- •Brian Carl Morgan, Doctor of Philosophy, 2006

- •1. Introduction

- •Introduction

- •Passive Techniques

- •Active Techniques

- •Thesis Objectives and Structure

- •Chapter 2: gray-scale technology

- •Introduction

- •Gray-scale Background

- •Theoretical Background

- •Optical Mask Constraints

- •Standard Lithography Process

- •Design and Lithography Advancements

- •Minimum Feature Limitations

- •2.3.3. Double Exposures

- •Pattern Transfer

- •Deep Reactive Ion Etching (drie)

- •Selectivity Characterizations

- •Technology Collaborations

- •Phase Fresnel Lens (nasa)

- •2.5.2.1. Compensated Aspect Ratio Dependent Etching (carde)

- •Conclusion

- •Chapter 3: elect rostatic comb-drives using goay-scale technology

- •Introduction

- •Electrostatic Actuation Fundamentals

- •Tailored Comb-finger Design and Simulation

- •Analytical Displacement Simulations (2-d)

- •Finite Element Analysis (3-d)

- •Instability Considerations

- •Reduced Height Suspensions

- •Fabrication

- •Comb-drive Testing

- •Reduced Height Comb-fingers

- •Conclusion

- •Introduction

- •Tunable mems Resonator Operation

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Gray-scale Electrostatic Springs

- •Testing and Characterization

- •Conclusion

- •Introduction

- •Device Concept

- •Figure 5.5: Calculated coupling as two co-axial single-mode fibers are separated longitudinally.

- •Figure 5.6: Alignment schematic for a bent fiber cantilever coupling to a fixed output fiber.

- •Alignment Wedges

- •Fabrication

- •Assembly

- •Actuation Concept Demonstration

- •Introduction

- •Experimental Setup

- •Static Testing

- •Table 6.3: Measured fiber locations for discrete actuation voltages. These 4 points form the corners of a diamond shaped alignment area.

- •Channel a (va2)

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Horizontal displacement

- •Voltage Squared (v2)

- •Auto-alignment Algorithms

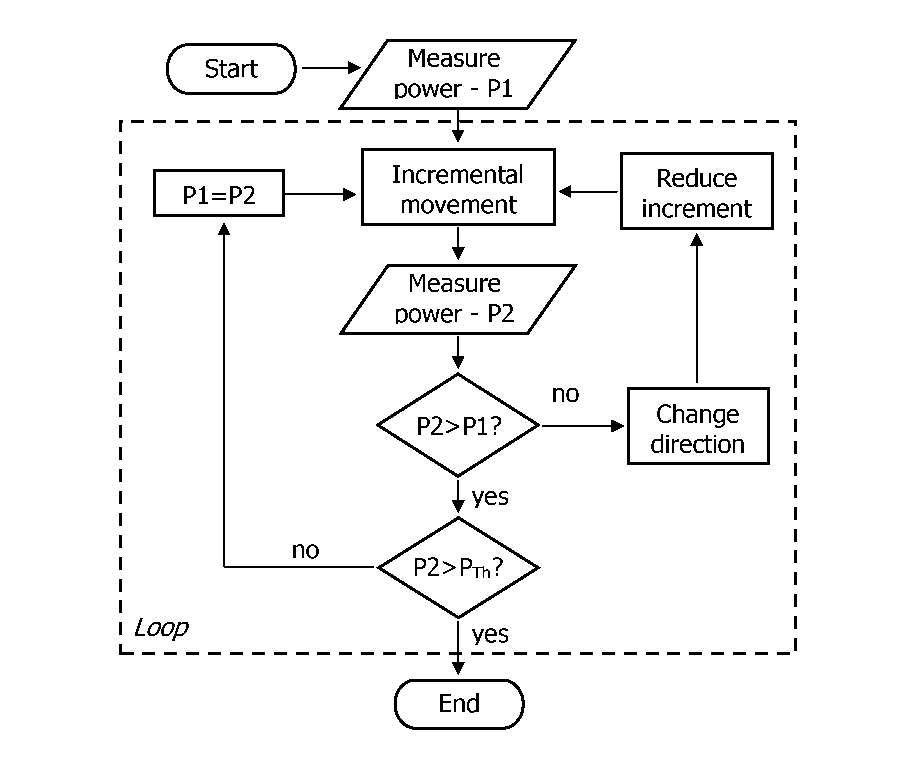

- •Figure 6.16: Simplified hill-climbing algorithm block diagram.

- •Automated Fiber Alignment Results

- •Settling Time, Coarse Threshold Power (%Peak)

- •Testing Summary and Discussion

- •Conclusion

- •Summary of Accomplishments

- •Future Work

The

primary drawback of the hill-climbing technique is the susceptibility

to trapping in false peaks. This limitation can sometimes be

addressed using a quasimomentum term within a hill-climbing

algorithm [171]. Alternative fine alignment algorithms have been

developed that work better in the presence of side modes, such as the

simplex method discussed in [175]. However, these algorithms can be

quite complex, making it difficult to distinguish between algorithm

complications and actuator performance. Since the targets used in

this research operate with a single fundamental mode, and the coarse

threshold is intended to avoid side modes, a hill-climbing algorithm

is sufficient for this device characterization.

Figure 6.16: Simplified hill-climbing algorithm block diagram.

The

most important parameters to be used during the hill-climbing

algorithm are the step sizes and the ultimate fine threshold power.

The initial step size determines how coarse a mesh the first 1-D

search will be, and after each reversal of direction the step size is

reduced (typically by */2).

Large

step sizes will climb the hill fast, but may overshoot the

optimum position and require many step size reductions to achieve the

resolution required for final alignment. Small step sizes will take

longer to climb a single hill, but should finalize alignment quickly

once there. Use of small steps does make one more vulnerable to local

false peaks caused by either secondary modes or artifacts of actuator

motion (like sticking or hysteresis). Ideally, a compromise must be

found between speed and reliability. A time-out function was also

included to avoid infinite attempts to climb a hill that peaks

outside of the possible area.

Automated Fiber Alignment Results

The experimental results presented in this section were performed entirely using the developed test setup described in Section 6.2. These tests were intended to specifically investigate the performance and limitations of the gray-scale fiber aligner using the implemented auto-alignment algorithms discussed in the previous section. Of specific interest are both the speed and resolution of the alignment process, each of which is focused on independently in the following two sections. Note that these tests make use of either lensed fibers or InP waveguides with approximately circular modes. While elliptical targets (like LEDs) may provide more coupling sensitivity along 1-axis, each power could correspond to multiple misalignment positions, significantly complicating evaluation of our device.

Cleaved Fiber - InP Waveguide (Speed)

The first auto-alignment tests using the gray-scale fiber aligner investigate the effect of algorithm parameters on speed of alignment within the constraints of the developed actuator and test setup. All experiments in this section utilized InP suspended waveguides (courtesy of fellow MSAL graduate student Jonathan McGee) [167] in an attempt to simulate in-package alignment to III-V photonic devices. It must be noted that due to the sensitive coupling between both facets of InP waveguides, alignment tests to InP waveguide were performed for a limited number of waveguide positions.

Initially, InP ribbed waveguides (2 by 2pm core with 400nm rib height) [167] were used as the alignment target, vertically misaligned by ~20pm with respect to the gray-scale fiber aligner. The waveguide location was somewhere towards the middle of the aligner’s range, but the precise location was left unknown to simulate ‘blind’ alignment. The final alignment threshold used for this first test was 92% peak, corresponding to ~3.5p,m misalignment due to the wide central mode emerging from the ribbed waveguide. While this resolution is far from the micron-level goal of this research, these tests serve to ensure that all alignment algorithms were implemented correctly.