- •G. Zayonchkovsky, V. Stadnychenko, y. Golovko «hydraulic machines and hydraulic/pneumatics equipment»

- •Introduction

- •Pump glossary

- •1.2 Pump history

- •1.3 Pump family group

- •1.3.1 Centrifugal pumps

- •1.3.2 Reciprocating pumps

- •1.3.3 Pump selection

- •2.1 Centrifugal pumps

- •2.2 Centrifugal pump characteristics

- •2.3 Performance modifications for varying pipelene applications

- •2.3.1 Cavitation

- •2.3.2 Net positive head

- •2.3.3 Net Positive Suction Head Avaible

- •2.3.4 Net Positive Suction Head Required

- •2.3.5 Correcting for Inadequate Suction Conditions

- •2.3.6 Npsha-nphsr Criteria

- •2.3.7 Viscous Liquids

- •2.3.8 Minimum Flow

- •2.3.9 Temperature Rise

- •2.3.11 Centrifugal Pump Station Piping Design

- •2.3.12 Centrifugal Pump Nozzle Loading

- •2.3.12 Pump Operational Hazards and Risk

- •3.1. Rotary

- •3.2 Types of rotary pumps

- •3.3 Reciprocating pumps

- •3.4 Piston pumps

- •4.1 Role of compression in a gas pipeline network

- •4.2 Gas pipeline hydraulics principles

- •4.3 Friction factor

- •4.4 Flow regimen profiles calculation

- •4.4 Pipeline design and optimization

- •4.4.1 Optimization Parameters

- •Optimization Process Overview

- •4.4.3 Selection of Alternative

- •4.4.4 Sensitivity Analysis

- •4.4.5 Pipeline Looping & Compression (Location & Spacing)

- •Hydraulics Simulations

- •4.4.7 Compressor Operation Costs

- •5.1. Pneumatic piping, hoses and connections

- •5.2 Flow control and pressure regulation valves

- •5.3 Relief valves dynamics

- •6.1 Linear actuators

- •6.2 Construction

- •6.3 Mounting arrangements an cylinder dynamics

- •7.1 Station piping layout

- •7.2 Scrubbers and filters

- •7.2.1 Dry scrubbers

- •7.2.1 Wet scrubbers

- •Categorization of wet scrubbers

- •Advantages and disadvantages

- •7.2.3 Filters

- •7.3 Gas coolers

- •7.4 Absorbers and regenerators

G. Zayonchkovsky, V. Stadnychenko, y. Golovko «hydraulic machines and hydraulic/pneumatics equipment»

(the Text book)

Branch: 0905 «Energy»

Speciality: 6.090500 «Gas turbines and compression stations»

Introduction

Pipelines affect the daily lives of people in most parts of the world. Modern-day life is based on structures in which energy fulfills a prevailing role. Oil and gas are the major participants in this energy supply. However, use of other forms of energy (such as hydrogen, biomass, etc.) [1] have continued and will continue to dominate energy usage in the future, depending on acceptability, safety, technical, and economic issues. However, pipelines are means by which most of these forms of energy are transported. It is of no coincidence that wherever there is the largest pipeline network, there is also the highest standard of living and technological progress.

Compared with other forms of transport, pipelines allow a more continuous, stable, and high-capacity supply of natural gas energy to reach end-users. Pipeline transportation has the advantages of being well established, cost-effective, and readily expandable. Its technology is well understood. The capital cost of a pipeline project is largely a function of its diameter and length, although other factors such as geography and topography are also significant. Operating expenditures and self-consumption of product are relatively minor and predictable. Economic feasibility of a pipeline is limited by variables such as volumes to be transported, supply-demand distance relationships, operating pressure, projected reserve life, and various risk factors. These limitations are more restrictive offshore than onshore.

Although pipelines were the most cost-effective mode of energy transportation, it can be inferred that cost of energy transportation by pipeline is distance- and location (offshore versus onshore)-dependent [2].

Pipelines are mostly buried. In virtual silence, pipelines supported by pumping and compression stations carry billions of cubic meters of our energy needs. Unattended pumping stations push oil and petroleum products in large volumes and under high pressure. Similarly, natural gas transmission systems supported by compressor stations move large volumes of gas to various destinations.

Gas Pipelines

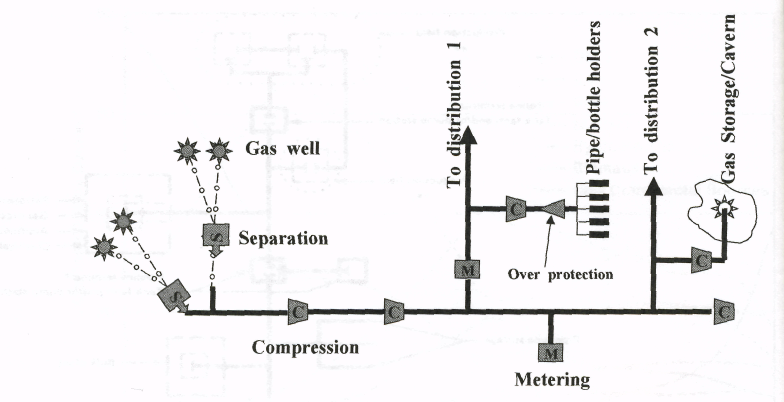

Gas is any gas or mixture of gases suitable for domestic or industrial fuel and transmitted or distributed to the user by a pipeline/piping system. The common types are natural gas — liquefied petroleum gas distributed as vapor with or without their mixture of air. A gas transmission and distribution system, Fig. 1-4, consists of the following components:

gas processing and treatment facilities to remove objectionable materials and con stituents

gathering pipeline facilities

production plants/compression

receipt meter stations

lateral lines

-

Figure 1-1. Components of gas pipeline systems

main lines

mainline control valves to regulate pressure or flow

mainline compression facilities

delivery meter stations/custody transfer/city gate stations

storage facilities used for peaking requirements (usually the pipeline itself)

The components include production wells, gathering lines within the production fields, processing plants, transmission pipelines, compressor stations (periodically along the transmission pipelines), storage wells and associated gathering pipelines, metering stations and city gate at distribution centers, distribution piping, and meters at distribution sites (residential or industrial).

Chapter 1. PUMPS FOR TRANSMITIONS PIPE LINE STATIONS_