- •Brian Carl Morgan, Doctor of Philosophy, 2006

- •1. Introduction

- •Introduction

- •Passive Techniques

- •Active Techniques

- •Thesis Objectives and Structure

- •Chapter 2: gray-scale technology

- •Introduction

- •Gray-scale Background

- •Theoretical Background

- •Optical Mask Constraints

- •Standard Lithography Process

- •Design and Lithography Advancements

- •Minimum Feature Limitations

- •2.3.3. Double Exposures

- •Pattern Transfer

- •Deep Reactive Ion Etching (drie)

- •Selectivity Characterizations

- •Technology Collaborations

- •Phase Fresnel Lens (nasa)

- •2.5.2.1. Compensated Aspect Ratio Dependent Etching (carde)

- •Conclusion

- •Chapter 3: elect rostatic comb-drives using goay-scale technology

- •Introduction

- •Electrostatic Actuation Fundamentals

- •Tailored Comb-finger Design and Simulation

- •Analytical Displacement Simulations (2-d)

- •Finite Element Analysis (3-d)

- •Instability Considerations

- •Reduced Height Suspensions

- •Fabrication

- •Comb-drive Testing

- •Reduced Height Comb-fingers

- •Conclusion

- •Introduction

- •Tunable mems Resonator Operation

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Gray-scale Electrostatic Springs

- •Testing and Characterization

- •Conclusion

- •Introduction

- •Device Concept

- •Figure 5.5: Calculated coupling as two co-axial single-mode fibers are separated longitudinally.

- •Figure 5.6: Alignment schematic for a bent fiber cantilever coupling to a fixed output fiber.

- •Alignment Wedges

- •Fabrication

- •Assembly

- •Actuation Concept Demonstration

- •Introduction

- •Experimental Setup

- •Static Testing

- •Table 6.3: Measured fiber locations for discrete actuation voltages. These 4 points form the corners of a diamond shaped alignment area.

- •Channel a (va2)

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Horizontal displacement

- •Voltage Squared (v2)

- •Auto-alignment Algorithms

- •Figure 6.16: Simplified hill-climbing algorithm block diagram.

- •Automated Fiber Alignment Results

- •Settling Time, Coarse Threshold Power (%Peak)

- •Testing Summary and Discussion

- •Conclusion

- •Summary of Accomplishments

- •Future Work

Gray-scale Electrostatic Springs

The design, simulation, and fabrication of variable height gray-scale electrostatic springs used here are quite similar to the methods developed in Chapter 3. The following sub-sections will introduce the three types of variable-height electrostatic springs investigated in this research, as well as simulation and fabrication results to predict their relative spring constants.

Design

As evident from simulations in Chapter 3, a vertical step in comb-finger height creates a smoothly varying force-engagement profile (see Figure 3.9), of which a portion appears to be quasi-linear and could be used an electrostatic spring. Therefore, the three designs presented here contain only a single gray level for simplicity, and the height of the gray level (in conjunction with the applied voltage) will determine the strength of the electrostatic spring. More precise force-engagement profiles are possible by incorporating more gray levels (as will be shown with simulations in Section 4.5).

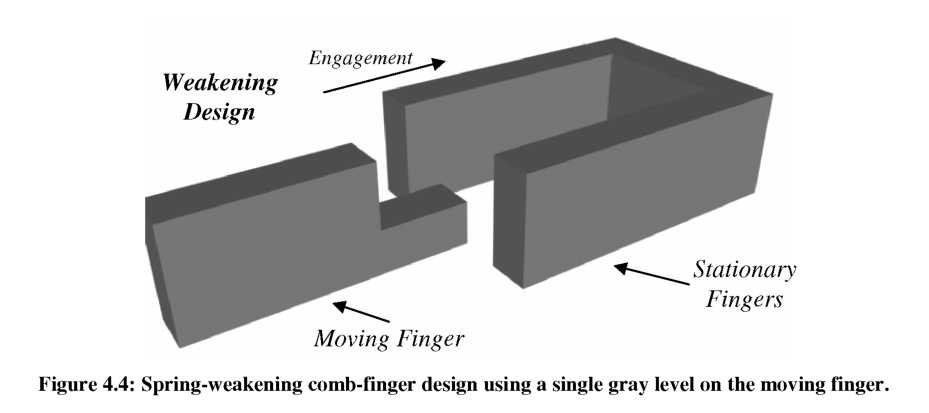

The first gray-scale electrostatic spring design is shown in Figure 4.4, where the moving comb-fingers initially engage with a reduced height section, followed by a full height (planar) section. Such a design is analogous to the decreasing gap design shown in Figure 4.2, and will thus be referred to as the “weakening” finger design.

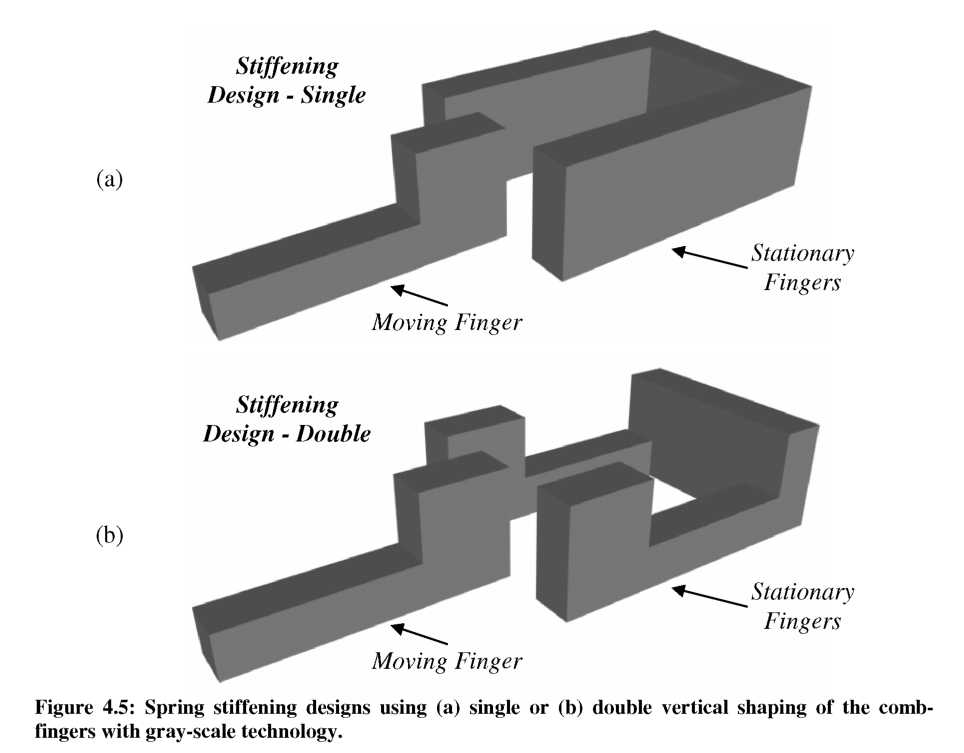

Figure 4.5(b) shows an additional novel design that vertically-shapes both stationary and moving comb-fingers. As the fingers engage in this “stiffening - double” design, there should be a dramatic change in force as the two full-height sections pass each other. Since the fully engaged force will be lower for the “double” design, it is anticipated that a more dramatic electrostatic spring “stiffening” effect will be observed (assuming the change in force from max to min occurs over a similar engagement change). A variable-gap comb-finger design would have particular difficulty replicating the analog to this “double” shaping design since it would require shaping both moving and stationary fingers, leading to an increase in device footprint. It must be noted that the electrostatic spring will be non-linear for each of these three cases due to their simplistic design, a trait that will be discussed in more detail towards the end of this chapter.

Simulation

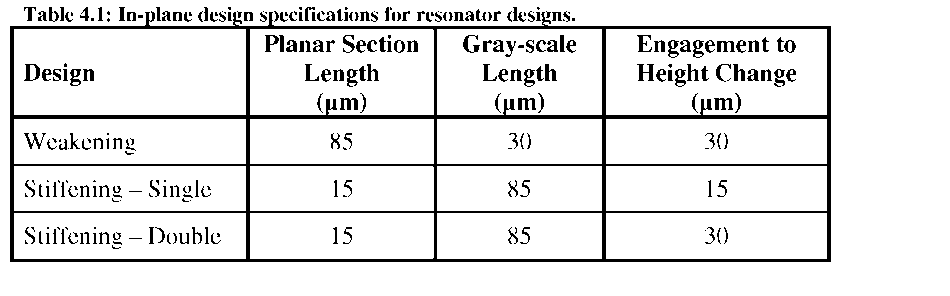

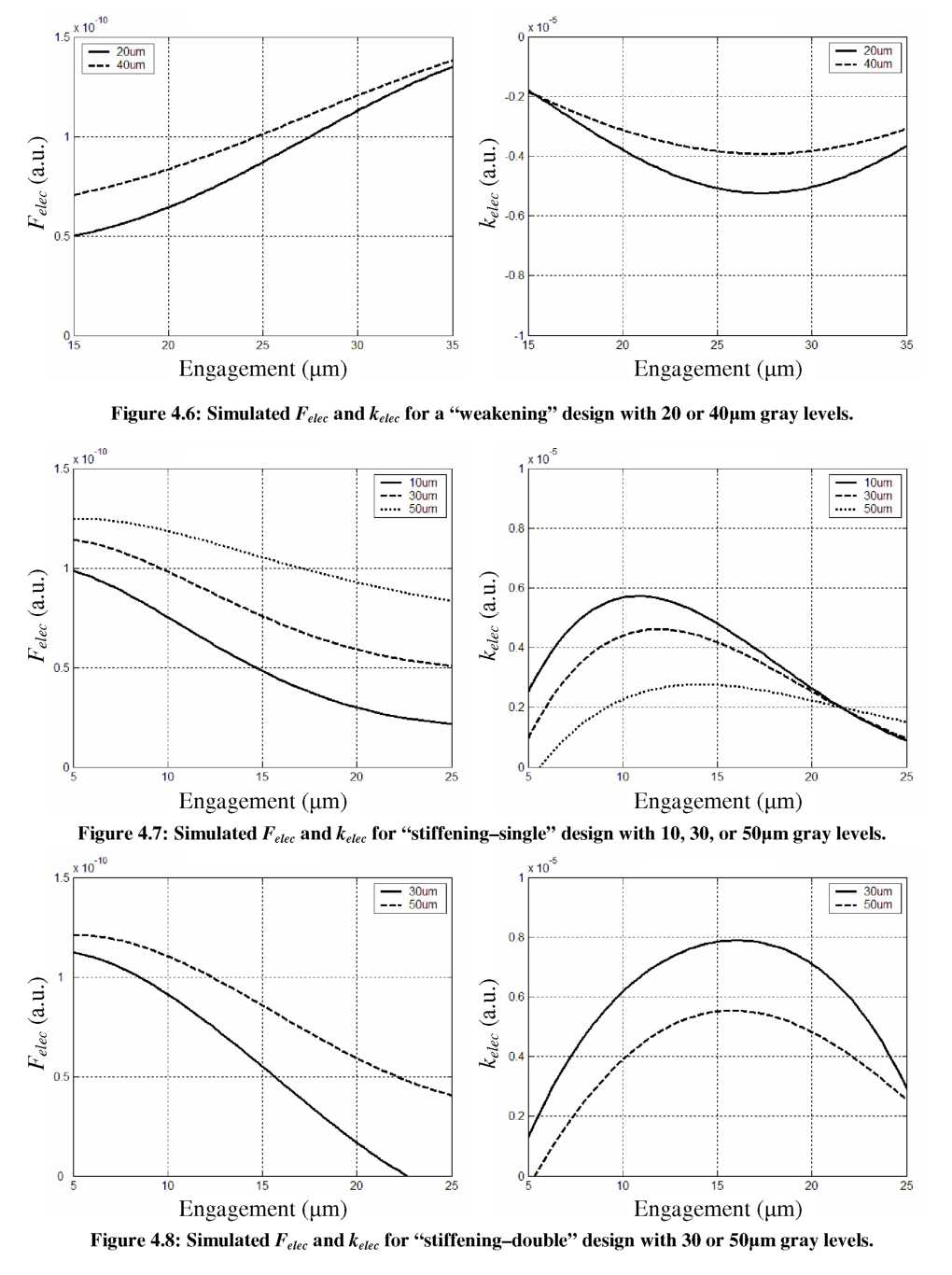

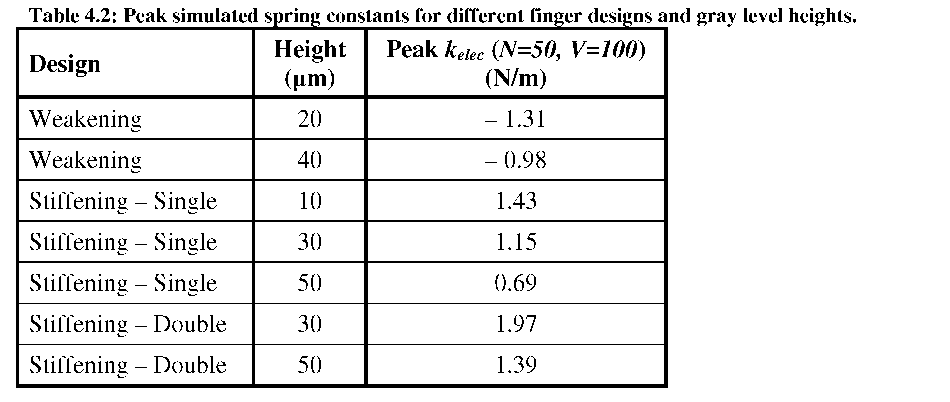

The capacitance as a function of engagement for each spring design was

simulated using FEMLAB for different gray level heights. As in Chapter 3, 100p,m SOI wafers are assumed, with 10p,m comb-finger gaps and widths. Capacitance-engagement data were fit with a 6th-order polynomial, and the derivative taken near the height change to obtain the local force-engagement profile. The horizontal geometry of each design and the engagement required to reach the edge height step(s) are shown in Table 4.1.

Layout and Fabrication

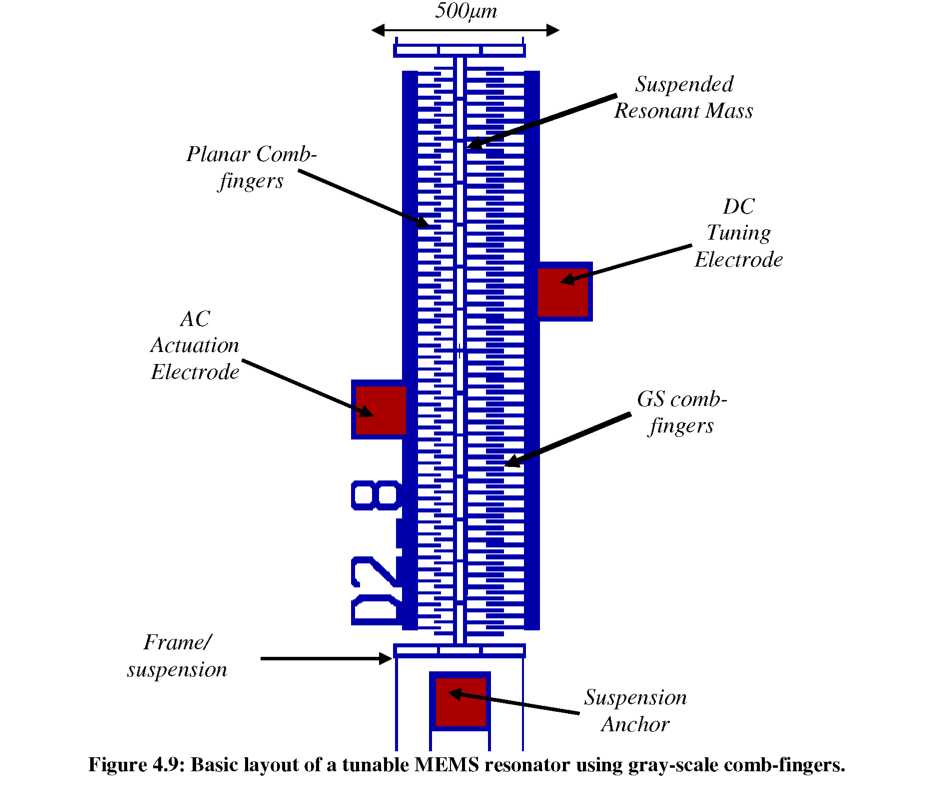

The layout of tunable gray-scale resonators is based on that shown in Figure 4.9.

A set of 48 stationary planar comb-fingers are connected to an actuation electrode, where the AC drive signal is applied. The “tune” electrode on the right side, which always receives a DC voltage, is attached to 48 stationary gray-scale comb-fingers. The resonant mass is made entirely of planar comb-fingers, except for the “stiffening - double” design that requires comb-fingers on the “tune” side of the resonant mass to be shaped vertically.

electrode on the right side to maximize kelec. This bias will cause the device to resonate around a deflected point (5-10p,m). Since kelec is position dependent in Figures 4.6-4.8, static deflections will effect the magnitude of the electrostatic spring. To anticipate these offsets, the rest position of the comb-fingers was biased so that the peak kelec occurs after ~5p,m of deflection.

All resonator devices were fabricated using the SOI gray-scale actuator process described in Chapter 3. The approximate measured gray level height for each type of device tested in the following section is shown below in Table 4.3. For comparisons with the models presented earlier above, the simulated value closest to the measured height will be used for kelec predictions.