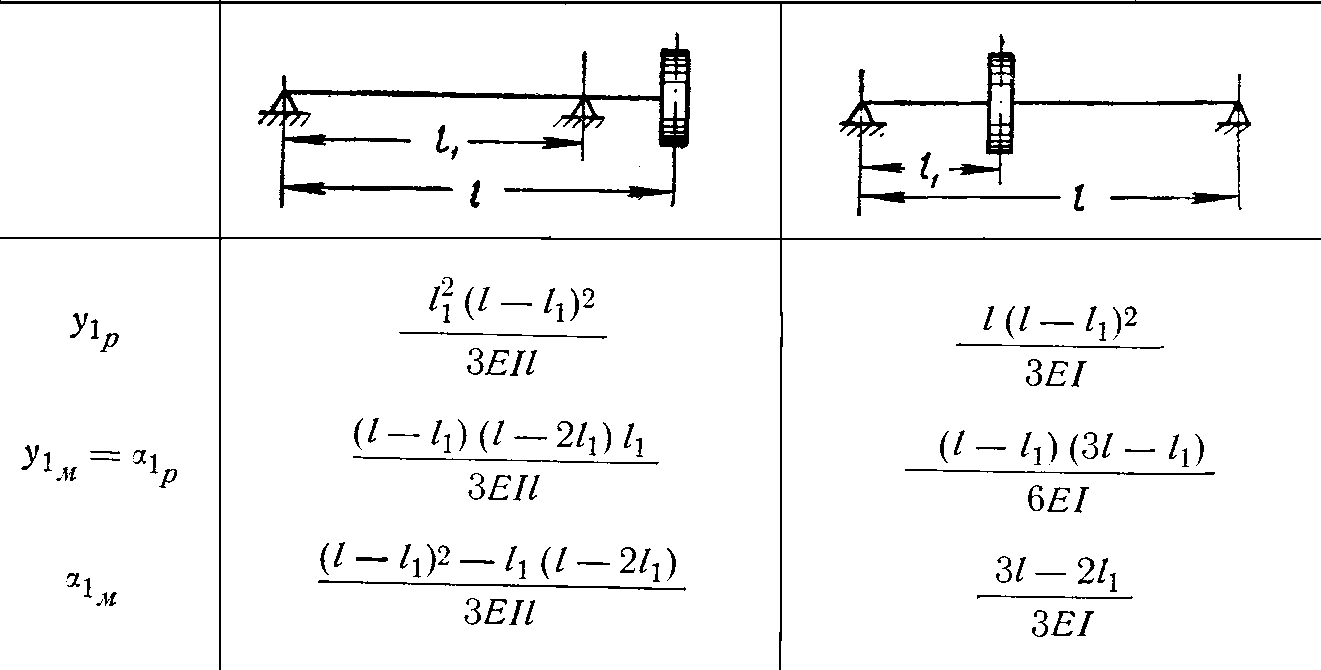

- •Fig. 8.8. Value of shaft static sag for different rotor schemes

- •Fig. 8.9. To the problem of a rotated rotor stability in a subcritical area

- •Connection of rotor critical rotational speed with its

- •Concept of two-support rotor critical rotational speeds of higher order

- •Critical rotational speed of the two-support ponderable shaft without disc

- •8.6. Critical rotational speeds of the ponderable shaft with several discs

- •8.6.1. Method of decomposition into elementary systems

- •8.7. Operational factors affecting critical rotational speeds of gas turbine engine rotor

- •Fig. 8.11. Taking into account supports elasticity influence on rotor critical speeds

- •Fig. 8.12. Static elastic anisotropy of a casing

- •Determination of critical rotational speeds taking into account

- •Influence of gyroscopic moment

- •Table 8.1

- •Values of the influence coefficients

- •8.7.2. Reduction of a real flexural system to equivalent computational

- •Example of rotor critical speed calculation

- •The rotor operational rotational speed margin is equal to:

- •The rotational speed margin at an idle is equal to:

- •8.8. Measures taken to reduce intensity of rotor oscillation connected with critical rotational speeds

- •Questions for self-check

- •8.7. What is dependence of rotor critical rotational speed on its cross-sectional oscillation frequency?

- •Of gas turbine engine shell designs

- •9.1. Shell strength calculation

- •Fig .9.1. Design scheme of a shell

- •9.2. Stability of cylindrical and conical shells

- •9.3. Vibrations of cylindrical shells

- •Questions for self-check

- •Chapter 10. Control of gas turbine engine

- •Vibration state

- •10.2. Control of gas turbine engine vibrations

- •10.3. The ways to lower the vibration level of gas turbine engines

- •10.3.1. The procedures of vibration level lowering at stage of designing

- •10.3.2. The procedures of the vibration level lowering at production stage

- •Fig. 10.3. Scheme of the rotor static balancing

- •Fig. 10.4. Scheme of the rotor dynamic balancing

- •Will be compensated by centrifugal force of balanced elements weights

- •10.3.3. The procedures of the vibration level lowering at maintenance stage

- •Questions for self-check

- •Сhapter 11. Gas turbine engine rotor supports

- •11.1. Brief data about gas turbine engine rotor supports

- •Fig. 11.3. Scheme of gte rotor support

- •11.2. Calculation of support bearings

- •Fig. 11.9. Ball bearing:

- •For roller bearings we use the formula

- •11.2.2. Estimation of the bearing safe life

- •11.2.3. Check of the bearing high-speed

- •11.2.4. Check of the bearing static load-bearing capacity

- •11.2.5. Definition of the necessary oil circulation through the bearing

- •Questions for self-check

Table 8.1

Values of the influence coefficients

8.7.2. Reduction of a real flexural system to equivalent computational

To facilitate rotor critical rotational speed determination a real system with composite mass distribution, as well as elastic elements, is substituted by a simpler, dynamically equivalent system, consisting of elastic weightless shaft and discs, fixed on it.

The reduced localized masses, inertia momenta of these weights and rigidity (yielding) of separate element of an equivalent system are selected such that the normal mode frequencies and forms of an equivalent system do not differ from normal mode frequencies and forms of a real system.

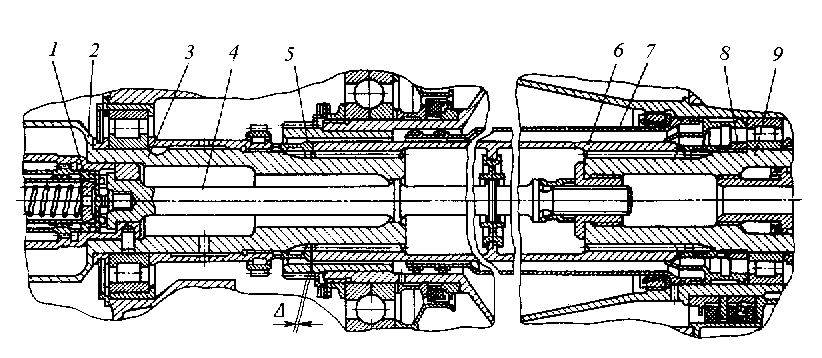

The multi-supported engine rotor consisting of compressor and turbine rotors, jointed by coupling muff, is disjointed on separate double-support compressor and turbine rotors. The rotors interference on their critical rotational speeds depends on design and location of rotors coupling with regard to a support (see Fig. 8.18…Fig. 8.27). For example, at hinged coupling (see Fig. 8.19…Fig. 8.22, Fig. 8.24…Fig. 8.27) this influence is much less, than at rigid coupling (see Fig. 8.18, Fig. 8.23).

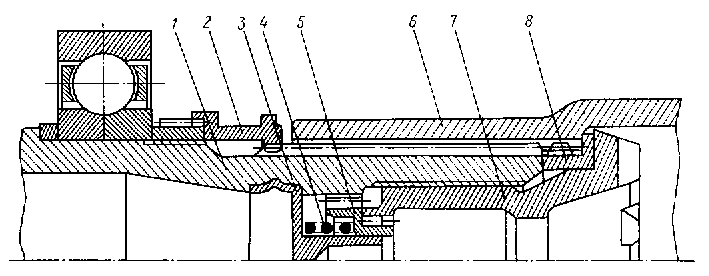

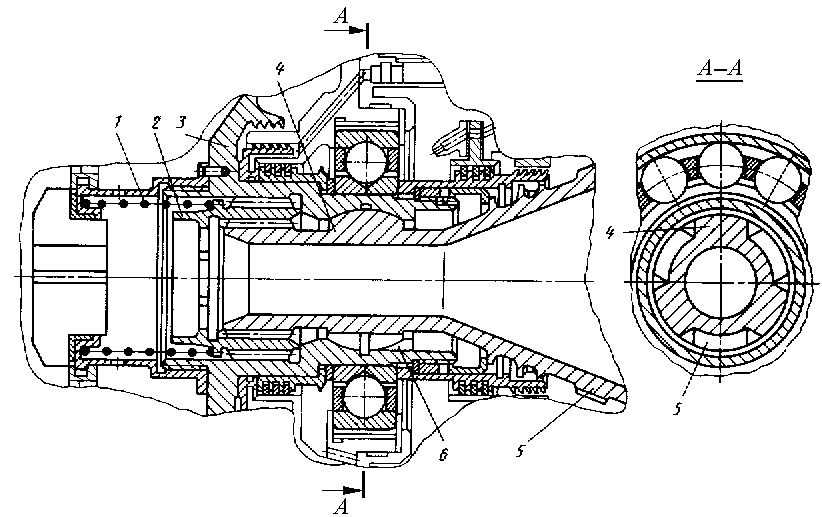

Fig. 8.18. Coupling muff of three‑supported TPE rotor:

1 – compressor shaft; 2 – distance sleeve; 3 – latch casing; 4 – latch spring; 5 – latch double-spline bushing; 6 – turbine shaft; 7 – coupling bolt; 8 – bolt bearing

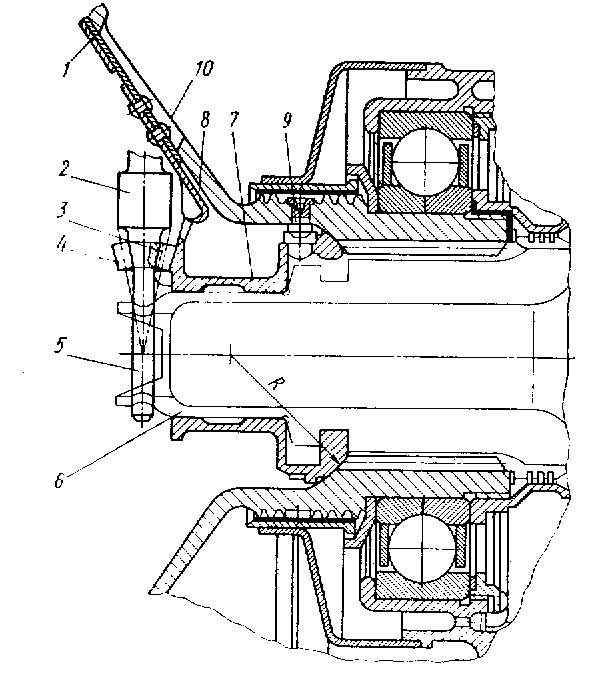

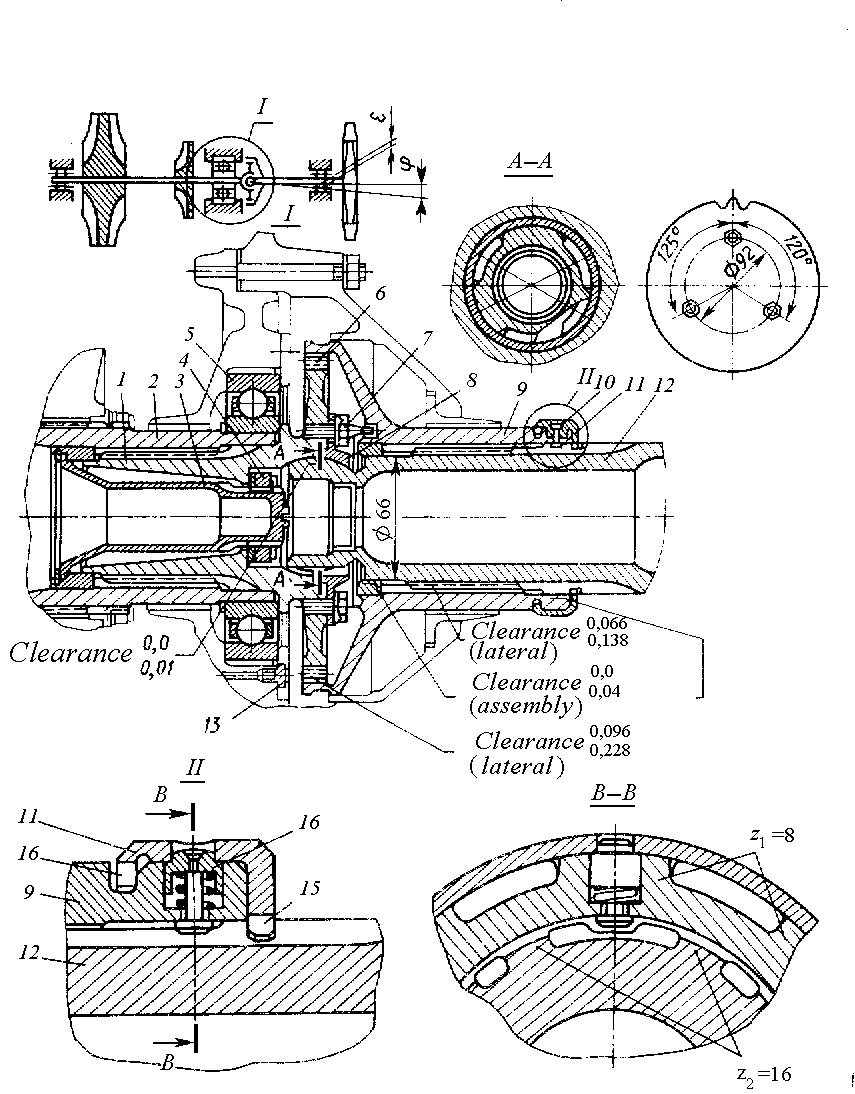

Fig. 8.19. Coupling muff of three‑supported TPE rotor:

1 – spring; 2 – toothed wrench; 3 – muff toothed sector; 4 – conical teeth on the wrench; 5 – wrench guide; 6 – turbine rotor; 7 – muff; 8 – detent for muff plugging; 9 – pin; 10 – window in compressor rotor journal for wrench input-output

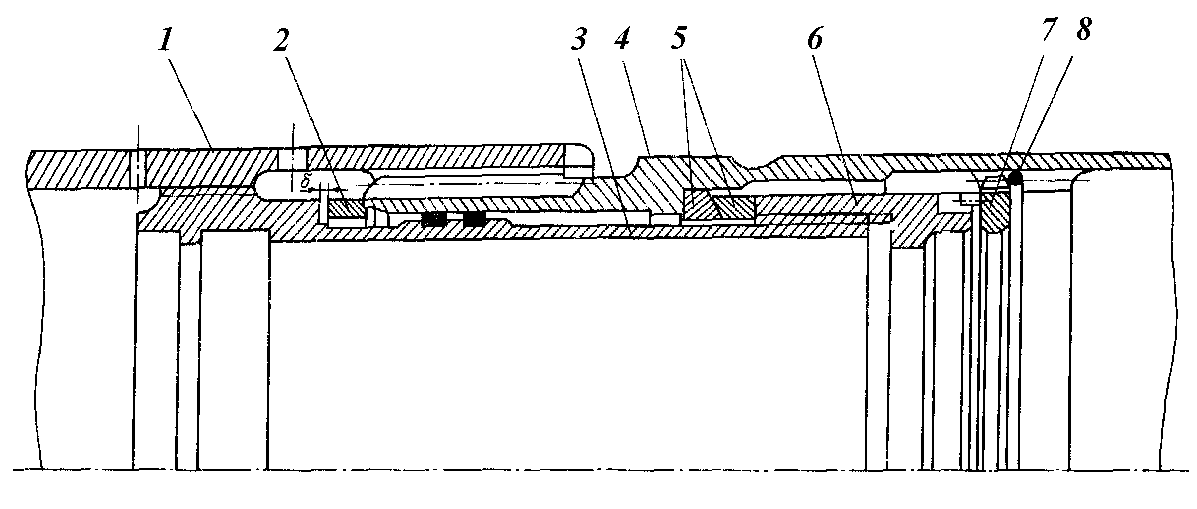

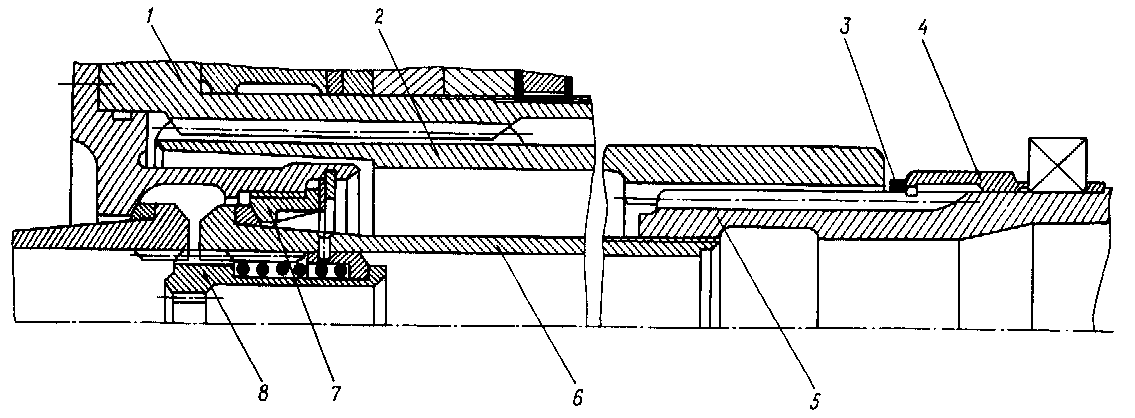

Fig. 8.20. Coupling muff of TFE high pressure rotors:

1 – compressor shaft; 2 – adjusting ring; 3 – intermediate thread bushing; 4 – turbine shaft; 5 – spherical rings; 6 – coupling bolt; 7 – split retaining ring; – axial clearance between shafts

Fig. 8.21. Coupling muff of three‑supported helicopter TShE rotors:

1 – spring; 2 – double-spline moving bushing; 3 – rear journal of compressor rotor; 4 – bulge; 5 – turbine rotor journal; 6 – groove (slot)

Fig. 8.22. Coupling muff of three‑supported TShE rotors:

1 – driven spline muff; 2 – compressor rotor journal; 3 – bolt; 4 – nut; 5 – support bearing; 6 – splines; 7 – scews-pins; 8 – flange; 9 – transitional driving muff; 10 – detent; 11 – retaining ring; 12 – turbine rotor journal; 13 – oil jet; 14, 15 – splines; 16 – detent

Fig. 8.23. Coupling muff of three‑supported TJE rotor:

1 – rear journal of compressor rotor; 2 – turbine shaft; 3 – coupling bolt; 4 – coupling bolt grooves; 5 – turbine shaft thread bushing

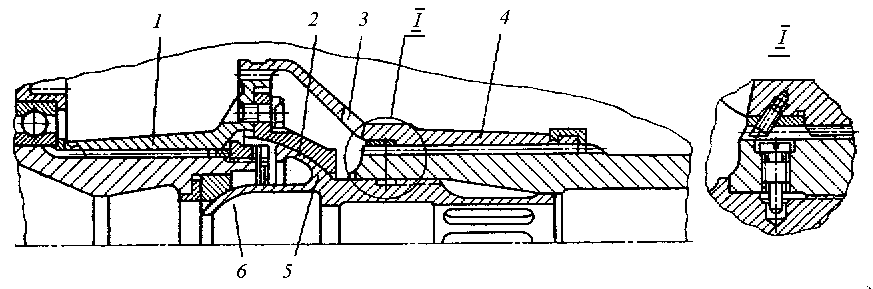

Fig. 8.24. Coupling muff of three‑supported TJE rotor:

1 – muff driven part; 2 – spherical surface, taken an axial force, directed to turbine; 3 – passage for oil support to muff cavity; 4 – muff driving part; 5 – stem; 6 – spherical surface, taken an axial force, directed to compressor

Fig. 8.25. Line diagram of four‑supported rotor coupling muff:

1 – compressor shaft; 2 – long spline shaft; 3 – flexible coupling bolt; 4 – nut of coupling bolt; 5 – turbine shaft

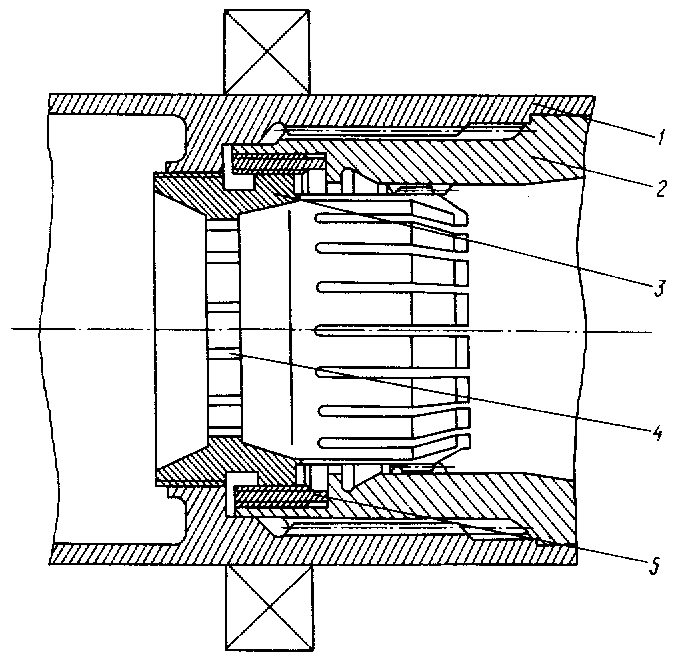

Fig. 8.26. Coupling of turbine and compressor shafts with the help of tubular

spring and tightening bolt (rod):

1 – lock; 2 – low pressure compressor shaft; 3 – low pressure compressor rotor rear journal; 4 – tightening bolt; 5 – lock bushing; 6 – tubular spring; 7 – thin-walled tube; 8 – nut; 9 – turbine shaft

Fig. 8.27. Coupling muff of four‑supported TFE rotor:

1 – compressor shaft; 2 – spline shaft-tube; 3 – adjusting ring; 4 – distance sleeve; 5 – spline turbine shaft; 6 – coupling bolt; 7 – spherical support; 8 – lock

The number of localized weights and their arrangement on the shaft are selected according to arrangement of weights in a real system. The dispersed weights of the shaft, drum and other elements result in one or several weights of an equivalent system, which are often added to discs weights.

At transition from the real system to the equivalent system the number of freedom degrees will decrease and be equal to the number of localized weights. The shaft weights reduction taking into account only first bending oscillation form is considered below.

Reduction of weights. The values of equivalent system weights are determined from the requirement of kinetic energies equality of real and equivalent oscillating systems. For this purpose the shape of an elastic line is set, which is approximately accepted as an elastic line of an equivalent system.

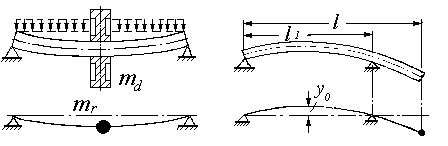

As an example we will consider the weights reduction of the double-support shaft with the disc in the middle (Fig. 8.29, a).

The kinetic energy of the oscillating real shaft with distributed load is equal to:

![]()

a b

Fig. 8.29. Scheme of weights reduction:

a – double-support shaft with disc in the middle; b – console shaft

For

![]()

the maximum value of shaft kinetic energy is equal to:

![]() (8.14)

(8.14)

Here l is length of the shaft; is density of shaft material; F is shaft cross-sectional area; p is frequency of shaft normal mode bending oscillations; уi is the centre of gravity displacement of shaft oscillating section corresponding to х coordinate.

Let the shape of an elastic line be determined by relation

![]() (8.15)

(8.15)

where y0 is sag in the middle of the shaft.

Having substituted (8.15) in the formula (8.14) and having made an integration, we will get:

![]()

But

![]()

Then

![]() (8.16)

(8.16)

The maximum kinetic energy of the equivalent reduced shaft with a reduced mass in the middle is equal to:

![]() (8.17)

(8.17)

The maximum kinetic energy of the disc arranged in the middle of the shaft is determined with the help of expression:

![]() (8.18)

(8.18)

Equating the expressions for kinetic energies, we will get:

![]()

From here we will get an expression for shaft reduced localized mass with the disc arranged in the middle between supports:

![]() (8.19)

(8.19)

In case, when the disc is asymmetrically arranged concerning the supports the point of disc location, as a point of shaft weight reduction is also taken. Let in a point of reduction arranged in distance х from a support, the maximum sag be y. Then, the maximum kinetic energy of a reduced mass is equal to:

![]()

The maximum kinetic energy of the shaft is equal to:

![]()

Comparing the two latter expressions, we will get:

(8.20)

(8.20)

Relation

(8.21)

(8.21)

is called a reduction coefficient of shaft weight.

Console shaft weight (Fig. 8.29, b) is reduced in the same way as the shaft weight with the disc asymmetrically arranged concerning supports. The point of disc location is taken as the point of reduction.

Equation of parabola can be taken as an equation of such shaft elastic line:

where l1 is distance between shaft supports; х is a moving coordinate along shaft length.

The reduced localized mass of the console shaft is equal to:

![]() (8.22)

(8.22)

The shaft weight of a multi-disc double-support rotor is normally added to the weight of one of the discs. If the shaft weight makes a small part of rotor total mass, the shaft influence can be neglected.

Reduction of inertia momenta. A mass inertia moment of the composite shape disc with elements, abutting to it, (flanges, clamps, etc.) is determined as the total of inertia momenta of the elementary bodies of revolution, this disc can be segmented into.

The total disc polar moment of inertia is equal to:

![]()

where n is the number of elements, the disc is segmented into.

The equatorial moment of disc element inertia concerning diameter passing through an element weight centre, is equal to:

![]()

The equatorial moment of disc inertia concerning diameter passing through a disc weight centre, is determined from the formula

![]()

where mi is weight of i-th element; хi is distance between weight centre of i‑th element and disc weight centre or reduced disc mass.

The mass reduced inertia moment of rotor blades fixed on the disc, is determined similarly.

The polar inertia moment of rotor blades assembly is equal to:

![]() (8.23)

(8.23)

where zb is the number of rotor blades in a rotor wheel; mb is mass of one blade; rc is distance between blade airfoil weight centre and rotation axis.

If the strength of a blade is calculated, the distance between blade airfoil weight centre and rotation axis can be determined from the formula (see Fig. 3.1)

![]()

The equatorial inertia moment of blades concerning diameter, passing through disc weight centre, is equal to:

![]() (8.24)

(8.24)

where xc is distance between blade assembly weight centre and disc weight centre (or reduced mass of discs) along rotor axis.

Finally, we will get for the whole rotor:

(8.25)

(8.25)

where n is the number of blades assemblies, whose momenta of inertia are reducted to the given disc or to reduced mass of discs.

The equatorial inertia moment of thin discs is equal to:

![]()

For impellers of centrifugal compressors it is equal to:

![]()