- •Brian Carl Morgan, Doctor of Philosophy, 2006

- •1. Introduction

- •Introduction

- •Passive Techniques

- •Active Techniques

- •Thesis Objectives and Structure

- •Chapter 2: gray-scale technology

- •Introduction

- •Gray-scale Background

- •Theoretical Background

- •Optical Mask Constraints

- •Standard Lithography Process

- •Design and Lithography Advancements

- •Minimum Feature Limitations

- •2.3.3. Double Exposures

- •Pattern Transfer

- •Deep Reactive Ion Etching (drie)

- •Selectivity Characterizations

- •Technology Collaborations

- •Phase Fresnel Lens (nasa)

- •2.5.2.1. Compensated Aspect Ratio Dependent Etching (carde)

- •Conclusion

- •Chapter 3: elect rostatic comb-drives using goay-scale technology

- •Introduction

- •Electrostatic Actuation Fundamentals

- •Tailored Comb-finger Design and Simulation

- •Analytical Displacement Simulations (2-d)

- •Finite Element Analysis (3-d)

- •Instability Considerations

- •Reduced Height Suspensions

- •Fabrication

- •Comb-drive Testing

- •Reduced Height Comb-fingers

- •Conclusion

- •Introduction

- •Tunable mems Resonator Operation

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Gray-scale Electrostatic Springs

- •Testing and Characterization

- •Conclusion

- •Introduction

- •Device Concept

- •Figure 5.5: Calculated coupling as two co-axial single-mode fibers are separated longitudinally.

- •Figure 5.6: Alignment schematic for a bent fiber cantilever coupling to a fixed output fiber.

- •Alignment Wedges

- •Fabrication

- •Assembly

- •Actuation Concept Demonstration

- •Introduction

- •Experimental Setup

- •Static Testing

- •Table 6.3: Measured fiber locations for discrete actuation voltages. These 4 points form the corners of a diamond shaped alignment area.

- •Channel a (va2)

- •1. Introduction 1

- •1.1. Introduction 1

- •2.1. Introduction 11

- •3.1. Introduction 36

- •4.1. Introduction 51

- •Horizontal displacement

- •Voltage Squared (v2)

- •Auto-alignment Algorithms

- •Figure 6.16: Simplified hill-climbing algorithm block diagram.

- •Automated Fiber Alignment Results

- •Settling Time, Coarse Threshold Power (%Peak)

- •Testing Summary and Discussion

- •Conclusion

- •Summary of Accomplishments

- •Future Work

Finite Element Analysis (3-d)

The glaring difference between the planar and variable height case is the

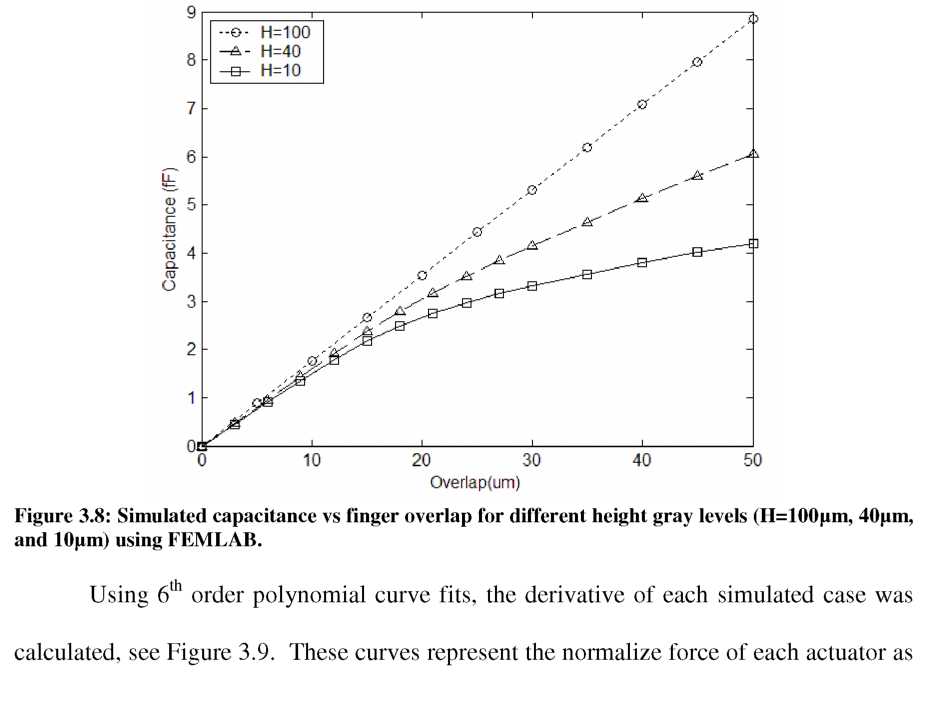

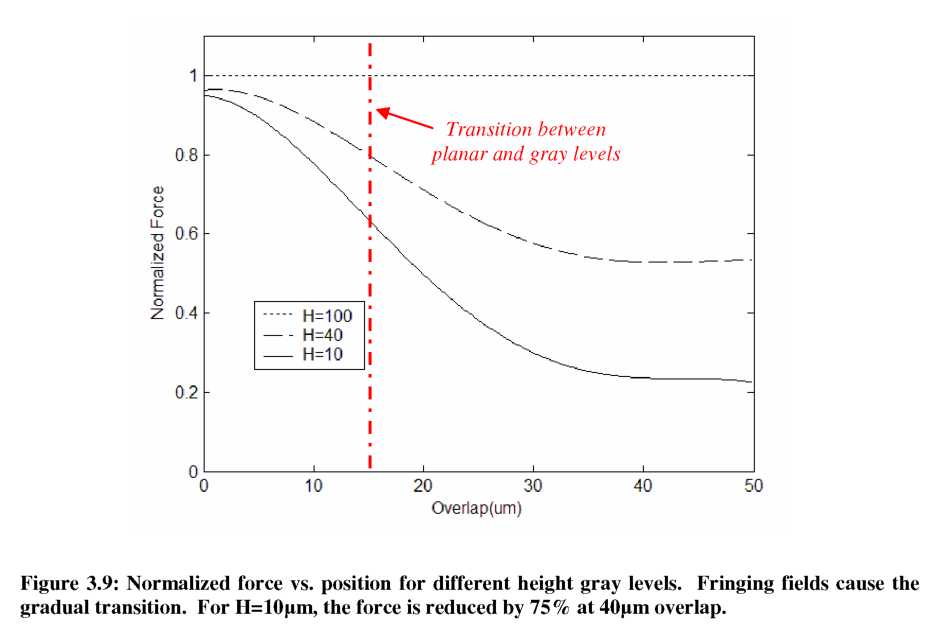

importance of fringing fields, which are neglected in planar devices. Given the dimensions and aspect ratios involved, simply reducing the height by 50% will not reduce the capacitance at each comb-position by exactly 50%. Thus, our parallel plate model must be extended to include the effects of fringing fields on the capacitance-position profiles to accurately predict actuator behavior using Finite Element Analysis (FEA). During our simulation, limitations imposed by fabrication processes must be considered, as achievable comb-finger gaps and feature aspect ratios will be fabrication dependent. Our analysis and designs will continue to assume 100pm SOI wafers and 10:1 feature aspect ratios, giving an initial gap of d=10^m as done before.

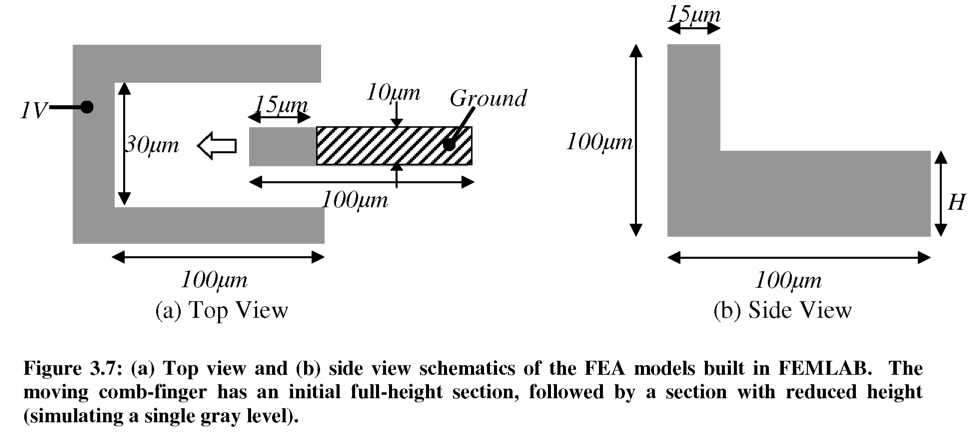

FEA models were constructed in the FEMLAB (V3.0) Electrostatics Module to emulate a grounded, variable height comb-finger moving between two stationary comb- fingers (held at a potential of V=1 Volt). The behavior of a device with N comb-pairs was estimated by multiplication. Top and side view schematics of the basic model geometry simulated are shown in Figure 3.7. While h(x) ^ 1/Ax profiles were discussed earlier for intuition, it will be shown that fringing fields cause a height step to act in a similar manner. All comb-fingers were 100pm long with a maximum height of 100pm. The moving comb-finger has an initial 15 pm full-height section, followed by 85 pm long section with a reduced constant height, H. A ground plane was included 10pm below the comb-fingers to simulate a grounded substrate below the moving fingers. The system was bounded by a 3mm by 3mm grounded box. A mesh containing approximately 200K elements was found to be sufficient to ensure convergence of our solution.

From the FEA simulation results, we see that the effects of fringing fields on the capacitance profile are significant. If a parallel-plate approximation was sufficient for the variable-height case, the normalized force profile would resemble the stepped height profile, h(x), shown in the side view of Figure 3.9. However, the fringing fields and our FEA model are able to “see” the change in height far before the reduced-height section arrives between the stationary fingers at an overlap of 15pm. Consequently, the force profile changes gradually around the transition point, and eventually settles to a smaller constant value. For the case of H=10pm, the total force is reduced by 75%, which should cause a corresponding improvement in displacement resolution of the actuator. Both the

analytical and FEA simulated force profiles will be compared to the experimental results of the fabricated gray-scale actuators in Section 3.6.1.