- •Brian Carl Morgan, Doctor of Philosophy, 2006

- •1. Introduction

- •Introduction

- •Passive Techniques

- •Active Techniques

- •Thesis Objectives and Structure

- •Chapter 2: gray-scale technology

- •Introduction

- •Gray-scale Background

- •Theoretical Background

- •Optical Mask Constraints

- •Standard Lithography Process

- •Design and Lithography Advancements

- •Minimum Feature Limitations

- •2.3.3. Double Exposures

- •Pattern Transfer

- •Deep Reactive Ion Etching (drie)

- •Selectivity Characterizations

- •Technology Collaborations

- •Phase Fresnel Lens (nasa)

- •2.5.2.1. Compensated Aspect Ratio Dependent Etching (carde)

- •Conclusion

- •Chapter 3: elect rostatic comb-drives using goay-scale technology

- •Introduction

- •Electrostatic Actuation Fundamentals

- •Tailored Comb-finger Design and Simulation

- •Analytical Displacement Simulations (2-d)

- •Finite Element Analysis (3-d)

- •Instability Considerations

- •Reduced Height Suspensions

- •Fabrication

- •Comb-drive Testing

- •Reduced Height Comb-fingers

- •Conclusion

- •Introduction

- •Tunable mems Resonator Operation

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Gray-scale Electrostatic Springs

- •Testing and Characterization

- •Conclusion

- •Introduction

- •Device Concept

- •Figure 5.5: Calculated coupling as two co-axial single-mode fibers are separated longitudinally.

- •Figure 5.6: Alignment schematic for a bent fiber cantilever coupling to a fixed output fiber.

- •Alignment Wedges

- •Fabrication

- •Assembly

- •Actuation Concept Demonstration

- •Introduction

- •Experimental Setup

- •Static Testing

- •Table 6.3: Measured fiber locations for discrete actuation voltages. These 4 points form the corners of a diamond shaped alignment area.

- •Channel a (va2)

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Horizontal displacement

- •Voltage Squared (v2)

- •Auto-alignment Algorithms

- •Figure 6.16: Simplified hill-climbing algorithm block diagram.

- •Automated Fiber Alignment Results

- •Settling Time, Coarse Threshold Power (%Peak)

- •Testing Summary and Discussion

- •Conclusion

- •Summary of Accomplishments

- •Future Work

Static Testing

The next step in characterizing the gray-scale fiber aligner motion is to measure static movements intended to create motion along easily predictable patterns. The tests described below seek to characterize the range, flexibility, and hysteresis of fiber actuation. Such static movements will serve as the foundation for the auto-alignment algorithms discussed in later sections. Unless otherwise mentioned, tests described in this and the following sections utilize devices with a fiber cantilever length of L=12mm.

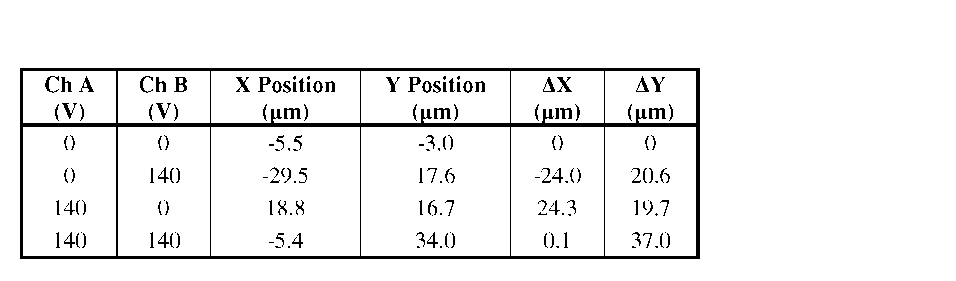

Table 6.3: Measured fiber locations for discrete actuation voltages. These 4 points form the corners of a diamond shaped alignment area.

“Diamond” Extents

The actuation mechanism of the gray-scale fiber aligner inherently defines a diamond-shaped area over which a fiber tip can be aligned, as described in Chapter 5. Thus, to establish the overall range of operation for this device, we must measure the size of this diamond-shaped area corresponding to the extreme movements of each alignment wedge. The voltage on either actuator was limited to 0-140V to avoid breakdown of the 2p,m buried oxide (based on experience), restricting the overall travel range.

Four

discrete voltage combinations were applied to the two actuators to

move the fiber to the four corners of the diamond-shaped alignment

area. The location of the cleaved fiber tip was measured for each

case using the facet scanning capability described earlier (with

Gaussian fits). The voltage combinations, as well as absolute and

relative fiber locations for this device, are given in Table 6.3.

These four points, shown graphically in Figure 6.6,

create a relatively symmetric diamond. Fiber positions within the

diamond-shaped bounds of these measurements (37 ^m tall, 48 ^m wide)

should be achievable with the appropriate set of applied voltages.

The fiber tip displacements measured in Figure 6.6

are slightly larger than the fiber displacement at the alignment

wedges because the fiber tip extends beyond the wedges for ease of

testing, causing a small additional tip displacement. More

discussion on this subtle point is given in Appendix C.

Four

discrete voltage combinations were applied to the two actuators to

move the fiber to the four corners of the diamond-shaped alignment

area. The location of the cleaved fiber tip was measured for each

case using the facet scanning capability described earlier (with

Gaussian fits). The voltage combinations, as well as absolute and

relative fiber locations for this device, are given in Table 6.3.

These four points, shown graphically in Figure 6.6,

create a relatively symmetric diamond. Fiber positions within the

diamond-shaped bounds of these measurements (37 ^m tall, 48 ^m wide)

should be achievable with the appropriate set of applied voltages.

The fiber tip displacements measured in Figure 6.6

are slightly larger than the fiber displacement at the alignment

wedges because the fiber tip extends beyond the wedges for ease of

testing, causing a small additional tip displacement. More

discussion on this subtle point is given in Appendix C.

Power Mapping

The diamond extents test was simply a demonstration of large single movements.

Yet, we would also like to show that the gray-scale fiber aligner provides some of the same functionality as the electrostrictive XYZ stages. Using LabVIEW, we implemented a raster actuation routine to map the fiber-fiber coupled power as a function of applied voltages to channels A and B of the gray-scale fiber aligner. This scan is analogous to the 2-D facet scan performed by the electrostrictive stages.

Shown in Figure 6.7 are coupled power contours that are plotted vs. voltage

2

squared (since comb-drive force scales with V ). The concentric circular power contours clearly demonstrate that movements of each alignment wedge behave predictably and rather symmetrically. The single dominant coupling peak is a result of the fiber-fiber setup being used in this test; however optimizing coupling to devices with secondary peaks is always a concern during fiber alignment and will be discussed in later sections.