- •Foreword

- •Предисловие

- •Chapter 1. Introduction

- •From the history of aeroengines development. Classification of air gas turbine engines

- •Table 1.1

- •Table 1.2

- •1.2. Design features of manifold types of gas turbine engines

- •Main specifications for some serial turboprop and turboshaft

- •Fig. 1.3. Principal scheme of a two-shaft afterburning

- •Fig. 1.4. Principal scheme of a two-shaft tfe

- •Fig. 1.5. Principal scheme of a three-shaft tfe

- •Fig. 1.8. Principal scheme of a tpfe with a coaxial propfan

- •Main stages of gas turbine engines creation

- •1.4. Absolute and specific parameters of gas turbine engines

- •1.4.1. Absolute and specific parameters of turbojet engines

- •1.4.2. Absolute and specific parameters of turboprop engines

- •I.5. Air gas turbine engine’s lives

- •1.5.1. Nomenclature of lives

- •1.5.2. Sequence of assigning, setting and increase of lives

- •1.5.3. General requirements to life testing of engines and their main elements

- •1.5.4. Forming of test cycles

- •1.5.5. Forming of programs of life tests

- •Questions for self-check

- •2.1. Types of loads acting upon gas turbine engine structural elements

- •2.1.1. Classification of loads

- •2.1.2. Gas loads

- •2.1.3. Mass (inertial) forces and momenta

- •2.1.4. Temperature stresses

- •Fig. 2.4. For determination of the centrifugal forces

- •Fig. 2.5. For determination of the disc temperature stresses

- •2.1.5. Concept of dynamic loads

- •Fig. 2.9. Gas flow velocity behind nozzle vanes

- •2.2. Axial gas forces coming into action in gas turbine engines. Formation of thrust in gas turbine engines of manifold types

- •2.2.1. Axial gas forces acting on the basic gas turbine engine units

- •Fig. 2.10. Scheme of axial forces acting on basic gte units

- •2.3. Determination of axial gas force acting on impeller of gas turbine engine centrifugal compressor

- •2.4. Torques coming into action in gas turbine engines. Balance of torques

- •In gas turbine engines

- •2.4.1. Torques in turbine and compressor

- •Fig. 2.14. For determination of turbine rotor wheel torque

- •2.4.2. Torque balance in gas turbine engines of manifold types

- •Questions for self-check

- •Engine blades

- •Loads acting on blades. The blade stressed state characteristic

- •Fig. 3.1. Loads acting on the blade (a) and the scheme of blade loading

- •Determination of rotor blade tensile stress caused by centrifugal forces

- •The design scheme

- •3.2.2. Equation of a rotor blade stressed state

- •Integrating equation (3.3) in view of the ratio (3.1), we will get

- •3.2.3. Calculation of tensile stress at manifold laws of change of blade section area along its length

- •If the blade section area decreases from the root to periphery under the linear law:

- •In this case an integration by formula (3.7) yields

- •Determination of rotor blade bending stress caused by gas forces

- •3.3.1. Design scheme of a blade

- •3.3.2. Determination of gas load intensities

- •Determination of the bending momenta in axial and circumferential planes

- •3.3.4. Determination of the blade section geometrical characteristics

- •Determination of bending stress caused by gas force

- •Determination of rotor blade bending stress caused by centrifugal forces

- •The design scheme

- •3.4.2. Equation of the bending momenta

- •3.5. Guide and nozzle diaphragm vanes strength calculation features

- •3.5.1. Console type vanes

- •3.5.2. Double-support vanes

- •3.5.3. Frame type vanes

- •3.6. Evaluation of gte rotor blades strength

- •3.6.1. Grounding of blade stressed state criterion

- •3.6.2. Estimation of the blade temperature

- •3.6.3. Determination of blade strength safety factor coefficients

- •Questions for self-check

- •4.1. Loads affecting discs

- •The design scheme and assumptions made at disc strength calculations

- •Fig.4.1. Design scheme of the disc

- •4.3. Design ratings

- •4.4. Disc thermal condition

- •4.5. The disc stressed state equation. Boundary conditions

- •4.5.1. An equilibrium equation

- •4.5.2. Equation of deformations generality

- •4.5.3. Determination of stresses in rotating, unevenly heated elastic disc with an arbitrary profile

- •Fig. 4.2. Elementary disc forms

- •Fig. 4.3. Discs of arbitrary profiles

- •4.5.4. The procedure of the arbitrary profile disc stresses calculation

- •4.6. Disc durability criteria and safety factor coefficients

- •4.6.1. Selection of the stressed state criteria

- •4.6.2. Disc safety factor coefficients

- •Integrating an equilibrium equation, we find

- •4.7. Features of strength calculation of centrifugal compressor and radial-inflow turbine discs

- •The weight of the carrier disc for a chosen ring makes

- •Fig. 4.5. Design scheme and character of the radial and circumferential stresses change along radius of two-sided impeller of centrifugal compressor

- •4.8. Peculiarities of stresses calculation in drum-and-disc designs

- •Fig. 4.6. Design scheme of a drum-and-disc rotor

- •From here

- •Questions for self-check

- •Chapter 5. Static strength of gas turbine engine shafts

- •Loads acting on shafts

- •Design schemes and stressed state of shafts. Safety factor coefficient estimation

- •In an axial direction the shaft tensile (compressive) stresses are equal to

- •The shaft static strength is estimated by a safety factor coefficient value

- •Questions for self-check

- •Chapter 6. Dynamic strength of gas turbine engine blades

- •6.1. Vibrations of blades and forces causing vibrations

- •6.2. Kinds and forms of blade normal modes

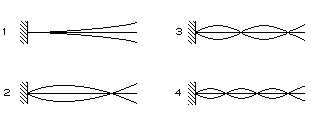

- •Fig. 6.3. Flexural vibration modes of rotor blades

- •Fig. 6.4. For rotor blade normal mode frequency definition

- •6.3. Normal modes of blades with a stationary cross-section area

- •6.4. Normal modes of blades with a variable cross-section area

- •6.5. Influence of blade attachment effort to the disc

- •6.6. Influence of centrifugal forces on blade vibration frequency

- •F ig. 6.7. Determination of blade dynamic normal mode frequency

- •Influence of variable temperature

- •6.8. Forces damping blade vibrations

- •6.9. Resonant modes of the blade vibrations. The frequency diagram

- •F ig. 6.8. Example of turbine rotor wheel frequency diagram

- •6.10. Torsional and composite blade vibrations

- •6.11. Elimination of blade vibrational breakages

- •6.12. Concept of blades self-oscillations

- •Versus vibration amplitude

- •Questions for self-check

- •Chapter 7. Dynamic strength of gas turbine engine discs

- •General information

- •Forms of disc normal modes

- •Wave linear speed equals

- •Disc normal mode frequency

- •The compressor and turbine rotor wheel vibration calculation

- •Factors influencing the disc normal mode frequency

- •Disc forced undulations

- •The ways to eliminate dangerous resonance oscillations of rotor wheels

- •Questions for self-check

- •Chapter 8. Critical rotational speeds of gas turbine engine rotor

- •8.8. Measures taken to reduce intensity of rotor oscillation connected with critical rotational speeds.

- •Concept of critical rotational speeds of gas turbine engine rotor

- •Critical rotational speed of the two-support weightless shaft with disc

- •Fig. 8.8. Value of shaft static sag for different rotor schemes

- •Fig. 8.9. To the problem of a rotated rotor stability in a subcritical area

- •Connection of rotor critical rotational speed with its

- •Concept of two-support rotor critical rotational speeds of higher order

- •Critical rotational speed of the two-support ponderable shaft without disc

- •8.6. Critical rotational speeds of the ponderable shaft with several discs

- •8.6.1. Method of decomposition into elementary systems

- •8.7. Operational factors affecting critical rotational speeds of gas turbine engine rotor

- •Fig. 8.11. Taking into account supports elasticity influence on rotor critical speeds

- •Fig. 8.12. Static elastic anisotropy of a casing

- •Determination of critical rotational speeds taking into account

- •Influence of gyroscopic moment

- •Table 8.1

- •Values of the influence coefficients

- •8.7.2. Reduction of a real flexural system to equivalent computational

- •Example of rotor critical speed calculation

- •The rotor operational rotational speed margin is equal to:

- •The rotational speed margin at an idle is equal to:

- •8.8. Measures taken to reduce intensity of rotor oscillation connected with critical rotational speeds

- •Questions for self-check

- •8.7. What is dependence of rotor critical rotational speed on its cross-sectional oscillation frequency?

- •Of gas turbine engine shell designs

- •9.1. Shell strength calculation

- •Fig .9.1. Design scheme of a shell

- •9.2. Stability of cylindrical and conical shells

- •9.3. Vibrations of cylindrical shells

- •Questions for self-check

- •Chapter 10. Control of gas turbine engine

- •Vibration state

- •10.2. Control of gas turbine engine vibrations

- •10.3. The ways to lower the vibration level of gas turbine engines

- •10.3.1. The procedures of vibration level lowering at stage of designing

- •10.3.2. The procedures of the vibration level lowering at production stage

- •Fig. 10.3. Scheme of the rotor static balancing

- •Fig. 10.4. Scheme of the rotor dynamic balancing

- •Will be compensated by centrifugal force of balanced elements weights

- •10.3.3. The procedures of the vibration level lowering at maintenance stage

- •Questions for self-check

- •Сhapter 11. Gas turbine engine rotor supports

- •11.1. Brief data about gas turbine engine rotor supports

- •Fig. 11.3. Scheme of gte rotor support

- •11.2. Calculation of support bearings

- •Fig. 11.9. Ball bearing:

- •For roller bearings we use the formula

- •11.2.2. Estimation of the bearing safe life

- •11.2.3. Check of the bearing high-speed

- •11.2.4. Check of the bearing static load-bearing capacity

- •11.2.5. Definition of the necessary oil circulation through the bearing

- •Questions for self-check

6.2. Kinds and forms of blade normal modes

By nature of deformations, blade normal (free) modes are grouped into:

- flexural oscillations;

- torsional oscillations;

- flexure-torsion (composite) oscillations.

The blade cross sections perform motions without a profile change at these oscillations.

There are also plate-flexural vibration modes with deformation of a profile midline.

At flexural vibrations a blade is considered as a console beam, with infinite number of normal mode forms. Only a few of the lowest forms are of practical interest.

T he

normal mode forms are distinguished by number of the

nodes

or nodal lines.

That are blade surfaces, which are not displaced at vibrations. At

the first flexural vibration mode there is only one node at the place

of a blade attachment to the disc (Fig. 6.3, 1).

At the second mode there are two nodes (Fig. 6.3, 2),

etc. (see Fig. 6.3, 3

and Fig. 6.3, 4).

The vibration frequency is the lowest at the first mode. Other

vibration modes have larger frequencies, and, hence, smaller

vibration amplitudes.

he

normal mode forms are distinguished by number of the

nodes

or nodal lines.

That are blade surfaces, which are not displaced at vibrations. At

the first flexural vibration mode there is only one node at the place

of a blade attachment to the disc (Fig. 6.3, 1).

At the second mode there are two nodes (Fig. 6.3, 2),

etc. (see Fig. 6.3, 3

and Fig. 6.3, 4).

The vibration frequency is the lowest at the first mode. Other

vibration modes have larger frequencies, and, hence, smaller

vibration amplitudes.

Fig. 6.3. Flexural vibration modes of rotor blades

Dangerous vibration mode will be the mode, at which the blade normal mode frequency coincides with the vibration excitation forces frequency.

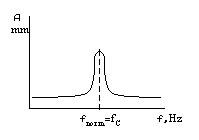

The normal mode frequency can be determined by computation or experimentally.

T he

simplest and most widespread experimental method is the

resonant method.

In this case the

vibrator

causes vibrations of an examined blade until the resonance. And then

the excitation forces frequency measurement is made. This measured

frequency will correspond to a blade normal mode frequency (Fig.

6.4).

he

simplest and most widespread experimental method is the

resonant method.

In this case the

vibrator

causes vibrations of an examined blade until the resonance. And then

the excitation forces frequency measurement is made. This measured

frequency will correspond to a blade normal mode frequency (Fig.

6.4).

Fig. 6.4. For rotor blade normal mode frequency definition

The vibration modes are more often defined with the help of the sand figures.

6.3. Normal modes of blades with a stationary cross-section area

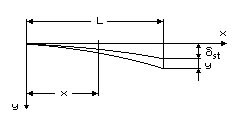

Let us consider a blade as a weightless console beam with the length L and a constant cross section (Fig. 6.5). Let the weight M be centred on the end of it. And this weight causes the static sag equal to

![]()

where c is a specific flexural stiffness of a blade, N/m (specific flexural stiffness is a force, which causes deformation equal to 1 m).

Fig. 6.5. Design scheme for the rotor blade normal mode frequency determination

For the vibrational motion of a blade with some weight an equilibrium equation can be written, applying d'Alembert’s principle

![]()

Let р2 = с/М, and we will get

![]()

where y is a blade deviation from an equilibrium position at vibrations.

The general solution of this equation will be written as

![]()

where A and B are the factors; р is a circular frequency of normal modes; t is time.

Vibration period Т and normal mode frequency fnorm are connected between themselves and a circular frequency by the following ratios:

As р2 = с/М and M = st с/g, we will get

![]()

Hence,

![]()

For the console beam with a stationary cross-section area, with a moment of inertia J, length L and weight M on the end, the static sag makes

![]()

where E is a material modulus of elasticity.

Thus the normal mode frequency will make, [Hz]:

![]()

To derive the formula of normal mode frequency in view of a blade weight it is possible to take advantage of Rayleigh’s method (energy method). In this case we set the form of an elastic line at the first flexural vibration mode, then evaluate the beam sag, kinetic energy and normal mode frequency.

The differential equation of an elastic line of a beam with the weight, which will be close to the form at a static load Q=Mg on the beam end, looks like:

![]()

Its solution for a sag of a beam section, which is in distance x from attachment point of a beam (see Fig. 6.5) is determined by the formula:

![]()

оr

![]()

where

![]() is the maximum sag of a beam.

is the maximum sag of a beam.

The kinetic energy at beam vibrations will equal to:

![]()

where q is weight of a beam length unit; t is time.

Subject to weight on the beam end the formula for kinetic energy looks like:

![]()

If

a period and vibration frequency of a substantial beam with weight

are considered

to be the same, as well as for a weightless beam, which has on its

end weight

![]() ,

the static sag of a beam will be equal to:

,

the static sag of a beam will be equal to:

![]()

and normal mode frequency of a beam without weight (at Q=0) will be equal to:

![]() ,

,

where q=F, F is a sectional area of a beam; is a material density, kg/m3.

Rayleigh showed, that any approximated expression of oscillating beam elastic line form gives the greater frequency value of normal mode, than the precise one.

For the first flexural vibration mode, at which the form of elastic line is close to the form at static load, affecting the end of the beam, the normal mode frequency makes

![]()

where F is a cross-section area of the beam (blade).

As inertia momenta of a blade concerning different axes are various, the oscillations concerning axis of the least rigidity represent greatest interest

From the formula it can be seen, that the normal mode frequency depends on relation Е/, which is determined by a blade material:

- for steel Е/ = 2,82107 Pam3 / kg;

- for aluminium alloys Е/ = 2,52107 Pam3 / kg;

- for titanium alloys Е/ = 2,48107 Pam3 / kg;

- for glass-fibre-reinforced plastics Е/ = 1,32107 Pam3 / kg.

Thus, fnorm of steel blades at the identical geometrical characteristics will be maximum. The blades from aluminium alloys have normal mode frequency that is 6 % smaller than steel blades’, titanium alloy blades frequency is 7 % smaller, glass-fibre-reinforced plastics – 45 % smaller.

At increase blade length the normal mode frequency decreases proportionally to square of relation of blades lengths:

However these ratios are true only for lengthy blades. For short blades with a thick section the idealized formulas give large errors (deviation from experimental data reaches 100 %). It is explained by the fact that the influence of elasticity of a shank in a short blade has a bigger effect, and also that at oscillations the short blade has the form, which is distinct from elastic line of a consol beam. Therefore normal mode frequencies of short blades need to be determined by empirically.

Increase in blade section profile thickness results in increase in its rigidity to a greater degree, compared to increase in its weight. Therefore normal mode frequency will increase with increase in profile thickness. The thinner the blade the more the dispersion of normal mode frequencies is, which is the result of manufacturing inaccuracy and non-uniformity of its wearing in operation.

The blade twist does not affect a blade normal mode frequency much. The vibration frequency under the first form slightly increases at increase of twist (up to 5 % at twist at 45), while the vibration frequency under the second form noticeably decreases (up to 15 % at twist at 45).

The normal mode frequency of a blade is also influenced by the form of transition from a shank to an airfoil part of a blade. It is necessary to note, that at blades oscillations the bending stresses appear not only in airfoil part, but also in a blade shank fixed in the disc. Therefore some correction should be made when calculating a blade normal mode frequency taking into account deformation of a blade shank. In this connection the frequency obtained experimentally, is always less than frequency calculated.

The frequencies of different blade normal mode forms with a stationary cross-section area make the following proportion:

fnorm1: fnorm2: fnorm3: fnorm4: fnormn = 1: 6,28: 17,53: 34,36=1:(k2/k1)2:(k3/k1)2:..:(kn/k1)2,

where k1=1,875; kn=(n–0,5); n=1,2,3,… .

For the blade with a hinged attachment the first flexural vibration mode is missing, therefore comparison begins with the second frequency

fnorm2: fnorm3: fnorm4= 1: 3,24: 6,76=1:(k3/k2)2:(k4/k2)2:..:(kn/k2)2,

where k1=0; kn=(n–0,75); n=2,3… .

For the blades with a variable cross-section area the relation of frequencies have different values, but their frequency always augments with vibration mode serial number increase.

For blades with a shroud ring, stator vanes with two built-in supports or two hinged supports are k1=4,73; kn = (n+0,5) and k1 =; kn=n, respectively.