- •Brian Carl Morgan, Doctor of Philosophy, 2006

- •1. Introduction

- •Introduction

- •Passive Techniques

- •Active Techniques

- •Thesis Objectives and Structure

- •Chapter 2: gray-scale technology

- •Introduction

- •Gray-scale Background

- •Theoretical Background

- •Optical Mask Constraints

- •Standard Lithography Process

- •Design and Lithography Advancements

- •Minimum Feature Limitations

- •2.3.3. Double Exposures

- •Pattern Transfer

- •Deep Reactive Ion Etching (drie)

- •Selectivity Characterizations

- •Technology Collaborations

- •Phase Fresnel Lens (nasa)

- •2.5.2.1. Compensated Aspect Ratio Dependent Etching (carde)

- •Conclusion

- •Chapter 3: elect rostatic comb-drives using goay-scale technology

- •Introduction

- •Electrostatic Actuation Fundamentals

- •Tailored Comb-finger Design and Simulation

- •Analytical Displacement Simulations (2-d)

- •Finite Element Analysis (3-d)

- •Instability Considerations

- •Reduced Height Suspensions

- •Fabrication

- •Comb-drive Testing

- •Reduced Height Comb-fingers

- •Conclusion

- •Introduction

- •Tunable mems Resonator Operation

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Gray-scale Electrostatic Springs

- •Testing and Characterization

- •Conclusion

- •Introduction

- •Device Concept

- •Figure 5.5: Calculated coupling as two co-axial single-mode fibers are separated longitudinally.

- •Figure 5.6: Alignment schematic for a bent fiber cantilever coupling to a fixed output fiber.

- •Alignment Wedges

- •Fabrication

- •Assembly

- •Actuation Concept Demonstration

- •Introduction

- •Experimental Setup

- •Static Testing

- •Table 6.3: Measured fiber locations for discrete actuation voltages. These 4 points form the corners of a diamond shaped alignment area.

- •Channel a (va2)

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Horizontal displacement

- •Voltage Squared (v2)

- •Auto-alignment Algorithms

- •Figure 6.16: Simplified hill-climbing algorithm block diagram.

- •Automated Fiber Alignment Results

- •Settling Time, Coarse Threshold Power (%Peak)

- •Testing Summary and Discussion

- •Conclusion

- •Summary of Accomplishments

- •Future Work

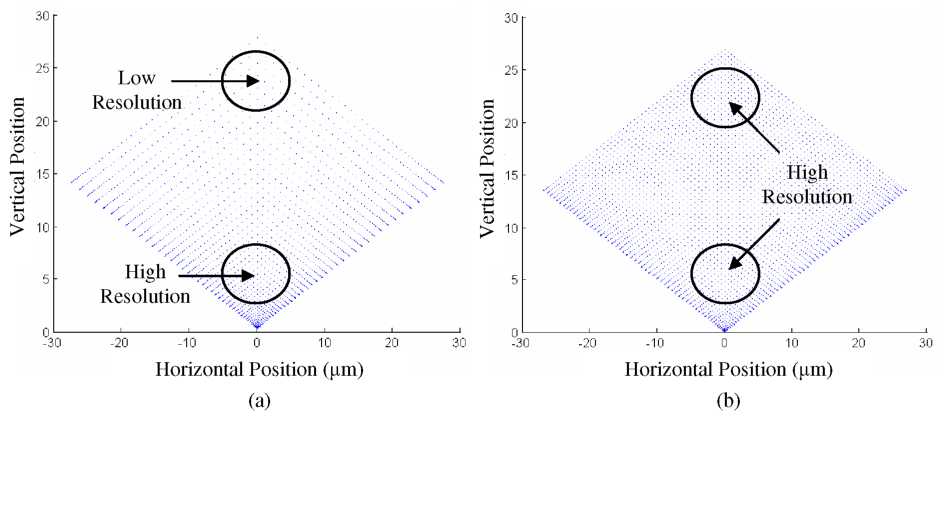

The

most critical components of this fiber actuator are the opposing

sloped

alignment

wedges, since they contact the fiber directly and enable the

out-of-plane

Figure

5.11: Possible alignment area covered (in the X-Y plane of Figure

9) for (a) a planar comb- drive actuator (k=5 N/m, gap=10^m, N=200,

Vmax=90V),

where the displacement resolution varies depending on position, and

(b) a gray-scale tailored force actuator exhibiting improved

resolution at large deflections (k=5 N/m, gap=10^m, N=200,

Vmax=120V).Alignment Wedges

For

the case of 45° alignment wedges and comb-drive actuators, we can

plot the rest position of the fiber as a function of applied

voltage. Figure 5.11(a) shows the possible v-groove alignment area,

where each point represents a case of discrete applied voltages to

comb-drives A and B from Figure 5.3. Taking the point (0,0) as the

initial fiber resting place before actuation, the center of an

optical fiber can be moved to any point within the boundaries of

this imaginary diamond-shaped alignment area. Note that the uneven

spacing of points in Figure 5.11(a) derives from the quadratic

displacement of planar comb-drive actuators, resulting in alignment

resolution that varies with position. Future devices could

incorporate the variable-height gray-scale comb-drives discussed in

Chapter 3 which could improve alignment resolution at large

displacements, as shown in Figure 5.11(b).

For

the case of 45° alignment wedges and comb-drive actuators, we can

plot the rest position of the fiber as a function of applied

voltage. Figure 5.11(a) shows the possible v-groove alignment area,

where each point represents a case of discrete applied voltages to

comb-drives A and B from Figure 5.3. Taking the point (0,0) as the

initial fiber resting place before actuation, the center of an

optical fiber can be moved to any point within the boundaries of

this imaginary diamond-shaped alignment area. Note that the uneven

spacing of points in Figure 5.11(a) derives from the quadratic

displacement of planar comb-drive actuators, resulting in alignment

resolution that varies with position. Future devices could

incorporate the variable-height gray-scale comb-drives discussed in

Chapter 3 which could improve alignment resolution at large

displacements, as shown in Figure 5.11(b).

actuation. Once again, gray-scale technology will be used to integrate the required 3-D silicon wedges with in-plane electrostatic MEMS comb-drives. The primary difficulty when designing the alignment wedges is balancing the wedge angle, ARDE effects (see Section 2.5.2.1), and number of gray levels (i.e. morphology).

The exact angle of the wedges is not critical, but excessively shallow or steep angles could cause slippage or jamming of the fiber. A target angle of approximately 45° was chosen as the initial goal for the wedge design, ideally resulting in similar horizontal and vertical resolution. The alignment wedges are located within the open fiber trench, which is almost an order of magnitude wider than the comb-drive finger spacing (200pm vs. 30pm). This large size difference will lead to significant ARDE between the two structures. To anticipate the over etching required to fully define the comb-drive fingers/spaces, the alignment wedges were designed to have a ~30pm vertical shift (created by introducing a constant offset in the CARDE process discussed in Chapter 2).

The selection of the gray-scale mask pitch and pixel set for defining the alignment wedges is extremely important. Ideally, after fabrication, the sloped wedges should be smooth compared to the size of the optical fiber (diameter=125jum) to enable continuous motion. Yet, considering the mask design limitations discussed in Chapter 2, tall and smooth slopes are a challenge when using a single gray-scale exposure. Compounding this difficulty is the fact that the CARDE offset renders a large number of lower gray levels unusable. Thus, the importance of pitch selection can be seen in the following simulations, based on the Gaussian approximation and pixel limitations discussed earlier in Chapter 2. Two different gray-scale alignment wedge profiles were simulated, both assuming an etch selectivity of 60:1 and a 30pm over-etch (due to ARDE). The first profile, shown in Figure 5.12(a), uses a mask pitch of 2.8pm with only ~25 useable gray levels, resulting in a prominent stair stepped profile. In contrast, Figure 5.12(b) shows a simulated profile using a pitch of 3.2pm, which enables ~50 gray levels within the desired range (pixel sets are given in Appendix E). Given these simulated profiles, the 3.2pm pitch is expected to produce smoother fiber motion, but still has room for improvement. These alignment wedges could be an excellent candidate for the doubleexposure lithography technique introduced in Chapter 2, however it would require significantly more characterization.