- •G. Zayonchkovsky, V. Stadnychenko, y. Golovko «hydraulic machines and hydraulic/pneumatics equipment»

- •Introduction

- •Pump glossary

- •1.2 Pump history

- •1.3 Pump family group

- •1.3.1 Centrifugal pumps

- •1.3.2 Reciprocating pumps

- •1.3.3 Pump selection

- •2.1 Centrifugal pumps

- •2.2 Centrifugal pump characteristics

- •2.3 Performance modifications for varying pipelene applications

- •2.3.1 Cavitation

- •2.3.2 Net positive head

- •2.3.3 Net Positive Suction Head Avaible

- •2.3.4 Net Positive Suction Head Required

- •2.3.5 Correcting for Inadequate Suction Conditions

- •2.3.6 Npsha-nphsr Criteria

- •2.3.7 Viscous Liquids

- •2.3.8 Minimum Flow

- •2.3.9 Temperature Rise

- •2.3.11 Centrifugal Pump Station Piping Design

- •2.3.12 Centrifugal Pump Nozzle Loading

- •2.3.12 Pump Operational Hazards and Risk

- •3.1. Rotary

- •3.2 Types of rotary pumps

- •3.3 Reciprocating pumps

- •3.4 Piston pumps

- •4.1 Role of compression in a gas pipeline network

- •4.2 Gas pipeline hydraulics principles

- •4.3 Friction factor

- •4.4 Flow regimen profiles calculation

- •4.4 Pipeline design and optimization

- •4.4.1 Optimization Parameters

- •Optimization Process Overview

- •4.4.3 Selection of Alternative

- •4.4.4 Sensitivity Analysis

- •4.4.5 Pipeline Looping & Compression (Location & Spacing)

- •Hydraulics Simulations

- •4.4.7 Compressor Operation Costs

- •5.1. Pneumatic piping, hoses and connections

- •5.2 Flow control and pressure regulation valves

- •5.3 Relief valves dynamics

- •6.1 Linear actuators

- •6.2 Construction

- •6.3 Mounting arrangements an cylinder dynamics

- •7.1 Station piping layout

- •7.2 Scrubbers and filters

- •7.2.1 Dry scrubbers

- •7.2.1 Wet scrubbers

- •Categorization of wet scrubbers

- •Advantages and disadvantages

- •7.2.3 Filters

- •7.3 Gas coolers

- •7.4 Absorbers and regenerators

1.3 Pump family group

Pumps convert externally supplied mechanical energy into potential energy within the fluid This energy is used to:

raise the liquid elevation,

force the fluid into a pressurized system, and overcome flow generated friction caused by pipe roughness.

The most commonly used pumps for transmission pipeline stations are either centrifugal or positive displacement (reciprocating).

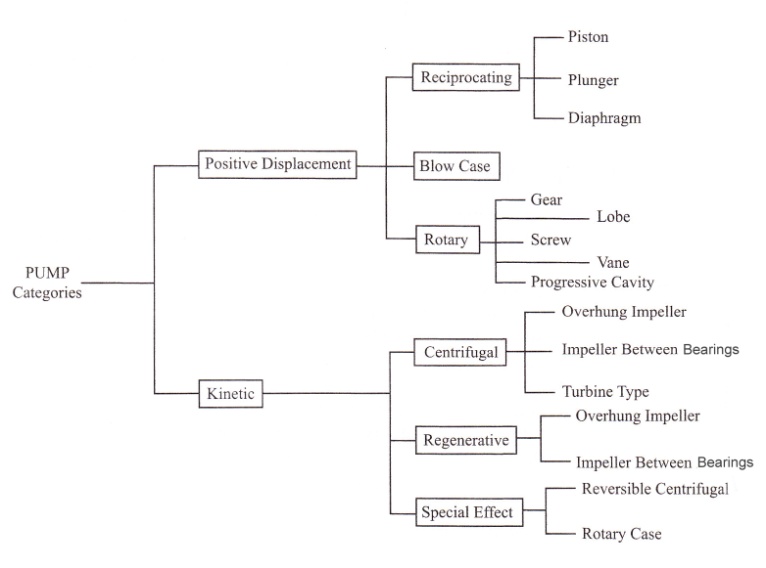

Figure 1-2 illustrates pump families and indicates that types of pumps to choose from are very diverse. To select the optimum pump for the application, technical and economic aspects must be carefully determined and evaluated. Two types of pumps are generally used by the pipeline transmission industry. These fall under the kinetic (fig. 1-3) and displacement pump groups shown in fig. 1-2.

Centrifugal pumps are generally high-speed, high-volume units connected through speed increasers to internal combustion engines or directly to electric motors. In large stations, such pumps are generally connected in series, allowing each pump to handle total flow, and each adds an increase in pressure (head) to the liquid being moved.

|

Figure 1-2 A generalized pump family group |

Centrifugal pumps offer certain distinct advantages; principal among these is that the flow of liquid from them is relatively even and smooth with very few pulsations. Properly installed and operated, little or no vibration results from their use. These pumps can be used outside or in small buildings, need only light foundations, and can be easily kept clean. In addition, they are comparatively low-cost, simple to construct and flexible to operate, and require a comparatively small space.

As previously indicated, positive displacement pumps are divided into two general classes: reciprocating and rotary. Reciprocating pumps are further divided into two types: plunger and piston.

Plunger pumps always have a plunger longer than their stroke, and only one end is available for pumping. Double-acting plunger pumps require at least two cylinders and plungers. Although not as adaptable as piston-type pumps, plunger pumps can be made to provide higher pressures and greater capacities. Nearly all large, high-pressure, reciprocating pumps used in transmission pipeline stations are plunger-type.

Pistons pumps usually have pistons shorter than their stroke, and both ends are available for pumping with the same cylinder. Piston-type pumps are used extensively at gathering stations because of their flexibility in capacity, range in pressure, and portability they can serve either as suction or discharge pumps. Most field pumps are piston pump. Capacity and pressure rating are varied easily by changing the diameter of the piston and cylinder liners.

Reciprocating pumps are usually of a single construction design, have a long service life, and are highly efficient. Disadvantages include their large weight, greater space requirements than required by other types, higher initial cost, pulsations, and sometimes, the need for speed reducers in the case of very slow-speed reciprocating pumps. Vertical, multi-B cylinder, high-speed plunger pumps used in some installations have helped overcome the disadvantages of the horizontal types. Vertical arrangement of cylinder reduces the amount of floor space required; the higher speed range allows direct connection (without reduction gearing), and the increased number of cylinders reduces the effects of surges (pulsations).